Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Riso GOCCOPRO QS200

- Page 2 116-36003-303 Digital Screen Maker Model: GOCCOPRO QS200 The user is cautioned that unauthorized changes or modifications not approved could avoid the user's authority to operate the equipment. NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

- Page 3 The screen displays and messages referred in procedures differ depending on models of PCs and applications. (Winows7 screens are used in this document.) Riso Kagaku Corporation London Office, 610 Centennial Park, Centennial Avenue, Elstree, Herts, WD6 3TJ U.K. Copyright © 2017 RISO KAGAKU CORPORATION...

-

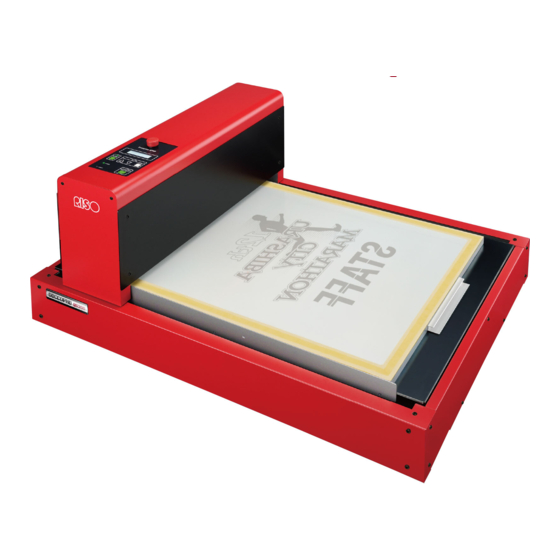

Page 4: Feature Of This Product

Feature of This Product This machine is a master maker exclusively for RISO DIGITAL SCREEN QS MASTER/GRAY. You can make a master directly on your screen frame. ________________________________________________ Quick, simple & clean operation ● No need for emulsion & washouts ●... -

Page 5: Expressions In The Text

Expressions in the Text The following expressions are used in this User's Guide. ________________________________________________ Warning, Caution, and Other Indications The following symbols are used throughout this User's Guide for warning, caution and other indications. Expressions dans le texte Le présent Guide de l'utilisateur emploie les expressions suivantes. ________________________________________________... -

Page 6: Operation Procedures And Functions

________________________________________________ Operation Procedures and Functions This User’s Guide illustrates functions and operation procedures as follows. Operation illustration Chapter title Relevant parts of the machine are illustrated, which are being described in each step. The operation panel of the machine and screens on PC are described. Operation procedure Step-by-step description of the operation procedure. -

Page 7: Orientations And Directions

Expressions in the Text ________________________________________________ Orientations and Directions Main unit front view Y direction Rear (side) X direction (side) START (side) Front (side) Screen frame Rear (side) START (side) Y direction Home (side) position X direction Front (side) |5|... -

Page 8: Table Of Contents

Table of Contents ________________________________________________ Feature of This Product ........2 •... - Page 9 Table of Contents ________________________________________________ Getting ready to use Installing Printer Driver ........29 Before Installation .

- Page 10 Table of Contents ________________________________________________ Appendix Uninstalling the Printer Driver ......80 • For Windows XP ........80 •...

- Page 11 Preface This section describes precautions you should know or pay attention to before you use the machine. |9|...

-

Page 12: Safety Guide

Preface Safety Guide This section describes the safety guide you need to know before operating the machine, such as installation location and power connection. Make sure to read this section. ________________________________________________ Warning indications The following warning indications are used to ensure correct use of this machine and to prevent injuries or property damage. -

Page 13: Grounding

Preface ________________________________________________ ● Do not damage, break or tamper • Lightning conductor with the power cable. Do not place • Water pipe and water tap with plastic parts a heavy object on the cable, pull, or forcibly bend the cable to avoid the ●... - Page 14 Preface ________________________________________________ ● Do not let someone who does not know how to use the ● Before using the machine, put the transport fixing machine touch it. It may cause an unexpected screw in the position shown in the figure below to accident by touching dangerous parts or by starting protect it against loss.

