Summary of Contents for Hydac MultiRheo MRFD4

- Page 1 MRFD4 MultiRheo Filter Installation and Maintenance Instructions English (translation of original instructions) Documentation no.: 3342322a...

-

Page 2: Trademarks

HYDAC FILTER SYSTMES GMBH all rights reserved All rights reserved. This manual may not be reproduced in part or whole without the express written consent of HYDAC Filter Systems GmbH. Contraventions are liable to compensation. Exclusion of liability We made every endeavor to ensure the accuracy of the contents of this document. -

Page 3: Table Of Contents

Filter element FlexMicron S (Standard) ............16 Filter element FlexMicron E (Economy) ............16 MRF components ....................17 Hydraulic diagram ....................18 Dimensions ......................19 Setting up / fastening MRF ..................20 HYDAC FILTER SYSTEMS GMBH Page 3 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... - Page 4 Replacing the filter elements ................28 Spare Parts ......................31 Disposing of the MRF..................... 32 Customer Service ....................32 Technical data ......................32 Model Code ......................33 HYDAC FILTER SYSTEMS GMBH Page 4 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20...

-

Page 5: Preface

If you discover errors while reading the documentation or have additional comments or suggestions, contact us at: HYDAC FILTER SYSTEMS GMBH Technische Dokumentation Postfach 12 51 66273 Sulzbach / Saar Germany We look forward to receiving your input. -

Page 6: Customer Service

Warranty For the warranty provided by us, please refer to the General Terms of Sale and Delivery of HYDAC FILTER SYSTEMS GMBH. Refer to these at www.hydac.com General terms and conditions. HYDAC FILTER SYSTEMS GMBH Page 6 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc... -

Page 7: Using The Documentation

The documentation number with its index enables you to order another copy of the operating and maintenance instructions. The index number is incremented upward by one number every time the manual is revised or changed. HYDAC FILTER SYSTEMS GMBH Page 7 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc... -

Page 8: Safety Information And Instructions

Make sure to keep the safety and hazard symbols and warnings on the product in a legible condition. HYDAC FILTER SYSTEMS GMBH Page 8 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc... -

Page 9: Explanation Of Symbols And Warnings, Etc

Improper use may result in hazards. Example of improper use: Improper connection of the pressure and return flow hoses and oil leakage pipe. Noncompliance with the restrictions on use HYDAC FILTER SYSTEMS GMBH Page 9 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 10: Training And Instruction Of Personnel

Dangers by pressure in the hydraulic system WARNING Hydraulic systems are under pressure Bodily injury ► The hydraulic system must be depressurized before performing any work on the hydraulic system HYDAC FILTER SYSTEMS GMBH Page 10 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 11: Mrf Modification

Wet the cleaned filter interior and all sealing surfaces such as the flange with a suitable corrosion inhibitor, e.g. ANTICORIT 3 by Fuchs-DEA. Storage temperature: +5°C to +30°C Humidity: up to 50% relative humidity HYDAC FILTER SYSTEMS GMBH Page 11 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 12: Checking The Scope Of Delivery

Do not put the unit into operation. The following items are included: Item Qty. Description MultiRheo Filter D4 34/- Filter elements (type and quantity as per order) Installation and Maintenance Instructions HYDAC FILTER SYSTEMS GMBH Page 12 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 13: Technical Description

Impermissible operating media The filter will be damaged. ► The unit is only to be used with mineral oils or mineral oil-based raffinates or for cooling lubricants. HYDAC FILTER SYSTEMS GMBH Page 13 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 14: Calculating The Pressure Differential Of The Filter Housing / Filter Element

/ ² min) Q = flow rate (l/min) inch 1000 N = Numbers of elements L = Length of element (inch) HYDAC FILTER SYSTEMS GMBH Page 14 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 15: R (Resistance) Factors

32.0 10.4 3 µm 24.0 5 µm 18.0 10 µm 17.0 20 µm 15.0 30 µm 14.0 40 µm 14.0 ß > 5,000 ß > 20,000 HYDAC FILTER SYSTEMS GMBH Page 15 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 16: Filter Element Flexmicron S (Standard)

Filter element FlexMicron E (Economy) Aqueous fluids Filtration rating 1 µm 3 µm 5 µm 10 µm 20 µm 30 µm 40 µm 50 µm 70 µm HYDAC FILTER SYSTEMS GMBH Page 16 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

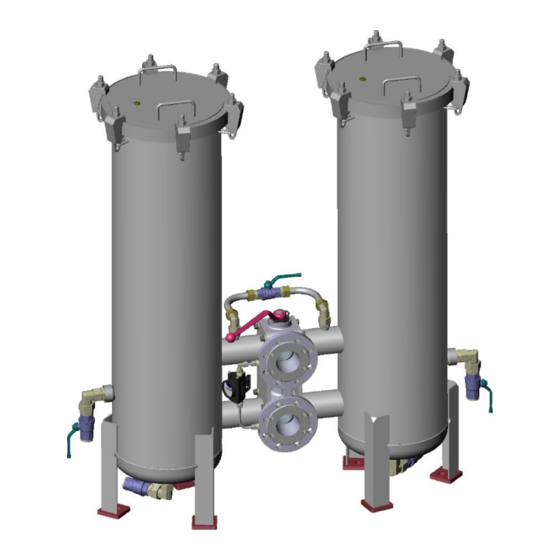

Page 17: Mrf Components

Filter switchover Pressure compensation line Air-vent plug Inlet flange (IN) DIN DN80 Outlet flange (OUT) DIN DN80 Drain valve, clean side Drain valve, dirt side Clogging indicator HYDAC FILTER SYSTEMS GMBH Page 17 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 18: Hydraulic Diagram

