Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Peak AMGO 409

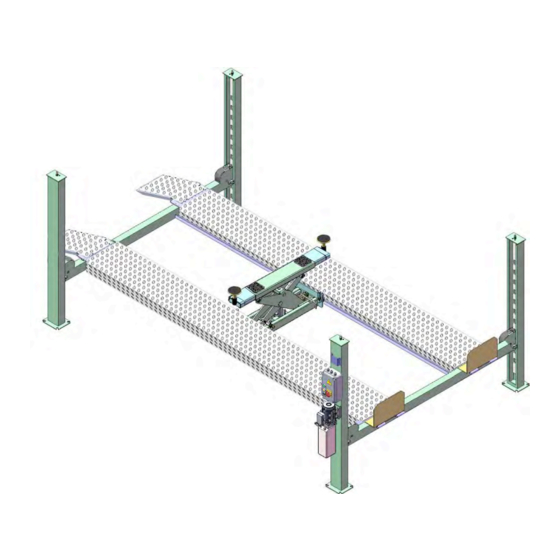

- Page 1 FOUR-POST LIFT Model:409(A440)

-

Page 2: Table Of Contents

CONTENTS Product Features and Specifications ............. 1 Installation Requirement ……………………………………………………………………………… 2 Steps of Installation …................ 3 Exploded View ................. 31 Test Run ……….................. 36 Operation Instruction ............... 38 Maintenance ................... 39 Trouble Shooting ................40 Parts List ..................41... -

Page 3: Product Features And Specifications

I. PRODUCT FEATURES AND SPECIFICATIONS 4-PO ST M ODEL 409(A440) FEATURES · Electric-air control operation system. · Mechanical self-lock and air-drived safety release. · Electrical hydraulic power system, cable-drived. · Non-skid diamond platforms. · Adjustable platform and adjustable safety lock ladders. ·... -

Page 4: Installation Requirement

II. INSTALLATION REQUIREMENT A. TOOLS REQUIRED ü Rotary Hammer Drill (Φ19) Carpenter’s Chalk ü ü Hammer Screw Sets ü ü Level Bar Tape Measure (7.5m) ü ü English Spanner (12") Pliers ü ü Ratchet Spanner With Socket (28 Socket Head Wrench (3 ü... -

Page 5: Steps Of Installation

B. SPECIFICATIONS OF CONCRETE (See Fig. 3) Specifications of concrete m ust be adhered to the specification as following. Failure to do so m ay result in lift and/or vehicle falling. 1. Concrete must be thickness 100mm minimum and without reinforcing steel bars, and must be dried completely before the installation. - Page 6 2. Open the outer packing carefully (See Fig. 5) Parts Box Control Box Drive-in Ramp Cross Beam Column Offside Platform Powerside Platform Shipment Parts List Fig. 3. Take off the drive-in ramps and columns (See Fig. 6) Fig. 4. Loose the screws of the upper package stand, take off the offside platform, take out the parts inside the powerside platform, than remove the package stand.

- Page 7 6. Open the carton of parts and check the parts according to the parts box list (See Fig. 8) Fig. 8 7. Check the parts of the parts bag according to the parts bag list (See Fig. 9) Fig. 9...

- Page 8 Use a carpenter’s chalk line to establish installation layout as per Table 1 Make sure the size is right and base is flat (see Fig. 10). Note: Reserve space front and behind the installation site. Use a carpenter’s chalk line to Car in Direction establish installation layout Fig.

- Page 9 D. Install cross beam s (See Fig. 11, Fig. 12) Hole towards inside Fig 11 Fig. 12...

- Page 10 E. Fix the anchor bolts Spring washer 1. Prepare the anchor bolts (See Fig. 13). Washer Fig. 13 2. Using the prescribed rotary hammer drill, and drill all the anchor holes and install the anchor bolts. Do not tighten the anchor bolts (See Fig.