- Page 15 Préface Guide de sécurité Cette section décrit les consignes de sécurité à observer avant d'utiliser l'imprimante, relatives, par exemple, à l'emplacement d'installation et au raccordement électrique. Veuillez lire cette section. ________________________________________________ Avertissements Les avertissements suivants permettent de garantir une utilisation correcte de l'imprimante et d'éviter des blessures ou des dommages matériels.

- Page 16 Préface ________________________________________________ ● N'utilisez pas de prise multiple ni de cordon avec câble de terre, raccordez la fiche à la terre avant de prolongateur. Ne surchargez pas le circuit électrique. l'insérer dans la prise électrique. Débranchez le câble de Si l'utilisation d'un cordon prolongateur terre après avoir retiré...

- Page 17 Préface ________________________________________________ ● N'introduisez pas d'objet métallique ni de substance ● N'introduisez jamais vos doigts, etc., dans les ouvertures inflammable dans l'imprimante par une ouverture. de l'imprimante, vous risqueriez de vous blesser. Cela pourrait provoquer un incendie ou un choc électrique.

-

Page 18: Before Use

Preface Before Use ________________________________________________ Notes on Installation Notes on Connection Notes on Installation Location Notes on Power Connection ● Your dealer will help you to determine an appropriate ● Ensure that the plug is fully location for the machine at the time of delivery. inserted into the power socket to avoid contact failure of the power ●... - Page 19 Préface Avant utilisation ________________________________________________ Remarques sur ● Les conditions environnementales appropriées s l'installation ont les suivantes. ● Plage de température : 15 °C - 30 °C Remarques sur l'emplacement d'installation ● Plage d'humidité : 40 % - 70 % ● Votre revendeur vous aidera à...

-

Page 20: Precautions For Connection With Pc

Do not use highly-soluble organic solvents such as thinner and benzene for cleaning. If they are used, coating peeling and failures will occur. For cleaning, use RISO Thermal Head Cleaner or neutral detergent. |18|... -

Page 21: Precautions On Image-Making Position

Preface ________________________________________________ Precautions on Image-making Position Image Direction The relationship between the direction of the Artwork This section is to describe the relationship between a data created on the computer and the direction of the Image-making position and a screen frame. Improper image transferred onto a screen is shown below. -

Page 22: Image-Making Position

Preface ________________________________________________ Image-making Position Image-making Area Image-making always starts from the home position Image-making area has to be 160mm or less then which is located 80 mm away from the Front side the outer frame size in both X-direction (Width) and and 80 mm away from the START side of the screen Y-direction(Height). - Page 23 Preface ________________________________________________ Artwork data size has to be less then The image-making area of screen frame size image-making area. 750mm x 450mm (outer size) will be 590mm x Image-making area is determined by 290mm as shown below. reducing 160mm from outer size of the screen frame size in both X-direction (Width) and Y-direction (Height).

-

Page 24: Artwork Data Larger Than Image-Making Area

Preface ________________________________________________ Artwork Data Larger Than (1) Create A3 size artwork data with computer Image-Making Area 297 mm applications. When the size of artwork data is larger than the maximum image-making area (620 mm × 420 mm), the area outside the image-making area is not transferred onto a screen. -

Page 25: Multi-Page Artwork Data

Preface ________________________________________________ ● Artwork data extends to multiple pages. Multi-Page Artwork data When the artwork data has multiple pages, the first page is transferred onto a screen, but the second and subsequence pages are not transferred and stored. Also when artwork data extends to multiple pages unintentionally, only the first page is transferred onto a screen. -

Page 26: Name And Function Of Each Part

(Emergency Stop Switch) (4) Screen Frame Press the Emergency STOP switch down to stop the machine. Strecth RISO DIGITAL SCREEN QS Once the switch is pressed down, the switch MASTER/GRAY to the frame. remains depressed. (5) Screen Frame Stopper... - Page 27 Preface ________________________________________________ Start side perspective view Front Rear START (10) Front (12) START (11) Rear (6) Transport Securing Screw (10) Height Adjustment Feet (Four Secures the head mount unit to the Rear side Locations) during transport of this machine. Turn the screws to adjust the position of the (7) USB Connector machine.

