Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Rohde & Schwarz FSWP

- Page 1 ® R&S FSWP Phase Noise Analyzer Getting Started (;ÛÇÆ2) 1177575602 Version 13...

- Page 2 Rohde & Schwarz GmbH & Co. KG. Trade names are trademarks of the owners. ® 1177.5756.02 | Version 13 | R&S FSWP Throughout this manual, products from Rohde & Schwarz are indicated without the ® symbol , e.g. ® R&S FSWP is indicated as R&S FSWP.

-

Page 3: Table Of Contents

3.3 Choosing the Operating Site............. 17 3.4 Setting Up the R&S FSWP..............18 3.4.1 Placing the Product on a Bench Top.............18 3.4.2 Mounting the R&S FSWP in a Rack............. 19 3.5 Connecting the AC Power..............20 3.6 Switching the Instrument On and Off..........21 3.7 Connecting to LAN................ - Page 4 ® Contents R&S FSWP 3.10 Windows Operating System...............25 3.11 Logging On..................27 3.12 Checking the Supplied Options............29 3.13 Performing a Self-Alignment............. 30 3.14 Considerations for Test Setup............30 4 Instrument Tour..............32 4.1 The Front Panel...................32 4.1.1 Display (Touchscreen)................33 4.1.2 Power Key.....................35 4.1.3 System Control Keys................

- Page 5 4.2.9 AUX Port....................48 4.2.10 GPIB Interface..................49 4.2.11 External Generator Control (Optional)..........49 4.2.12 OCXO (Optional)...................49 4.2.13 REF INPUT / REF OUTPUT..............50 4.2.14 Labels on R&S FSWP................51 4.2.15 Device ID....................51 5 Trying Out the Instrument...........52 5.1 Initial Setup..................54 5.2 Measurements..................55 5.2.1 Measurement Selection................

- Page 6 ® Contents R&S FSWP 5.3.4 Miscellaneous Evaluation Tools............67 5.4 Measurement Configuration.............. 68 5.4.1 Frequency Configuration...............68 5.4.2 The Half Decade Configuration Table........... 69 5.4.3 Pulsed Measurement Configuration............70 5.4.4 Signal Generation................. 71 5.4.5 DUT Power Supply................72 6 Operating the Instrument............74 6.1 Understanding the Display Information..........74...

- Page 7 ® Contents R&S FSWP 6.5.1 Activating and Deactivating Channels..........92 6.5.2 Laying out the Result Display with the SmartGrid.........94 6.5.3 Changing the Size of Windows............. 98 6.5.4 Switching Between a Split and Maximized Window Display....99 6.5.5 Changing the Display................100 6.6 Remote Control................. 100 6.6.1 Remote Desktop Connection..............

- Page 8 ® Contents R&S FSWP Getting Started 1177.5756.02 ─ 13...

-

Page 9: Safety And Regulatory Information

® Safety and Regulatory Information R&S FSWP Safety Instructions Safety and Regulatory Information The product documentation helps you use the product safely and efficiently. Fol- low the instructions provided here and in the Chapter 1.1, "Safety Instructions", on page 9. - Page 10 ® Safety and Regulatory Information R&S FSWP Safety Instructions Using the product requires specialists or specially trained personnel. These users also need sound knowledge of at least one of the languages in which the user interfaces and the product documentation are available.

- Page 11 ® Safety and Regulatory Information R&S FSWP Safety Instructions uct is moved without lifting it. The foldable feet are designed to carry the weight of the product, but not an extra load. If stacking is possible, keep in mind that a stack of products can fall over and cause injury.

