Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Skov DA 1200

- Page 1 DA 1200 wall inlet Mounting Guide English For other language variants of this document we refer to: Español Para otras variantes del idioma de este documento, visite: Français Pour les versions dans d'autres langues de ce document veuillez consulter: http://docs.skov.com/1020...

- Page 2 The date of change appears from the front and back pages. Note • All rights belong to SKOV A/S. No part of this manual may be reproduced in any manner whatsoever without the expressed written permission of SKOV A/S in each case.

-

Page 3: Table Of Contents

DA 1200 wall inlet 1 Product description............................ 4 2 Product survey ............................... 5 Wall inlet ............................. 6 Accessories.......................... 6 3 Mounting guide............................. 11 Recommended tools........................ 11 Wall inlet positioning....................... 13 Mounting inlet .......................... 13 3.3.1 Modular System ......................... 13 3.3.2 Installation in wall........................ 14 3.3.2.1... -

Page 4: Product Description

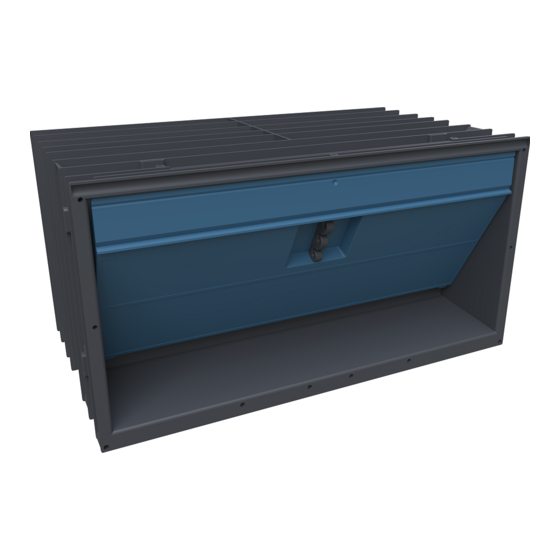

Combi-Tunnel ventilation. The DA 1200 inlet can be built directly into a wall without any additional support, or it can be embedded directly in prefab elements at factories manufacturing such elements. The inlet can be assembled from modules in a number of different ways. -

Page 5: Product Survey

DA 1200 wall inlet 2 Product survey Mounting Guide... -

Page 6: Wall Inlet

433004 DA 1233 wall inlet, transp. without net Used for wall dimensions from 33 to 35 cm. DA 1200 is for building in or casting in prefab elements. The sturdy inlet can be built directly into a wall without any additional support, or it can be em- bedded directly in prefab elements at factories manufacturing such ele- ments. - Page 7 Coarse net does not reduce the inlet capacity. One per inlet. 433022 DA 1200 set w. screws x10 for block Used for assembly of DA 1200 inlets where these are to be mounted in blocks. Includes 40 5x45 mm stainless screws. One set for each 10 inlets.

- Page 8 The extension rod is made of stainless steel. One per inlet. 401902 DA 1000/1200 single operation set If individual operation of each inlet is required, DA 1200 single operation set is mounted. One per inlet. 401935 Carrier roller f. pull rod, built-in inlet Is used for built-in inlets.

- Page 9 The flange is included in 433064 but can also be mounted on the outside in connection with DA 1211/1211B flange inlets to • increase the output to the same level as DA 1200. Correct the number of inlets, if needed.

- Page 10 DA 1200 wall inlet 433155 DA 1200 inlet cover DA 1200 inlet cover can be used together with the inlets of the DA 1200 se- ries. The inlet cover is designed to protect the livestock house against rain/snow and to provide a certain amount of wind and light dimming effect.

-

Page 11: Mounting Guide

DA 1200 wall inlet 3 Mounting guide Check that all ordered parts are present and undamaged prior to starting the work. Read the directions carefully before starting mounting. 3.1 Recommended tools See a list of tools recommended for the installation of the flange inlet below. - Page 12 DA 1200 wall inlet Item Description Wedge Foam gun Ladder Mounting Guide...

-

Page 13: Wall Inlet Positioning

3.2 Wall inlet positioning The positioning of the inlet in a wall depends on the layout of the building and the house layout. The positioning may therefore only be made according to directions communicated by SKOV A/S or representatives of the com- pany. -

Page 14: Installation In Wall

DA 1200 is a plastic wall inlet and not as sturdy as a brick. When temperature changes plastic is working con- siderably more than brickwork (up to 1.5 mm at a change of temperature of approx. 30 °C), and consequently some conditions should be considered when handling and building in. -

Page 15: Building-In The Inlet

DA 1200 wall inlet 3.3.2.2 Building-in the Inlet Place the wall inlet horizontally, flush with the finished inner wall. Ensure that the flap faces towards the build- ing with the transportation screw at the top. Transportation screw Lay the inlet "loosely" down into the mortar and fix it symmetrically to prevent unnecessary loads which may cause the inlet to warp. -

