Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Geeetech A10

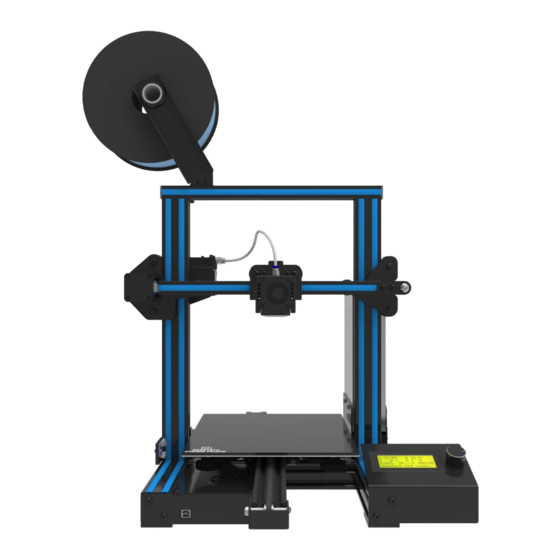

- Page 1 SHENZHEN GETECH TECHNOLOGY CO., LTD Geeetech A10 3D Printer User Manual (V2.0)

-

Page 2: Table Of Contents

SHENZHEN GETECH TECHNOLOGY CO., LTD Content 1 Attention ..........................3 1.1 Safety instruction ......................3 1.2 Factory test before delivery ..................3 2 Printer display ........................4 3 Assembling ..........................7 3.1 Assembling the main frame ..................7 3.2 Wire connection ......................10 3.3 Check the power input mode. -

Page 3: Attention

SHENZHEN GETECH TECHNOLOGY CO., LTD 1 Attention 1.1 Safety instruction Please switch to the correct local voltage (110V-220V) before turning on the printer. Be sure the switch is in the correct position or it would cause damage to the power supply unit (PSU). -

Page 4: Printer Display

SHENZHEN GETECH TECHNOLOGY CO., LTD 2 Printer display (Picture 2-1) - Page 5 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 2-2)

- Page 6 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 2-3) Gantry frame Reset button Y axis USB port Pedestal Z axis end stop X axis end stop Filament spool holder kit Teflon tube 10. Extruder head kit 11. Hot bed 12. LCD2004 screen 13.

-

Page 7: Assembling

SHENZHEN GETECH TECHNOLOGY CO., LTD Please check the accessories first when you’ve received the printer (Refer to picture 2-4). If missing any spare part, please contact your sales timely. (Picture 2-4) 3 Assembling 3.1 Assembling the main frame The main frame consists of the gantry frame and the pedestal, PSU kit, LCD kit, spool holder kit, and their supporting screws. - Page 8 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 3-1) Assemble the gantry frame and pedestal from bottom to top with 4 M5x45 screws and 4 M5 spring washers. See picture (3-2). (Picture 3-2)

- Page 9 SHENZHEN GETECH TECHNOLOGY CO., LTD Fix the PSU kit to the gantry frame with 2 M4x20 screws. See picture (3-3). (Picture 3-3) Fix the LCD kit to the correct holes on the right side of the pedestal with 2 M5x10 screws. See picture (3-4).

-

Page 10: Wire Connection

SHENZHEN GETECH TECHNOLOGY CO., LTD Fix the spool holder to the top gantry with 2 M3x6 and 2 M3 T-shape nuts. Details see picture (3-5). (Picture 3-5) 3.2 Wire connection The teflon tube is connected to the quick-insert connector of the extruder and the extruder head. - Page 11 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 3-7) Insert the flat ribbon of the LCD into the socket behind the LCD screen. See picture (3-8) (Picture 3-8) Connect the PSU cable. See picture (3-9) (Picture 3-9) Plug the extruder cables into the socket of the extruder head extension board as firmly as possible.

- Page 12 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 3-10) Connect the extruder motor wires. See picture (3-11). (Picture 3-11) Connect the wires of X axis’ motor and end stop. See picture (3-12). (Picture 3-12)

- Page 13 SHENZHEN GETECH TECHNOLOGY CO., LTD Connect the wires of Y axis’ motor and end stop. See picture (3-13). (Picture 3-13) Connect the wires of Z axis’ motor and end stop. See picture (3-14, 3-15). (Picture 3-14) (Picture 3-15)

-

Page 14: Check The Power Input Mode

SHENZHEN GETECH TECHNOLOGY CO., LTD 3.3 Check the power input mode. Choose the correct voltage according to your local standard requirement. See picture (3-16) (Be sure the voltage is switched to the correct one. We provide 220V and 110V for option.) (Picture 3-16) 3.4 Check the filament Put the filament on the spool holder. -

Page 15: First Print

SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 3-18) When print PLA, set the target nozzle temperature about 180-210℃. When the temp is stable, control the extruder filament feeding on LCD screen (“Move axis”), extruder will automatically feed until there is molten material flowing from the nozzle. Observe the nozzle, if there is no obvious stuck and the filament is out smoothly, then stop filament feeding, clear the nozzle with tweezers. - Page 16 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 4-1) When the extruder head moves to the left bottom, adjust the corresponding nut until the distance between the nozzle and bed is about the thickness of a piece of paper (about 0.1-0.2mm). Twitch the paper back and forth to see if you feel any slight resistance. If yes, it means the leveling of this corner is finished and you can proceed to level the rest corners with the same method.