-

Page 12: Warning Messages In The Documentation

® Safety and Regulatory Information R&S FSWP Warning Messages in the Documentation Cleaning the product Use a dry, lint-free cloth to clean the product. When cleaning, keep in mind that the casing is not waterproof. Do not use liquid cleaning agents. -

Page 13: Korea Certification Class A

® Safety and Regulatory Information R&S FSWP Korea Certification Class A NOTICE Potential risks of damage. Could result in damage to the supported product or to other property. Korea Certification Class A 이 기기는 업무용(A급) 전자파 적합기기로서 판매자 또는 사용자는 이 점을 주의하... -

Page 14: Documentation Overview

R&S FSWP product page at: www.rohde-schwarz.com/manual/FSWP Getting Started Manual Introduces the R&S FSWP and describes how to set up and start working with the product. Includes basic operations, typical measurement examples, and general information, e.g. safety instructions, etc. -

Page 15: Instrument Security Procedures

Rohde & Schwarz information system (GLORIS): https://gloris.rohde-schwarz.com Instrument Security Procedures Deals with security issues when working with the R&S FSWP in secure areas. It is available for download on the Internet. Printed Safety Instructions Provides safety information in many languages. The printed document is deliv- ered with the product. -

Page 16: Application Notes, Application Cards, White Papers, Etc

® Documentation Overview R&S FSWP Application Notes, Application Cards, White Papers, etc. www.rohde-schwarz.com/firmware/FSWP Application Notes, Application Cards, White Papers, etc. These documents deal with special applications or background information on particular topics. www.rohde-schwarz.com/application/FSWP Getting Started 1177.5756.02 ─ 13... -

Page 17: Preparing For Use

"Lifting and carrying the product" on page 10. Unpacking and Checking 1. Unpack the R&S FSWP carefully. 2. Retain the original packing material. Use it when transporting or shipping the R&S FSWP later. 3. Using the delivery notes, check the equipment for completeness. -

Page 18: Setting Up The R&S Fswp

If class A equipment causes radio disturbances, take appropriate measures to eliminate them. Setting Up the R&S FSWP The R&S FSWP is designed for use on a bench top or in a rack. See also: ● "Setting up the product"... -

Page 19: Mounting The R&S Fswp In A Rack

To mount the R&S FSWP in a rack 1. Use an adapter kit to prepare the R&S FSWP for rack mounting. a) Order the rack adapter kit designed for the R&S FSWP. For the order num- ber, see the data sheet. -

Page 20: Connecting The Ac Power

FSWP Connecting the AC Power 3. Grab the handles and push the R&S FSWP onto the shelf until the rack brack- ets fit closely to the rack. 4. Tighten all screws in the rack brackets with a tightening torque of 1.2 Nm to secure the R&S FSWP in the rack. -

Page 21: Switching The Instrument On And Off

► Press the [Power] key. The operating system shuts down. The LED changes to orange. If the instrument temperature exceeds the limit specified in the data sheet, the R&S FSWP automatically shuts down to protect the instrument from damage. Getting Started 1177.5756.02 ─ 13... -

Page 22: Connecting To Lan

Switch", on page 46. The LED of the standby key is switched off. 2. Disconnect the R&S FSWP from the power source. Connecting to LAN You can connect the instrument to a LAN for remote operation via a PC. Provided the network administrator has assigned you the appropriate rights and... -

Page 23: Connecting A Keyboard

● Changing IP addresses ● Exchanging hardware Errors can affect the entire network. Connect the R&S FSWP to the LAN via the LAN interface on the rear panel of the instrument. Windows automatically detects the network connection and activates the required drivers. -

Page 24: Connecting An External Monitor

46). Screen resolution and format The touchscreen of the R&S FSWP is calibrated for a 16:10 format. If you connect a monitor or projector using a different format (e.g. 4:3), the calibra- tion is not correct and the screen does not react to your touch actions prop- erly. -

Page 25: Windows Operating System

After the R&S FSWP is started, the operating system boots and the instrument firmware is started automatically. - Page 26 ® Preparing for Use R&S FSWP Windows Operating System Tested software The drivers and programs used on the instrument under Microsoft Windows are adapted to the instrument. Only install update software released by Rohde & Schwarz to modify existing instrument software.