-

Page 28: Operation Panel

Preface ________________________________________________ Operation Panel The operation panel displays the machine status, and you can operate image remaking, image-making parameters setting, and others with the offline menu. Emergency STOP SETTING ONLIN ENTER STORAG POWER (10) START/STOP ERROR (1) Display Blinks when Artwork data is being received. Displays the machine status and information of (7) <START/STOP>... -

Page 29: Flow From Image-Making To Printing

Preface Flow from Image-Making to Printing The flow from image-making with PC artwork data to printing is as follows. In this User’s Guide, up to Step 4 are described. ________________________________________________ Create and output (transmit) artwork data with PC. “Transmitting Artwork Data from PC” page Set a screen frame to the machine. -

Page 30: Getting Ready To Use

Getting ready to use The following operations are required when you use the machine for the first time after installation. ”Installing Printer Driver” page 29 ・ |28|... -

Page 31: Installing Printer Driver

1 Getting ready to use Installing the Printer Driver ________________________________________________ Before Installation ● Prepare a commercially available USB cable (3 m or less, compliant with Hi-Speed USB). • If you use a USB cable longer than 3 m or an unqualified USB cable, the machine may not operate normally. -

Page 32: Installation Procedure

1 Getting ready to use ________________________________________________ Installation Procedure Insert the CD-ROM for driver installation (RISO ® Windows GOCCOPRO Printer Driver for/GOCCOPRO QS200) into your computer's CD-ROM drive. Before you update the printer driver, first uninstall the old version of printer driver. - Page 33 1 Getting ready to use ________________________________________________ [Hardware Installation] dialog box appears. Click (1) Click [Search for the best driver in these [Continue Anyway]. locations.]. (2) Click [Include this location in the search], and specify the folder that contains the printer driver files from [Browse].

- Page 34 1 Getting ready to use ________________________________________________ When [Completing the Found New Hardware Wizard] dialog box appears, the installation of printer driver is completed. Click [Finish]. |32|...

-

Page 35: For Windows Vista/7/8/8.1/10

[Add a printer]. This may prevent normal installation, leading to failure of data communications. Insert the CD-ROM for driver installation (RISO Click [Drivers] tab on the [Print Server Properties] GOCCOPRO Printer Driver for/GOCCOPRO dialog box. QS200) into your computer's CD-ROM drive. - Page 36 1 Getting ready to use ________________________________________________ Click [Add]. (1) Check [x86] (32-bit) or [x64] (64-bit) checkbox. (2) Click [Next]. Select [x84] (32-bit) or [x64] (64-bit) to fit your computer system. [Add Printer Driver Wizard] dialog box appears. On [Printer Driver Selection] dialog box, click Click [Next].

- Page 37 1 Getting ready to use ________________________________________________ Click [Browse], and specify the folder that Click [Next]. contains the printer driver. The CD-ROM for driver installation is stored in the On [Completing the Add Printer Driver Wizard] following folder structure. Select a folder that matches the computer (32-/64-bit version) on dialog box, click [Finish].

- Page 38 (1) Connect the USB cable between this machine and the computer. (2) Turn on the power switch of the machine. When [RISO GOCCOPRO QS200] icon appears, the installation of printer driver is completed. *) Note that the installed printer driver may not be recognized for some period of time when Windows Update starts.

-

Page 39: For Mac Os

• If you fail to connect a USB cable as instructed or disconnect it, the printer drive may not be installed normally. Insert the CD-ROM for driver installation (RISO GOCCOPRO Printer Driver for/GOCCOPRO QS200) into your computer's CD-ROM drive. (1) [Select Destination] dialog box appears. - Page 40 1 Getting ready to use ________________________________________________ (1) [Authenticate] dialog box appears. Enter a [Print & Fax] dialog box appears. name and a password. (2) Click [OK]. (1) [Finish Up] dialog box appears, and the message “The software was successfully installed” is displayed on the dialog box. (2) Click [Close].

