Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

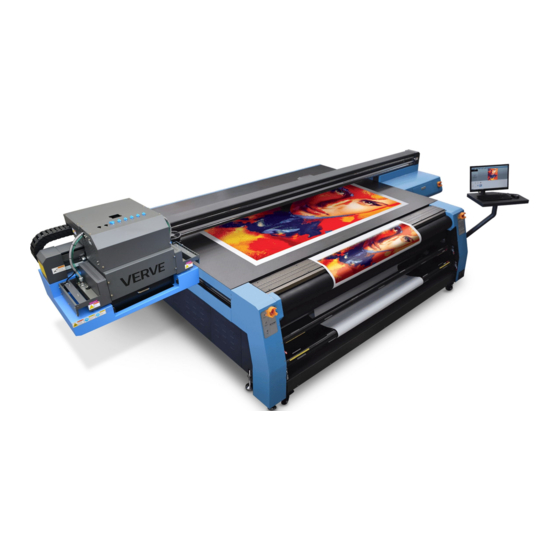

Summary of Contents for Colorjet VerveLED VLY 2513

- Page 2 Disclaimer The information and instructions provided in this installation manual have been checked for accuracy, uniqueness, and reliability. ColorJet group reserves all the rights to modify and revise this manual as per the company requirements without any prior notice. “No part of this document shall be reproduced or used by externals without prior permission of the ColorJet group”.

-

Page 3: Table Of Contents

Table of Contents 1. Site Layout ..............................5 2. Site Preparation ............................5 System Requirements ..........................5 Supporting Software Requirements ......................6 Environmental Requirements ........................6 3. Safety Precautions ............................ 7 4. Electric Requirements ..........................7 Proper Earth Connection .......................... 7 5. - Page 4 14. Media Loading ............................36 15. Nozzle Testing ............................37 16. Head Calibration and Alignment ......................38 Calibration Wizard ..........................38 Mechanical Checks ..........................39 Angle Check ............................39 Angle Alignment ..........................40 Step Calibration ........................... 41 Vertical Check ............................. 42 Vertical Alignment ..........................

- Page 5 12. “Media not sticking to Bed” ......................53 13. “Print not drying” ..........................53 14. “UV Lamp Shutter Not Working” ...................... 53 VERVE LED Page | 4...

-

Page 6: Site Layout

1. Site Layout The Site Layout of the machine is shown in the image below: Fig 1: Displaying the Site Layout of the Machine Machine Dimension (L x W x H): 4900 x 2680 1620 mm Dimension with Packing (L x W x H): 5030 x 2280 x 1890 mm 2. -

Page 7: Supporting Software Requirements

Supporting Software Requirements The Supporting Software Requirements are given as follow: Table 2: Supporting Software Requirements Requirements Specifications Printer Software Provided by ColorJet RIP Software Provided by ColorJet Tool Requirements The Tool Requirements for printer installation are given as follow: •... -

Page 8: Safety Precautions

3. Safety Precautions Before operating the printer and Printer Manager software for the first time, please read the document carefully and follow all the usage instructions. While using the printer, kindly follow all the safety instructions which are given below: Fire Prevention Inks and solvents must be enclosed in a special storage cabinet for inflammable liquids or within a separate storage room and must be clearly identified to meet the professional requirements of safety regulations. -

Page 9: Preparation Before Installation

5. Preparation before Installation To install the printer, you must follow the below mentioned instructions: • Prepare the site as per the requirements like environmental temperature. • Configure PC as per the given system specification viz. RAM, operating system, processor, and storage space. -

Page 10: Unpacking And Unloading The Printer Box

7. Unpacking and Unloading the Printer Box Machine and Tool Requirements The Machine and Tool Requirements are shown as follow: • Fork lift • Crane • Heavy duty lifting belt/sling • Powered screw/nut driver • Nut driver • Spanner Unloading the Machine The net weight of the machine is 1962 Kgs. -

Page 11: Input Power Checklist

Now, the machine is unpacked and ready for installation process, as shown below: Fig 2: Unpacking the Machine Caution: Don’t move or unload the machine before ensuring that the place where the machine is landed, is even or level. Precautions: •... -

Page 12: Software Installation

9. Software Installation Printer Manager Installation Follow these steps to install the Printer Manager software: Step 1: Insert pen drive and paste the Printer Manager software from the CD to the secure location. Step 2: Double-click on the Printer Manager software (.exe file) icon, as shown below: Fig 3: Starting the Printer Manager Installation On-clicking the Printer Manager icon, the Startup screen appears, as shown below: Fig 4: Starting the Installation Process... - Page 13 Now, the Printer Manager gets installed successfully and displayed the Ready status. In case, if it is not properly installed, then the status is Offline. To open the Printer Manager, click on the Printer Manager icon. The Printer Manager window appears on the screen, as shown below: Please verify the selected configuration with printer manager settings...