-

Page 27: Logging On

3.11 Logging On Microsoft Windows requires that users identify themselves by entering a user name and password in a login window. By default, the R&S FSWP provides two user accounts: ● "Instrument": a standard user account with limited access ● "Admin" or "Administrator" (depends on firmware image): an administrator account with unrestricted access to the computer/domain Some administrative tasks require administrator rights (e.g. - Page 28 ® Preparing for Use R&S FSWP Logging On Passwords For all default user accounts, the initial password is 894129. Note that this pass- word is very weak, and it is recommended that you change the password for both users after initial login. An administrator can change the password in Microsoft Windows for any user at any time via "Start >...

-

Page 29: Checking The Supplied Options

However, you can switch the user account to be used even when the auto-login function is active. 1. Select the "Windows" icon in the toolbar to access the operating system of the R&S FSWP (see also "To access the "Start" menu" on page 27). -

Page 30: Performing A Self-Alignment

Considerations for Test Setup 3.13 Performing a Self-Alignment When strong temperature changes occur in the environment of the R&S FSWP, or after updating the firmware, you have to perform a self-alignment to align the data to a reference source. During self-alignment, do not connect a signal to the RF input connector. Running a self-alignment with a signal connected to the RF input can lead to false mea- surement results. - Page 31 ● Ensure that connected external devices comply with EMC regulations. Signal input and output levels Information on signal levels is provided in the data sheet. Keep the signal levels within the specified ranges to avoid damage to the R&S FSWP and connected devices. Getting Started 1177.5756.02 ─ 13...

-

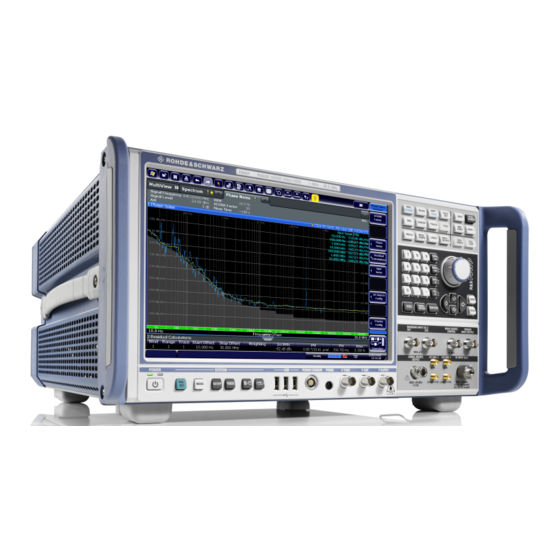

Page 32: Instrument Tour

Instrument Tour R&S FSWP The Front Panel Instrument Tour On the instrument tour, you can learn about the different control elements and connectors on the front and back panel of the R&S FSWP. ● The Front Panel....................32 ● The Rear Panel.................... -

Page 33: Display (Touchscreen)

(Optional)................. 44 4.1.1 Display (Touchscreen) The touchscreen on the front panel of the R&S FSWP displays the measurement results. Additionally, the screen display provides status and setting information and allows you to switch between various measurement tasks. The screen is touch-sensitive, offering an alternative means of user interaction for quick and easy handling of the instrument. - Page 34 ® Instrument Tour R&S FSWP The Front Panel 1 = Toolbar: contains general functionality of the firmware. 2 = Channel tab: contains measurement channel. 3 = Channel bar: shows measurement settings. 4 = Result display: contains measurement results. 5 = Window title bar: contains diagram-specific (trace) information.

-

Page 35: Power Key

® Instrument Tour R&S FSWP The Front Panel ● Scrolling through a result list ● Saving or printing results and settings To imitate a right-click by mouse using the touchscreen, for example to open a context-sensitive menu for a specific item, press the screen for about 1 second. -

Page 36: The Function Keys

® Instrument Tour R&S FSWP The Front Panel 4.1.4 The Function Keys Function keys provide access to the most common measurement settings and functions. Refer to the user manual for an extensive description of the measurement set- tings and functions. -

Page 37: The Keypad

® Instrument Tour R&S FSWP The Front Panel Provides functionality to position and control markers, for example: ● to configure the marker search ● to configure the peak excursion Provides the measurement functions, for example: ● the phase noise measurement ●... -

Page 38: Navigation Control

® Instrument Tour R&S FSWP The Front Panel Select a particular unit for a numeric value. The labels on and next to the key state the units it selects. Pressing one of the unit keys also completes the entry of a numeric value. - Page 39 ® Instrument Tour R&S FSWP The Front Panel knob. If the dialog box covers more than one screen page, it also scrolls through the dialog box. Turning it to the right corresponds to a downward movement. Moving it to the left to an upward movement.

