Summary of Contents for Technosoft iPOS4808 MY-CAN

- Page 1 MY-CAN Intelligent Servo Drive for Step, DC, Brushless DC Intelligent Servo Drives and AC Motors Technical Reference © Technosoft 2022 P091.027.iPOS4808.MY.CAN.UM.0522...

-

Page 2: Table Of Contents

Single loop configurations ...................... 11 2.4.2 Dual loop configurations ......................11 ..iPOS4808 MY I/O Evaluation board ................12 Hardware Installation ..................... 13 iPOS4808 MY-CAN Board Dimensions ..............13 Mechanical Mounting ....................13 3.2.1 Mechanical Mounting Options ....................13 ..3.2.1.1 Option 1 - Standoffs (spacers) .................. - Page 3 SSI/EnDAT encoder interface ....................38 3.7.16 BiSS Encoder Interface......................38 ..Analog 0…5V Inputs (REF, FDBK) ..................38 3.7.17 ..3.7.18 ..RS-232 ........................... 39 3.7.19 CAN-Bus (for CAN drives) ..................... 39 ..Memory Map ......................40 © Technosoft 2022 iPOS4808 MY-CAN Technical Reference...

-

Page 4: Read This First

Whilst Technosoft believes that the information and guidance given in this manual is correct, all parties must rely upon their own skill and judgment when making use of it. Technosoft does not assume any liability to anyone for any loss or damage caused by any error or omission in the work, whether such error or omission is the result of negligence or any other cause. -

Page 5: Related Documentation

SI units and the drive internal units. Help of the EasySetUp software – describes how to use EasySetUp to quickly setup any Technosoft drive for your application using only 2 dialogues. The output of EasySetUp is a set of setup data that can be downloaded into the drive EEPROM or saved on a PC file. -

Page 6: If You Need Assistance

NOT TOUCH LIVE PARTS WHILE THE POWER SUPPLIES ARE ON TO AVOID ELECTRIC ARCING AND HAZARDS, NEVER CONNECT / WARNING! DISCONNECT WIRES FROM THE DRIVE WHILE THE POWER SUPPLIES ARE ON WARNING! THE DRIVE MAY HAVE HOT SURFACES DURING OPERATION. © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 7: Cautions

Evaluation, Authorization and Restriction of Chemicals), which came into force on 01.06.2007. RoHS Compliance - Technosoft SA here with declares that this product is manufactured in compliance with the RoHS directive 2002/95/EC on the restriction of the use of certain... -

Page 8: Product Overview

PLC functionality in a single compact unit and are capable to execute complex motions without requiring intervention of an external motion controller. Using the high-level Technosoft Motion Language (TML) the following operations can be executed directly at drive level: ❑... -

Page 9: Product Features

Hence neither the iPOS4808 TML programming capability nor the drive camming mode are used. EasySetUp can be downloaded free of charge from Technosoft web page. EasyMotion Studio platform includes EasySetUp for the drive setup, and a Motion Wizard for the motion programming. -

Page 10: Identification Labels

Two CAN operation modes selectable by HW pin (only for CAN drives): CANopen – conforming with CiA 301 v4.2, CiA WD 305 v2.2.13 and CiA DSP 402 v3.0 • TMLCAN – intelligent drive conforming with Technosoft protocol for exchanging TML commands via • CAN-bus •... -

Page 11: Supported Motor-Sensor Configurations

-PMSM motor with Incremental encoder (from feedback #1) on motor and Incremental encoder (from feedback#2) on load -DC brush motor with SSI encoder (from feedback #2) on motor and Sin/Cos encoder (from feedback #1) on load. © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

