Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for KEENCUT Excalibur 5000

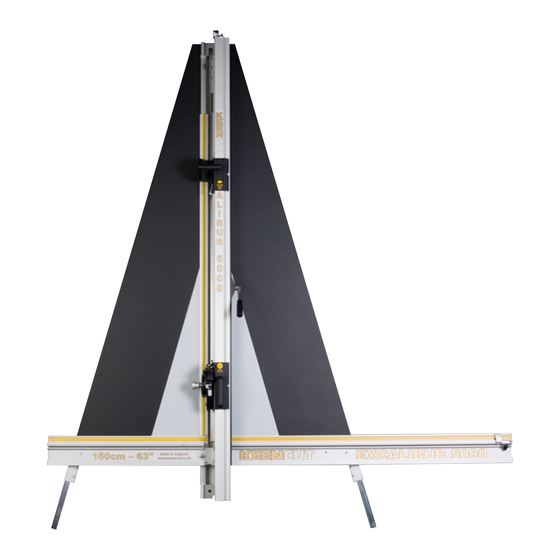

- Page 1 Keencut 63" Excalibur 5000 Substrate Cutter - EXC5160 Instruction Manual...

- Page 2 Download auf www.keencut.co.uk erhältlich. La version et les schémas des pièces en une seule langue peuvent être téléchargés depuis www.keencut.co.uk MyBinding.com En www.keencut.co.uk puede descargar versiones en idiomas 5500 NE Moore Court individuales y diagramas de piezas. Hillsboro, OR 97124 È...

-

Page 3: Table Of Contents

Contents 2 Packing list Unpacking your machine 3 Assembly Adjusting the Legs Preparing to fit the Squaring arm Fitting the Squaring arm Fitting the Wall mounting bracket Fitting the Free standing kit Fitting the Backing panels 4 Squaring Checking your machine for squareness Adjusting the squareness 5 Calibration Calibrating the vertical square... -

Page 4: Unpacking Your Machine

Unpacking your Machine MyBinding.com 5500 NE Moore Court Hillsboro, OR 97124 Toll Free: 1-800-944-4573 Local: 503-640-5920 NOTE: When lifting the main body from the box, DO NOT lift using the black handles on the cutters. Main body 11. M8 screws Squaring arm 12. -

Page 5: Assembly

Assembly Adjusting the Legs MyBinding.com 5500 NE Moore Court Hillsboro, OR 97124 Toll Free: 1-800-944-4573 Local: 503-640-5920 The first stages of assembly are carried out with the machine laying on the floor. NOTE: When lifting the main body from the box do not lift using the black handles on the cutters. -

Page 6: Preparing To Fit The Squaring Arm

Assembly Preparing to fit the Squaring Arm MyBinding.com 5500 NE Moore Court Hillsboro, OR 97124 Toll Free: 1-800-944-4573 Local: 503-640-5920 Move the lower cutting head to the middle of the Main body. Remove the following: A. One screw from each leg, using 5mm Hexagon wrench. B. -

Page 7: Fitting The Squaring Arm

Assembly MyBinding.com Fitting the Squaring Arm 5500 NE Moore Court Hillsboro, OR 97124 Toll Free: 1-800-944-4573 Local: 503-640-5920 Slide the Squaring arm in from the left hand side through the gap in the Main body and align the corresponding screw holes. Fit the two Hexagon bolts from the back of the Main body, fit the washers and nuts finger tight only. -

Page 8: Fitting The Wall Mounting Bracket

Assembly Fitting the Wall Mounting Bracket MyBinding.com 5500 NE Moore Court Hillsboro, OR 97124 Toll Free: 1-800-944-4573 Local: 503-640-5920 NOTE A: If you are going to fit the Free standing kit (optional) turn to next page. NOTE B: Ensure the wall is stable and use the appropriate fixings. Move the lower cutting head to the bottom of the Main assembly. -

Page 9: Fitting The Free Standing Kit

Assembly Fitting the Free Standing Kit (optional) NOTE: The Free standing kit is an optional extra and does not come packed with the main machine. Attach the bracket to the top of the machine using the nuts and screws (provided with the main machine). -

Page 10: Fitting The Backing Panels

Assembly Fitting the Left Backing Panels Remove the screws and nuts from the edge of the Left small back panel. Fit panel into the groove on the top edge of the Squaring arm, slide the panel to the right and locate the vertical edge into the groove in the Main body. be careful not to damage the edge of the panel. - Page 11 Assembly Fitting the Right Backing Panels Repeat for the Right hand panels. In place of a vertical groove in the main body the panels have metal strips fixed to the back which grip the edge of the main body as shown. MyBinding.com 5500 NE Moore Court Hillsboro, OR 97124...