- Page 11 2. Install safety ladders (See Fig. 16). This height should be the same for four safety ladders Safety ladder pass through the hole of the top plate, then tighten the two nuts Fig. 16 G. Put the cross beam s at the sam e height (See Fig.

- Page 12 H. Install pow erside platform . 1. Put the powerside platform upon the cross beams by fork lift or manual, offset the cross beams to the outside till the pulleys of both platforms can set up into the cross beams , Install the powerside platform and screw up the bolts (See Fig.18) (See...

- Page 13 I. Assembly offside platform and slider block, check the plumbness of columns with level, adjusting with the shims if not, and then tighten the anchor bolts (See Fig. 20). 3-15 3-16 Using the Ratchet Spanner With Socket to tighten the bolts 3-14 Install the slider block on the cross beam...

- Page 14 J. Illustration for cable installation 1. Pass through the cables from the platform to the columns according to the number of the cables (See Fig. 21). Cable Length 3250mm 9260mm 4850mm 7654mm (inc. connecting fitting) 128” 364 1/2” 191” 301 3/8” Fig.

- Page 15 2. The cable pass through the cross beam to top plate of columns and be screwed with cable nuts. Installation for Cable limit Pin on cross beam (See Fig. 22). Cable pass through Cable pass through top between the big pulley plate and be screwed and tension pulley with cable nuts.

- Page 16 3. Illustration for platform cables (See Fig. 23). Limit slider cable ④ cable ② cable ② cable ④ cable ① cable ③ cable ④ cable ④ cable ③ cable ② cable ② cable ① cable ② cable ④ Hex Bolt Fig.

- Page 17 K. Install oil-w ater separator, hydraulic solenoid valve, control box and pow er unit 1.For Electric control air-operated four post lift (See Fig. 24). 24 25 26 27 28 Air inlet Air outlet 30 22 Oil-water separator and Air Solenoid Valve Oil-water separator and hydraulic Solenoid Valve Fig.

- Page 18 L. Install hydraulic system (See Fig. 25). Note: Oil hoses and oil return pipe connected to oil cylinder must be passed above the cable and cylinder inlet port must swing upward to avoid the oil hose and oil return pipe scratched by cable. clamp Protective Ring cylinder inlet port...

- Page 19 M . Install air-line system 1. Cut the ¢6×¢4 black air line by scissor between two retainer, then connect the air line with T fitting. (See Fig. 26). 2. Connecting front and rear Cross Beam cylinders by using ¢6×¢4 black air line (See Fig.

- Page 20 3. Connecting oil-water separator and air solenoid valve using air line (See Fig. 28) Connecting Oil-water separator and Air solenoid valve using black air line ¢8×¢6×180mm Oil-water separator Air solenoid valve Air line ¢6×¢4 Fig. 28 4. Connecting air inlet (air supply pressure 5kg/cm - 8kg/cm ), adjusting the air pressure of oil-water separator to 0.4 - 0.6MPa...

- Page 21 N. Install electrical system 1. Install high limit switch (See Fig. 30) Connecting 11 & 12 (NC) of limit switch to terminals & 5 of control box High limit swit ○ wire Fig. 30 2. Install lower alarm limit switch (See Fig.

- Page 22 3. Connecting wire of limit switch on cross beam to control box (See Fig. 32) Terminal block Female Terminal block Support Terminal block ○ 、 Take out Support Terminal block A/B Support Terminal block for wire ○ 、 Connect A/B Support Terminal block with female Terminal block Optional air line...

- Page 23 4. Connecting wire with control box (See Fig. 33) Note: 1) Specification of wire of lim it switch and Air solenoid valve is 2×1 (two wires cable, wire size 1 m m 2) W ire cable for power source and m otor are 4×2.5 (Four wires cable, wire size 2.5 m m 3) Using white bobbin to wind around wire and air line.

- Page 24 In general, the electric current of thermal relay should equal or larger than that of motor. The following table shows rated current regulation of thermal relay in case of different hydraulic power unit. PEAK Monarch Hydraulic...

