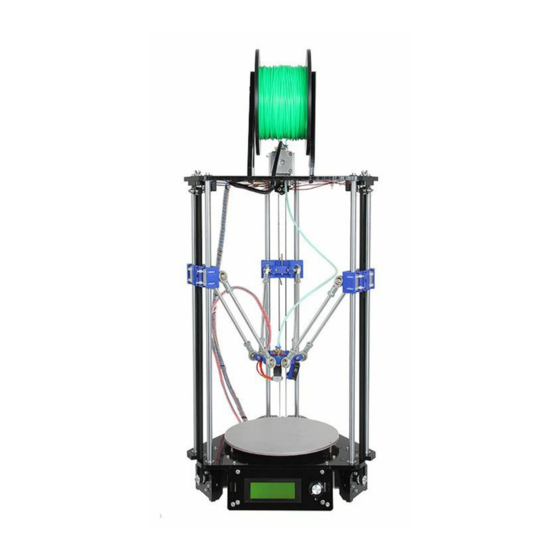

Geeetech Delta Rostock mini G2 Building Instruction

Hide thumbs

Also See for Delta Rostock mini G2:

- Building instructions (78 pages) ,

- Quick starter manual (85 pages)

Summary of Contents for Geeetech Delta Rostock mini G2

- Page 1 ShenZhen GETECH CO.,LTD GEEETECH Delta Rostock mini G2& G2s Building instruction www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 2: Table Of Contents

ShenZhen GETECH CO.,LTD GEEETECH Safety Instructions..........................3 Preparation............................4 Chapter1 Base Assembly........................5 1.1 Motor end assembly......................5 1.2 Connect motor ends to base plate..................8 1.3 Mount the LCD panel......................10 1.4 Mount the fan........................16 1.5 Mount the control board......................18 1.6 Mount the print bed......................20 Chapter 2 Top Plate Assembly...................... -

Page 3: Safety Instructions

ShenZhen GETECH CO.,LTD GEEETECH Safety Instructions Building the printer will require a certain amount of physical dexterity, common sense and a thorough understanding of what you are doing. We have provided this detailed instruction to help you assemble it easily. -

Page 4: Preparation

ShenZhen GETECH CO.,LTD GEEETECH Preparation 1. Unpack the kit and check if all parts are in the box and check the condition of each part, there might be some damage during shipping. To help you with this, there is BOM in the box and each bag was labeled with part number. -

Page 5: Chapter1 Base Assembly

ShenZhen GETECH CO.,LTD GEEETECH Chapter1 Base Assembly 1.1 Motor end assembly Name Part NO. Stepper motor Pulley Motor holder Motor holder support Square nut M3 X 12 Screw M3 X 16 Screw M3 washer www.geeetech.com Tel: +86 755 2658 4110... - Page 6 ShenZhen GETECH CO.,LTD GEEETECH Step1. Mount the pulley on the motor shaft, one of the screws should be screwed on the cross section of the shaft. Do not screw too tight to turn smoothly. Step2. Assemble A3 and 2 A4 together, and screw up with M3 X 16 screw and M3 square nut.

- Page 7 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 8: Connect Motor Ends To Base Plate

ShenZhen GETECH CO.,LTD GEEETECH Repeat the steps for the other 2 motor ends 1.2 Connect motor ends to base plate Name Part NO. base plate Square nut M3 X 16 Screw www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858... - Page 9 ShenZhen GETECH CO.,LTD GEEETECH M3 washer Step1. Mount the 3 assembled motor ends on the base plate (A1); screw it up with M3x16 screws and M3 square nuts. Repeat the step for the other 2 motor ends www.geeetech.com Tel: +86 755 2658 4110...