-

Page 12: Squaring

Squaring Checking your machine for Squareness For your machine to produce accurate square cuts the Main Body needs to be set so that it is 90° to the Squaring Arm, for the following procedure you will need a piece of card or matboard at least 60cm x 100cm (2’ x 3’) the larger the board the more accurate you can set the machine. -

Page 13: Adjusting The Squareness

Squaring Adjusting the Squareness Second cut to the left of previous cut Turn adjustment screw counter clockwise Second cut to the right of previous cut Turn adjustment screw clockwise NOTE: Before making any adjustments carry out the squareness check as described on the previous page. -

Page 14: Calibration

Calibration Calibrating the Vertical scale 120.5cm (47 ") 120.5cm (47 ") 0 - ZERO NOTE: The Vertical rules can be identified from the Squaring arm rule by the orientation of the printed measurements – see diagram. Trim the bottom scale at zero and 120.5cm (47 ") with scissors. -

Page 15: Calibrating The Squaring Arm Scale

Calibration Calibrating the Squaring arm scales MyBinding.com 5500 NE Moore Court Hillsboro, OR 97124 Toll Free: 1-800-944-4573 Local: 503-640-5920 NOTE: The Squaring arm rule can be identified from the Vertical rules by the orientation of the printed measurements – see diagram. LEFT HAND SCALE Place a piece of card in the machine and apply the clamp. -

Page 16: Fitting The Sight-Line Strip

NOTE: A spare Sight-line strip is included with the machine, replacement strips are available from Keencut distributors. The Sight-line strip is fixed to the clamp and then trimmed by the cutting blade to give an accurate guide when cutting to trim lines, the edge of an image or pencil marks. The clamp simply operates by moving the handle in and out, (more information on operating the clamp is given later). -

Page 17: Operation

Operation Using the clamp The Clamping system of the Excalibur has been carefully designed to give a controlled clamping force easily set by the operator to suit the task in hand. The clamp has an integral friction brake that regulates clamping force on the material in relation to the amount of pressure applied to the operating lever. -

Page 18: The Multi-Tool Cutter And The Counterbalance - 5000

The Multi-tool cutter head & the counterbalance – 5000 The Excalibur 5000 is fitted with two sliding carriages running on a vertical slideway, each carriage being fitted with a cutting head. The top carriage is fitted with a twin wheel cutter for use with rigid particle boards such as MDF, hardboards and some mount- boards, refer to ‘Using the twin wheel cutter’... - Page 19 Operation Using the Cutting blade Changing the Cutting blade Basic Cutting Technique Select the Cutting Blade position on the turret and clamp the material in the machine. Move the cutting head beyond the top of the material to be cut. Press to engage the cutter.

- Page 20 Eject the blade using the black ejector pin, replace the blade to the right of the clamping plate, push the blade in as far as it will go and tighten the blade clamping screw. Rotate the turret back to the cutting position. Replace the guard ensuring it is locked closed. Replacement blades are available from Keencut or your distributor.

- Page 21 Operation Using and changing the Glass cutter ALWAYS WEAR EYE PROTECTION WHEN CUTTING GLASS Select the Glass cutter position on the turret, place the glass on the machine loading from the right hand side. Apply the clamp lightly and raise the cutting head beyond the top of the glass. Press to engage the cutter fully.

- Page 22 6mm hexagon wrench. MyBinding.com Slide the cutter towards the top of the main body and lift out. 5500 NE Moore Court Replacement wheels or cutters are available from Keencut or your distributor. Hillsboro, OR 97124 Toll Free: 1-800-944-4573 Local: 503-640-5920...

-

Page 23: Maintenance

Local: 503-640-5920 Cleaning Keencut machines are designed to be virtually maintenance free, however we do recommend regular cleaning. Do not wipe the squaring arm channels or remove any debris with fingers, as it may contain sharp particles such as glass. Use a vacuum cleaner if possible or if a soft brush is used, work slowly and do not allow particles to flick off of the bristles.

Need help?

Do you have a question about the Excalibur 5000 and is the answer not in the manual?

Questions and answers