Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Huck 4652

-

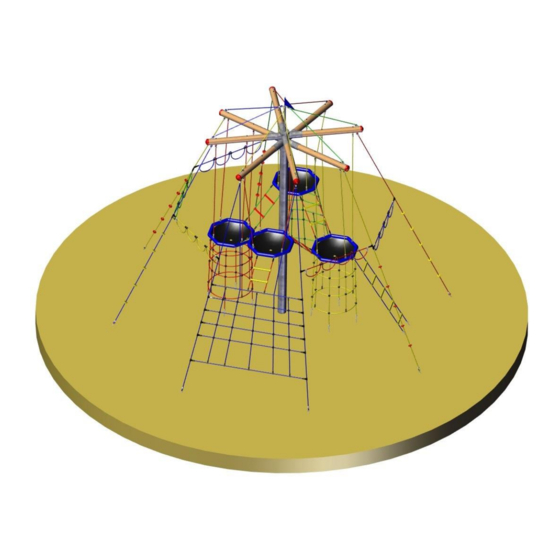

Page 1: A Assembly Instructions Bird's Nest Tree (Eu-Gsm) Art. 4652

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net A Assembly instructions Bird’s nest tree (EU-GSM) Art. 4652 \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc - 1 -... - Page 2 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net Revision history Revision 0 – 2006-02-13 The first allowed version Assembly instruction Revision 20 -2019-09-13 Einschraubanker statt Fundamenteisen PM All rights reserver © Copyright 2006 Huck Seiltechnik GmbH - 2 -...

-

Page 3: Table Of Contents

Delivery contents (parts list with part numbers) ................. 8 Abbreviations ..........................12 Assembly instructions ......................... 14 Post installation checks ....................... 27 Maintenance instructions Bird’s nest tree (EU-GSM) Art. 4652 ..........29 Introduction Maintenance ......................31 General maintenance information ....................32 Maintenance timetable ......................... 34 10 Regular maintenance ........................ -

Page 4: Introduction Assembling

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net 1 Introduction Assembling General information This equipment should be installed, inspected, maintained and operated in accordance with EN1176-7 guidelines. Before installation work commences, please check that you have all of the equipment and fixation components in the parts list provided (see Tables 3-1 and 3-2). - Page 5 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net Drawings / Views All optical drawings are showing only the measurements/dimensions and are no mandatory technical views of the complete item. We reserve the right to change technical details of our articles which are serving for the further development of our articles and are reasonable for the customer.

-

Page 6: Datasheet Bird's Nest Tree, Article 4652

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net Datasheet Bird’s nest tree, article 4652 Equipment space: Ø 8240 mm safety zone: Ø 11000 mm height of fall: 2800 mm Required safety surface: Surface material Description Minimum Maximum... - Page 7 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net Round off foundation edges (min.R = 100 mm)! Sizes of fundations are “4-5” (natural ground). Soil class 4: soft to medium plasticity, interleave bound, with minor portion of stone (portion < 30% with bigger diameter of 63 mm grain size).

-

Page 8: Delivery Contents (Parts List With Part Numbers)

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net Delivery contents (parts list with part numbers) In words Table 3-1: Delivery contents, in words Pos. Quantity Element / Size O.K. Missing Description Ø 193,7 mm / Steel mast 6200 mm lg. -

Page 9: Table 3-2: Delivery Contents, In Symbols

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net In symbols Table 3-2: Delivery contents, in symbols Pos. Quantity Symbol Ø 193,7 mm / 6200 mm lg. Ø 219,1 mm / 1240 mm Ø 139 mm / 1650 mm lg. - Page 10 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net 1850 mm lg. (pre-assembled on Pos. 03) 365 mm lg. (1x pre-assembled) Ø 139 mm 3,5 x 25 mm - 10 - \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc...

- Page 11 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net M10 x 175 mm 3 ml M12 x 25 mm 500mm x 500mm (Ring nut M16 pre-assembled) (2x pre-assembled) Ø 400 mm / 850 mm lg. \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc - 11 -...

