Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Colorjet Verve Hybrid

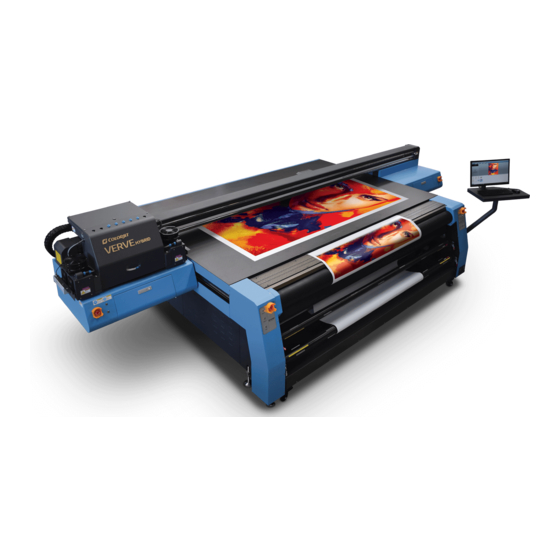

- Page 2 This guide refers as the reference tool which guides the service engineer how to install the Verve Hybrid machine without anyone else assistance. The information provided in this document ensures its uniqueness and language quality.

-

Page 3: Table Of Contents

Negative Pressure Settings .......................... 38 Setting Procedure – Negative Pressure Control Board ................38 Setting Procedure – Pressure Display Meter ................... 39 13. Head Cleaning ............................40 Head Wiping ..............................40 Head Spraying .............................. 40 Verve Hybrid Page | 2... - Page 4 10. “UV Lamp Not Working” ........................48 11. “Negative pressure drop / not working” ....................48 12. “Media not sticking to Bed” ........................49 13. “Print not drying” ........................... 49 14. “UV Lamp Shutter Not Working” ......................49 Verve Hybrid Page | 3...

-

Page 5: Site Layout

1. Site Layout The site layout of the Verve Hybrid printer (with dimension LXWXD) is shown as below: Fig 1: Displaying the Verve Hybrid Site Layout 2. Site Preparation System Requirements The system requirements for the printer manager software are given as follow:... -

Page 6: Safety Requirements

• Proper earthing should be required • Printer and computer must share same exclusive earthing. Power requirement for Verve Hybrid is 11KW which is categorized into the following way: • 2 UV Lamps: each 2.5KW • X and Y Servo Driver: 1.5KW •... -

Page 7: Preparation Before Installation

Appropriately calibrate the print head for high-quality printing services • o Use recommended ink only o Don’t shake the ink bottle or pouch o Store ink in the mentioned site area to avoid dry or damage Verve Hybrid Page | 6... -

Page 8: Assembling The Printer

7. Assembling the Printer The Verve Hybrid machine packs into two boxes: Box 1: Flatbed Unit Fig 2: Displaying the Flatbed Unit Packing Dimension (LxWxH): 5200 x 2200 x 1600 MM Box 2: Roll to Roll Unit Fig 3: Displaying the Rollo to Roll Unit... - Page 9 Assembly steps for the Verve Hybrid machine: Step 1: Place the Roll unit in front of the Flatbed unit and carefully align both units, as shown below: Fig 4: Placing and Aligning Roll to Roll and Flatbed Units Step 2: Fix the L bracket of Roll to Roll unit with the Flatbed unit at both ends, as shown below:...

- Page 10 Displaying L Brackets of the Machine to Fix Roll to Roll Unit with Flatbed Unit Image 1 Image 2 Verve Hybrid Page | 9...

- Page 11 Step 3: Connect wires, cables and suction pipes from both sides Left and Right. Image 1: Displaying the Left Side Connections, as shown in the image below: Image 2: Displaying the Right-Side Connections, as shown in the image below: Verve Hybrid Page | 10...

- Page 12 Step 4: Carefully align and fix covers, as shown below: Fig 6: Fixing the Covers Step 5: Level both units while fixing Roll to Roll unit with Flatbed unit: Fig 7: Displaying Fixed Roll to Roll Unit with Flatbed Unit Verve Hybrid Page | 11...

-

Page 13: Installation Of Print Control Center

Step 3: Double-click on the Printer Manager software (.exe file) icon, as shown below: Fig 8: Starting the Printer Manager Installation On-clicking the Printer Manager icon, the Startup screen appears, as shown below: Fig 9: Starting the Installation Process Verve Hybrid Page | 12... - Page 14 Note: USB driver is automatically installed with the Printer Manager software. If not, then follow the below given steps. Step 5: Open Device Manager, right-click on the My Computer icon and select the Manage option from the context menu, as shown below: Fig 11: Selecting the Manage Option Verve Hybrid Page | 13...