-

Page 10: Mount The Lcd Panel

ShenZhen GETECH CO.,LTD GEEETECH 1.3 Mount the LCD panel Name Part NO. LCD frame LCD support LCD2004 www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858... - Page 11 ShenZhen GETECH CO.,LTD GEEETECH Square nut M3 X 16 Screw M3 X 12 Screw Spacer M3 washer Knob Step1. Assemble the LCD frame and support plate together, screw up with M3 X 16 Screws and M3 square nuts. www.geeetech.com Tel: +86 755 2658 4110...

- Page 12 ShenZhen GETECH CO.,LTD GEEETECH Step2. Plug the aircraft- type spacer into the 4 screw hole on the LCD2004. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 13 ShenZhen GETECH CO.,LTD GEEETECH Step3. Screw up the frame and LCD2004 with 4 M3 X 12 Screws. Step4. Cover the knob and screw it up on the cross section, the screw is in the hole. www.geeetech.com Tel: +86 755 2658 4110...

- Page 14 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 15 ShenZhen GETECH CO.,LTD GEEETECH Step5. Mount the assembled LCD kit onto the base plate. Screw it up with 2 M3 X 16 screws and M3 square nuts. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 16: Mount The Fan

ShenZhen GETECH CO.,LTD GEEETECH 1.4 Mount the fan Name Part NO. Fan(40x40x10) M3 X 16 Screw M3 x 25 screw M3 Square nut www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858... - Page 17 ShenZhen GETECH CO.,LTD GEEETECH M3 nut M3 washer Step1. Mount the fan on the fan mount; screw it up with 2 M3 X 25 screw and M3 nut and washer. Step2. Mount the assembled fan mount on A2 with a M3 X 16 screw and M3 nut and washer.

-

Page 18: Mount The Control Board

ShenZhen GETECH CO.,LTD GEEETECH 1.5 Mount the control board. Name Part NO. Control board GT2560 Spacer M3 X 12 Screw M3 washer Step1. Plug the aircraft- type spacer into the 4 screw hole on the control board. The directions of the spacer are as the arrow showing. - Page 19 ShenZhen GETECH CO.,LTD GEEETECH Step2. Screw the control board to the base plate (A2) with 4 M3 X 12 Screws and m3 washer. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 20: Mount The Print Bed

ShenZhen GETECH CO.,LTD GEEETECH 1.6 Mount the print bed. Name Part NO. Building platform Heatbed Counter- sunk-head screw Spring 3.5 x 20mm Wing nut M3 washer www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858... - Page 21 ShenZhen GETECH CO.,LTD GEEETECH *for your convenience, the heatbed for you is pre-soldered, you can mount them directly. step1. Stack the heatbed and the building platform together. Step2. Thread the M3X30 screw through the two plates and add washers and spring at this end.

- Page 22 ShenZhen GETECH CO.,LTD GEEETECH Step3. Lock the other end with a wing nut. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 23 ShenZhen GETECH CO.,LTD GEEETECH Here is the finished picture. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 24: Chapter 2 Top Plate Assembly

ShenZhen GETECH CO.,LTD GEEETECH Chapter 2 Top Plate Assembly 2.1 endstop mount Name Part NO. Top plate Endstop mount Endstop Square nut M3 washer M3 X 16 Screw Step1. Mount the three end stops onto the Endstop mount (A6), screw with M3 X 16 screws. - Page 25 ShenZhen GETECH CO.,LTD GEEETECH Step2. Mount the assembled parts onto the top plate. Screw up with M3 x 16 screws and M3 square nuts. Note the directions of the endstop. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 26 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 27: Drive Wheel Mount

ShenZhen GETECH CO.,LTD GEEETECH 2.2 Drive wheel mount Name Part NO. Drive wheel mount Driven wheel holder 624zz ball bearing M3 X16 Screw M3 X25 Screw M4 X 25 Screw M3 nut M4 lock nut Wing nut M3 washer www.geeetech.com... - Page 28 ShenZhen GETECH CO.,LTD GEEETECH Step1. Mount the Drive wheel mount on A1; screw them up with M3 X25 screws, M3 nut and washers. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 29 ShenZhen GETECH CO.,LTD GEEETECH Step2. Thread the M3 x 16 screw through the driven wheel holder. Step3. Put the M4 x25 screw through the holes with the two 624ZZ bearings in between. Lock the other end with a M4 lock nut. You may need a spanner to tighten locking nut.