- Page 41 1 Getting ready to use ________________________________________________ When the machine is recognized and the printer information of GOCCOPRO QS200 is displayed, the installation of printer driver is completed. |39|...

-

Page 42: Registering Screen Frame Size [For Windows Xp/Vista/7/8/8.1/10]

(2) The default setting after the installation of On [Devices and Printers] dialog box, double-click printer driver is “Maximum Size” only. [RISO GOCCOPRO QS200 Driver] icon to open the properties of this printer. |40|... - Page 43 1 Getting ready to use ________________________________________________ To register a new screen frame size, click (1) The registered screen frame size is displayed [Register]. in the pulldown menu. (2) To change the size, click [Edit]. (3) To delete the size, click [Delete]. (1) Enter a name to be registered.

-

Page 44: Registering Image-Making Size [For Mac Os]

1 Getting ready to use ________________________________________________ Registering Image-making Size [For Mac OS] • You must register the page size as the “image-making area”. Not of the screen frame size. • You should correctly understand the relationship of the registered screen frame size, the image-making position, and the size of the image-making. - Page 45 (2) In [Page Size] field, enter a width and a height registered as default. of the image-making size in [Width] and [Height] field. (3) Select “GOCCOPRO QS200” in the pulldown menu of [Printer Margins], and “0.00mm/0.00 in” is displayed in all margins. (4) Click [OK].

-

Page 46: How To Make Image On Screen

How to Make Image on Screen This chapter describes how to make a artwork image from PC to screen. Create artwork data with PC in advance. Setting Screen Frame page 45 ・ ・ Preparing Machine page 46 Transmitting PC Artwork Data from the Computer ・... -

Page 47: Setting Screen Frame

2 How to Make Image on Screen 1) Setting the Screen Frame ________________________________________________ Position the screen frame against the three Hold the screen frame with the screen frame screen frame guides. stopper to prevent displacement of the screen frame. When it is hard to see the screen frame guides, move the Head Mount Unit by hand. -

Page 48: Preparing Machine

2 How to Make Image on Screen 2) Preparing the Machine ________________________________________________ Connect the power cable to the machine. Connect a USB cable to the machine. Turn on the power switch of the machine. |46|... -

Page 49: Transmitting Artwork Data From Pc

[Print] dialog box. An improper size setting may damage the thermal print head by contact with the screen frame. Select “RISO GOCCOPRO QS200 Driver” (name • When the machine receives of this machine) in [Printer Name]. multi-page artwork data, only the... - Page 50 2 How to Make Image on Screen ________________________________________________ (2) [Setting] tab: When the dialog box returns to [Print] dialog box, Set the image-making conditions. click [Print]. The artwork data is transmitted from your computer to the machine. The data that you output in the last job can be reproduced.

-

Page 51: For Mac Os

[Page Setup] dialog box appears. "Details of Printer Driver Settings" page 51 (1) Select “GOCCOPRO QS200” in [Format for]. (2) Select a paper size to fit the set screen frame Click [OK]. in [Paper Size]. - Page 52 2 How to Make Image on Screen ________________________________________________ Click [File] on the menu bar of the application (1) [Setting] screen is displayed Set the image-making conditions. software, and select [Print] from the pulldown menu. Print (2) [Image Setting] screen is displayed Set the image conditions.

-

Page 53: Details Of Printer Driver Settings

• Increase/decrease step: 1 Data save/retrieval is made on the dialog box • Setting range: -16 to +16 showing the properties of “RISO GOCCOPRO • Default: 0 QS200 Driver” (start from [Devices and Printers] dialog box). (2) Adjusting Length... - Page 54 2 How to Make Image on Screen ________________________________________________ (4) Repeat Writing(Image-Making) This is the function of repeatedly transferring the same artwork data onto a screen under the same image-making conditions. This is to increase perforation rate. Select the number of times Image-making is repeated from the pulldown menu.