-

Page 40: Rf Input (50 Ω)

4.1.7 The RF Input allows you to connect a device under test (or DUT) to the R&S FSWP, usually via cable and an appropriate connector (for example a male N connector). The supported frequency range depends on the R&S FSWP model you have. -

Page 41: Usb Ports

The three USB ports on the front panel (type A) allow you to connect devices like keyboards, mouses or memory sticks. The R&S FSWP provides additional USB ports (including one type B port) on the rear panel. All USB ports support standard 2.0. -

Page 42: Noise Source Control

® Instrument Tour R&S FSWP The Front Panel 4.1.12 Noise Source Control The female BNC connector labeled "Noise Source" allows you to connect and control an external noise source, and supplies the required supply voltage. You can use a noise source, for example, to measure the noise figure and gain of amplifiers and frequency converting devices. -

Page 43: External Mixer (Optional)

® Instrument Tour R&S FSWP The Front Panel Risk of instrument damage Do not overload the baseband input. An overload condition can damage or destroy the baseband inputs. For maximum allowed values, see the data sheet. 4.1.15 External Mixer (Optional) The two (optional) SMA connectors (LO OUT/IF IN and IF IN) allow you to con- nect external mixers. -

Page 44: Lo Aux Input (Optional)

® Instrument Tour R&S FSWP The Rear Panel 4.1.17 LO AUX Input (Optional) The two optional connectors labeled "LO AUX Input - Ch1" and "LO AUX Input - Ch2" are two female SMA connectors that you can use to connect an external local oscillator (LO). - Page 45 ® Instrument Tour R&S FSWP The Rear Panel Figure 4-2: Rear panel of the R&S FSWP 1 = Removable hard disk 2 = AC power connector and power switch 3 = DisplayPort and DVI 4 = LAN interface 5 = USB ports...

-

Page 46: Removable Hard Disk

20. 4.2.3 Display Port and DVI You can connect an external monitor or other display device to the R&S FSWP to provide an enlarged display. Two different types of connectors are provided for this purpose: ● Display Port... -

Page 47: Lan

The four USB ports on the rear panel (type A) allow you to connect devices like keyboards, mouses or memory sticks. The male USB connector (type B) allows you to connect the R&S FSWP to a computer and establish a remote control connection, for example. -

Page 48: Sync Trigger Input And Output

The Rear Panel You can activate and deactivate the bandwidth extension manually in the I/Q ana- lyzer that is integral part of the optional spectrum analyzer (R&S FSWP-B1) or other optional applications that require the spectrum analyzer hardware. Together with the bandwidth extension an additional IF output connector is provi- ded (if wide output). -

Page 49: Gpib Interface

48). For details on connecting an external generator see the "External Generator Con- trol" section of the R&S FSWP User Manual. 4.2.12 OCXO (Optional) This optional OCXO generates a 10 MHz reference signal with a very precise fre- quency. -

Page 50: Ref Input / Ref Output

The REF OUTPUT connectors can be used to provide an external reference sig- nal or the OCXO reference signal from the R&S FSWP to other devices that are connected to this instrument. Various connectors are provided for different reference signals:... -

Page 51: Labels On R&S Fswp

ID", on page 51 Table 4-1: Labels regarding R&S FSWP and environment safety Labeling in line with EN 50419 for disposal of electrical and electronic equipment after the product has come to the end of its service life. For more information, see the prod- uct user manual, chapter "Disposal". -

Page 52: Trying Out The Instrument

® Trying Out the Instrument R&S FSWP Trying Out the Instrument Overview of tutorials Initial setup: ● "Preparing the R&S FSWP" on page 54 ● "Selecting the phase noise application" on page 54 ● "Performing a preset" on page 54 Measurement selection ●... - Page 53 DUT power supply ● "How to supply DUTs with current or voltage" on page 72 An in-depth description of all features, including remote commands, is available in the R&S FSWP user manual. ● Initial Setup..................... 54 ● Measurements....................55 ●...

