Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Parker TQ10X

- Page 1 (217) 352-9330 | Click HERE Find the Parker / Compumotor TQ10X at our website:...

- Page 2 TQ10X Servo Controller / Drive User Guide a ti a ti L IM L IM Compumotor Division Parker Hannifin Corporation p/n 88-015174-02 B June 1999 Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 3 The information in this user guide, including any apparatus, methods, techniques, and concepts described herein, are the proprietary property of Parker Compumotor or its licensors, and may not be copied, disclosed, or used for any purpose not expressly authorized by the owner thereof.

- Page 4 Change – The range has been increased by the addition of a third DIP switch on the bottom of the product. This allows improved current-loop performance with a wider range of motor electrical pole frequencies, including all Parker Neometric 70mm and some of the 92mm motors. If the new switch, SW3-3 is placed in the OFF (up) position, settings are backward-compatible with earlier product.

- Page 5 Change – The illustration on the back cover of this User Guide has been updated to incorporate the changes listed in this change summary. TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 6 93/68/EEC CE Marking Directive The TQ10X Drive, when installed according to the procedures in the main body of this User Guide, may not necessarily comply with the Low Voltage Directive (LVD) of the European Community. To install the TQ10X Drive so that it com- plies with LVD, Appendix B, you must follow the additional procedures described in LVD Installation Instructions.

- Page 7 TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 8: Table Of Contents

Table of Contents Chapter One—Introduction ................1 TQ10X Controller/Drive—Description & Block Diagram .................. 2 Compumotor SM and NeoMetric Series Brushless Servo Motors ............... 3 Chapter Two—Installation ................5 What You Should have (ship kit) ........................... 6 Precautions ................................7 Installation Overview ............................7 Quick Test ................................ - Page 9 Servicing the TQ10 Drive .......................... 123 Do Not Replace Fuses ..........................123 Thermal Safety ............................123 Table of Graphic Symbols and Warnings ......................124 TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 10: Chapter One-Introduction

C H A P T E R O N E Introduction IN THIS CHAPTER • TQ10X Servo Controller/Drive – Description & Block Diagram Introduction Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 11: Tq10X Controller/Drive-Description & Block Diagram

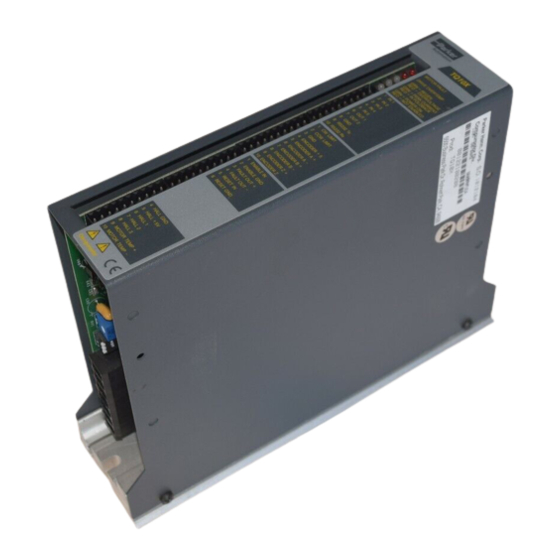

TQ10X Controller/Drive—Description & Block Diagram The TQ10X Servo Controller/Drive is a servo drive designed to run three phase brushless DC servo motors equipped with Hall effect sensors, using trapazoidal commutation. It can also operate brushed DC servo motors. The block diagram for a typical system is shown below. -

Page 12: Compumotor Sm And Neometric Series Brushless Servo Motors

PWM circuit sends shorter pulses, resulting in less motor current. Other Features Dip Switches The TQ10X Drive has 12 DIP switches on the top and three DIP switches on the bottom. You can set these switches to configure the drive for your particular application. - Page 13 TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 14: Chapter Two-Installation

C H A P T E R T W O Installation IN THIS CHAPTER • Product Ship Kit List • Installation Procedure Installation Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 15: What You Should Have (Ship Kit)

External Heatsink/Fan Unit TQ-HS3 Top & Bottom Covers (to enclose drive) TQ-ENCL NOTE: If you ordered a TQ10X-EHS, the External Fan/Heatsink Unit and the Top & Bottom Covers are installed at the factory. SM Motor Information SM with SM with... -

Page 16: Precautions

Precautions The TQ10X Drive has an open-frame style of construction. The top and bottom of the sheet metal enclosure is open, and internal components are exposed. Hazardous voltages are present inside the drive and on many of its terminals. Therefore, observe the following precautions: •... - Page 17 HALL 1 HALL 2 HALL 3 MOTOR TEMP + DIP Switches MOTOR TEMP - Motor Connector Compumotor TQ10X Servo Controller/Drive TQ10X – Component Locations TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 18: Quick Test

TQ10X Drive and motor. 1. Set DIP Switches (Top of Drive) Configure the TQ10X Drive’s DIP switches for your motor and application. Two 6-position DIP switches—Switch 1 (SW1) and Switch 2 (SW2)—are located on top of the drive. The table below summarizes their settings. A three-position DIP switch—Switch 3 (SW3)—is located on the bottom of the drive. - Page 19 Time at Peak Current Set DIP switches SW1-#4 — SW1-#6 to control the length of time the drive can produce peak current, before it goes into current foldback. TQ10X DIP SWITCH SETTINGS SW 1 SW 2 1 2 3 4 5 6...