- Page 14 The Device Manager and its related options get expanded on the middle pane of the Computer Management window, as shown below: Fig 7: Displaying the Device Manager Screen Step 6: Select the Wide-Format Printer option under Other devices and right-clicked on it. The context menu appears on the screen (Refer to Fig 8.

- Page 15 Step 8: Select the Browse my computer for driver software option from the Update Driver Software window (Refer to Fig 9). Step 9: Select the location where the driver software is stored by clicking on the Browse button, as shown below: Fig 10: Selecting the Driver Location Step 10: Click on the OK button to start the driver update process (Refer to Fig 10).

-

Page 16: Disable Driver Signature Enforcement

Disable Driver Signature Enforcement Follow these steps to temporary Turn OFF the Driver Signature Enforcement to install unsigned driver: Step 1: Open the Run dialog box by pressing the Windows + R keys from the keyboard. Step 2: Type the shutdown /r/o command and then, click on the OK button. A window appears by stating that you are about to be signed off and close the window by pressing the Close button. - Page 17 The Advanced Options window appears on the screen. Step 5: Select the Startup Settings option from the window, as shown below: Fig 13: Selecting the Startup Settings Option The Startup Settings window appears on the screen. Step 6: Click on the Restart button to reboot your computer again, as shown below: Fig 14: Rebooting the System VERVE LED Page | 16...

- Page 18 Step 7: After restarting the system, press the F7 key from your keyboard and select “Disable driver signature enforcement “, as shown below: Fig 15: Disabling the Driver Signature Enforcement Step 8: Your PC starts rebooting and proceeds to install your unsigned drivers. During the installation procedure, Windows will inform you that can’t verify the publisher of this driver software.

-

Page 19: Printer Manager Settings

Printer Manager Settings Printer Settings This option enables users to update the default settings of the printer viz. Print, Move, Preference, and Calibration. To open the Setting window, click on the Main Menu→Setting→Edit path. The Setting window appears on the screen, as shown in the image below: Fig 16: Displaying the Setting Window Describing the different sections of the Setting window, as given below: •... - Page 20 o Idle Spray: Spray during carriage at home position. This option must be enabled. o Spray Before Print: This option works with the Print Pre-spray Time option. When enabled, one can specify the duration, if spray before issuing the Print command. The Move tab is shown in the image below: Fig 17: Displaying the Move Tab Using the Move tab, the Y and Z Speeds can be updated as per the requirements.

- Page 21 The Calibration tab is shown in the image below: Fig 19: Displaying the Calibration Wizard The Multilayer print tab is shown in the image below: Fig 20: Displaying the Multilayer print VERVE LED Page | 20...

-

Page 22: Head Temperature Settings

Head Temperature Settings Follow these steps to update the head voltage: Step 1: Click on the Main Menu→Tools→Real Setting path, as shown in the image below: Fig 21: Selecting the Real Setting Option The Temperature and Voltage window appears on the screen. Step 2: Enter the head and nozzle temperture values of each color Print Head under the Temperature and Voltage section, as shown below: Fig 22: Setting the Base Voltage Value... -

Page 23: Save To Printer

Save to Printer After making the desire changes in the printer settings, save these settings into the printer for future usage. To save the settings to the printer, click on the Main Menu→Setting→Save To Printer path, as shown below: Fig 23: Selecting the Save To Printer Option On clicking the Save To Printer option, all the previously made settings get saved on the Main Board. -

Page 24: Switch On Procedure

10. Switch ON Procedure Follow these steps to switch ON the printer: Step 1: Check and maintain the room temperature for smooth printing operations. Step 2: Check Ink Level. Step 3: Release the Emergency button, if pressed. Step 4: Switch ON the printer from the main power and MCB. The automatic initialization of the machine gets started. - Page 25 Step 7: Run the full (2500/1220 MM) dry print command (without Ink and Head) to verify the functioning of the printer like XYZ axis, sensors, Limit Switch, etc. Now, printer is ready for printing. VERVE LED Page | 24...

-

Page 26: Ink Filling

11. Ink Filling Please use the recommended ink in the printer for high printing quality and long life of print and Print Head. Follow these steps to fill ink in the printer: Step 1: Switch ON the printer. Step 2: Fill recommended ink in each main ink tank as per the color stickers, as shown below: 26:Displaying the Main Ink Tanks Note: Main tanks are equipped with ink level sensor which beeps once the ink level goes down. - Page 27 Now, pumps start working and ink start moving in the ink pipes. The ink sub tanks are shown in the below image: Fig 28: The Sub Ink Tanks with Heaters The sub ink tanks are equipped with Heaters and float sensors to maintain the temperature of inks and indicate if ink level goes down.