- Page 55 2 How to Make Image on Screen ________________________________________________ (6) Overlap *) When the amount of overlap is -3 to -1 This is the function of overlapping images in Lane 4 the adjacent lanes when an imaged screen is produced. When the set amount of overlap is a minus Lane 3 Amount of value, this field is blank.

- Page 56 2 How to Make Image on Screen ________________________________________________ *) When “OFF” (Without inverse) is selected X direction 80 mm ⑦ (7) Inverse This is the function of flipping an image horizontally (mirror inversion). The X-direction center of an image is used as an inversion axis.

- Page 57 2 How to Make Image on Screen ________________________________________________ ● [Image Setting] tab (4) Screen angle When [Dot screen: frequency/angle] is selected for [Halftone screening],the angle at which dots are arranged can be set. Adjusted if moire (interference pattern) occurs. • Unit: degree •...

- Page 58 2 How to Make Image on Screen ________________________________________________ (8) Edge enhancement: When [Dot screen: frequency/angle] is selected for [Halftone screening],the check mark can be placed in the check box. edge enhancement is applied to the image to accent contours. (9) Tone smoothing: When [Dot screen: frequency/angle] is selected for [Halftone screening], the tonal expressions used in screen-covered processing are smooth.

- Page 59 2 How to Make Image on Screen ________________________________________________ ● [Option] tab 1) Test print A: QS200 Logo Frame size: W 580 x H 360 mm (Artwork data size: W 420 x H 200 mm) 2) Test print B: Adjustment 580 Frame size: W 580 x H 360 mm (Artwork data size: W 420 x H 200 mm) Test pattern image-making...

-

Page 60: For Mac Os

2 How to Make Image on Screen ________________________________________________ Mac OS The function of the printer driver for Mac The [Setting] screen is displayed OS is implemented in application software. This section explains Adobe® ® ® Acrobat Reader as an example. The operation procedure is about the same in other applications. - Page 61 2 How to Make Image on Screen ________________________________________________ (3) Writing(Image-Making) Speed (5) Line enhancement Select an X-direction wiring speed from the This is the function of enhancing the white pulldown menu. faint characters and lines in black solid area. The length of an image does not change. Select a desired setting in the pulldown menu.

- Page 62 2 How to Make Image on Screen ________________________________________________ (6) Overlap *) When the amount of overlap is -3 to -1 This is the function of overlapping images in the adjacent lanes when an imaged screen is produced. Lane 4 When the set amount of overlap is a minus value, this field is blank.

- Page 63 2 How to Make Image on Screen ________________________________________________ ● Image Setting Click [Copies & Pages] on [Print] dialog box, and select [Image Setting] from the pulldown menu. (7) Inverse This is the function of flipping an image horizontally (mirror inversion). The X-direction center of an image is used as an inversion axis.

- Page 64 2 How to Make Image on Screen ________________________________________________ (3) Screen frequency When [Dot screen: frequency/angle] is selected for [Halftone screening],the fineness of dots can be set in the lines per inch. Indicates how many dots are arranged in one inch / 25.4 mm. •...

- Page 65 2 How to Make Image on Screen ________________________________________________ ● Option ( Test pattern image-making ) [Test print pattern] menu appears. This is the function of making a screen of driver’s test pattern. The images differ from those produced in Test Mode which is one of the Offline Modes of this printer machine.

- Page 66 2 How to Make Image on Screen ________________________________________________ 3) Test print C: Adjustment 475 ● About (Version Frame size: W 475 x H 360 mm (Artwork data size: W 315 x H 200 mm) Click [Copies & Pages] on [Print] dialog box, and select [About] in the pulldown menu.