-

Page 54: Initial Setup

2. Select the "Phase Noise" item in the "Mode" dialog box. There's more than one way to skin a cat In most cases, the firmware of the R&S FSWP provides several ways to change measurement parameters. For example, the measurement range can be defined via the [FREQ] key, the "MEAS CONFIG"... -

Page 55: Measurements

R&S FSWP and a DUT. Some measurements require additional equipment. ● For additive noise measurements, the R&S FSWP must be equipped with the optional Signal Source hardware. ● For pulsed noise measurements, the R&S FSWP must be equipped with the optional Pulsed Phase Noise Measurement application. -

Page 56: The Phase Noise Measurement

Trying Out the Instrument R&S FSWP Measurements 5.2.2 The Phase Noise Measurement Test setup Connect the DUT via cable to the RF input of the R&S FSWP as shown in the illustration. required connections R&S FSWP optional connections supply tune... - Page 57 The spurious list contains all detected spurs (including their characteristics) on all traces and all windows. For more information see the R&S FSWP user manual. Measuring spot noise Spot noise is the phase noise or AM noise at a specific offset frequency (for example the phase noise at 500 kHz).

-

Page 58: The Additive Noise Measurement

The table contains a list of spot noise values for selected frequency offsets (in the default state, these are the decade edges) on each active trace. For more information on the table contents see the R&S FSWP user manual. Tip: You can define custom spot noise frequencies in the "Spot Noise" tab of the "Noise Config"... -

Page 59: The Baseband Noise Measurement

1 mHz (the lowest supported frequency on the RF input is 1 MHz). Using the baseband input, you can, for example, test the voltage supply of DC sources. Test setup required connections R&S FSWP optional connections supply tune RF / BB* * = See text below for instructions on how to use the baseband input. -

Page 60: The Pulsed Phase Noise Measurement

Trigger Input How to measure the phase noise of a pulse 1. Connect the DUT via cable to the RF input of the R&S FSWP as shown in the illustration. 2. Perform a [PRESET]. 3. Select the [MEAS] key and select the "Pulsed Phase Noise" measurement. -

Page 61: The Pulsed Additive Noise Measurement

The test setup depends on whether you use internal or external modulation with a pulse modulator. Test setup (internal pulse modulation) required connections R&S FSWP optional connections Signal Source supply tune... -

Page 62: Adding Another Measurement Channel

® Trying Out the Instrument R&S FSWP Result Evaluation For pulsed measurements using the LO AUX input, do not apply pulses with a frequency below 1024 MHz. Pulses below that frequency will abort the measurement. 5.2.7 Adding Another Measurement Channel... -

Page 63: Trace Smoothing

® Trying Out the Instrument R&S FSWP Result Evaluation 5.3.1 Trace Smoothing How to smooth the trace by averaging the measurement data When you average the trace, the application measures the data several times and builds an average over all measurements when it is done. Averaging mea- surement data yields a smoother trace. - Page 64 (in %) in the corresponding input field. Trace smoothing is applied immediately after you have applied it to a trace. For more information on how this is done, refer to the R&S FSWP user man- ual. How to remove spurs from a trace By default, the application already shows a trace without spurs (the yellow one).