-

Page 20: Set Dip Switches (Bottom Of Drive)

Foldback Fault Enable If DIP switch SW2–#1 is in the off position, the drive can go in and out of current foldback without causing a fault condition. If DIP switch SW2-#1 is in the on position, then going into foldback will cause a latched fault condition; this setting can aid in troubleshooting your system. -

Page 21: Mount The Drive

The TQ10X has an “open frame” enclosure—sheet metal encloses the front and sides, but the top and bottom are open. A TQ10X-EHS drive has top and bottom covers, and an attached heatsink and fan. You can purchase the heatsink or covers separately, and install them on your drive. - Page 22 45°C (113°F) (for non -EHS version) HUMIDITY Keep the relative humidity below 95%, non-condensing. LIQUIDS Do not allow liquids or fluids to come into contact with the TQ10X Drive or its cables. AIRBORNE CONTAMINANTS Particulate contaminants, especially electrically conductive material such as metal shavings or grinding dust, can damage the TQ10X Drive and motor.

- Page 23 Mounting the Drive to a Heat Sinking Surface Move profiles and loads affect the amount of heat dissipated by the TQ10X Drive. If yours is a low power application with moderate ambient temperature, the drive may not need a large heatsink. The mounting surface may be adequate as a heatsink, provided it has sufficient mass and surface area.

- Page 24 TQ10X-EHS, the heatsink/fan unit was installed at the factory. The next drawing shows minimum spacing and clearance requirements you should follow when you mount TQ10X Drives. Dimensions are shown with and without heatsink/fan units attached to the drive.

- Page 25 Perforated sheet metal covers that enclose the top and bottom of the drive are available from Compumotor (part number TQ-ENCL). The drawing above shows how to attach these optional parts to your TQ10X Drive. Because the covers will reduce convection available for cooling internal compo- nents, drive temperature may increase.

- Page 26 The heatsink/fan unit has a cable with connector attached. Plug the connector into the TQ10X’s fan power connector. Connector provides power for fan Fan Power Connector Mounting Options with Heatsink/Fan Unit If your drive has a TQ-HS3 Heatsink/Fan Unit attached, you have several options for mounting the drive, as the next drawing shows.

-

Page 27: Mount The Motor

Servo motors used with the TQ10X can produce large torques and high accelera- tions. These forces can shear shafts and mounting hardware if the mounting is not adequate. -

Page 28: Connect The Motor To The Drive

In the following installation procedure, we assume you are using a Compumotor SM or NeoMetric Series Motor with your TQ10X Drive. If you are using a non- Compumotor motor, consult the Appendix at the end of this user guide for informa- tion you may need during the following installation steps. - Page 29 If the motor overheats and the thermostat opens, the loss of continuity triggers protection circuitry in the TQ10X. It will turn off power output to the motor, and illuminate the LED labeled MOTOR FAULT This is a latched fault.

- Page 30 Phase B Phase C Motor Ground Motor Connector Connecting Compumotor SM or NeoMetric Series Motors To connect a Compumotor SM or NeoMetric Series servo motor to the TQ10X, follow the color code shown in the next drawing. Shield Black Encoder +5...

- Page 31 OVERVOLTAGE will be illuminated green. The TQ10X also has an overvoltage circuit; it protects the drive from excessive regeneration. If the motor regenerates more energy than the internal resistor can dissipate, voltage on the power bus will rise and trigger an overvoltage fault. The drive will shut down power output to the motor.

- Page 32 For example, in a tensioning applica- tion, two TQ10Xs apply tension (opposite torques) to a single moving load. In this situation, one TQ10X could receive substantial regenerated power from its motor. In such applications, you can connect the power buses for the TQ10Xs in parallel,...

- Page 33 Compumotor. Connecting a Brushed DC Servo Motor You can use the TQ10X as a drive for brushed DC servo motors. To do this, follow these steps: Connect drive terminals...

-

Page 34: Connect Inputs And Outputs

Enable Input To enable the drive, you must connect the enable input to ground. If you break the connection to ground while the drive is on, the TQ10X’s fault circuitry will acti- vate, with the following results: •... - Page 35 Latched means you must cycle power before the drive will operate again. You can use the TQ10X’s fault output as a signal to a PLC or other equipment that a fault has occurred. The following drawing shows several ways to connect exter- nal devices to the TQ10X’s fault output.

