Harmonic Drive RSF supermini Series Manual

Brushless servo actuator

Hide thumbs

Also See for RSF supermini Series:

Subscribe to Our Youtube Channel

Summary of Contents for Harmonic Drive RSF supermini Series

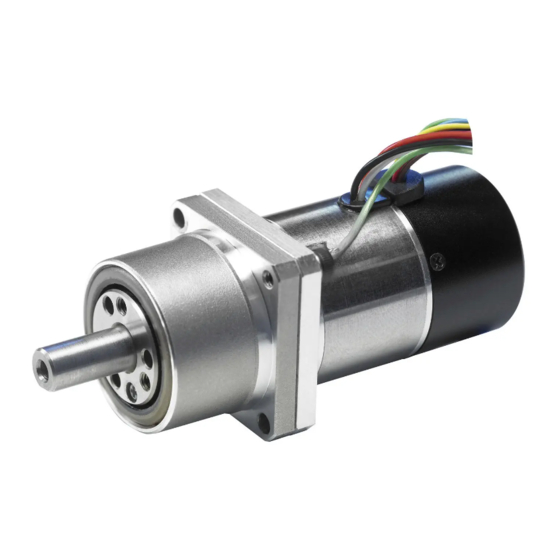

- Page 1 RS F S u p e rmi ni A ctu at or RSF Brushless Servo Actuator Total Motion Control Harmonic Drive actuator ® P r e c i s i o n G e a r i n g &...

- Page 2 RSF supermini Series AC Servo Actuator Manual (RSF-3C and RSF-5B) Thank you very much for your purchasing our RSF supermini series servo actuator. Be sure to use sufficient safety measures when installing and operating the equipment so as to prevent an accident resulting in a serious physical injury damaged by a malfunction or improper operation.

- Page 3 SAFETY GUIDE For RSF supermini series, HA series manufactured by Harmonic Drive Systems Inc Read this manual thoroughly before designing the application, installation, maintenance or inspection of the actuator. Indicates a potentially hazardous situation, Indicates a potentially hazardous situation, which, if...

-

Page 4: Table Of Contents

RSF supermini series AC servo actuator manual Contents Chapter 1 Overview of the RSF supermini series ................... 6 Major characteristics ........................6 Ordering information ........................7 Combinations with drivers ......................7 Specifications of RSF supermini actuators ................. 8 External dimensions of actuators ....................9 One-way positioning accuracy .................... - Page 5 RSF supermini series AC servo actuator manual Location and installation ......................30 3-3-1 Environment of location ....................30 3-3-2 Considerations into External Noise ................. 30 3-3-2 Installation ........................31 Chapter 4 Motor shaft retention brake(RSF-5B) ................... 32 Motor shaft retention brake specifications ................32 Controlling the brake power supply ..................

-

Page 6: Chapter 1 Overview Of The Rsf Supermini Series

Actuators with an electromagnetic brake are also included in the lineup. They can meet fail-safe requirements of equipment to prevent accidents upon power supply failure. The RSF supermini series can contribute to downsizing of driving of robot joints, semiconductor/LCD panel manufacturing equipment, machine tools, and other FA equipment. By utilizing its small and high-torque characteristics, it can also be used for small equipment and for research. -

Page 7: Ordering Information

With brake (with connector) Special specification 1-3 Combinations with drivers The RSF supermini series actuators are used in combination with the DCJ, DDP, DEP and HA-680 drivers. Drivers can perform position control, speed control, and torque control. For details of the drivers, refer to the “driver manual or data sheet”. -

Page 8: Specifications Of Rsf Supermini Actuators

Note 3: All values are typical. Note 4: The moment of inertia is the total value of the motor shaft and Harmonic Drive moment of inertia values converted to the output side. The values in parentheses are for equipment with a brake. -

Page 9: External Dimensions Of Actuators

Chapter 1 Overview of the RSF supermini series 1-5 External dimensions of actuators The external drawings are shown as follows: Note) For detailed outside dimensions, check the delivery specification drawing issued by us. - Page 10 Chapter 1 Overview of the RSF supermini series Note) For detailed outside dimensions, check the delivery specification drawing issued by us.

