Subscribe to Our Youtube Channel

Summary of Contents for Avery Dennison ALX 720

-

Page 1: Table Of Contents

Service Manual ALX 720 Adjustment 720 Contents 5.1 General update information 1 HOUSING 5.2 Program-Download (new board) 1.1 Important notes 5.3 Program-Download (new version) 2 CONNECTIONS PRINT MODULE 2.1 Important notes Disassembly print module 2.2 Main connector 6.2 Feed roller 2.3 Transformer... - Page 2 Service Manual ALX 720 8.7 Foil end sensor 9.5 Foam roller at the dispensing edge Foil saving 9.6 Adjustment of the label web 8.9 Sensor head position 9.7 Paper brake 9 MECHANICAL SETTINGS 10 FULLSIZE LABEL SENSOR 9.1 Unwind brake, dancer arm driven (Option) 39 10.1 Assemble Option...

-

Page 3: Housing

Service Manual ALX 720 1 Housing 1.1 Important notes ♦ Open of the cover is only allowed authorised technical personal! ♦ The machine is to switch off and the line connector has to be removed before opening the cover. Attention! Inside the machine is high dangerous voltage. -

Page 4: Connections

Service Manual ALX 720 2 Connections 2.1 Important notes ♦ Open of the cover is only allowed authorised technical personal! ♦ The machine is to switch off and the line connector has to be removed before opening the cover. Attention! Inside the machine is high dangerous voltage. -

Page 5: Transformer

Service Manual ALX 720 Disassembly / Mounting line filter 1. Remove line cable 2. Loose both screws the line filter is fastened. 3. Disconnect the cable to the transformer and the earth connection to the front plate. 4. Remove and replace the line filter. -

Page 6: Fuses

Service Manual ALX 720 2.5 Fuses For protection of the electronic standard 5x20mm fuses are in use. In case of changing a fuse use only the recommended value. Inserting fuses with a wrong value can destroy the machine. Function Value... -

Page 7: Sensors

Service Manual ALX 720 3 Sensors 3.1 Overview Sensors Sensors are used to detect the status of the machine. Sensor Function Location Comment Label sensor (Full Detection of label edge also Print module Nothing to size) end of label open, full width... -

Page 8: Full Size Label Sensor

Service Manual ALX 720 CN14 CN13 CN15 CN12 CN32 CN30 CN16 CN10 CN35 CN34 CN31 CN17 CN18 CN33 CN23 CN26 3.2 Full size label sensor Function The label sensor measure the correct label length and detect the start of a new label. The position of the sensor could be set nearly of the whole label width. -

Page 9: Loop Sensor

Service Manual ALX 720 Sensor Connector Adjustment condition Value Para Display Test point meter value Label sensor CN15 without material in label Pot. P7 7 Pxxx sensor (Full size) with material >7 Adjustment Without Material in the label sensor (only backing paper): For adjustment select the function OTHR/SCHK/Pxxx and turn the po- tentiometer P7 (I/O-board) to get the display value P7. -

Page 10: Sensor Head Position

Service Manual ALX 720 3.4 Sensor head position Function This sensor is used to check the actual position of the print head. Dur- ing printing the print head is pressed against the label: For foil saving the print head is lifted Location The sensor is mounted on the slotted disk of the foil save motor. -

Page 11: Sensor Material End

Service Manual ALX 720 3.6 Sensor material end Function The material end sensor controls the presence of label material and detects also broken label web. The print process is immediately stopped if a failure is recognised. Location The sensor is mounted in the inner material guide of the print module. -

Page 12: Service Information

Service Manual ALX 720 4 Service information 4.1 Factory setting In case of loading new software or if the machine doesn’t work correctly for any reason all parameter should be reset to factory programmed values. This can be done by calling the function OTHR/FACT. -

Page 13: Increment Service Counter

Service Manual ALX 720 4.3 Increment service counter To have information about the reliability of the machine there are sev- eral counters available, indicating how often a service was necessary. The counter should be incremented with every service. Procedure to increment service counter: Input 1. -

Page 14: Software-Update

Service Manual ALX 720 5 Software-Update 5.1 General update information Flash-RAM The machine is supported with a FASH memory. Programming is done from a computer without any change of parts. The memory contains the operating program, fonts and bar code. -

Page 15: Program-Download (New Board)

Service Manual ALX 720 5.2 Program-Download (new board) This chapter describes the downloading process of a not programmed board. After power on a CPU-board the first time the display shows .LDR and the machine is waiting for the download at the parallel port. -

Page 16: Program-Download (New Version)

Service Manual ALX 720 5.3 Program-Download (new version) This chapter descriptes the download of a new program to the machine. 1. Switch on the machine and set the parameter IFAC/PORT to CENT (= Centronics). 2. Transfer the file START.LDR in Online-Mode. -