- Page 15 Step 7: Select the Wide-Format Printer option under Other devices and right-clicked on it. The context menu appears on the screen (Refer to Fig 13). Step 8: Select the Update Driver Software option from the context menu, as shown below: Fig 13: Configuring the USB Driver Verve Hybrid Page | 14...

- Page 16 Step 11: Click on the OK button to start the driver update process (Refer to Fig 15). The process gets started for updating the driver software and the process progress screen appears, as shown below: Fig 16: Displaying the Process Progress Verve Hybrid Page | 15...

-

Page 17: Printer Manager Settings

Feather: Select the type of feather effect and intensity percentage of the feather. o Multiple Ink: Enable to select the color depth of an image according to the passes. The available options are Default, Double, and More. Verve Hybrid Page | 16... - Page 18 Print command. The Move tab is shown in the image below: Fig 19: Displaying the Move Tab Using the Move tab, the Y Speed can be updated as per the requirements. Verve Hybrid Page | 17...

- Page 19 The Preference tab is shown in the image below: Fig 20: Displaying the Preference Tab The Calibration tab is shown in the image below: Fig 21: Displaying the Calibration Wizard Verve Hybrid Page | 18...

-

Page 20: Head Temperature Settings

Follow these steps to update the head voltage: Step 1: Click on the Main Menu→Tools→Real Setting path, as shown in the image below: Fig 23: Selecting the Real Setting Option The Temperature window appears on the screen. Verve Hybrid Page | 19... -

Page 21: Save To Printer

Load From Printer option. Note: In Setting, the Save option is used for saving the previously made settings and created an .xml file of further use. Verve Hybrid Page | 20... -

Page 22: Uv Settings

Setting window appears as shown below: Fig 26: Displaying UV Settings Note: • We can switch UV lamp power to Low/Medium from the Front panel switch • We can select shutter working based on the printing requirements. Verve Hybrid Page | 21... - Page 23 Note: Other calibration value remains same. Dry Movement Test Run the full (3200/2000 mm) dry print command (without Ink and Head) to verify the functioning of the printer like XYZ axis, sensors, Limit Switch, etc. Verve Hybrid Page | 22...

-

Page 24: Head Installation

The installation of Print Heads is to be done only by a service engineer. If the Print Head is not installed correctly, it can affect the printing quality. The following print head is used in the Verve Hybrid machine: Fig 28: Displaying the Print Head Note: Don’t apply much pressure on... - Page 25 Fig 31: Removing the Cover on the Carriage Plate Step 3: Mount the print head on the head plate. Step 4: Tight the M4 Allen screws to fix the print head on the head plate (Refer to Fig 32). Verve Hybrid Page | 24...

- Page 26 Step 5: Fix all the Head Aligners viz. front and back sides, as shown below: Front Side Fig 32: Fixing Front Side Head Aligners Back Side Fix Push Fitting Connectors (both sides) Fix Aligner Fig 33: Fixing Back Side Aligners Verve Hybrid Page | 25...

- Page 27 Step 8: Similarly, insert the second end of the head cable on the Head Board and gently lock the head cable with the Head Board. To verify the head cable orientation, please carefully view the image as shown above. Verve Hybrid Page | 26...

- Page 28 Similarly, perform this action for each color. Step 12: Perform the Head Blotting to gently clean the Print Head. Step 13: Perform the Nozzle Test to check the nozzle status of all the Print Heads. Now, the Print Head gets installed. Verve Hybrid Page | 27...

-

Page 29: Ink Filling

Step 2: Fill recommended ink in each main ink tank as per the color stickers, as shown below: Fig 37: The Main Ink Tanks Note: Main tanks are equipped with ink level sensor which beeps once the ink level goes down. Verve Hybrid Page | 28... - Page 30 Now, pumps start working and ink start moving in the ink pipes. The ink sub tanks are shown in the below image: Fig 39: The Sub Ink Tanks with Heaters The sub ink tanks are equipped with Heaters and float sensors to maintain the temperature of inks and indicate if ink level goes down. Verve Hybrid Page | 29...

-

Page 31: Head Calibration

Print Heads should be calibrated to ensure good printing quality. To open the Calibration Wizard, click on the Main Menu→Tools→Calibration Wizard path, as shown below: Fig 40: Selecting the Calibration Wizard Option This should bring up the Calibration Wizard, as shown below: Fig 41: Displaying the Calibration Wizard Verve Hybrid Page | 30... -

Page 32: Step Calibration

Fig 43: The Step Calibration Parameters First, feed the Base Step Value as 62000 for Roll to Roll and 116485 for Flatbed (this is the approximate value and this need to be corrected by following the below steps). Verve Hybrid Page | 31... -

Page 33: Mechanical Checks

Fig 44: The Good Quality Angle Test When there is angular error in a head’s placement, the line formed by a particular Print Head will appear broken, as shown in the image below: Overlapping Fig 45: Defect in Angle Check Verve Hybrid Page | 32... - Page 34 Magenta, and Yellow) with the reference color (Magenta). Note: During the mechanical checks, it may possible that it will disturb the angle check or vertical check. Thus, repeat the mechanical check until the perfect alignment condition is achieved. Verve Hybrid Page | 33...