- Page 30 ShenZhen GETECH CO.,LTD GEEETECH Step4. Mount the assembled driven wheel holder onto the top plate. And screw it with a wing nut. Pay attention to the direction of the driven wheel. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 31: Mount The Extruder

ShenZhen GETECH CO.,LTD GEEETECH Repeat the above 4 steps for the other 2 driven wheels. 2.3 Mount the extruder Name Part NO. Extruder M5 x 16 screw Find out the locating holes on the top plate; screw up the extruder with 4 M5 x 16 www.geeetech.com... -

Page 32: Mount The Spool Holder

ShenZhen GETECH CO.,LTD GEEETECH screws and washers. The screws are bottom - up. Note: If your are assembly the G2s, you will need 8 Mher5 x 16 screws and 4 washers to mount another extruder. 2.4 Mount the spool holder This step can also be finished at last. - Page 33 ShenZhen GETECH CO.,LTD GEEETECH M3X16 screw Square nut Screw up the spool holder panel on the top plate separately with M3X16 screw and M3 nut and washer. EXAMPLE 1: G2 EXAMPLE 2: G2S www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 34: Chapter3 Mount The Smooth Rods

ShenZhen GETECH CO.,LTD GEEETECH For this one, you need to use the locking ring to lock the spool on both end. Chapter3 mount the smooth rods Name Part NO. Smooth Rod Linear Bearing M4 X12 Screw M8 Washers M4 washer www.geeetech.com... - Page 35 ShenZhen GETECH CO.,LTD GEEETECH Step1. Insert the smooth rods into the slot on the base plate; put a M8 washer on the end of the rod. Step2. Screw up the rods with M4x 25 screws and M4 nuts. www.geeetech.com Tel: +86 755 2658 4110...

- Page 36 ShenZhen GETECH CO.,LTD GEEETECH Repeat the above two steps for other rods. Step3. Slide the 6 linear bearings into the 6 smooth rods separately. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 37 ShenZhen GETECH CO.,LTD GEEETECH Step4. Put a M8 washer on each top end of the rods and cover the top plate on the rods, screw them up with M4x 25 screws and M4 nuts. www.geeetech.com Tel: +86 755 2658 4110...

- Page 38 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 39: Chapter 4 Assemble The Print Platform

ShenZhen GETECH CO.,LTD GEEETECH Chapter 4 Assemble the print platform Name Part NO. Diagonal Rod rod-end bearing holder (30x30x10) Hotend Endstop Spider Hotend bracket www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858... - Page 40 ShenZhen GETECH CO.,LTD GEEETECH Hotend half bracket Fan mount Carriage Probe Zip tie Round head screw with M3 x 8 screw M3 x 12 screw M3 x 16 screw M3 x20 screw M3 x40 screw M4 x 16 screw www.geeetech.com...

-

Page 41: Assemble The Spider

ShenZhen GETECH CO.,LTD GEEETECH 3.5*30 spring M3 nut M4 nut M3 washer M4 washer M6 washer Printed lock ring 4.1 Assemble the spider Step1. Insert the hotend into the half bracket, stack the hotend bracket and half bracket together, screw up with 4 M3 x 16 screws and M3 nut. - Page 42 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 43 ShenZhen GETECH CO.,LTD GEEETECH If you are building G2s, the steps are the same. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 44 ShenZhen GETECH CO.,LTD GEEETECH Step2. Screw the fan onto the fan mount with 2 M3x 20 screws. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 45 ShenZhen GETECH CO.,LTD GEEETECH Step2. Mount the assembled fan and hotend onto the spider, using the following screws and nuts as shown in the picture. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 46 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 47: Assemble The Auto-Leveling Probe