-

Page 11: One-Way Positioning Accuracy

Chapter 1 Overview of the RSF supermini series 1-6 One-way positioning accuracy The following table shows the “one-way positioning accuracy” and “repeated positioning accuracy.” The following table contains representing values. (JIS B 6201:1987) The one-way positioning accuracy of RSF supermini actuators is almost equal to the angular positioning accuracy of the Harmonic®... -

Page 12: Torsional Stiffness

Chapter 1 Overview of the RSF supermini series 1-7 Torsional stiffness When a torque is applied to the output flange of the actuator with the motor locked, the resulting torsional wind up is near proportional to the torque. The upper right figure shows the torsional stiffness... -

Page 13: Detector Resolution

Chapter 1 Overview of the RSF supermini series 1-8 Detector resolution An encoder with 500 pulses per rotation is incorporated in the motor unit of the RSF supermini series actuators, and the motor output is decelerated by 1/30, 1/50, or 1/100 by the precision control decelerator Harmonic Drive™. -

Page 14: Allowable Load

1-10 Allowable load 1-10-1 Allowable radial load and allowable thrust load The gear head used in the RSF supermini series incorporates the high-precision 4-point contact ball bearing for direct support of external load (output part). The allowable radial load and thrust load of the output shaft are shown below. -

Page 15: Rotary Direction

Chapter 1 Overview of the RSF supermini series 1-11 Rotary direction The rotary direction of the RSF supermini series actuators when a forward rotation command is given from the driver is forward rotation seen from the output shaft side (i.e. counterclockwise: CW). -

Page 16: Torque-Speed Characteristics

Chapter 1 Overview of the RSF supermini series 1-14 Torque-speed characteristics The following graphs show the usable ranges of the RSF supermini series actuators. • Acceleration and deceleration range: The range allows instantaneous operation like acceleration and deceleration, usually. • Continuous duty range: The range allows continuous operation for the actuator. - Page 17 Chapter 1 Overview of the RSF supermini series RSF-5B-30-US050-C, RSF-5B-30-US050-BC RSF-5B-30-US050-C, RSF-5B-50-US050-BC RSF-5B-30-US050-C, RSF-5B-100-US050-BC Note: The values of the graph are obtained when the aluminum radiation plate shown at the upper right of the graph. Note: Even in the continuous range, if it is used continuously in one direction, please consult with us.

-

Page 18: Cable Specifications

Chapter 1 Overview of the RSF supermini series 1-15 Cable specifications The following tables show specifications of the cable for the motor and the encoder of the RSF supermini actuators. Motor cable Pin No. Color Signal name Remark (RED) Motor phase-U... -

Page 19: Chapter 2 Selection Of The Rsf Supermini Series

Chapter 2 Selection of the RSF supermini Series 2-1 Allowable load moment of inertia To make full use of high precision and high performance of the RSF supermini series actuator, perform temporary selection by considering the load moment of inertia and rotation speed. -

Page 20: Duty Cycles

2-4-2 Load moment of inertia Calculate the load moment of inertia driven by the RSF supermini series actuator. Refer to appendix 1 for the calculation. Tentatively select an RSF supermini actuator referring to section [2-1 allowable load moment of inertia] with the calculated value. -

Page 21: Acceleration Time And Deceleration Time

Chapter 2 Selection of the RSF supermini Series Horizontal linear motion The following formula calculates the torque for horizontal linear motion of mass [W] fed by the screw of pitch [P]. µ Mass: W 2 x ! Pitch: P torque (Nm) µ:... -

Page 22: Calculating Equivalent Duty

Chapter 2 Selection of the RSF supermini Series • Example: 1 The load conditions are: • Rotary speed: 140r/min • Load moment of inertia: 0.9!10 kg m • Load torque is so small as to be negrected. • Acceleration/deceleration time is 0.03sec (30msec) or less. - Page 23 Chapter 2 Selection of the RSF supermini Series • Example 2: getting duty factors of K and K As a result of Calculation Example 1 shown below, the selected actuator RSF-5B-50 works fine, so RSF-5B-50 can be used for duty factor graphs.

- Page 24 Chapter 2 Selection of the RSF supermini Series Graphs of duty factor Radiation plate: 85!85!3[mm] RSF-3C-30-US020-C Allowed range Speed [r/min] Radiation plate: 85!85!3[mm] RSF-3C-50-US020-C Allowed range Speed [r/min] Radiation plate: 85!85!3[mm] RSF-3C-100-US020-C Allowed range Speed [r/min]...

- Page 25 Chapter 2 Selection of the RSF supermini Series RSF-5B-30-US050-C RSF-5B-30-US050-BC Radiation plate: 150!150!3[mm] Radiation plate: 150!150!3[mm] Allowed range Allowed range Speed [r/min] Speed [r/min] RSF-5B-50-US050-C RSF-5B-50-US050-BC Radiation plate: 150!150!3[mm] Radiation plate: 150!150!3[mm] Allowed range Allowed range Speed [r/min] Speed [r/min]...