-

Page 28: Head Installation

12. Head Installation Use this section, if Print Head is not installed in the printer. The installation of Print Heads is to be done only by a service engineer. If the Print Head is not installed correctly, it can affect the printing quality. The following print head is used in the machine: Fig 29: Displaying the Print Head Note: Don’t apply much pressure on... - Page 29 Now, the head cap gets removed, as shown below: Fig 30: Removing the Head Cap Step 2: Unscrew the screws available on the carriage plate and remove the cover, as shown below: Fig 31: Removing the Cover on the Carriage Plate Step 3: Mount the print head on the head plate.

- Page 30 Step 5: Fix all the Head Aligners viz. front and back sides, as shown below: Front Side Fig 32: Fixing Front Side Head Aligners Back Side Fix Push Fitting Connectors (both sides) Fix Aligner Fig 33: Fixing Back Side Aligners VERVE LED Page | 29...

- Page 31 Step 6: Fix the Head Tensioner Strip for aligning head left and right, as shown below: Fig 34: Fixing the Head Tensioner and Push Fitting Connectors Step 7: Insert one end of the head cable on the top of the Print Head and gently press it to fix, as shown in the image below: Fig 35: Inserting the Head Cable Step 8: Similarly, insert the second end of the head cable on the Head Board and gently lock the head...

- Page 32 Step 9: Insert one end of the power cable on the top of the Print Head and gently press it to fix, as shown in the image below: Fig 36: Fixing the Power Cable Step 10: Similarly, insert the second end of the power cable on the Power Supply Board and gently lock the cable with the Power Supply Board.

-

Page 33: Negative Pressure Adjustment

13. Negative Pressure Adjustment Understanding Negative Pressure Condition after purging: Ink drops hold on the nozzle plate, neither drop nor sucked back (as shown in the image below). This is perfect and ideal condition Ink drop easily from the head Increase the negative pressure (for eg. -

Page 34: Negative Pressure System Working

Negative Pressure System Working Pressure adjustment setting has to be done at two stages, first in the negative pressure control board and secondly in the pressure display meter mounted near this board. There are two display meters mounted in the machine. The first meter is available near the control board which displays the exact negative pressure value. -

Page 35: Negative Pressure Settings

Negative Pressure Settings Fig 39: Displaying the Negative Pressure Settings The Negative Pressure Control Board is shown in the image below: Fig 40: Displaying the Negative Pressure Control Board Setting Procedure – Negative Pressure Control Board Step 1: a) Enter setting mode→ Press “ESC”→Number “13.2” will flash, this is setting 1. b) Press “ESC”... -

Page 36: Setting Procedure - Pressure Display Meter

Note: Max negative value should be higher than min value eg. Min value is -0.1 then max value should be at least -0.15. Step 2: Click on the MOV to change the number you need change. Note: The flush number means current adjust one. Step 3: Use the ADD button to adjust the numbers. -

Page 37: Media Loading

14. Media Loading Follow these steps to load the media on the machine: Follow these steps to load media: Step 1: Place the media on the Print Bed. Step 2: Switch ON the Print Bed vacuum by pressing the Bed Vacuum button available on the front side of the machine, as shown below: Fig 41: Turning ON the Bed Vacuum Button Step 3: Switch ON the required vacuum chambers by moving the Vacuum Chamber knob, as shown below:... -

Page 38: Nozzle Testing

15. Nozzle Testing Before starting with calibration tests, the Print Heads should be checked for blockage. Each Print Head has multiple tiny nozzles through which ink drops emerge and get deposited onto the print medium. Any nozzle blockage can compromise the print quality by forming discolored horizontal streaks or bands. The good and bad nozzle test results are shown in the image below: Fig 44: Displaying the Good and Bad Nozzle Test Result To check the nozzle, click on the Nozzle Test icon available on the Quick Access Toolbar, as shown below:... -

Page 39: Head Calibration And Alignment

16. Head Calibration and Alignment To improve and enhance the printing quality, you must carefully align the Print Head. The Print Head alignment process consists the following tests: • Mechanical Check: Includes Vertical Check and Angle Check • Software Calibration: Includes Horizontal Calibration Viz. Left, Right, and Bi-direction. Calibration Wizard Print Heads should be calibrated to ensure good printing quality. -

Page 40: Mechanical Checks

Based on the above figure, the list of mechanical checks appears and as per these checks, Print Heads need to be adjusted with the help of tools provided. The list of mechanical checks is given as below: • Angle Check •... -

Page 41: Angle Alignment

Alignment Correction Tools are shown in the image below: Fig 50: Displaying Front and Back Sides Aligners Angle Alignment To align head in left or right direction, tight the Head Tensioning Strip screw as per requirements: Head Tensioning Strip Screw Fig 51: Aligning Head in Left or Right Direction Note: After correcting the Angle alignment, issue the Print command using the RIP file and verify print with respect to its quality. -