Page 16: Mounting The Regulation Set

DA 1200 wall inlet 3.4 Mounting the regulation set 3.4.1 Regulation set with advanced inlet control It is recommended to mount the regulation set before the in- let is mounted in the wall. The regulation set including filler plug is located in a bag be- hind the flap. - Page 17 DA 1200 wall inlet Mount the filler plugs included. Only when all reels have been mounted, the pull rod is pushed into place. Place the screw in the clamp on the pull rod. Always place the clamp identically in relation to the roller so there will be as little readjustment as possible.

- Page 18 DA 1200 wall inlet Place the string in the upper line guide and on the outer roller. Open and close the ventilation system twice. Adjust all the inlets to be fully open at fully open ventilation system. Close the ventilation system. Check that the inlets can close (5% slack on the winch motor).

-

Page 19: Check The Position Of The String At Advanced Inlet Control

DA 1200 wall inlet The ventilation system is opened until the first inlets reach an open position of 85mm. The delayed inlets are now ap- prox. 25 mm open 3.4.1.1 Check the position of the string at advanced inlet control... -

Page 20: Adjustment Of Wall Inlets

DA 1200 wall inlet 3.4.2 Adjustment of wall inlets Ensure that the actuator is set and calibrated as de- scribed in Technical User Guide (DA 175 actuator) based on the effective tensile length of the inlet which is 370 mm. - Page 21 DA 1200 wall inlet The picture illustrates various kinds of mounting and pull to the right and left side respectively. Place the clamp as shown; clamp must be placed iden- tically along the entire length of the pull rod. Mount the string and the pull rod holder using the in- cluded stainless screws.

-

Page 22: Mounting Of Accessories

DA 1200 wall inlet At manual operation the strings can be placed in the string and pull rod holder where they can be locked in any position. 3.5 Mounting of accessories 3.5.1 Air direction plate Click the holder onto the air direction plate in one side. -

Page 23: Extension Rod

DA 1200 wall inlet The mortise tenon should engage in one of the oblong holes in the side plate. Place the side pieces in the mortise tenon on the air di- rection plate and fasten them on the inlet with 1 screw 5x20 mm. -

Page 24: Baffle Plate

DA 1200 wall inlet Drill 2x6 mm holes in the front of the inlet casing, note the center marks. Drill approx. 28 mm deep holes. Mount inlet bracket. Mount the bracket for the extension rod as illustrated in the photo. -

Page 25: Regulation Set For 2 Inlets

DA 1200 wall inlet 3.5.4 Regulation set for 2 inlets The vertical distance between the holes must be min. 150 mm if long air direction baffles are mounted on the lower inlets. Min. 150 mm The vertical distance between the holes must be min. -

Page 26: Mounting Of Regulation Set For Modular System

DA 1200 wall inlet 3.5.6 Mounting of regulation set for modular system Min. 400 mm Pull rod Pull rod 3.5.7 Door set for wire drive Min. 400 mm Min. 400 mm Mounting Guide... -

Page 27: Maintenance

DA 1200 wall inlet 4 Maintenance The flap must be open and then closed during cleaning. The product may be cleaned by a high-pressure cleaner without using: • solvents • corrosive/caustic agents 4.1 Recycling/Disposal Products suitable for recycling are marked with a pictogram. -

Page 28: Technical Data

DA 1200 wall inlet 5 Technical data DA 1200 Mechanical 100% recyclable thermoplastic, high-impact material, dimen- Material sionally stable and UV stabilized Stainless steel Springs Graphite gray Color - inlet casing Blue Color - inlet flap Black Color - light trap... -

Page 29: Dimensioned Sketch

DA 1200 wall inlet 5.1 Dimensioned sketch All dimensions are in mm. 5.1.1 Wall inlet Front view (seen from the livestock house) Net = wall dimension is increased by 10 mm Mounting Guide... -

Page 30: Light Trap Complete/Outside Flange

DA 1200 wall inlet 5.1.2 Light trap complete/outside flange * Dimension is 640 mm of item no. 433067. 5.1.3 Inlet Cover Mounting Guide... -

Page 31: Light Trap For Inlet Cover

DA 1200 wall inlet 5.1.4 Light trap for inlet cover 5.1.5 Fly screen for inlet cover Mounting Guide... - Page 32 SKOV A/S • Hedelund 4 • Glyngøre • DK-7870 Roslev Tel. +45 72 17 55 55 • www.skov.com • E-mail: skov@skov.dk...

Need help?

Do you have a question about the DA 1200 and is the answer not in the manual?

Questions and answers