Sandpiper G Series Service & Operating Manual

Natural gas-operated diaphragm pumps

Hide thumbs

Also See for G Series:

- Service & operating manual (19 pages) ,

- Service & operating manual (25 pages)

Table of Contents

Advertisement

Quick Links

SERVICE & OPERATING MANUAL

Original Instructions

2.00

51

Certified Quality

3/8" NPT AIR EXHAUST

ISO 9001 Certified

ISO 14001 Certified

0

0

1.42

36.12

Certified to CSA Technical Letter No, R-14

SUCTION PORT

1/2" NPT

Certified to ANSI LC6-2008

R.19

4.83

5.50

139.70

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone 419.524.8388

Fax 419.522.7867

SANDPIPERPUMP.COM

© Copyright 2017 Warren Rupp, Inc.

All rights reserved

Tel: 866-777-6060

Fax: 866-777-6383

3/8 NPT

AIR EXHAUST

9.19

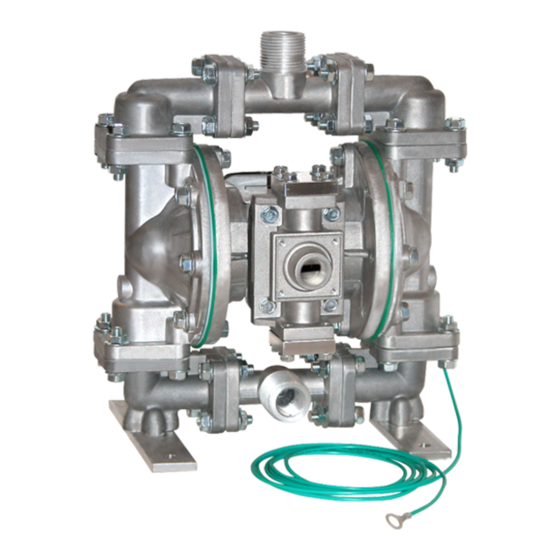

Model G05

233

Metallic

7.19

4X

183

Design Level 1

Natural Gas-Operated

Diaphragm Pumps

SUCTION PORT(OPTIONAL)

1/2" NPT

7.19

183

6.90

175.13

79.12

1.25

1.76

32

44.61

.38

MTG. HOLE

10

7.75

197

Springer Pumps, LLC

3.12

DISCHARGE PORT

1/2" NPT

6.12

AIR INLET

1/4 NPT

10.48

266.17

5.60

142.32

s a n d p i p e r p u m p

Website: www.springerpumps.com

1.42

3.06

78

3.78

96

155

.

c o m

Int'l: +001 267 404 2910

5.60

142

36

SUCTION P

1/2" RF ANS

4X

.62 [1

ON A

2.

Advertisement

Table of Contents

Need help?

Do you have a question about the G Series and is the answer not in the manual?

Questions and answers