Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Pfeiffer Vacuum WS 5100 WW2D

- Page 1 OPERATING INSTRUCTIONS PUMPING STATION WS 5100 WW2D Part No.: PP S30 596 A...

-

Page 2: Table Of Contents

Contents Contents About this manual ........3 Validity . -

Page 3: About This Manual

1 About this manual 1.1 Validity This operating manual is for customers of Pfeiffer Vacuum. It describes the functioning of the designated product and provides the most important information for safe use of the unit. The description follows applicable EU guidelines. All information provided in this op- erating manual refer to the current state of the product's development. - Page 4 About this manual Pictogram definitions Prohibition of an action to avoid any risk of accidents, the disregarding of which may result in serious accidents. Warning of a displayed source of danger. Command to perform an action or task associated with a source of dan- ger, the disregarding of which may result in serious accidents.

-

Page 5: Safety

NOTE Installation and operation of accessories Pfeiffer Vacuum pumps can be equipped with a series of adapted accessories. The installation, operation and maintenance of connected devices are described in detail in the operating instructions of the individual components. -

Page 6: Proper Use

• Only use the pumping station for creating vacuum. • Only use the pumping station for evacuation of dry and inert gases; other applications only after consultation with Pfeiffer Vacuum. • Use suitable gases (process-specific) such as sealing gas, flushing gas and cooling gas at the inlets of the pumping station components. -

Page 7: Transport And Storage

Transport and storage 3 Transport and storage 3.1 Unpacking / repacking For transport, the pumping station is fastened to a pallet in a slip-free manner, covered with a plastic sheet and secured in wooden holders or wooden crates. NOTE Disposal of packaging materials The packaging materials cannot be reused after unpacking. -

Page 8: Storage

Transport and storage Fig. 1: Lifting eyes Lifting eyes 3.3 Storage The pumping station is suitable for storage. Enclosed, dry and dust-free rooms are suita- ble storage locations. Check that all the openings on the pumps are securely closed. ... -

Page 9: Product Description

Product description 4 Product description 4.1 Product identification To correctly identify the product when communicating with Pfeiffer Vacuum, always have the information from the rating plate available. • Pumping station type and article number • Serial number • Voltage and rated current •... -

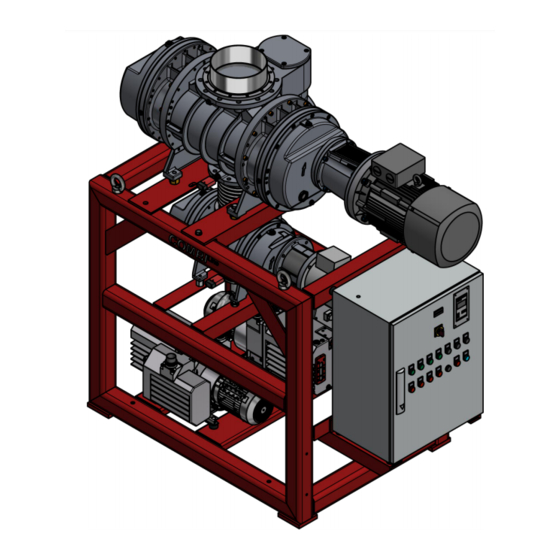

Page 10: Function

Installation Fig. 3: Pumping station rear view 2nd Gas outlet 2nd OME 40 M 2nd DUO 65 M 4.3 Function The pumping station is intended for evacuating vacuum chambers to pressure values in the medium vacuum range. 5 Installation 5.1 Installation location Observe the following requirements when setting up the pumping station: •... -

Page 11: Assembly

NOTE Use approved operating fluids only! The use of operating fluids that have not been approved by Pfeiffer Vacuum shall result in a limited warranty. In such cases, it is not possible to guarantee that product-specific performance data will be achieved. -

Page 12: Connections

Installation WARNING There is a risk of injury if the system is not transported properly Danger to life from falling or protruding loads if the system is not properly secured to lifting devices or is not transported properly. Use suitable lifting devices and tools. ... -

Page 13: Operation

Operation Connecting the ex- haust side CAUTION High pressure in the exhaust line! Danger of damage to the seals and danger of the pump bursting. Install the line without shut-off valves on the exhaust side. If there is danger of a build-up of excess pressure (> 1500 hPa abs.) in the lines, ob- serve all official accident prevention safety regulations. -

Page 14: Before Switching On

Operation • The operator advises in recurring training courses the operating, maintenance, and service personnel in the correct behaviors while handling the pumping station. He ex- plains that damages to persons and systems can occur, if the pumping station is not operated correctly. - Page 15 Operation For Local Operation with disabled automatic mode In local operation with disabled automatic mode, the pumping station is operated via the control elements on the control cabinet. In this case, the responsibility for switching the pumping station on and off lies with the operator. ...

-

Page 16: Malfunctions

Decontaminate affected parts before carrying out maintenance work. NOTE Disclaimer of liability Pfeiffer Vacuum accepts no liability for personal injury or material damage, losses or operating malfunctions due to improperly performed maintenance. The liability and warranty entitlement expires. WARNING... -

Page 17: Removal Of Components For Their Maintenance

Decommissioning • For all other cleaning, maintenance or repair work, please contact your Pfeiffer Vacu- um service location. 8.2 Removal of components for their maintenance In some cases, components may need to be dismantled from the pumping station so that customers can carry out necessary maintenance work on them (they should then be re- assembled in reverse order). -

Page 18: Re-Starting

The following steps are necessary to ensure a fast, smooth servicing process: Download the forms "Service Request" and "Declaration on Contamination". Fill out the "Service Request" form and send it by fax or e-mail to your Pfeiffer Vacuum service address. -

Page 19: Spare Parts

11 Spare parts NOTE Service work should be carried out by qualified personal only! Pfeiffer Vacuum is not liable for any damage to the pump resulting from work carried out improperly. Take advantage of our service training programs; additional information at www.pfeiffer-vacuum.de. - Page 20 Technical data...

- Page 21 DIN EN 1012-2:2011-12 DIN EN ISO 2151:2:2008 DIN EN 13849-1:2015 The authorized representative for the compilation of technical documents is Mr. An- dreas Würz, Pfeiffer Vacuum GmbH, Berliner Str. 43, 35614 Asslar. Signature: Pfeiffer Vacuum GmbH Berliner Straße 43 35614 Asslar Germany (Daniel Sälzer)

- Page 22 VACUUM SOLUTIONS FROM A SINGLE SOURCE Pfeiffer Vacuum stands for innovative and custom vacuum solutions worldwide, technological perfection, competent advice and reliable service. COMPLETE RANGE OF PRODUCTS From a single component to complex systems: We are the only supplier of vacuum technology that provides a complete product portfolio.

Need help?

Do you have a question about the WS 5100 WW2D and is the answer not in the manual?

Questions and answers