Description Filter switchover Pressure compensation line Inlet flange (IN) DIN DN80 Outlet flange (OUT) DIN DN80 Drain valve, clean side Drain valve, dirt side Clogging indicator HYDAC FILTER SYSTEMS GMBH Page 18 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 19: Dimensions

MRFD4 Dimensions Dimensions Ø 355.6 Ø ~1077 HYDAC FILTER SYSTEMS GMBH Page 19 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 20: Setting Up / Fastening Mrf

Connect the MRF hydraulically using a flexible hose connection or pipeline. Make sure that no vibrations and/or stress from other machinery and equipment are carried over to filter housing. Use expansion joints if necessary. HYDAC FILTER SYSTEMS GMBH Page 20 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 21: Notes On Piping / Hosing

Make sure that no tension or vibrations are carried over to the pump or filter housing when the pipes are connected. Use hoses or expansion joints if necessary. HYDAC FILTER SYSTEMS GMBH Page 21 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc... -

Page 22: Starting Up The Mrf

28 in the chapter "Replacing the filter elements". Before commissioning, fill and bleed a filter housing in accordance with the description on page 26 in the chapter "Filling/bleeding passive filter housing". HYDAC FILTER SYSTEMS GMBH Page 22 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc... -

Page 23: Filter Housing Switchover

Switch the flow rate on the change-over valve (A) from the active filter housing to the passive one. Make sure that the pressure equalization valve (B) is closed. Switch-off Passive Passive Switch-off Active Active HYDAC FILTER SYSTEMS GMBH Page 23 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 24: Performing Maintenance

Once the dirt holding capacity of the filter elements has been reached, the clogging indicator responds. Switch to the other filter housing and replace the filter elements in what is now the passive filter housing. HYDAC FILTER SYSTEMS GMBH Page 24 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc... -

Page 25: Define Passive Filter Housing

To define the passive filter housing, observe the position of the change-over valve. The following diagram shows the passive filter housing with a determined position of the change-over valve. Switch-off Passive Passive Switch-off Active Active HYDAC FILTER SYSTEMS GMBH Page 25 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 26: Filling/Bleeding Passive Filter Housing

Wait until the filter housing is completely filled and no more air escapes. Close the pressure equalization valve (B). HYDAC FILTER SYSTEMS GMBH Page 26 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... - Page 27 MRFD4 Filling/bleeding passive filter housing Screw the air bleed screw (C) back onto the cover of the passive filter housing. HYDAC FILTER SYSTEMS GMBH Page 27 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20...

-

Page 28: Replacing The Filter Elements

Observe the cover's weight of approx. 23 kg. Remove all filter elements and dispose of them in accordance with local regulations. Clean the inside of the filter housing of coarse dirt. HYDAC FILTER SYSTEMS GMBH Page 28 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... - Page 29 Engage all toggle screws. Tighten the toggle screws with a 24 mm box wrench crosswise with a maximum of 85 Nm force. HYDAC FILTER SYSTEMS GMBH Page 29 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20...

- Page 30 (B). Screw in the air bleed screw (C) on the cover. The passive filter housing is now ready for switching to active filtration. HYDAC FILTER SYSTEMS GMBH Page 30 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20...

-

Page 31: Spare Parts

625356 Clogging indicator V02 3 VZ.0 1277300 1277300 Change-over valve 1273046 1293544 Ball valve for depressurization 551094 551094 Label set Filter elements * Available on request HYDAC FILTER SYSTEMS GMBH Page 31 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 32: Disposing Of The Mrf

NBR / FPM Housing weight (empty) ~ 380 kg Fluid temperature -10 … +90°C Ambient temperature 10 … 40°C DIN 2633 DN80 PN16 Hydraulic port (IN, OUT) HYDAC FILTER SYSTEMS GMBH Page 32 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... -

Page 33: Model Code

D5 = VM 2 LZ.1/-DB = VR 2 F.0 (pressure switch, electrical) Modification ID = Index Supplementary details OE = no draining = no base / oil pan HYDAC FILTER SYSTEMS GMBH Page 33 / 36 BeWa MRFD4 3342322a us 2010-05-20.doc 2010-05-20... - Page 36 HYDAC FILTER SYSTEMS GMBH Industriegebiet Postfach 1251 66280 Sulzbach/Saar 66273 Sulzbach/Saar Germany Germany Phone: +49 (0) 6897 509 01 Central Fax: +49 (0) 6897 509 846 (Technical Department) Fax: +49 (0) 6897 509 577 (Sales Department) Internet: www.hydac.com E-Mail: filtersystems@hydac.com...

Need help?

Do you have a question about the MultiRheo MRFD4 and is the answer not in the manual?

Questions and answers