-

Page 12: Abbreviations

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net Abbreviations Setting time min. 7-8 days C25/30 concrete (for foundations) Q.ty required: 3.2 m Fill in around the central mast with concrete. D.be. (between drainage tube and central mast) Detail turn the ground anchor in to foundation / don’t press... - Page 13 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc - 13 -...

-

Page 14: Assembly Instructions

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net Assembly instructions - 14 - \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc... - Page 15 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc - 15 -...

- Page 16 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net - 16 - \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc...

- Page 17 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc - 17 -...

- Page 18 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net - 18 - \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc...

- Page 19 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc - 19 -...

- Page 20 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net - 20 - \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc...

- Page 21 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc - 21 -...

- Page 22 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net - 22 - \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc...

- Page 23 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc - 23 -...

- Page 24 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net - 24 - \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc...

- Page 25 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc - 25 -...

- Page 26 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net - 26 - \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc...

-

Page 27: Post Installation Checks

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net Post installation checks If the equipment has not been installed safely, you must ensure that the public is prevented from using it. Marking filler depth • Labelling the posts to show the depth of material provided as fall protection (i.e. -

Page 29: B Maintenance Instructions Bird's Nest Tree (Eu-Gsm) Art. 4652

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net B Maintenance instructions Bird’s nest tree (EU-GSM) Art. 4652 \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc - 29 -... - Page 30 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net Revision history Revision 0 – 2006-02-13 The first allowed version Maintenance instruction Revision 19 -2019-02-11 Einschraubanker statt Kette FH All rights reserved © Copyright 2006 Huck Seiltechnik GmbH - 30 -...

-

Page 31: Introduction Maintenance

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net Introduction Maintenance General information This equipment should be installed, inspected, maintained and operated in accordance with EN 1176-7 guidelines. Please note: Providing any necessary repairs are carried out, a piece of play equipment that is inspected regularly cannot become so damaged that it is dangerous. -

Page 32: General Maintenance Information

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net General maintenance information Maintenance intervals Maintenance intervals are based on average use. Please note that more frequent inspections and/or maintenance are required if the play equipment is subject to intensive use. - Page 33 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net 8.10 Faults Faults must be repaired as soon as they are detected. If serious defects that compromise safety cannot be repaired straight away, the public must be prevented from using the equipment with immediate effect.

-

Page 34: Maintenance Timetable

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net Maintenance timetable Special advices 9.1.1 Maintenance interval We strongly advise you to carry out inspections and maintenance work within the specified periods as use of the equipment, the weather and malicious vandalism cause wear and tear that compromises the safety and function of the equipment. -

Page 35: Regular Maintenance

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net 10 Regular maintenance \\CAD1\Standard\4652\Montageanleitung\Vogelnestbaum_Leimbinder_4652_SO_B_L_1_GBR.doc - 35 -... - Page 36 Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net 10.1 Regular maintenance (Text) m = monthly j = 1/4 quarterly j = 1/2 half-yearly ¼ j ½ j Check ground in fall and protection area for hard objects and loose foundations.

-

Page 37: Monthly Maintenance

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net 11 Monthly maintenance • Check the spaces between the equipment and the ground (clearance and height of fall). • Check the ground surface in the area with fall protection for hard objects and loose foundations. -

Page 38: Half Yearly Maintenance

Zinc paint should be applied to corroded areas and scratches. The equipment must be inspected by someone with the necessary expertise in strict compliance with the instructions issued by Huck Seiltechnik GmbH. A copy of the inspection record should be given to the operator, who must confirm receipt. -

Page 39: Maintenance Printout

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net 15 Maintenance printout Name of item: Bird’s nest tree / Art. No. 4652 ______________ Location: _______________________________________________________________________________________ Customer or operator: _____________________________________________________________________________ (Town, Town council, Kindergarten) Date of Inspector O.K. Accessible... -

Page 41: Hand Over Document

Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany seiltechnik@huck.net • www.huck.net 16 Hand over document After the installation of the equipment pass the installation and maintenance documents to the operator. The operator has to receive the hand over documents. The complete filled and signed hand over document should be sent to the supplier.

Need help?

Do you have a question about the 4652 and is the answer not in the manual?

Questions and answers