-

Page 67: Offline Mode

Offline Mode In “Offline Mode,” image remaking, frame height setting,image making start location adjustment are available. Offline Mode Operations page 66 ・ Settings and Setting Ranges in Offline Mode page 67 ・ Offline Mode Hierarchy page 71 ・ |65|... -

Page 68: Offline Mode Operations

3 Offline Mode Offline Mode Operations ________________________________________________ Offline mode is used to reproduce an imaged screen by changing the detailed settings of the artwork data that has been once used for image-making. SETTING ONLINE ENTER (1) When “Ready” is shown in the display of this because the settings of the computer’s machine (in [Ready] status), press <ONLINE>... -

Page 69: Settings And Setting Ranges In Offline Mode

3 Offline Mode Settings and Setting Ranges in Offline Mode ________________________________________________ Initial setting Mode name Item name Explanation Setting range (Factory default) Adjusts the image-making density. Density When the value is larger, the –16 to +16 (Image-making density is higher (hole diameter is (One step: 1) density setting) larger). - Page 70 3 Offline Mode ________________________________________________ Initial Mode setting Item name Explanation Setting range name (Factory default) Y - pos [ L- 1] Adjusts the Lane 1 horizontal -99 to +99 (Y direction start scanning direction position. (-0.7 mm to +0.7 mm) 0 mm position adjustment When the value is larger, it...

-

Page 71: Test Print

3 Offline Mode ________________________________________________ Test Print The image-making size used in Test Print is 200mm in the X direction and 420mm in the Y direction regardless of the size of the set screen frame. Note that if you use a screen frame smaller than that shown in the figure below, it may damage the thermal print head by contact with the screen frame. - Page 72 3 Offline Mode ________________________________________________ ● Test pattern 3 Dot pattern of 25% coverage Test Print which is one of the Offline Modes of this machine allows you to check the performance of image-making without connecting to a computer. The images and sizes differ from those of the test patterns A, B, and C for Test print pattern that can be produced on [Option] tab of the printer driver.

-

Page 73: Offline Mode Hierarchy

3 Offline Mode Offline Mode Hierarchy ________________________________________________ The offline mode has the following hierarchy. Go up/down the menu with [▲][▼] keys and select a setting item with <ENTER> key (Set key) to go to each setting screen. You can go to the upper menu with <ONLINE> key. Density Setting (Image-making density setting) -

Page 74: Cleaning

Cleaning Thermal Print Head Cleaning page 73 ・ ・ Machine Exterior Cleaning page 74 |72|... -

Page 75: Thermal Print Head

4 Cleaning Cleaning ________________________________________________ ● Do not perform operations not specified in this guide such as adjustment and repair. Be sure to ask your dealer for adjustment or repair of this machine. Thermal Print Head When dust adheres to the thermal print head, the screen may not be correctly perforated according to the Artwork data, and graphics or text may be missing or blur. -

Page 76: Machine Exterior Cleaning

4 Cleaning ________________________________________________ Machine Exterior Cleaning In order to protect the machine from dirt, wipe the machine exterior periodically with a soft cloth using mild detergent. The color might run, but this does not affect the performance of the machine. |74|... -

Page 77: Troubleshooting

Troubleshooting Causes and actions when malfunction occurs on the machine are explained in this section. Troubleshooting Tips page 75 ・ |75|... -

Page 78: Troubleshooting Tips

The machine is at the machine and check if the indicator <OFFLINE> state. lights. ・Double click “RISO GOCCOPRO The data transmission on the QS200 Driver” in the [Printer] folder to computer may not be finished. check if the data transmission has (The output operation may not finished. -

Page 79: Actions Using The Printer Driver

Actions using the Printer Driver Status Check item Action The data transmission from ・Double click “RISO GOCCOPRO QS200 the computer may not have Driver” in the [Printer] folder to check if the data finished. transmission have finished. (The output operation may ・Until the data sending from the computer has... -

Page 80: Unexpected Print Result

5 Troubleshooting ________________________________________________ Unexpected print result Status Possible Cause Action Exceeded artwork data from The page image for The artwork data created by the image-making area will be cut off. image-making is not application software exceeds the Check the image-making size and centered or is cropped. -

Page 81: Appendix

Appendix ・ Uninstalling the Printer Driver page 80 Disposing consumables page 86 ・ Specifications page 87 ・ |79|... -

Page 82: Uninstalling The Printer Driver

(administrator, etc.). When the [Printers] dialog box appears, then Windows XP click [Yes]. [RISO GOCCOPRO QS200 Driver] icon is deleted. Be sure to uninstall the printer driver with the machine off or with the USB cable disconnected. - Page 83 When ”RISO GOCCOPRO QS200 Driver” disappears from the list of [Installed printer drivers], the uninstallation of the printer driver is completed. The list of [Installed printer drivers] is displayed. (1) Click on “RISO GOCCOPRO QS200 Driver” in the list. (2) Click [Remove]. |81|...