ShenZhen GETECH CO.,LTD GEEETECH 4.2 Assemble the auto-leveling probe Note please: as the auto-leveling probe was added to Rostock miniG2 after we finished the design, so this picture is taken after we finished the whole building, but we suggest you assemble the auto-leveling probe at this step. - Page 48 ShenZhen GETECH CO.,LTD GEEETECH Step2. Thread the probe into the hole. You can use the file to trim the probe hole before thread it in to make sure the probe can move smoothly. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 49 ShenZhen GETECH CO.,LTD GEEETECH Step3. Thread the spring and the lock ring around the prob and screw up the M3 screw in the ring.screw it tightly. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 50: Assemble The Diagonal Rods

ShenZhen GETECH CO.,LTD GEEETECH 4.3 Assemble the diagonal rods Step1. Mount the diagonal rod onto the carriage. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858... - Page 51 ShenZhen GETECH CO.,LTD GEEETECH washer here is very important, do remember! You can even use M4 washer here. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 52 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 53 ShenZhen GETECH CO.,LTD GEEETECH Step2. Repeat the above steps for the other diagonal rods. And mount another end of the diagonal rods to the spider. The directions should be as shown in the following picture. www.geeetech.com Tel: +86 755 2658 4110...

- Page 54 ShenZhen GETECH CO.,LTD GEEETECH Step3. Insert the M3 x 40 screw into the carriage, this screw is for the hitting of the endstop. * Distinguish the up and down side of the carriage. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 55 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 56 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 57 ShenZhen GETECH CO.,LTD GEEETECH Step4. Connect the assembled print platform to the smooth rods. Mount the carriage onto the rods where the linear bearing is, insert the bearings into the slot. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 58 ShenZhen GETECH CO.,LTD GEEETECH Step5. Tie up the carriage and the bearings with two zip ties. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 59 ShenZhen GETECH CO.,LTD GEEETECH To help you see clearly, here is a detailed picture for the carriage. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 60 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 61: Chapter5 Mount The Belt

ShenZhen GETECH CO.,LTD GEEETECH Chapter5 Mount the Belt Name Part NO. Timing Belt Step1. Thread the belt through the drive wheel end. Pull it down to the pulley. Step2. Thread the belt around the pulley, and take both ends to the carriage. - Page 62 ShenZhen GETECH CO.,LTD GEEETECH Step3. Insert the belt into the slot. If the slot is too thin, you can use the grater to file it larger. Tie up the belt if needed. *Pay attention to the tooth mesh of the belt and that on the bracket. Tie up both ends tightly.

- Page 63 ShenZhen GETECH CO.,LTD GEEETECH To help you better understand this step, here is a short video for you to refer. https://www.youtube.com/watch?v=RP-J7jWmabg Repeat the above steps for the other 2 belts. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 64: Chapter6 Connect The Ptfe Tube

ShenZhen GETECH CO.,LTD GEEETECH Chapter6 Connect the PTFE tube Name Part NO. Feeding pipe Step1. Plug one end of the tube into the push-fitting on the hotend and the other end into that of the extruder. * If you need to pull the tube out, please press the blue part while pulling. -

Page 65: Chapter7 Wiring

ShenZhen GETECH CO.,LTD GEEETECH Chapter7 Wiring Before you start wiring, please take a look at the wiring schematics. You can see original picture here. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858... - Page 66 ShenZhen GETECH CO.,LTD GEEETECH Step1. Connect wires for motors. 1) Connect wires for X-axis motor. 2) Connect wires for Y-axis motor. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 67 ShenZhen GETECH CO.,LTD GEEETECH 3) Connect wires for Z-axis motor. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 68 ShenZhen GETECH CO.,LTD GEEETECH For G2s, connect the second Z motor here. 4) Connect extruder motor www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 69 ShenZhen GETECH CO.,LTD GEEETECH Step4. Connect heating wires. Loosed the screws in the green terminal and put the red wires into the slot and screw it up. * There is no “+” and “-“for heating wires www.geeetech.com Tel: +86 755 2658 4110...

