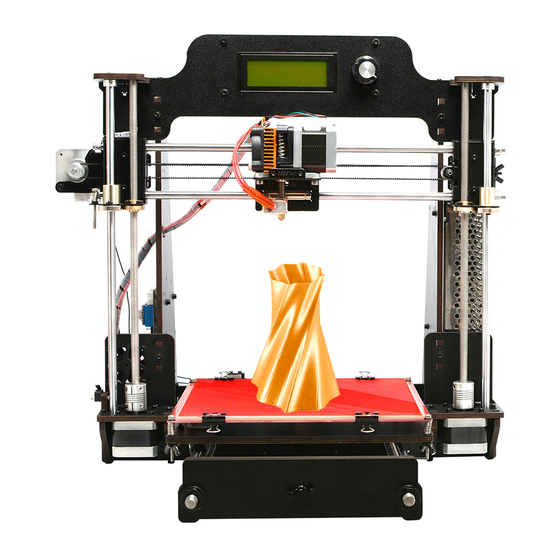

Geeetech Prusa I3 Manual

Hide thumbs

Also See for Prusa I3:

- Assembly instructions manual (109 pages) ,

- Assemble manual (59 pages) ,

- Assemble manual (58 pages)

Table of Contents

Advertisement

Quick Links

Identify the Printed Parts---------------------------------------------------------------- 3

Assemble the port and starboard sides of the chassis------------------- 4

Assemble the Y idler--------------------------------------------------------------5

Assemble the front and back of the chassis-------------------------------- 6

The finished chassis---------------------------------------------------------------7

Attach the Y Plate--------------------------------------------------------------------------9

Build the X-Z axes--------------------------------------------------------------------------11

Build the X-Z plate-------------------------------------------------------------------------16

Attach the heatbed------------------------------------------------------------------------19

Assemble the extruder--------------------------------------------------------------------21

Attach the end stoppers-------------------------------------------------------------------24

Table of Content

Advertisement

Table of Contents

Summary of Contents for Geeetech Prusa I3

-

Page 1: Table Of Contents

Table of Content Identify the Printed Parts---------------------------------------------------------------- 3 Build the chassis Assemble the port and starboard sides of the chassis------------------- 4 Assemble the Y idler--------------------------------------------------------------5 Assemble the front and back of the chassis-------------------------------- 6 The finished chassis---------------------------------------------------------------7 Attach the Y Plate--------------------------------------------------------------------------9 Build the X-Z axes--------------------------------------------------------------------------11 Build the X-Z plate-------------------------------------------------------------------------16 Attach the heatbed------------------------------------------------------------------------19... -

Page 2: Identify The Printed Parts

Identify the Printed Parts Number of Part Name ID Number Parts Chassis corners Y motor mount Y idler Y belt holder assembly Y belt holder assembly Z left bottom Z right bottom X motor mount X idler X carriage Z right top Z left top End stopper mount Wade’s extruder body... -

Page 3: Build The Chassis

Build the chassis 1. Assemble the port and starboard sides of the chassis Number Required parts printed chassis corners (no. 1) 380mm M8 threaded rod 350mm 8mm precision rod fender washer LM8UU bearing m8 nut M8 washer 1. Hold the printed chassis corners with the semi-circular opening facing upward and inward 2. -

Page 4: Assemble The Y Idler

Note: the top assembly is on the port side, and the bottom assembly goes to the starboard side. 2. Assemble the Y idler Number Required parts 623ZZ bearing Printed Y idler (ID no. 3) M3-25 screw M3 nut 1. Put the M3-25 screw thru the printed Y idler piece, with two 623ZZ bearings in between. Lock the other end of a M3 nut. -

Page 5: Assemble The Front And Back Of The Chassis

3. Assemble the front and back of the chassis Number Required parts 205mm M8 threaded rod 310mm M8 threaded rod Printed Y motor mount (no. 2) Assembled Y idler M8 nut M8 washer M8 fender washer Note: the easier way to put on these nuts and washers is to put one the inside ones first, then sandwich the rod between two chassis corners, and then put on the outside nuts and washers. -