-

Page 65: Integration Ranges

Signals with levels below the threshold are not regarded as spurs and are still displayed. For more information about spur removal, refer to the R&S FSWP user man- ual. Note: Note that the threshold is always taken into account in the spur table, regardless of whether spur removal is on or off. -

Page 66: The Cross-Correlation Gain Indicator

Figure 5-3: Custom integration ranges are represented in the diagram as colored lines For more information on integrated measurement result calculation refer to the R&S FSWP user manual. 5.3.3 The Cross-Correlation Gain Indicator How to control the cross-correlation gain indicator (gray area) The gray trace, or cross-correlation gain indicator, indicates the ideal position of the measurement trace for the current number of cross-correlation operations. -

Page 67: Miscellaneous Evaluation Tools

® Trying Out the Instrument R&S FSWP Result Evaluation 2. Select the "Noise Config" tab. 3. Change the "XCORR Factor", run a single measurement, and see how the position of the gray area changes. Figure 5-4: Increasing XCORR operations changes shape of gray area 4. -

Page 68: Measurement Configuration

Note: In case of baseband measurements, the measurement range is defined by an absolute start and stop frequency instead of offsets. For more information on the measurement range, refer to the R&S FSWP user manual. Getting Started 1177.5756.02 ─ 13... -

Page 69: The Half Decade Configuration Table

® Trying Out the Instrument R&S FSWP Measurement Configuration How to search for signals The application allows you to search for a carrier signal, instead of defining the carrier frequency manually. 1. Enter the "Overview" dialog box, and from there, enter the "Frequency" dialog box. -

Page 70: Pulsed Measurement Configuration

® Trying Out the Instrument R&S FSWP Measurement Configuration You can either enter the values for the measurement bandwidth and number of cross-correlation operations directly. Or you can let the application calculate ideal values for each half decade. 1. Enter the "Overview" dialog box, and from there, enter the "Noise Config" dia- log box. -

Page 71: Signal Generation

How to generate a CW signal Some measurement setups require you to feed a signal into the DUT. You can equip the R&S FSWP with an optional Signal Source that is able to generate such a signal. Available only for additive noise measurements and with the optional signal source hardware component. -

Page 72: Dut Power Supply

® Trying Out the Instrument R&S FSWP Measurement Configuration 5. Turn on the signal source with the "Source Power" feature. Tip: You can turn the signal source on and off effectively with the "RF On/Off" button in the toolbar. The "RF Config" button provides access to a softkey menu that lets you change the signal source characteristics without entering a dialog box. - Page 73 Trying Out the Instrument R&S FSWP Measurement Configuration The R&S FSWP can provide both, when you set it up that way. 1. Enter the "Overview" dialog box and, from there, enter the "Output" dialog box. 2. Select the "DC Config" tab.

-

Page 74: Operating The Instrument

Understanding the Display Information Operating the Instrument The following topics provide an overview on how to work with the R&S FSWP. They describe what kind of information is displayed in the diagram area, how to operate the R&S FSWP via the front panel keys and other interaction methods, and how to use the Online Help. -

Page 75: Channel Bar

6.1.1 Channel Bar Using the R&S FSWP you can handle several different measurement tasks (channels) at the same time (although they can only be performed asynchro- nously). For each channel, a separate tab is displayed on the screen. In order to switch from one channel display to another, simply select the corresponding tab. - Page 76 ® Operating the Instrument R&S FSWP Understanding the Display Information MultiView tab An additional tab labelled "MultiView" provides an overview of all active channels at a glance. In the "MultiView" tab, each individual window contains its own chan- nel bar with an additional button. Tap this button to switch to the corresponding channel display quickly.

- Page 77 ® Operating the Instrument R&S FSWP Understanding the Display Information Table 6-1: Channel settings displayed in the channel bar Label Information Signal Frequency Current carrier frequency of the applied signal. Signal Level Currently level measured on the carrier frequency. Current RF attenuation.