- Page 70 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 71 ShenZhen GETECH CO.,LTD GEEETECH 1) Connect heating wires for heatbed. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 72 ShenZhen GETECH CO.,LTD GEEETECH 2) Connect heating wires for extruder 0. 3) Connect heating wires for extruder 1. (needed if you are building G2s) www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 73 ShenZhen GETECH CO.,LTD GEEETECH Step4. Connect wires for thermistor. 1) Connect wires for thermistor of heatbed. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 74 ShenZhen GETECH CO.,LTD GEEETECH 2) Connect wires for thermistor of extruder 0. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 75 ShenZhen GETECH CO.,LTD GEEETECH 3) Connect wires for thermistor of extruder 1. (needed if you are building G2s) Step5. Connect wires for endstop. 1) Connect wires for endstop of X-axis at X-max. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 76 ShenZhen GETECH CO.,LTD GEEETECH 2) Connect wires for endstop of Y-axis at Y-max. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 77 ShenZhen GETECH CO.,LTD GEEETECH 3) Connect wires for endstop of Z-axis at Z-max. 3) Connect wires for endstop of auto-leveling probe at Z-min. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 78 ShenZhen GETECH CO.,LTD GEEETECH Please note that, at the end of the endstop, the two wires are connected to 1 and 3, which you can see on the endstop. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 79 ShenZhen GETECH CO.,LTD GEEETECH Step6. Connect wires for Fan. 1) Connect fan for control board at FAN1. 2) Connect fan for extruder at FAN3. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 80 ShenZhen GETECH CO.,LTD GEEETECH If you use the 2-pin extension wire for the fan, just plug them on the + and - of the slot. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 81 ShenZhen GETECH CO.,LTD GEEETECH 2) Connect fan for hotend at FAN-PWM. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 82 ShenZhen GETECH CO.,LTD GEEETECH Step7. Connect wires for LCD panel. There are two cables, one is for LCD encoder, the other is for SD card, do not connect them reversed. EXP1 to LCD EXP2 to SD card BTW, do you see the small screw above the SD card reader, if the text in of the LCD phases in an out or there is only blocks on the screen, you can adjust this screw to recovery it.

- Page 83 ShenZhen GETECH CO.,LTD GEEETECH Step8. Connect wires for power input. Name Part NO. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 84 ShenZhen GETECH CO.,LTD GEEETECH Power cable Plug the other end into the PSU. Do not forget to cover it. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 85 ShenZhen GETECH CO.,LTD GEEETECH Step9.Connect the power cable to the input connector of PSU Name Part NO. 3D Power cable As shown in the red box. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 86 ShenZhen GETECH CO.,LTD GEEETECH Note the correspondence between the color of wires and the connector. Brown------L Blue ------N Yellow ------GND ------ --+ V Black------COM That is all for the wiring of GT2560. That is all for the wiring of GT2560.

-

Page 87: Chapter8 Tidy Out The Wires

ShenZhen GETECH CO.,LTD GEEETECH Chapter8 Tidy out the wires Use the spiral coil to tie put those wires together. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858... - Page 88 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 89: Chapter 9 How To Set Up

ShenZhen GETECH CO.,LTD GEEETECH So far, the Rostock mini G2 has been fully assembled. Please refer to the following instructions: Chapter 9 How to set up Please DO NOT rush to start your first printing and start the Auto-leveling command... -