Page 6: Chassis Corners

3. nut – washer – chassis corner – washer – nut – nut – washer – Y motor mount – washer – nut – nut – washer – chassis corner – washer – nut. Do not tighten yet. Align the rods and tighten all nuts so the chassis will not fall apart. You might need to adjust the chassis later when mounting the Y plate. -

Page 7: Attach The Y Plate

Attach the Y Plate Number Required parts Acrylic bed M3-16 screw M3 nut Y belt holder assembly 1 (no.4) Y belt holder assembly 2(no. 5) M3-10 screw Zip ties ~70cm GT-2 timing belt Nema-17 motor... - Page 8 GT-2 20 teeth pulley 1. Insert four M3 nuts into the hexagonal slots in the Y belt holder assembly 1. 2. Loosely attach the two rectangular pieces to the main piece using four m3-16 screws. Make sure the flat surface is facing outward. 3.

- Page 9 4. Attach the Y belt assembly to the acrylic bed using two m3-16 screws and two m3 nuts. Take 70cm of GT2 timing belt and insert one end into the Y belt holder. Tighten the two m3-16 screws to hold down the belt. 5.

- Page 10 m3-16 screws. The belt should be tight with tension. As the bed moves on the chassis, there should be no skipping.

-

Page 11: Build The X-Z Axes

Build the X-Z axes Number Required parts Printed x idler (no. 9) Printed x motor holder (no.8) Printed x carriage (no. 10) 370mm 8mm precision rod LM8UU bearings M5 nut Zip ties Nema-17 motor GT2 20 teeth pulley M3-16 screw GT-2 20 teeth pulley 90cm GT-2 timing belt... - Page 12 3. Use the M3-20 screw and nut to attach two 623zz bearing to the X idler. 4. Attach the two 300mm M5 threaded rod through the M5 nuts.

- Page 13 5. Attach the two 370mm 8mm precision rods with three LM8UU bearings. 6. Attach the two 320mm 8mm precision rods through the LM8UU bearings. 7. Attach the Nema 17 motor to the printed X motor holder using three M3-16 screws. Attach a GT2 aluminum pulley to the motor’s shaft.

- Page 14 8. Attach the X carriage to the x axis using 6 zip ties. The X carriage should sit tightly on the LM8UU bearings.

- Page 15 9. Wrap the GT2 timing belt around the X motor and the 623zz bearings. Tie both ends to the X carriage using zip ties. Make sure the belt is tight and there is no skipping when the carriage moves.

-

Page 16: Build The X-Z Plate

Build the X-Z plate Number Required parts Acrylic main frame Acrylic side panels Nema 17 motor Z left top (no. 12) Z right top (no. 11) Z left bottom (no. 6) Z right bottom (no. 7) M3-16 screw M3 nut M3-10 screw Motor coupler M3-25... - Page 17 2. Attach the X-Z system assembled in the previous section to the Z plate. The precision rods of the X-Z system should fit into the circular openings on the z bottom pieces. The precision rods then sit right on top of the z motors (you might need to gently hammer the rods for them to go all the way in). The threaded rods should fit into the motor coupler.

- Page 18 4. Attach the finished XZ plate to the chassis. The XZ plate should be sitting between the two fender washers on the chassis. Do not tighten the nuts yet. 5.6.

- Page 19 Place the side panel with holes on the starboard side (the side with X motor). Place the bottom slot of the side panel between the fender washers on the longer rear threaded rod (second picture). You should have your Prusa i3 looking like the one shown below. Tighten all nuts to have a sturdy frame.

-

Page 21: Attach The Heatbed

Attach the heatbed Number Required parts MK2BA heatbed Borosilicate glass Spring M3 locking nut Paper clip M3-30 screws 1. Attach the borosilicate glass to the MK2A heatbed with paper clips 2. Attach the heatbed to the acrylic bed using m3-30 screws, springs, and m3 locking nuts. The order is: m3-25 screw –... -

Page 22: Attach The End Stoppers

Attach the End Stoppers Number Required parts Printed end stopper mount (no. 13) End stopper 3(6) Zip ties M3-25 screw (Optional) M3 nut (Optional) 1. Attach the end stoppers to the end stopper mounts using zip ties. Wrap zip-ties around the two holes on the end stopper mount and the two holes on the end stopper.

Need help?

Do you have a question about the Prusa I3 and is the answer not in the manual?

Questions and answers