-

Page 35: Horizontal Calibration

“0” position, but at some other point on the calibration scale. The position at which the test head aligns perfectly with the reference head, indicates the error in position. Verve Hybrid Page | 34... - Page 36 The Left Calibration Result is shown in the image below: Fig 48: The Horizontal Left Check The Right Calibration Result is shown in the image below: Fig 49: The Horizontal Right Check Verve Hybrid Page | 35...

-

Page 37: Negative Pressure Adjustment

Ink drops disappear (sucked up by the head) Reduce the negative pressure (For eg. If -4.0, make it -3.9) This condition can clog nozzle on the running print. Negative Pressure Schematic Fig 50: Displaying the Negative Pressure Schematic Verve Hybrid Page | 36... -

Page 38: Negative Pressure System Working

ON for the time period, to maintain the set value. If current pressure value crosses max value set, it will leak pressure with the help of protection valve. Fig 51: Displaying the Negative Pressure Verve Hybrid Page | 37... -

Page 39: Negative Pressure Settings

Note: Max negative value should be higher than min value eg. Min value is -0.1 then max value should be at least -0.15. Step 2: Click on the MOV to change the number you need change. Note: The flush number means current adjust one. Verve Hybrid Page | 38... -

Page 40: Setting Procedure - Pressure Display Meter

Press the SET button for one second and set the value 1 – P with “UP” and “DOWN” button. Note: 2-P value should be bigger than current value. Set 2-P Protection Value Press the SET button again, it will redirect to 2-P Set 2-P with the UP and DOWN button. Verve Hybrid Page | 39... -

Page 41: Head Cleaning

To perform head spraying, click on the Spray icon available under the Quick Access Toolbar, as shown in the below figure: Fig 55: Selecting the Spray Button Verve Hybrid Page | 40... -

Page 42: Head Purging

Please make sure that all other colors Negative Pressure knob must be turned OFF. Step 2: Press the Cleaning button to start the purging process, as shown below: Fig 57: Displaying the Cleaning Button Now, the Print Heads get cleaned. Verve Hybrid Page | 41... -

Page 43: Maintenance

• Some parts of the machine viz. UV lamps and motor generate lots of heat during working. Thus, one should arrange proper ventilation for long life of the machine. Verve Hybrid Page | 42... -

Page 44: Control System Maintenance

• Keep water, ink, and oil away from the Encoder ruler to avoid Encoder ruler error. • Encoder sensor shouldn’t work in corrosion environment, thus environmental condition should be according to the environment condition. Verve Hybrid Page | 43... -

Page 45: Ink Supply System Maintenance

Keep the print head away from light to avoid dry out situation. • Prevent the object or human body with static contact the print head. • Print head nozzles should be kept away from hands, ink, flush, etc. • Should be kept clean and prevent oxidation. Verve Hybrid Page | 44... -

Page 46: Troubleshooting

2. USB Cable USB Cable is loosely connected Check and tighten the USB cable to the printer Replace it, if faulty USB Cable is faulty 3. Printer Not Initialized Refer to Printer Not Initialized Section Verve Hybrid Page | 45... -

Page 47: Ink Not Filling

Replace it, if faulty Head Cables are faulty 3. Ink Pipes No ink in ink pipes Refill ink Cuts in ink pipe Replace ink pipe, if faulty Loose connection Check the connection and fix it, if loose Verve Hybrid Page | 46... -

Page 48: Print Stops In Between Printing

Correctly Align the Print Heads (Refer to the Head Alignment section) 2. Ink Recommended ink is not used Only use the recommended ink Ink is stored at unfavorable Ink is stored at favorable environment environment Verve Hybrid Page | 47... -

Page 49: Lines In Print

Check and replace the pump pump (pump failure) Vacuum Pump Vacuum pump connector is loose Tighten the Vacuum Pump connector Ink/Air Tube ink/air tube having Check and replace it, if required leakage/cut/loose on fitting joints Verve Hybrid Page | 48... -

Page 50: Media Not Sticking To Bed

Check and replace, if required (Contact to factory for more details) 14. “UV Lamp Shutter Not Working” Problematic Parts Reasons Correction Steps 1. UV Lamp Settings UV Lamp settings are incorrect Correct the UV Lamp settings Verve Hybrid Page | 49... - Page 52 For Any Query Please Contact Us www.colorjetgroup.com Call us on +91-120-4548195 Email on info@colorjetgroup.com For Ink Enquiry:- sales@colorjetgroup.com For Support:- support@colorjetgroup.com...

Need help?

Do you have a question about the Verve Hybrid and is the answer not in the manual?

Questions and answers