Page 90: How To Modify And Upload Firmware

1. Download the firmware here: Firmware for Delta Rostock mini G2 Firmware for Delta Rostock mini G2S 2. Connect GT2560 to your PC with a USB cable,install FTDI drive. Usually it will install automatically. - Page 91 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 92 ShenZhen GETECH CO.,LTD GEEETECH 4 Most of the code you need to modify is in Configuration.h . www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 93 ShenZhen GETECH CO.,LTD GEEETECH Find the value you need to compile according to your printer. Upon compiling, you can upload the firmware to your control board. Simply click www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 94 ShenZhen GETECH CO.,LTD GEEETECH Compiling www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 95 ShenZhen GETECH CO.,LTD GEEETECH Uploading www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 96: Printer Preparing

ShenZhen GETECH CO.,LTD GEEETECH Upload successfully 9.2 Printer preparing 1. Adjust the printing bed Put a level meter on the bed when adjusting the 3 screws of the bed to check if it is level. www.geeetech.com Tel: +86 755 2658 4110... - Page 97 ShenZhen GETECH CO.,LTD GEEETECH 2. To protect the bed and the nozzle from crashing, please attach a piece of tape on the bed. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 98: Printer Setting

ShenZhen GETECH CO.,LTD GEEETECH 9.3Printer setting Step1. Connect the USB to your Rostock mini G2 or G2s and power it up. You can see the LED lights and fan come to life, you may be able to hear the motors idling. - Page 99 ShenZhen GETECH CO.,LTD GEEETECH Step 3. Choose the Connection menu to select the COM6 port and the Baud rate 250000. Click OK to continue. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 100 ShenZhen GETECH CO.,LTD GEEETECH If you can not fond the COM port, click “refresh ports” and see if it appears. (It is usually the last one; you can check the device manager to see which port it is). PS: if you still cannot find the port, please re -install your USB driver.

- Page 101 ShenZhen GETECH CO.,LTD GEEETECH Step5. Hit "connect" in the upper left-hand corner. You should see the details of the connection in the console window in the bottom section of the screen. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 102: Homing The Printer

ShenZhen GETECH CO.,LTD GEEETECH 9.4 Homing the printer Homing is the first and foremost hing you need to test. To home the printer, you can check if the three axis of the printer move in the same direction,if not, there will be crack for the spider and the carriage. - Page 103 ShenZhen GETECH CO.,LTD GEEETECH 2. Hook up the probe with your hand, we are not testing the auto-leveling function right now. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 104 ShenZhen GETECH CO.,LTD GEEETECH 3. Move the extruder head to the middle and be ready for emergency stop. You can click the emergency stop icon on the Repetier host or shut the power supply directly. www.geeetech.com Tel: +86 755 2658 4110...

-

Page 105: Define The Initial Z Axis Height

ShenZhen GETECH CO.,LTD GEEETECH If the three axis move in the different directions, please check the connection of the stepper motor wires. 9.5 Define the initial Z axis height If the printer can home normally, the three axis move in the same directions, we can set the height of the Z axis now, but this value may not be the final height. - Page 106 ShenZhen GETECH CO.,LTD GEEETECH to measure after homing. 2. Or you can use manual control to move the Z axis down to the building platform till the nozzle just touches the bed. When moving the Z axis, please slow it down.

- Page 107 ShenZhen GETECH CO.,LTD GEEETECH Move 0.1mm per click 3. Read the coordinates of the Z axis when the nozzle just touches the bed. E.g. if it is (0,0,1), then the Z axis height is 200-1=199。If it is (0,0,2) the height is 200-2=198.

- Page 108 ShenZhen GETECH CO.,LTD GEEETECH #define MANUAL_HOME_POSITIONS // MANUAL_*_HOME_POS below will be used // For deltabots this means top and center of the Cartesian print volume. #define MANUAL_X_HOME_POS 0 #define MANUAL_Y_HOME_POS 0 #define MANUAL_Z_HOME_POS 200// For delta: Distance between nozzle and print surface after homing.