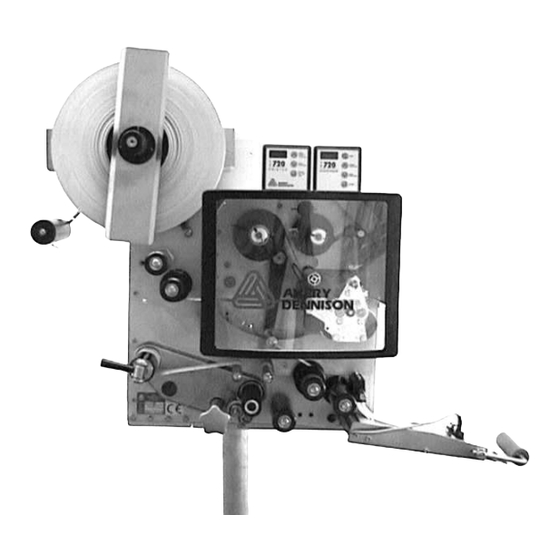

Page 17: Print Module

Service Manual ALX 720 6 Print module 6.1 Disassembly print module Construction print module Built to the cast-metal case (1) are following parts: – feed unit – material guiding – foil unwind Print module – foil rewind – foil transport –... -

Page 18: Feed Roller

Service Manual ALX 720 6.2 Feed roller Disassembly 1. Loosen feed stepper motor and remove ( 3 self locking hex nut’s). 2. Remove toothed belt 3. Loosen and open print head (knurled screw). 4. Remove lock washer (1) from gear and... -

Page 19: Pressure Unit

Service Manual ALX 720 6.3 Pressure unit The pressure roller is responsible for the mate- rial transport in the printer section. The both rollers are moveable on the axle. By pressing the lever you can open the pres- sure unit to feed in or pull out material. -

Page 20: Print Head

Service Manual ALX 720 6.4 Print head The print head is a sensitive component, especially against electrostatic discharge! Be aware - before touching the thermal head - that you remove static electricity from your body. As well if the print head is disassembled. -

Page 21: Disassembly Print Head

Service Manual ALX 720 6.4.4 Disassembly print head During handling the print head, take care that you not destroy the compo- nent by electrostatic. Electrostatic discharge could cause internal failures. So the failure is not immediately visible! Disassembly For the following operations the print head may be not supplied. -

Page 22: Position Print Head

Service Manual ALX 720 6.4.5 Position print head Has a thermal print head to be replaced, it could be - reasoned by manufacturing tolerances in this part, necessary to ad- just the part! A factory adjustment was done before - if possible, this adjustment should not be changed. -

Page 23: Pressure Print Head

Service Manual ALX 720 6.4.6 Pressure print head The thermal head is pressed with a constant pressure against the material and feed roller - done by an adjustable spring . Given by the media width - or thickness this pressure has to be adjusted ! •... -

Page 24: Adjustment Print Head

Service Manual ALX 720 6.4.7 Adjustment print head Three steps are necessary to properly adjust the print head ! 1. Adjustment of x/y parallelism of the print head position in reference to the feed roller 2. The gap between print head and feed roller! 3. - Page 25 Service Manual ALX 720 Adjustment 1. Before the adjustment check if all special tools are available. 2. To realign the print module remove the print head and as well remove foil and media. 3. Mount tool 1 to the print head fixation part (be sure that both watches are adjusted to the same level (±0,01 mm) before you...

- Page 26 Service Manual ALX 720 8. Loosen slightly all head screws. 9. Use alignment screws to adjust the print head mounting plate until both watches show the same level (±0.01 mm) (pic 6). 10. Tighten head screws and check again the watches - if the values are different refer to figure 7 again –...

-

Page 27: Adjustment Head Lift

Service Manual ALX 720 6.4.9 Adjustment head lift Target If the machine is switched on and foil is threaded the distance between print head and pressure roller should be 0.75 mm up to 1.00 mm. If not the adjustment should be done in the following way: Adjustment 1. - Page 28 Service Manual ALX 720 14. Loose screw on pressure lever. 15. Loose disk. Don’t fasten too strong on assembly! 16. Turn rocker in print position (lowest Po- sition). 17. Put 0.1 mm thick material between rocker and pressure lever. 18. Press pressure lever (1) against the rocker and fasten the screw.