-

Page 17: Sd Card Printing

Avoid the nozzle touching the bed; put a piece of A4 paper instead. Or it will scratch the bed. For more details, please refer to this link: http://geeetech.com/forum/viewtopic.php?f=112&t=62296 4.2 SD card printing Insert the SD card into the slot. See picture (4-7) - Page 18 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 4-7) Press and rotate the knob to enter the main menu. Select the option of "Print from SD". See picture (4-8). (Picture 4-8) Choose the files in the SD card. See picture (4-9). (Picture 4-9) The printer will heat automatically.

- Page 19 SHENZHEN GETECH TECHNOLOGY CO., LTD When heating done, the printer will start printing. See picture (4-11, 4-12). (Picture 4-11) (Picture 4-12)

-

Page 20: Introduction To The Lcd Menu

SHENZHEN GETECH TECHNOLOGY CO., LTD 5 Introduction to the LCD menu 5.1 Tree diagram (Picture 5-1) -

Page 21: Main Functions

SHENZHEN GETECH TECHNOLOGY CO., LTD 5.2 Main functions LCD rotating knob: 1) Press the knob: Confirm or enter the next menu. 2) Rotate the knob: Roll the select options or change parameters. LCD homepage (Picture 5-2): ① Extruder temperature: Current temp/target temp ②... - Page 22 SHENZHEN GETECH TECHNOLOGY CO., LTD The main functions of Prepare menu (Picture 5-4, 5-5, 5-6): 1. Disable steppers: Unlock motors 2. Auto home: Auto home of X/Y/Z axis 3. Preheat PLA: Manually pre-heat the hot bed and extruder before printing PLA. 4.

- Page 23 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 5-7) After getting familiar with the LCD function, press the knob on the LCD to enter the next level menu and select "Prepare". See picture (5-8) (Picture 5-8) Choose “Auto home” to home the printer, see picture (5-9). (Picture 5-9) Choose “Move axis”...

- Page 24 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 5-11) Note: Only the two options 10mm and 1mm are valid for extruder. 0.1mm is invalid. We suggest choosing 1mm for each axis to test. Choose the corresponding axis you want to move “Move X/Y/Z/Extruder”. Rotate the knob to make the axis move.

-

Page 25: Software Setting

The details of USB printing are as follows: Firstly, turn on the printer, and connect the printer to computer with a USB cable. Normally, the computer will automatically search the install drive. The newest communication chip of A10 is CH340. See picture (6-1). - Page 26 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 6-2) Download link for CH340: https://www.geeetech.com/index.php?main_page=download&download_id=30 After the drive installed, check the “Device manager” of yours and see if it is same as the picture below (6-3). If so, it means the drive is successfully installed.

-

Page 27: Install Slicing Software

SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 6-3) 6.2 Install slicing software Repetier-Host is the default slicing software here. Download address: https://www.repetier.com/download-software/ 1) Set printer parameters When Repetier-Host is installed, turn on the printer and open the Repetier-Host. Repetier-Host supports several languages. You can choose your mother language from Config>Language (Picture 6-4 for details). - Page 28 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 6-4) English interface for your reference (picture 6-5). (Picture 6-5) Using the Repetier-Host for the first time, printer parameters need to be configured before connecting. Click “Printer settings” on the top right corner, see picture (6-6).

- Page 29 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 6-6) It pops up the content as the picture below (6-7). Write down the relevant info accordingly. (Pay attention to the highlighted parts) a. Connection dialog: (Picture 6-7) b. Printer dialog (Picture 6-8):...

- Page 30 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 6-8) c. Extruder dialog (Picture 6-9): (Picture 6-9)

- Page 31 SHENZHEN GETECH TECHNOLOGY CO., LTD d. Printer shape dialog (Picture 6-10): (Picture 6-20) Now the printer parameters are set. Note: If the operation system is Mac OS, the baud rate is still 250000. Set slicing parameters After setting the printer parameters, click “Connect” on the top left corner. The color of the icon changed to green means the printer connects to the Repetier-Host successfully.

- Page 32 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 6-11) After successfully connected, choose “Slicer> CuraEngine” and open the configuration menu. See picture (6-12). (Picture 6-12)

- Page 33 Printer parameters are important to print quality. Customers need to test to find out the best parameters for their printers. Here we provide a configuration file for your reference (“Geeetech A10 PLA high.rcp”). You can import it according to the steps as follows.