-

Page 26: Effective Torque And Average Speed

Chapter 2 Selection of the RSF supermini Series 2-4-6 Effective torque and average speed Addionally to the former studies, the effective torque and the average speed should be studied. (1) The effective torque should be less than allowable continuous torque specified by the driver. -

Page 27: Permissible Overloaded Time

2-4-7 Permissible overloaded time In case RSF supermini series is intermittently operated in allowable continuous torque or more, the overloaded time is limited by the protective function in the driver even if the duty cycle is allowed. The limits are shown in the figure below. -

Page 28: Chapter 3 Installing The Actuator

If the item is damaged, immediately report the damage to the dealer it was purchased from. (2) A label is attached on the right side of the RSF supermini series actuator. Confirm the products you ordered by comparing with the model on the [TYPE] line of the label. If it is different, immediately contact the dealer it was purchased from. -

Page 29: Notice On Handling

Chapter 3 Installing the actuator 3-2 Notice on handling Handle RSF supermini series actuators with care, specifically: Do not plug the actuators directly into a commercial line power source. This could burn out the actuator, potentially resulting in a fire and/or electrical hazard. -

Page 30: Location And Installation

3-3 Location and installation 3-3-1 Environment of location The environmental conditions of the location for RSF supermini series actuators must be as follows. Service temperature: 0°C to 40°C ◆ When the actuator is installed in a closed space, the temperature in the space may be higher than the atmosphere because of heat emission by the actuator. -

Page 31: Installation

Chapter 3 Installing the actuator 3-3-3 Installation Since the RSF supermini series actuator is a high precision servo mechanism, great care is required for proper installation. Install the actuator taking care not to damage accurately machined surfaces. Do not hit the actuator with a hammer. -

Page 32: Chapter 4 Motor Shaft Retention Brake(Rsf-5B)

Chapter 4 Motor shaft retention brake Chapter 4 Motor shaft retention brake(RSF-5B) The RSF supermini series provides an actuator with a motor shaft retention brake as standard (Option symbol: B), which can meet the fail-safe requirement without any additional brake. -

Page 33: Not Using A Relay Cable

Chapter 4 Motor shaft retention brake 4-2-2 Not using a relay cable If the optional relay cable for brakes (EWA-B!!-JST03-TMC) is not used, the customer must control the brake power supply to the brake release coil and release retention coil. Supply the power upon brake release and during brake release retention, as shown below. -

Page 34: Chapter 5 Options

Chapter 5 Options 5-1 Extension cables There are extension cables that connect the RSF supermini series actuator and driver. There are 3 types of extension cables for encoders, motors, and brakes. Select an appropriate type according to the model of the actuator you ordered. - Page 35 Chapter 5 Options 5-1 Extension cables There are extension cables that connect the RSF supermini series actuator and driver. There are 3 types of extension cables for encoders, motors, and brakes. Select an appropriate type according to the model of the actuator you ordered.

-

Page 36: Connectors

Chapter 5 Options 5-3 Connectors HA-680 Driver There are 2 types of connectors for the driver for different set types: Connector model: CNK-HA68-S1 For CN1, CN2, actuator line connection, power supply connection ......4 types Connector model: CNK-HA68-S2 For CN2, power supply connection ................. 2 types Connector for CN1 Connector for CN2 Mfg by Sumitomo 3M... -

Page 37: Appendix 1 Conversion Of Unit

Appendix 1 Conversion of unit Angle SI unit Unit Deg. Min. Sec. Coefficient 0.01755 2.93x10 4.88x10 Unit Deg. Min. Sec. Coefficient 57.3 3.44x10 2.06x10 SI unit Angular speed SI unit rad/s Unit Deg./s Deg./min r/min Coefficient 0.01755 2.93x10 6.28 0.1047 Unit Deg./s Deg./min... -

Page 41: Moment Of Inertia Of Circular Cylinder

■ Warranty period Under the condition that the actuator are handled, used and maintained properly followed each item of the documents and the manuals, all the RSF supermini series actuators are warranted against defects in workmanship and materials for the shorter period of either one year after delivery or 2,000 hours of operation time. - Page 42 137 N. Oak Park Ave., Suite 410 6-25-3 Minami-Ohi, Shinagawa-ku Oak Park, IL 60301 Tokyo 141-0013, Japan Harmonic Drive AG T: 800.921.3332 Hoenbergstrasse, 14, D-6555 T: 978.532.1800 Limburg/Lahn Germany F: 978.532.9406 www.HarmonicDrive.net Rev 7-14 Harmonic Drive is a registered trademark of Harmonic Drive LLC.

Need help?

Do you have a question about the RSF supermini Series and is the answer not in the manual?

Questions and answers