Summary of Contents for SMC Networks PB1313A

- Page 1 Doc. no. PAB-OM-O003 Operation Manual Product name Process pump Model / Series PB1313A SMC Corporation...

- Page 2 Foreword Thank you for purchasing SMC’s process pump. This manual is intended to explain the operation of the product. This manual will help you to use the product effectively. Read the operation manual carefully to understand the outline of the product and issues relating to safety.

-

Page 3: Table Of Contents

Contents Safety Instructions ........................3 1. Precautions for system design ....................6 2. Precautions for installation ...................... 7 3. Maintenance and check ......................9 4. Handling Precautions ......................10 5. Names and functions of parts ....................10 6. How to use ..........................11 7. -

Page 4: Safety Instructions

Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.” They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC) , and other safety regulations. - Page 5 Safety Instructions Caution 1.The product is provided for use in manufacturing industries. The product herein described is basically provided for peaceful use in manufacturing industries. If considering using the product in other industries, consult SMC beforehand and exchange specifications or a contract if necessary. If anything is unclear, contact your nearest sales branch.

- Page 6 Do not touch. Sign warning of possible injury by touching the product surface with hazardous fluid on it, or when the product is hot. Fluid leakage Warning of external leakage of circulating fluid. Warning related to corrosion Warning indicating risk of chemical corrosion Read and understand the Material Safety Data Sheet (MSDS) carefully before using the product, and use appropriate protective equipment.

-

Page 7: Precautions For System Design

1. Precautions for system design Warning (1)Confirm the specifications. Fully understand the applications, fluids, environment and other operating conditions to use this product within the specified range shown in this operation manual. (2)Applicable fluids ●If the fluid contains foreign matter, the inside of the pump will become worn out , causing problems. -

Page 8: Precautions For Installation

(9)Countermeasures against static electricity Since static electricity may be generated depending on the fluid being used, implement suitable countermeasures. (10)The pump cannot transfer gas. Do not allow it to idle for a long time. If the pump is operated for a long time without any fluid inside, the diaphragm may be damaged or the life may be shortened. - Page 9 (5)Observe the tightening torque for screws. When screwing fittings into the product, tighten them with proper tightening torque as shown below. Over-tightening can damage the thread. PB1313A series Thread size Proper tightening torque Rc,NPT,G 1/8 1.5 to 2.0 N・m...

-

Page 10: Maintenance And Check

60 (min.) x 60 (sec.) Model How to operate Reference life (time) A The discharge for one cycle. PB1313A Note1) Air operated type 50 million times Approx. 3ml Note1) This is not a metering pump. The amount of discharge depends on the operating condition. -

Page 11: Handling Precautions

4. Handling Precautions Warning (1)Perform testing before the actual operation. Verify with the actual equipment used with this product. Even if the test over a short period shows no problem, it may cause a malfunction depending on the components of the fluid. (2)Storage When the product is stored for a long period of time after usage, remove the fluid completely from the pump before storage to prevent sticking and deterioration of the pump material. -

Page 12: How To Use

(2) Use the ball valve connected to the discharge side to adjust the flow at the fluid side. (3) When exhausting air, using a meter-out will reduce the suction speed of the fluid and so reduce the generation of bubbles. ON/OFF signal Ball valve Pressure regulator PB1313A c c Filter FLUID Air supply source Solenoid... -

Page 13: Specification And How To Order

7. Specification and how to order ●Specifications Model PB1313A Type of operation Air operated type Rc,NPT,G 1/8 Female thread, 1/4” PFA tube, Main fluid Suction/discharge port LQ1 size 2 with nuts, LQ3 size 2 with nuts Port size Pilot air... - Page 14 ●How to Order Female thread / P B 1 3 1 3 A Tube extension P B 1 3 1 3 A S - With nut ●Port size Material of diaphragm ● Main fluid Pilot air Symbol Symbol Material of diaphragm connection size connection size Female thread...

-

Page 15: Discharge Capability

8. Discharge capability 1) Flow-rate characteristics PB1313A流量特性(5Hz作動時) PB1313A Flow-rate characteristics (5Hz) SUP=0.5MPa SUP=0.4MPa SUP=0.3MPa SUP=0.2MPa 1000 吐出量 (mL/min) Discharge rate (mL/min) Caution -The above flow characteristic graph is for clean water (viscosity 1mPa・s, specific gravity 1.0). If a fluid with higher viscosity such as oil is used, convert the fluid to clean water with reference to the viscosity characteristic graph. - Page 16 3) Viscosity characteristics With reference to the viscosity characteristic graph (shown below), discharge amount of transported fluid with higher viscosity can be calculated. 粘度(mPa・s) Viscosity (mPa・s) ●How to calculate the pilot air pressure and consumed air flow < Example of required specifications > -Discharge : 200mL/min -Discharge pressure : 0.2MPa -Viscosity : 15mPa・s...

-

Page 17: Troubleshooting

Caution -The graph of flow-rate characteristics is in the condition of no piping for suction and discharge. It may not be possible to obtain the discharge in the graph depending on the piping conditions. In air operated type, the discharge is greatly affected by the piping conditions of pilot air. -The viscosity of the operating fluid depends on the operating conditions (temperature, transportation distance). - Page 18 3)The discharge amount is -Check valve at suction side (IN port) or -Cleaning insufficient. discharge side (OUT port) is clogged. -Excessive viscosity of transported fluid. -Non-conformance -Large suction or discharge pump head. -Reduce the pump head. -The filter of suction side (IN port) is -Clean or replace the filter.

-

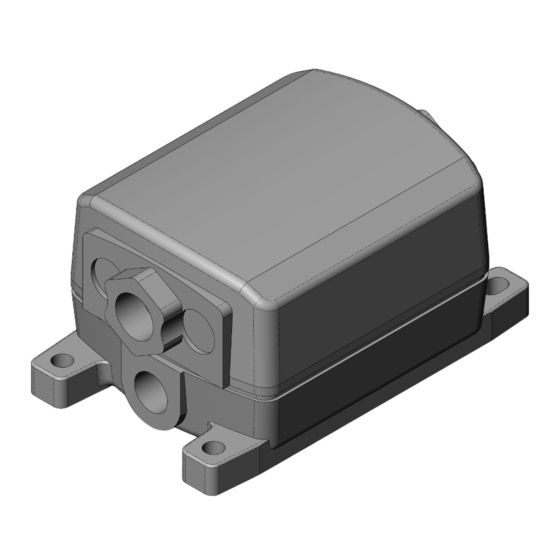

Page 19: Outer Dimensions

10. Outer dimensions -18-... - Page 20 付表 2 Revision history 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021 JAPAN Tel: + 81 3 5207 8249 Fax: +81 3 5298 5362 http://www.smcworld.com Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer. ©...

Need help?

Do you have a question about the PB1313A and is the answer not in the manual?

Questions and answers