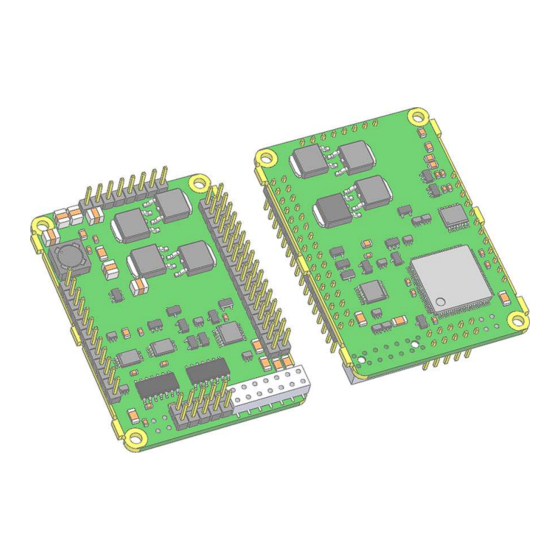

Page 12: Ipos4808 My I/O Evaluation Board

MY-CAT-STO P027.314.E121 or Drive with EtherCAT® and STO inputs P027.324.E121 It comes with multiple types of connectors for easy access to the iPOS4808 features. Figure 2.5.1. iPOS4808 MY-CAN mounted on the I/O-iPOS4808MY extension board Ordering information Part number Description P091.084.IO-iPOS4808MY.UM.xxxx Evaluation board User Manual (available for download on our website) P027.414.E881... -

Page 13: Hardware Installation

3.4.2 Mating Connectors. Several drives can be hosted by a single motherboard. For thermal calculations: the iPOS4808 MY-CAN drive can be assumed to generate 2.2 Watt (= 8 BTU/hour) at idle, and up to 5.7 Watt (= 20 BTU/hour) worst case while driving a motor. -

Page 14: Option 2 - M2.5 Bolts And Self-Locking Nuts

Image Essentra DLCBST-8-01 3.2.2 iPOS4808 MY-CAN PCB Footprint For iPOS4808 MY-CAN motherboard PCB design, use the dimensional drawing from below. Figure 3.2 Figure 3.2 iPOS4808 MY-CAN PCB Footprint All dimensions are in mm. Holes are marked with RED. © Technosoft 2022... -

Page 15: Motherboard Pcb Design

CONTENT IS ACCIDENTALLY CORRUPTED. THE iPOS4808 IS AN ELECTROSTATICALLY SENSITIVE DEVICE, WHICH WILL BE DAMAGED BY INCORRECT HANDLING. THEREFORE CAUTION! THE DRIVE SHALL BE REMOVED FROM ITS ORIGINAL PACKAGE ONLY IN AN ESD PROTECTED ENVIRONMENT! © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 16: Connectors And Pinouts

Connectors and Pinouts 3.4.1 Pinouts for iPOS4808 MY-CAN 3.4.2 Mating Connectors for CAN Connector Description Manufacturer Part Number Image High-current socket 2.54mm-pitch accepting Samtec SSQ-112-01-G-S 0.635mm square pin; 1x12 pin 87606-305LF 2x5 contacts, socket, 2.54mm-pitch accepting 0.635mm square pin 534206-5 Connectivity High-current socket 2.54mm-pitch accepting... -

Page 17: Connection Diagrams

Connection diagrams 3.5.1 iPOS4808 MY-CAN connection diagram Figure 3.3. iPOS4808 MY-CAN Connection diagram * For other available feedback / motor options, check the detailed connection diagrams below © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 18: 24V Digital I/O Connection

The inputs are compatible with NPN type outputs (input must be pulled to GND to change its default state) The length of the cables must be up to 30m, reducing the exposure to voltage surges in industrial environment. © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 19: Npn Outputs

Figure 3.6. 24V Digital NPN Outputs connection Remarks: The outputs are compatible with NPN type inputs (load is tied to common +V , output pulls to GND when active and is floating when inactive) © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 20: 5V Digital Outputs Connection

The length of the cables must be up to 30m, reducing the exposure to voltage surges in industrial environment. The output loads can be individually and independently connected to +5V or to GND. © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 21: Analog Inputs Connection

(GND); shield is connected only at the drive side, to the drive GND, and is left unconnected at the source side. The source minus (negative, out-of-phase) output remains unconnected. © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 22: Motor Connections

Brushless Motor connection Figure 3.10. Brushless motor connection 3.5.5.2 2-phase Step Motor connection Figure 3.11. 2-phase step motor connection, one coil per phase Figure 3.12. 2-phase step motor connection, two coils per phase © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 23: 3-Phase Step Motor Connection

The inductors must be magnetically shielded (toroidal, for example), and must be rated for the motor surge current. Typically the necessary values are around 100 μH. A good shielding can be obtained if the motor wires are running inside a metallic cable guide. © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 24: Feedback Connections

For encoder#1 differential connection, external 120Ω (0.25W) terminators are required for long encoder cables, or noisy environments. The length of the cables must be up to 30m, reducing the exposure to voltage surges in industrial environment. © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 25: Differential Incremental Encoder #2 Connection