-

Page 78: Window Title Bar

6.1.2 Window Title Bar Each channel in the R&S FSWP display may contain several windows. Each win- dow can display either a graph or a table as a result of the channel measurement. Which type of result evaluation is displayed in which window is defined in the dis- play configuration (see Chapter 6.5, "Displaying... -

Page 79: Marker Information

® Operating the Instrument R&S FSWP Understanding the Display Information Spur removal Spur removal characteristics. Only displayed if spur removal has been turned on for a trace. Trace offset Trace offset characteristics. Only displayed if an offset has been defined for a trace. -

Page 80: Spot Noise Information

Spot noise information in spot noise table The R&S FSWP also provides a numerical result table for the spot noise mea- surement. The spot noise table has to be added deliberately. Note that the spot noise table only contains information when the calculation of spot noise has been turned on. -

Page 81: Frequency Information In Diagram Footer

® Operating the Instrument R&S FSWP Understanding the Display Information The numbers within the green bar show the progress of the cross-correlation operations in the half decade the application currently works on. The first number is the current, the second number the total count of cross- correlations for that half decade. - Page 82 = DC Power has been turned on and violates the defined limits The R&S FSWP is configured for operation with an external reference. Progress The status of the current operation is displayed in the status bar. This includes the remaining measurement time for measurements that last longer than 1 second.

-

Page 83: Error Information

® Operating the Instrument R&S FSWP Understanding the Display Information 6.1.8 Error Information If errors or irregularities are detected, a keyword and an error message, if availa- ble, are displayed in the status bar. Depending on the type of message, the status message is indicated in varying colors. -

Page 84: Accessing Functions

Until the firmware version is updated, this error mes- sage is displayed and self-alignment fails. (For details refer to the R&S FSWP User Manual). Accessing Functions All tasks necessary to operate the instrument can be performed using the user interface. -

Page 85: Toolbar

You can hide the toolbar display, for example when using remote control, in order to enlarge the display area for the measurement results ("Setup > Dis- play > Displayed Items"). See the R&S FSWP User Manual for details. Windows: opens the Windows "Start" menu and task bar. -

Page 86: Softkeys

® Operating the Instrument R&S FSWP Accessing Functions Sequencer: opens the "Sequencer" menu to perform consecutive measure- ments. DC Power: turns the DC power output on and off. DC Configuration: provides quick access to configure the main parameters for DC power supply. -

Page 87: Context Menus

® Operating the Instrument R&S FSWP Accessing Functions Recognizing the softkey status by color Color Meaning orange associated dialog box is open blue associated function is active; for toggle keys: currently active state gray instrument function is temporarily not available due to a specific setting or missing option You can hide the softkey display, e.g. -

Page 88: Changing The Focus

® Operating the Instrument R&S FSWP Changing the Focus The on-screen keyboard display can be switched on and off as desired using the "On-Screen Keyboard" function key beneath the screen. When you press this key, the display switches between the following options: ●... -

Page 89: Entering Data

® Operating the Instrument R&S FSWP Entering Data Entering Data You can enter data in dialog boxes using any of the following methods: ● Using the touchscreen, via the on-screen keyboard ● Using other elements provided by the front panel, e.g. the keypad, rotary knob, or navigation keys The rotary knob acts like the [ENTER] key when it is pressed. -

Page 90: Entering Alphanumeric Parameters

For details, see "System Configuration Setttings" in the R&S FSWP base unit user manual. To enter numbers and (special) characters via the keypad 1. - Page 91 ® Operating the Instrument R&S FSWP Entering Data To correct an entry 1. Using the arrow keys, move the cursor to the right of the entry you want to delete. 2. Press the [BACKSPACE] key. The entry to the left of the cursor is deleted.

-

Page 92: Displaying Results

The results of a measurement channel can be evaluated in many different ways, both graphically and numerically. For each evaluation method the results are dis- played in a separate window in the tab. The R&S FSWP allows you to configure the display to suit your specific require- ments and optimize analysis. 6.5.1... - Page 93 ® Operating the Instrument R&S FSWP Displaying Results To start a new channel 1. Select the [Mode] key. 2. In the "Mode" dialog box, select the required application on the "New Chan- nel" tab. A new tab is displayed for the new channel.