-

Page 84: For Windows Vista/7/8/8.1/10

Be sure to uninstall the printer driver with the machine off or with the USB cable disconnected. Click [Devices and Printers] in [Control Panel]. [RISO GOCCOPRO QS200 Driver] icon disappears from [Devices and Printers] dialog box. Right-click [RISO GOCCOPRO QS200 Driver] icon, and then click [Remove device] in the pulldown menu. - Page 85 Appendix ________________________________________________ (1) Click an appropriate printer on [Devices and (1) Select “RISO GOCCOPRO QS200 Driver” in Printers] dialog box. the list of [Installed printer drivers]. (2) Click [Print server properties] on the menu (2) Click [Remove]. bar. Click [Drivers] tab on [Print Server Properties] dialog box.

- Page 86 Appendix ________________________________________________ [Print Server Properties] dialog box appears. When ”RISO GOCCOPRO QS200 Driver” Click [Yes]. disappears from the list of [Installed printer drivers] on [Print Server Properties] dialog box, the uninstallation of the printer driver is completed. [Remove Driver Package] dialog box appears.

-

Page 87: For Mac Os

Appendix ________________________________________________ Mac OS When “GOCCOPRO QS200” disappears from the list, the uninstallation of the printer driver is completed. Be sure to uninstall the printer driver with the printer machine off or with the USB cable disconnected. Double-click [Print & Fax] on [System Preferences] dialog box. -

Page 88: Disposing Consumables

● To find the details, contact your dealer (or authorized service representative). ________________________________________________ Screen Master Make sure to use the screen master dedicated to the machine supplied by Riso. Improper use of screen master can result in malfunction or other trouble. Product Name... -

Page 89: Specifications

Appendix Specifications Caractéristiques ________________________________________________ GOCCOPRO_QS200 Image-making High-speed digital image-making method Image-making time Within 2 minutes (A4 size) Min:100 mm (Width) × 100 mm (Length) Image-making size Max:420 mm (Width) × 620 mm (Length) Resolution 600 dpi × 600 dpi (Perforation Density1200dpi) User Interface LED panel TOP side 80 mm or more, END side 80 mm or more... - Page 90 Appendix ________________________________________________ Excluding the screen frame and master. The pollution degree of the usage environment due to dirt and dust in the air. Degree “2” corresponds to a general indoor environment. ● Note Some of the diagrams and descriptions in this User's Guide may differ from your machine due to ・...

-

Page 91: Index

<Error> Lamp ........... 26 Reprint ............. 2,66, 67 Reset ..........47, 49, 66, 68 Front (side) ........... 5, 24 RISO Digital Screen Master QS......86 RISO DIGITAL SCREEN QS MASTER GRAY Grounding Wire ..........11 ……..............86 Halftone screening ........55, 62 Selection Key ............. - Page 92 Index ________________________________________________ Uninstallation ......... 81, 84, 85 USB cable …..18, 25, 29, 37, 76, 77, 80, 82, 85 USB connector ........... 25 Y direction ............4, 5 Y - pos ............68, 71 Version ......30, 31, 33, 35, 37, 51, 64 Weight(s).............

- Page 93 ● Do not make any modifications to the machine or remove any parts. ● Neither Riso nor its dealer is responsible for maintenance service performed by onto-Riso-authorized personnel. ● Contact your dealer immediately if you suspect any dangerous situations or have questions or problems with the machine.

- Page 94 2017/8...

Need help?

Do you have a question about the GOCCOPRO QS200 and is the answer not in the manual?

Questions and answers