The encoder #2 input has internal terminators, equivalent to 120Ω (0.25W) , present in the drive. The length of the cables must be up to 30m, reducing the exposure to voltage surges in industrial environment. 3.5.6.4 Sine-Cosine Analog Encoder Connection Figure 3.18. Sine-Cosine analogue encoder connection © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 26: Ssi / Endat Encoder #2 Connection

The encoder #2 input has internal terminators, equivalent to 120Ω (0.25W) , present in the drive. The length of the cables must be up to 30m, reducing the exposure to voltage surges in industrial environment. © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 27: Digital Hall Connection For Motor + Hall + Incremental Encoder

This connection is required when using only Digital hall signals as the main feedback device for motor control. In this case, no incremental encoder is needed. The length of the cables must be up to 30m, reducing the exposure to voltage surges in industrial environment. © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 28: Linear Hall Connection

If the iPOS4808 5V supply output is used by another device (like for example an encoder) and the connection cable is longer than 5 meters, add a decoupling capacitor near the supplied device, between the +5V and GND lines. The capacitor value can be 1...10 μF, rated at 6.3V. © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 29: Power Supply Connection

= 53V is the over-voltage protection limit is the nominal motor supply voltage = the overall energy flowing back to the supply in Joules. In case of a rotary motor and load, E can be computed with the formula: © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... - Page 30 to limit the average current below the drive nominal current I CYCLE where t is the time interval between 2 voltage increase cycles in case of repetitive moves. CYCLE © Technosoft 2022 iPOS4808 MY-CAN Technical Reference...

-

Page 31: Serial Rs-232 Connection

Do not rely on an earthed PC to provide the iPOS4808 GND connection! The drive must be earthed through a separate circuit. Most communication problems are caused by the lack of such connection © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 32: Can-Bus Connection (For Can Drives Only)

For 1 Mbit/s (worst case), the maximum stub length must be below 0.3 meters. The 120 termination resistors must be rated at 0.2W minimum. Do not use winded resistors, which are inductive. Figure 3.27. Multiple-Axis CAN network © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 33: 3.5.10 Removal From Autorun Mode

Pin 2: On = CANopen mode; Off = TMLCAN mode Pins 3 … 9: ID-Bitx. • ▪ The drive axis/address number is set when H/W is selected in Drive Setup under AxisID field or when the Setup is invalid. © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 34: Electrical Specifications

In case of forced cooling (conduction or ventilation) the spacing requirements may drop down to mechanical tolerances as long as the ambient temperature is kept below the maximum operating limit © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 35: Logic Supply Input

Recommended value, for ±5% current Motor electrical time-constant (L/R) = 60 kHz µs measurement error due to ripple = 80 kHz = 100 kHz Current measurement accuracy FS = Full Scale ±4 ±8 © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 36: Digital Inputs (In0, In1, In2/Lsp, In3/Lsn, In4, In5/Enable)

Logic “LOW”; Pull to GND Input current Logic “HIGH”; Internal 1K pull-up to +5 Minimum pulse width µs ESD protection Human body model ±5 The digital inputs are software selectable as PNP or NPN © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 37: Encoder #1 Inputs (A1+, A1-, B1+, B1-, Z1+, Z1-,)

Encoder #2 differential input pins have internal 120Ω termination resistors connected across For many applications, a 120Ω termination resistor should be connected across SIN+ to SIN-, and across COS+ to COS-. Please consult the feedback device datasheet for confirmation. © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 38: 3.7.15 Ssi/Endat Encoder Interface

Units Operational range Input voltage Absolute maximum values, continuous † Absolute maximum, surge (duration 1s) ±36 kΩ Input impedance To GND Resolution bits Integral linearity ±2 bits Offset error ±2 ±10 bits © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 39: Rs-232

±2 † Stresses beyond values listed under “absolute maximum ratings” may cause permanent damage to the device. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability. “FS” stands for “Full Scale” © Technosoft 2022 iPOS4808 MY-CAN Technical Reference... -

Page 40: Memory Map

4000h ROM memory for: TML programs Cam tables Setup information 7FFFh 8000h Reserved 8FFFh Data acquisitions C000h cam tables at runtime SRAM memory TML Programs FFFFh Figure 7.1. iPOS4808 MY Memory Map © Technosoft 2022 iPOS4808 MY-CAN Technical Reference...

Need help?

Do you have a question about the iPOS4808 MY-CAN and is the answer not in the manual?

Questions and answers