Table of Contents

Advertisement

Table Of Contents

1 Introduction ........................................................................................ 2

1.1

1.2

2 Safety notes ........................................................................................ 3

2.1

2.2

3 Description of machine ........................................................................ 7

3.1

3.2

4 Machine Setup ................................................................................... 10

4.1

4.2

4.3

5 Using the Conveyor ............................................................................ 12

5.1

5.2

6 Technical Specification ...................................................................... 14

6.1

6.2

7 Troubleshooting Guide ....................................................................... 15

200 Series Conveyor Operator Manual

Pictograms ........................................................................... 2

Notes on the use of this handbook ........................................... 3

General safety notes .............................................................. 4

End of life ............................................................................ 5

Description of operation ......................................................... 7

Identification of parts ............................................................. 8

3.2.1

Angled (Default) Version ........................................... 8

3.2.2

Inline Version .......................................................... 9

Angled Version .....................................................................10

Inline Version ......................................................................11

Backrest adjustment .............................................................11

Output settings ....................................................................12

Adjusting the speed ..............................................................13

Physical sizes .......................................................................14

Electrical .............................................................................14

Issue 1 May 2011

1

Advertisement

Table of Contents

Summary of Contents for quadient 200 Series

-

Page 1: Table Of Contents

Backrest adjustment .............11 5 Using the Conveyor ................12 Output settings ..............12 Adjusting the speed ..............13 6 Technical Specification ..............14 Physical sizes ...............14 Electrical ................14 7 Troubleshooting Guide ............... 15 200 Series Conveyor Operator Manual Issue 1 May 2011... -

Page 2: Introduction

1 Introduction With this conveyor you have an ouput device intended for use with a 200 Series folder/ inserter. It provides a means of receiving filled envelopes prior to hand removal for subsequent further handling. Its speed of operation and jog steps between batches are under software control by the inserter. -

Page 3: Notes On The Use Of This Handbook

In not adhering to this handbook, there is the danger of • an electrical shock, • injuries from the intake at the rotating rollers, • damage to the machine. 200 Series Conveyor Operator Manual Issue 1 May 2011... -

Page 4: General Safety Notes

When cleaning sensors use only non-flammable airdusters, eg. part number Cleaning 9103707C. Other types may use flammable propellants, which could result in sensors fire or explosion. 200 Series Conveyor Operator Manual Issue 1 May 2011... -

Page 5: End Of Life

More particularly, certain materials and components of waste electrical and electronic equipment needs selective treatment as their injudicious handling or disposing of on or into land, water or air would represent a major threat to the environment and human health. 200 Series Conveyor Operator Manual Issue 1 May 2011... - Page 6 For more information on the correct disposal of this product please contact your local dealer. 200 Series Conveyor Operator Manual Issue 1 May 2011...

-

Page 7: Description Of Machine

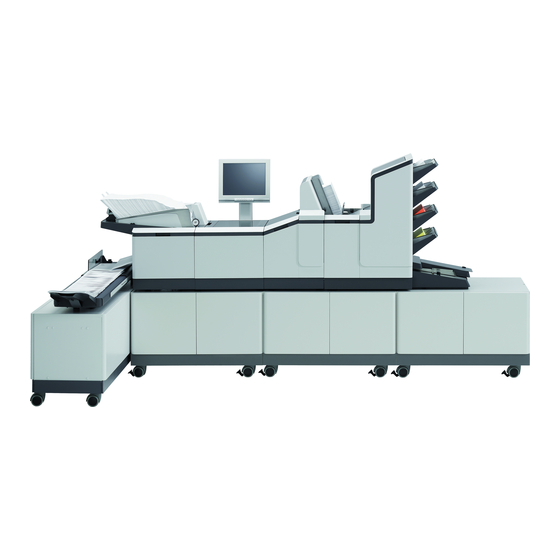

3 Description of machine 3.1 Description of operation The function of the machine is to receive mailpieces from a 200 Series in- serter and stack them along the surface for hand removal. The speed of the conveyor can be adjusted in the operating software for the relevant job, and batches can be ‘jogged’... -

Page 8: Identification Of Parts

1 DS200 Folder/Inserter 2 Adjustable Roller Plate (see section 4) 3 Adjustable Backstop (see section 4) 4 Conveyor Surface 5 Conveyor Stand Unit 6 Adjustable Backrest (see section 4) 7 Operator Screen 200 Series Conveyor Operator Manual Issue 1 May 2011... -

Page 9: Inline Version

1 DS200 Folder/Inserter 2 Adjustable Roller Plate (see section 4) 3 Adjustable Backrest (see section 4) 4 Conveyor Stand Unit 5 Conveyor Surface 6 Adjustable Rollers (see section 4) 7 Operator Screen 200 Series Conveyor Operator Manual Issue 1 May 2011... -

Page 10: Machine Setup

Note: Some envelopes may be found to feed better if the plate is pulled out and turned round the other way. Roller plate Envelope Backstop When adjustments are complete, ensure the adjustment knob is fully tightened. 200 Series Conveyor Operator Manual Issue 1 May 2011... -

Page 11: Inline Version

When the envelopes reach the end of the conveyor, they will stack up against the backrest. This can be adjusted to suit the required amount of tilt: slacken the adjustment knob each side and retighten when you are satisfied with the angle. Adjustment knob 200 Series Conveyor Operator Manual Issue 1 May 2011... -

Page 12: Using The Conveyor

(the steps are unitless), and pause for the specified time. When settings are com- plete, press Next to save the job. 200 Series Conveyor Operator Manual Issue 1 May 2011... -

Page 13: Adjusting The Speed

Fine Tuning settings in the Run Screen. Press the Fine Tuning button – this will open the settings box. Adjust the Con- veyor Pulse Multiplier (speed) as required using the keys. 200 Series Conveyor Operator Manual Issue 1 May 2011... -

Page 14: Technical Specification

235mm (9.¼”) Height Speed 4m/minute Max. Linear Speed (controlled by inserter) Selectable jog function for batching. 6.2 Electrical Electrical Voltage: 24VDC (supplied via DIN lead from inserter) Rating Power: 12W Max. Fuse: 200 Series Conveyor Operator Manual Issue 1 May 2011... -

Page 15: Troubleshooting Guide

5. Adjust batch jog steps in Output batches when in batch mode. Settings (section 5.1). 6. Adjust Conveyor Pulse Multiplier 6. Excessive or insufficient overlap of envelopes on conveyor surface. in Fine Tuning screen (section 5.2). 200 Series Conveyor Operator Manual Issue 1 May 2011... - Page 16 Page intentionally left blank 200 Series Conveyor Operator Manual Issue 1 May 2011...

Need help?

Do you have a question about the 200 Series and is the answer not in the manual?

Questions and answers