-

Page 29: Further Adjustments

Service Manual ALX 720 6.4.10 Further adjustments After replacement of the print head you have to check following adjust- ments: 1. Program the resistance of the print head with the function HRES. 2. Check print quality. If ok the adjustment is done else see 3. -

Page 30: Material Guide

Service Manual ALX 720 7 Material guide The material guiding is - built on two axles - fixed with two clamping rings in the left and right base plate. The outer media guiding is adjustable - by moving the guiding free on the axle - the inner one is fixed on the zero line. -

Page 31: Foil Movement

Service Manual ALX 720 8 Foil movement The Foil transport - consist out of • foil unwind • foil turning axle • foil transport axle • foil rewind axle 8.1 Foil unwind axle Disassembly 1. unhinge brake spring and open self secure 2. -

Page 32: Foil Rewind Axle

Service Manual ALX 720 8.2 Foil rewind axle Disassembly 1. unhinge round belt (4) and loosen self se- cure nut (2) 2. loosen spring cover part (1) and limiting part, remove spring and break disc as well the round belt disk (3) 3. -

Page 33: Foil Zero Line Adjustment

Service Manual ALX 720 8.3 Foil zero line adjustment Moving zero line disc of unwind and rewind pin gives the possibility to separate media and foil zero line. Adjustment 1. loosen hexagonal screw in zero line disc 2. move disc to new position 3. -

Page 34: Foil Core Break

Service Manual ALX 720 8.4 Foil core break Changing the position of the spring leaf gives more or less friction to the foil core. Adjustment 1. loosen cross recessed screws and adjust spring leaf to new position (1) 2. fix spring leaf with screws 3. -

Page 35: Foil Rewind Axle

Service Manual ALX 720 8.6 Foil rewind axle Foil and material movements are normally the same. Only during foil saving the print head is lifted and the foil motor not driven. Disassembly 1. Loose 3 mounting screw of foil motor 2. -

Page 37: Foil End Sensor

Service Manual ALX 720 8.7 Foil end sensor The foil end sensor is used to recog- nise a broken foil or end of foil! A moving timing disc is watched con- stantly. The foil end sensor is mounted on the slotted disk at the inner side of the foil unwind axle. -

Page 38: Foil Saving

Service Manual ALX 720 8.8 Foil saving If foil save is active, the print head is lifted and the foil movement is stopped. Disassembly / Mounting 1. Loose Philips screw to dismount head sensor. 2. Remove the spring. 3. Loose the 3 Allen screw and remove lift motor. -

Page 39: Mechanical Settings

Service Manual ALX 720 9 Mechanical settings Dancer arm Foam roller 9.3 Drive Adjustment belt Pressure roller Adjustment Label Web 9.1 Unwind brake, dancer arm driven (Option) For special cases like side labelling, you can get a dancer arm driven unwind brake as an option. -

Page 40: Dancer Arm

Service Manual ALX 720 9.2 Dancer arm The dancer arm supports constant unwind of the label material. If the dancer arm is always reaching its end position, the dancer arm spring has to be replaced. 9.3 Rewind, drive belt Apart from the drive roller, the rewind is driven by the motor by the means of a drive belt. In order to compensate different diameters at the rewind, the drive belt works as well as a slip clutch. -

Page 41: Adjustment Of The Label Web

Service Manual ALX 720 9.6 Adjustment of the label web Depending on the used dispensing edge there are different ways for the adjustment of the label web. V-dispensing edge At this type of dispensing edge the dispensing blade is screwed in elongated holes. The track can be steered by turning the dispensing blade slightly. -

Page 42: Fullsize Label Sensor

Service Manual ALX 720 10 Fullsize label sensor 10.1 Assemble Option 10.1.1 Change position of pressure lever The lever position has to be changed from its normal position to a position rotated 90 degrees (see photo). pressure lever axle lock washer Open the lock washer, push back the axle –... - Page 43 Service Manual ALX 720 The upper – front axle has to be moved into the hole of the side plate (near print head) – and the upper part of the full size sensor has to be slipped onto. Screw the metal plate to the inner side plate Attention: Take care that the screw is not tighten –...

- Page 44 Service Manual ALX 720 Slip the assemble to the upper – front axle. The end of the axle has to end with the inner side of the plate (please take care about that) and fix the axle by using the hexagonal screw in the plate.

- Page 45 Service Manual ALX 720 The two lower axles slip into the holes of the inner side plate and have to be adjusted in a way that 1,8 mm (+/- 0,1 mm) of the axles are looking out of the inner side plate Fix the axles by use of the hexagonal screws.

-

Page 46: Adjustment Of The Sensor

Service Manual ALX 720 Take care that the inner media guiding is fixed in the correct position to the axle (inner zero line) Connect the connector of the sensor cable to CN 15 on the I/O board. 10.2 Adjustment of the sensor After the sensor is mounted to the printer –... -

Page 47: Check Sensor

Service Manual ALX 720 Both parts of the sensor are equipped with screws – used to fix the sensor on the axle. Both parts have to be adjusted in the correct position! Then activate the sensor and test it. 10.3 Check Sensor The function of the full size sensor –... - Page 48 Service Manual ALX 720 Index Adjustment ........23, 33 Material end sensor ......... 30 Adjustment of the sensor ......46 Material guide .......... 30 Assemble Option ........42 Mount full size sensor ......42 Change position of pressure lever ... 42 Pressure unit..........

Need help?

Do you have a question about the ALX 720 and is the answer not in the manual?

Questions and answers