- Page 34 SHENZHEN GETECH TECHNOLOGY CO., LTD It pops up the dialog as below (Picture 6-15). Choose “Geeetech A10 PLA high.rcp” and open it. (Picture 6-15) Now, the configuration file is imported, click “Save”. See picture (6-16). (Picture 6-16)

- Page 35 SHENZHEN GETECH TECHNOLOGY CO., LTD Click “Filament>Import”, see picture (6-17). It pops up dialog as below (Picture 6-18); choose “Geeetech A10 PLA high fi.rcf”. (Picture 6-18) Now, the configuration file is imported. Click “Save”. See picture (6-19).

- Page 36 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 6-19) Choose “Geeetech A10 PLA high” as print configuration and “Geeetech A10 PLA high fi” as printing material setting. Details see picture (6-20) below. (Picture 6-20) Now parameters setting are finished.

-

Page 37: Usb Printing

SHENZHEN GETECH TECHNOLOGY CO., LTD 6.3 USB printing You can start USB printing when the parameters setting are finished. The model file format is .stl for 3D printer. You can download free models from websites such as thingiverse. You can also design your own model. Load the printing model Open the Repetier-Host and click “load”. - Page 38 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 6-23) Adjust the direction of the model to let the flat part of the model to touch the hot bed. See picture below (6-24): (Picture 6-24) Note: If the model loaded is too big and beyond the printing platform, you need to zoom out the model.

- Page 39 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 6-25) Or zoom in/out them separately, see picture (6-26). (Picture 6-26) Model slicing When the size and direction of the model are set, choose the imported slicing parameters, and click “Slice with CuraEngine”. See picture (6-27, 6-28).

- Page 40 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 6-27) (Picture 6-28) You can find the model information such as estimated print time, the amount of filament needed, etc. Click “Print” to start USB printing. Refer to picture (6-29). The printer will heat to the target temp and then start printing. Under high temperature, the filament will flow out of the nozzle, which is normal.

-

Page 41: Sd Card Printing

SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 6-29) 6.4 SD card printing When all parameters are set, click “Save for SD print”. It will pop up a dialog as picture below (See picture 6-30) and then click the save button to generate a .gcode file. Copy the gcode file to the SD card. - Page 42 SHENZHEN GETECH TECHNOLOGY CO., LTD (Picture 6-31) Choose the corresponding gcode file to start printing. Note: The printer can only read gcode file and the file name should be English letters, a space, an underscore or their combination. The Gcode file cannot be placed in any folder of the SD card, otherwise it cannot be read.

-

Page 43: Function Introduction

SHENZHEN GETECH TECHNOLOGY CO., LTD 7 Function introduction 7.1 Break-resuming capability A10 has the break-resuming capability. When the power recovery, it will pop up a dialog to ask if continuing the unfinished print caused by power outage, choose “Resume print”. See picture (7-1). -

Page 44: Filament Run-Out Sensor (Optional)

SHENZHEN GETECH TECHNOLOGY CO., LTD 7.3 Filament run-out sensor (Optional) Before using this function, please check whether it is turned on or not. Choose “Control”>”Filament”>“Runout sensors” and make sure it shows “ON”. See pictures (7-3, 7-4). (Picture 7-3) (Picture 7-4) It will pop up the notification “Err: No Filament”... -

Page 45: Touch For Auto Bed Leveling (Optional)

7.4 3D touch for auto bed leveling (Optional) This printer supports auto bed leveling. Refer to the link below to know how to install the 3d touch sensor. https://www.youtube.com/watch?v=_RtsZDbR2po&t=66s Visit our official forum. http://www.geeetech.com/forum/ 8 Parameters Printing parameters Printing technology: FDM Printing volume: 220*220*260mm Printing accuracy: 0.1~0.2mm... -

Page 46: Contact

SHENZHEN GETECH TECHNOLOGY CO., LTD 9 Contact Official website: https://www.geeetech.com/。 Facebook Group: Email us for technical support: https://www.geeetech.com/contact_us.html... -

Page 47: Faq (Frequently Asked Questions)

SHENZHEN GETECH TECHNOLOGY CO., LTD 10 FAQ (Frequently Asked Questions) 10.1 Abnormal extrusion The filament is tangled The nozzle temp is too low to reach the melting temperature required. There is carbonized residue inside the nozzle. Please replace it with the spare nozzle Insufficient heat dissipation of radiator of the extruder head causes the filament in the tube to melt in advance and the extrusion strength is insufficient. -

Page 48: Print Stopped

All information in this Manual is subject to change at any time without notice and is provided for convenience purposes only. Geeetech reserves the right to modify or revise this Manual in its sole discretion and at any time. You agree to be bound by any modifications and/or revisions. - Page 49 SHENZHEN GETECH TECHNOLOGY CO., LTD Shenzhen Getech Technology Co.,Ltd www.geeetech.com...

Need help?

Do you have a question about the A10 and is the answer not in the manual?

Questions and answers