- Page 36 The reset input is internally pulled up to +5V. If your equipment requires, you can connect the input to an external voltage as high as +24V. You can also connect it to a dry contact closure to ground. TQ10X Internal Connections Normally Open Reset Switch 2.49KΩ...

- Page 37 If you do not connect an encoder Z-channel output to the TQ10X, then you must ground the Z+ input on the TQ10X. To do this, connect a jumper wire between the Z+ input and the nearest available ground terminal (labeled GND).

- Page 38 Ø = low, pulled to ground 1 = high, 5VDC STOP or KILL INPUT – The TQ10X can dedicate up to one Stop and one Kill input. The active state is high. The Stop or Kill input is identical in function to the effect of the S or K command respectively.

- Page 39 ). When you power up the TQ10X, these inputs are enabled (high). To test the TQ10X without connecting the CCW and CW limits, you must disable the limits with the LD3 command. You can use the Limit Switch Status Report (RA) and Input Status (IS) commands to monitor the limits’...

-

Page 40: Connect Ac Power

The TQ10X does not have an on/off switch. When you plug the power cord into the drive, the system will turn on. Therefore, before you apply power to the TQ10X, verify the following: •... -

Page 41: Test Your System

TQ10X, and that the drive is functioning properly. If the test was unsuccessful, observe the LEDs on the front panel of the TQ10X while you try the test procedure—they may indicate the cause of the problem. - Page 42 Misalignment & Couplers Align the motor shaft and load as accurately as possible. In most applications, some misalignment is unavoidable, due to tolerance variations in components. However, excessive misalignment may degrade your system’s performance. The three misalignment conditions, which can exist in any combination, are illustrated and described in the next drawing.

-

Page 43: What's Next

What’s Next This completes the system installation procedure. Proceed to Chapter 4 ,Tuning for instructions about tuning the TQ10X Drive. TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 44: Chapter Three-Specifications

C H A P T E R T H R E E Specifications IN THIS CHAPTER • Drive Specifications • SM and NeoMetric Motor Specifications • SM and NeoMetric Motor Speed/Torque Curves • SM and NeoMetric Motor Dimensions • SM and NeoMetric Encoder Specifications •... -

Page 45: Specifications - Tq10X Servo Controller/Drive

Specifications – TQ10X Servo Controller/Drive Parameter Value Power Input Voltage 95-132 VAC single phase Frequency 50/60 Hz Power Output—Motor Peak Current 10 A (approx 2 sec max duration at 45°C ambient temperature) Continuous Current 5 A with TQ-HS3 or mounted to heatsink at or below 45°C... -

Page 46: Motor Specifications - Compumotor Sm Series Servo Motors

Motor Specifications – Compumotor SM Series Servo Motors Symbol Units SM161A SM162A SM231A SM232A SM232B SM233A SM233B Continuous Stall Torque oz-in 0.17 0.31 0.32 0.65 0.65 0.99 0.99 Continuous Stall Current amps-rms ω Rated Speed 7,500 7,500 7,500 4,500 7,500 2,800 7,500 Peak Torque... -

Page 47: Motor Specifications - Compumotor Neometric Series Servo Motors (70Mm)

+/- 30% line-to-line, inductance bridge measurement @ 1KHz. Peak current for 2 seconds maximum with initial winding temperature of 40°C. All specifications are subject to engineering change. TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 48: Motor Specifications - Compumotor Neometric Series Servo Motors (92Mm)

Motor Specifications – Compumotor NeoMetric Series Servo Motors (92mm) Parameter Symbol Units N0921F N0921G N0922G Stall Torque Continuous lb-in 1.81 1.81 3.50 Stall Current Continuous amps-rms 4.16 5.76 6.17 ω Rated Speed 2500 3575 1975 41.7 59.6 32.9 Peak Torque lb-in 5.42 5.42... -

Page 49: Speed/Torque Curves

5000 6000 7000 8000 (8.5) (17) (25) (33) (41) (50) (58) (67) (rps) (17) (33) (50) (67) (83) (100) (117) (133) (rps) Speed Speed TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 50 Speed/Torque Curves NOTE: Curves are based on 120VAC line, nominal motor K and K . Actual values may vary ±10%. Line voltage directly limits maximum speed. TQ10X with lb-in N0701D, N0341D (N-m) (2.24) (1.68) (1.12) (.560) 1000 2000 3000 4000 5000 6000 7000 8000...