-

Page 94: Laying Out The Result Display With The Smartgrid

® Operating the Instrument R&S FSWP Displaying Results Select the "Close" icon on the tab of the measurement channel. The tab is closed, any running measurements are aborted, and all results for that channel are deleted. 6.5.2 Laying out the Result Display with the SmartGrid Measurement results can be evaluated in many different ways, for example graphically, as summary tables, statistical evaluations etc. -

Page 95: Background Information: The Smartgrid Principle

® Operating the Instrument R&S FSWP Displaying Results ● Background Information: The SmartGrid Principle..........95 ● How to Activate SmartGrid Mode..............96 ● How to Add a New Result Window..............97 ● How to Close a Result Window...............97 ● How to Arrange the Result Windows.............. -

Page 96: How To Activate Smartgrid Mode

® Operating the Instrument R&S FSWP Displaying Results Positioning the window The screen can be divided into up to four rows. Each row can be split into up to four columns, where each row can have a different number of columns. However, rows always span the entire width of the screen and may not be interrupted by a column. -

Page 97: How To Add A New Result Window

® Operating the Instrument R&S FSWP Displaying Results ● Select the "SmartGrid" icon from the toolbar. ● Select the "Display Config" button in the configuration "Overview" . ● Select the "Display Config" softkey from the [Meas Config] menu. The SmartGrid functions and the evaluation bar are displayed. -

Page 98: Changing The Size Of Windows

® Operating the Instrument R&S FSWP Displaying Results 6.5.2.5 How to Arrange the Result Windows 1. Select an icon from the evaluation bar or the "Move" icon for an existing eval- uation window. 2. Drag the evaluation over the SmartGrid. -

Page 99: Switching Between A Split And Maximized Window Display

® Operating the Instrument R&S FSWP Displaying Results The splitters are not available in SmartGrid mode. ► To change the size of two neighboring windows, drag the splitter between the windows in either direction. 6.5.4 Switching Between a Split and Maximized Window Dis-... -

Page 100: Changing The Display

● Zooming into the diagram Remote Control In addition to working with the R&S FSWP interactively, located directly at the instrument, it is also possible to operate and control it from a remote PC. Various methods for remote control are supported: ●... -

Page 101: Remote Desktop Connection

6.6.2 Connecting a PC via the GPIB Interface You can connect a PC to the R&S FSWP via the GPIB interface to send remote commands to control and operate the instrument. You can configure the GPIB address and the ID response string. The GPIB language is set as SCPI by default but can be changed to emulate other instruments. -

Page 102: Contacting Customer Support

® Contacting Customer Support R&S FSWP Contacting Customer Support Technical support – where and when you need it For quick, expert help with any Rohde & Schwarz product, contact our customer support center. A team of highly qualified engineers provides support and works with you to find a solution to your query on any aspect of the operation, program- ming or applications of Rohde &... -

Page 103: Index

® Index R&S FSWP Index OCXO ..........49 Probe Power ........41 Alphanumeric keys ........37 RF INPUT ........... 40 Alphanumeric parameters ....... 90 Signal source output ......40 AM (trace information) ......78 SYNC TRIGGER ........ 48 Application cards ........16 Trigger Input ........42... - Page 104 ® Index R&S FSWP Evaluation Keyboard Modes, adding ........97 On-screen ........... 87 Evaluation bar Keypad ............ 90 Using ...........97 Key layout ........... 91 EXT REF Overview ..........37 Status message ........82 External generators ......... 49 External Mixer ......... 43 External monitor Connector ...........

- Page 105 ® Index R&S FSWP Overheating Evaluation bar ........97 Shutdown ..........21 Features ..........94 Mode ........... 96 Softkeys Status ..........86 Parameters Source frequency (channel bar) ....77 Entering ........89, 90 Source level (channel bar) ...... 77 PN (trace information) ......78 Split PN + AM (trace information) ....

- Page 106 ® Index R&S FSWP VIEW (trace information) ......78 White papers ........... 16 Window title bar ........78 Windows Adding ..........97 Arranging ..........98 Closing ..........97 Dialog boxes ........89 Size ............. 98 WRH (trace information) ......78 WRONG_FW Error ............ 84 XCORR Factor (channel bar) ....

Need help?

Do you have a question about the FSWP and is the answer not in the manual?

Questions and answers