- Page 25 6. 380V Wire connection and circuit diagram 6.1 Wire connection diagram in the control box (See Fig. 35) Wire of motor ○ High limit switch wire Air solenoid valve ○ wire Lower limit switch Wire of hydraulic solenoid valve ○ ○...

- Page 26 6.3 380V Circuit diagram (See Fig. 37) 3 phase Fig. 37 Circuit component Item Name Code Specification Item Name Code Specification Power switch 380V AC Down triplex Push button Fuse duplex Fuse Push button LOCK single AC contactor 24V AC Motor 3 phase Time relay...

- Page 27 7. 220V Wire connection and circuit diagram 7.1 Wire Connection diagram in the control box (See Fig. 38) Wire of motor High limit switch Wire ○ Air solenoid valve ○ wire Lower limit switch Wire of hydraulic solenoid valve ○ ○...

- Page 28 7.3 220V Circuit diagram (See Fig. 40) Single phase Fig. 40 Circuit component Item Name Code Specification Item Name Code Specification Power switch 380V AC Down triplex Push button Fuse duplex Fuse Push button LOCK single AC contactor 24V AC Motor Single phase Time relay...

- Page 29 P. Install drive-in ram p, tire stop plate, platform lock plates, steel ball set (See Fig. 42 Install Drive-in ramp Install Tire stop plate Fig. 42...

- Page 30 Q Install optional Air line kits 1 Install lift w ell( include air line system and hydraulic system ). ( See fig.43) Connecting air source Connecting air line kits Hydraulic solenoid valve Air cylinder hose of Cross Beam Safety lock...

- Page 31 2, Install air line kits 2.1 Install with black air hoseφ8*φ6 (cut by installer)and connectors as Fig44. 201-1 201-2 201-4 201-3 201-5 201-5 201-6 201-7 201-5 Enlarged View of a Enlarged View of b...

- Page 32 201-8 201-11 201-10 Air bump 201-5 201-9 201-5 Spring air line is connected to the fitting of Enlarged View of c bump on Jack. Enlarged View of d All the air hose and oil hose installed well as above manual are tied up and pass through The another side of spring air line shown Protecting plastic hose as d is connected to the fitting installed on...

-

Page 33: Exploded View

IV. EXPLODED VIEW M odel 409(A440) Fig. 46... - Page 34 CRO SS BEAM Fig. 47 CYLINDERS Fig. 48...

- Page 35 CO NTRO L BO X Fig. 49 SPX ELECTRIC PO W ER UNIT 220V/5HZ, single phase (Fig. 50) Fig. 50...

- Page 36 PEAK ELECTRIC PO W ER UNIT (Fig. 51) 220V/50HZ, 1 Phase 380V/50HZ, 3 phase Fig. 51 Illustration of hydraulic valve for SPX & PEAK hydraulic pow er unit a. SPX Electric power unit, 220V/50HZ, Single phase (See Fig. 52) Capacitor Relief valve Oil return port...

- Page 37 PEAK electric power unit, 220V/50HZ, 1 phase (See Fig. 53) Running capacitor Start capacito Relief valve Oil return port Solenoid valve Throttle valve Check valve Oil Outlet Fig. 53 Fig. 50 C. PEAK electric power unit, 380V/50HZ, 3 phase (See Fig. 54)

-

Page 38: Test Run

V. TEST RUN: 1. Fill the reservoir with approximately 12L Hydraulic Oil (Note: In consideration of Power Unit’s durability,please use Hydraulic Oil 46# ). 2. Press button , the Cables will be strained. Check whether the Cables match the Pulley. Make sure the Cables are not across. 3. - Page 39 7. After finishing the above adjustment, test running the lift with load. Run the lift with Platforms in low position first, make sure the Platforms can rise and lower synchronously and the Safety Device can lock and release synchronously. And then test run the lift to the top completely.