- Page 109 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 110: Define The Final Z Axis Height

ShenZhen GETECH CO.,LTD GEEETECH 9.6 Define the final Z axis height Step1. Homing the printer. Step2. Tighten the screw trigger for each endstop, make sure they reach as long as possible. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858... - Page 111 ShenZhen GETECH CO.,LTD GEEETECH Adjust the screw on these 3 carriages. Step3. Set 3 probing points (0,50) 、 (43.3, -25) 、 (-43.3, -25), using G-code command to adjust the print head to the 3 points and record the distance between the nozzle and the print surface separately.

- Page 112 ShenZhen GETECH CO.,LTD GEEETECH 1)send command: G0 X0 Y50 Z2, record the distance;e.g. it is 3mm in my case. 2)send command: G0 X43.3 Y-25 Z2, record the distance;e.g. it is 2.7mm in my www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 113 ShenZhen GETECH CO.,LTD GEEETECH case. 3)send G 0 X-43.3 Y-25 Z2, record the distance;e.g. it is 2.2mm in my case. The distance is the height of Z axis, you can just read the c ordinates of the Z axis. You may need to adjust again and again till the three distance are the same or at least very close.

-

Page 114: Check The Status Of Endstop

ShenZhen GETECH CO.,LTD GEEETECH the nozzle just hit the print bed, and screw the endstop screw trigger tightly. At this step, we are trying to adjust the distance between the nozzle and the print surface to keep the center point and its around point in one plain, that is to say, we need to make sure that when the nozzle touches the bed, whichever point it is, the Z Coordinate value should be the same, or almost the same. - Page 115 ShenZhen GETECH CO.,LTD GEEETECH 1. Homing the printer 2. Put down the auto-level probe. 3. Send M119 command Send the command M119 to verify the endstop first. You can see the following message at the bottom of the Repetier Host.

-

Page 116: Define The Z_Probe_Offset

ShenZhen GETECH CO.,LTD GEEETECH z_min is for the probe: When probe is put down, the feedback is Open; When probe is hooked up, the feedback is Triggered; If the status is normal, we can go on with the auto-leveling set-up. - Page 117 ShenZhen GETECH CO.,LTD GEEETECH www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 118 ShenZhen GETECH CO.,LTD GEEETECH if your slic3r is not the latest version, you can update or download it here, unzip the file and drag them into the directory of your previous slic3r directory. do please delete the old version. Restart your Repetier and continue.

- Page 119 ShenZhen GETECH CO.,LTD GEEETECH Step2. Choose printer setting-- Custom G-code. You can see from the start G-code, there is no G29. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 120 ShenZhen GETECH CO.,LTD GEEETECH So you need to add the G29 after G28 to start it. And change Z5 into Z50. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

-

Page 121: Calibration Of Auto-Leveling

ShenZhen GETECH CO.,LTD GEEETECH Save the current printing setting, click “OK” to continue. 9.10 Calibration of auto-leveling Auto-leveling probe is controlled by G29 command. As this is a DIY 3d printer, you may need to help it complete the leveling: 1.You need to put down the auto-leveling probe manually. - Page 122 ShenZhen GETECH CO.,LTD GEEETECH 2.Send G29 command. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 123 ShenZhen GETECH CO.,LTD GEEETECH 3.auto-leveling probe will probe the 3 pre-setted probing points. After probing, the print head will raise up a bit and stop. 4.Hook up the probe manually. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 124 ShenZhen GETECH CO.,LTD GEEETECH As this calibration needs to be done several time before you can start printing, you can refer to this guide. www.geeetech.com Tel: +86 755 2658 4110 Fax: +86 755 2658 4074 - 858...

- Page 125 ShenZhen GETECH CO.,LTD GEEETECH 1.Manually put down the probe, then send M119 command to check if the Z-min is open. 2.Send G28 command to auto home the printer. 3.Send G29 command to start the auto-leveling. *there might be collisions, please always be ready to cut off the power supply.

Need help?

Do you have a question about the Delta Rostock mini G2 and is the answer not in the manual?

Questions and answers