Page 42: Step Calibration

Step Calibration The printer step calibration is performed to verify and correct media feeding. The printer prints a complete image pass by pass. A pass is the horizontal carriage sweep perpendicular to the media movement. After each pass the printer moves the media forward for the next pass. This movement of media is called a step. The distance by which the media is moved is called the step size and it has to be accurate. -

Page 43: Vertical Check

Vertical Check The vertical alignment test is performed to check the vertical alignment of all heads with reference to the Magenta head. To execute vertical alignment test, click on the Vertical Check button on the Calibration Wizard. Samples of Good and Bad Vertical Alignment Test Result is shown in the image below: Fig 53: The Good and Bad Vertical Alignment Test Result When a Print Head is aligned with the reference Print Head (Magenta), then in the test print this would be evident by perfectly aligned vertical nozzle lines. -

Page 44: Vertical Alignment

Vertical Alignment To align head in upward or downward direction, tight the Push Fitting Connectors from front or back side as per requirements: Fig 54: Aligning Head in Upward or Downward Direction Push Fitting Connectors Note: After correcting the Angle alignment, issue the Print command using the RIP file and verify print with respect to its quality. - Page 45 The Bi-direction Calibration result is shown in the image below: Fig 55: The Bi-Direction Calibration Output Based on the above figure, you can notice that the Bi-direction Calibration is good at “0” position. The correction value is “0” which means you need not to correct the bi-direction value. Sometimes, the correction value can either positive or negative.

- Page 46 The Right Calibration Result is shown in the image below: Fig 57: The Horizontal Right Check VERVE LED Page | 45...

-

Page 47: Maintenance

17. Maintenance Machine Maintenance In order to keep the machine in a good working condition, one must regularly perform the following tasks: • Before printing, one should issue the nozzle test command to check print head’s nozzles status. In case, nozzles are blocked or test result is not good, then one should perform head cleaning process to clean print head’s nozzles (Refer to Head Cleaning section). -

Page 48: Control System Maintenance

Control System Maintenance Follow the below given instructions for control system maintenance: • Static Discharge o One must discharge electrostatic waste of the machine before touch the electronic components and parts of it. o Don’t touch the pin connectors and welded joints on circuit boards and integrated circuit boards. -

Page 49: Ink Supply System Maintenance

Ink Supply System Maintenance Follow the below instruction for maintaining the ink supply system • Appearance Inspection o Check for any leak between joints, ink tanks and valve seating. o Check for any cut on ink tubes. • Filter Replacement o Check the disk filters which should be changed after 3 months or 800 hours working. -

Page 50: Troubleshooting

18. Troubleshooting 1. “Printer Not Initializing” Problematic Parts Reasons Correction Steps 1. Emergency Switch Switch is Pressed Release the Emergency Switch 2. 220V AC No power supply to the Head Check the Input/output Volt Board Check MCB and ON it, if not 3. -

Page 51: Ink Not Filling

3. “Ink Not Filling” Problematic Parts Reasons Correction Steps 1. Main Tank Main tank is empty Refill the Main Tank 2. Ink pump Ink pump is not working Replace the pump, if faulty Connectors are loose Tighten the connectors, if loosen 3. -

Page 52: Print Stops In Between Printing

6. “Print Stops In Between Printing” Problematic Parts Reasons Correction Steps 1. USB Cable Cable is loose Tighten the USB cable Cable is faulty Replace it, if faulty 4. File Size File size exceeded the limit Use compatible and small size images for printing 5. -

Page 53: Lines In Print

9. “Lines In Print” Problematic Parts Reasons Correction Steps 1. Head Nozzles Head nozzles are blocked Clean the Print Head 2. Feed Adjustments Incorrect feed steps Correct the feed steps using the Calibration Wizard 3. Head Alignment Head alignment is incorrect Refer to the Head Alignment section 4. - Page 54 12. “Media not sticking to Bed” Problematic Parts Reasons Correction Steps 1. Vacuum Pump Vacuum pump is not ON Switch ON the Vacuum Pump 2. Vacuum Settings Incorrect vacuum settings Correct vacuum settings adjustment 3. Run Button on the Run button is not pressed after After adjusting vacuum pump Vacuum Regulator settings...

- Page 56 For Any Query Please Contact Us www.colorjetgroup.com Call us on +91-120-4548195 Email on info@colorjetgroup.com For Ink Enquiry:- sales@colorjetgroup.com For Support:- support@colorjetgroup.com...

Need help?

Do you have a question about the VerveLED VLY 2513 and is the answer not in the manual?

Questions and answers