-

Page 40: Operation Instruction

VI. OPERATION INSTRUCTIONS To lift vehicle 1. Keep clean of environment near the lift; 2. Drive vehicle to the Platform and put on the brake; 3. Turn on the power and press the button UP , raise the lift to the working position; Note: m ake sure the vehicle is steady w hen the lift is raised. -

Page 41: Maintenance

VII. MAINTENANCE SCHEDULE M onthly: 1. Re-torque the anchor bolts to 150Nm; 2. Lubricate cable with lubricant; 3. Check all cable connection, bolts and pins to insure proper mounting; 4. Make a visual inspection of all hydraulic hoses/lines for possible wear or leakage; 5. -

Page 42: Trouble Shooting

VIII. TROUBLE SHOOTING TROUBLE CAUSE REM EDY 1. Button does not work 1.Replace button 2.Wiring connections are not in good 2.Repair all wiring connections condition Motor does 3. Motor burned out 3.Repair or replace motor not run 4. AC contactor burned out 4.Replace AC contactor 5. -

Page 43: Parts List

IX. PARTS LIST FOR 409(A440) Item Part# Description QTY. Note Powerside Column 420011A Offside Column 420002 Cross Beam ASSY. 420252 420239 Limit slider Anchor Bolt 209059 Safety Ladder 410022 Hex Nut 420175A Powerside Platform 420218 Pulley Shaft Weldment 420022A Washer 420023A Pulley 420024B... - Page 44 Item Part# Description QTY. Note 420204 Wire protective cover 420156 Protecting Rubber Ring 420004 Pin for Drive-in Ramp 420005 Fixing Bolt 420003 Drive-in Ramp 620063 Roller for drive-in Ramp 620043 Roller pin for drive-in Ramp 209010 Ø10 Snap ring 420031 Tire Stop Plate Lower limit switch assy.

- Page 45 Parts For Hydraulic System Fitting 420166 Straight Fitting 420243 Straight Fitting 420245 Compensation Valve 209119 Fitting 201020 Oil Hose 420246 420120 Extended Straight Fitting (with Nut) Oil Hose 207026 Fitting For Hydraulic Power Unit 209060 420095 Straight Fitting Parts For Air Line System 420124 T-Fitting For Air Line T-Fitting For Air Line...

- Page 46 Item Part# Description QTY. Note Parts For Cylinder 57-1 420059 Dust Ring 57-2 420060 Y- Ring 57-3 410082 Head Cap 57-4 410083 O- Ring 57-5 410084 Bore Weldment 57-6 420064 Piston Rod 57-7 410085 57-8 410086 Support Ring 57-9 410087 Y- Ring 57-10 410088...

- Page 47 Parts For SPX Electric Power Unit 220V/50HZ/1 Phase Item Part# Description QTY. Note Motor 200-1 81400185 200-2 81400063 Motor Connecting Shaft Valve Body 200-3 81400186 Relief Valve 200-4 81400160 200-5 81400161 Lock Washer Socket Bolt 200-6 81400162 Inlet Pipe 200-7 81400121 O-ring 200-8...

- Page 48 Parts For PEAK Electric Power Unit 220V/50HZ/1 Phase Motor 200A-1 81400190 Motor Connecting Shaft 200A-2 81400127 Valve Body 200A-3 81400198 Relief Valve 200A-4 81400106 Throttle Valve 200A-5 81400107 Lock Washer 200A-6 209149 Socket Bolt 200A-7 81400148 Inlet Pipe 200A-8 81400134...

- Page 49 Parts For PEAK Electric Power Unit 380V/50HZ/3 Phase 200B-1 81400197 Motor Motor Connecting Shaft 200B-2 81400127 Valve Body 200B-3 81400198 Relief Valve 200B-4 81400106 Throttle Valve 200B-5 81400107 Lock Washer 200B-6 209149 Socket Bolt 200B-7 81400148 Inlet Pipe 200B-8 81400134...

- Page 50 72114202 12/2015...

Need help?

Do you have a question about the AMGO 409 and is the answer not in the manual?

Questions and answers