-

Page 51: Motor Dimensions - Compumotor Sm Series, Size 16

10 ft. Cable 4.98 (126.49) 232 Motor 3.98 (101.09) 231 Motor Longer lengths available Consult Compumotor for information (None) (Flat) (Sq Key) (1.25 (31.75) Lg.) TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 52: Motor Dimensions - Compumotor Neometric Series, Size 70

Motor Dimensions – Compumotor NeoMetric Series, Size 70 Brake Option -B MS Connectors Cable Flying Leads Shaft Options -MS, -TQ -10, -25 0.197 Ø0.43 (11) 0.409 (10.4) - N (None) - F (Flat) 0.500 Feedback Conn 2.05 Motor Conn (12.7) MS 14 - 18 0.158 (52.1) -

Page 53: Motor Dimensions - Compumotor Neometric Series, Size 92

Input Power 5VDC ± 5% @ 135 mA Operating Frequency 100 kHz maximum (pre-quadrature) Output Device 26LS31 Sink/Source, nominal 20 mA Suggested User Interface 26LS32 TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 54: Motor Part Numbering System-Compumotor Neometric Series Servo Motor

16 motors cable is hardwired to motor size 23 with MS or TQ connectors–IP65 MS recommended for TQ10X; TQ can be used also. Example: SM-231AE-NMSN = 23 Frame, 1" magnet, A winding, 1,000 line Encoder, Normal shaft, MS cable, No options Motor Part Numbering System—... - Page 55 TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 56: Chapter Four-Tuning

C H A P T E R F O U R Tuning IN THIS CHAPTER • PID Tuning – Description • TQ10X Tuning Procedure • Configuring an In Position Window Tuning Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 57: Tuning And Performance

All tuning is performed via RS232-C communications. PID Tuning The TQ10X generates a move profile based upon the user supplied acceleration, velocity, and distance commands (A, V, and D). At each servo sampling period (every 266 microseconds), the TQ10X calculates the position the motor should reach as it follows the move profile. -

Page 58: Cpg - Proportional Gain

load new parameters by using buffered versions of the five tuning commands (BCPG, BCDG, BCTG, BCIG, BCIL). WARNING During servo tuning, the system can undergo accidental and violent movement due to improper gain settings and programming errors. Please use extreme caution while prototyping. -

Page 59: Tuning The System

6.0 amps for N0701D and N0702E motors • 8.9 amps for N0702F motor This helps protect SM and NeoMetric motors from overheating when you begin tuning the drive. TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 60: Avoid Instability

Prepare to Disable the Drive Quickly: Wire a normally closed switch between the input and ground. Use this switch to quickly and reliably disable the ENABLE IN drive if the system becomes unstable during tuning. Avoid Instability After you change current settings, adjust a tuning parameter, or command a move, closely monitor the motor. - Page 61 CIG to the lowest value that will correct following errors and static position errors, but not increase overshoot or settling time. In a system without static torque loading, a CIG of zero may be appropriate. TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 62: Configuring An In Position Window

Configuring an In Position Window You can define an In Position Window, and use it to indicate that the preceding move is done. Two commands—CEW and CIT—determine the height and width of the window. A third command—SSC—can turn on output #1 when the In Position criteria are met. - Page 63 TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 64: Chapter Five-Software Commands

C H A P T E R F I V E Software Commands IN THIS CHAPTER • Descriptions of each command for the TQ10X Controller/ Drive • Descriptions of the function, range, default, and sample use of each command for the TQ10X Controller/Drive. - Page 65 The second attribute explains how you can save the command. • Savable in Sequence • Never Saved • Automatically Saved TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 66 Savable in Sequence commands are saved when they are defined in a sequence (see XT command). Savable in Sequence commands can be stored in system memory (nonvolatile) and retained when power is removed from the system. A command that is Never Saved is executed without being saved into the system’s permanent memory .

- Page 67 This gain will improve overall accuracy but may increase settling time and, if excessive, may cause a low frequency oscillation around the commanded position. TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 68 This buffered command defines the maximum allowable position or following error. If the actual position error ever exceeds the allowable position error, the TQ10X will generate a fault condition and shut down power output to the motor. If the maximum allowable position error is set to Ø, the function is disabled and no amount of position error will...

- Page 69 Otherwise, commands may be lost. Each character (including delimiters) uses one byte. The range for the response is 0 - 512 bytes. Command Response *122 (122 bytes available in the buffer) TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 70 C—Continue Command Type: Motion Valid Software Version: A Syntax: <a>C Units: N/A Range: N/A Default Value: N/A Attributes: Immediate, See Also: PS, U Never Saved The Continue (C) command ends a pause state. It enables your controller to continue executing buffered commands. After you enter a Pause (PS) or the Pause and Wait for Continue (U) command, you can clear it with a Continue (C) command.

- Page 71 Command Description CIL40 Set the integral limit term to 40 CIG10 Set the integral gain term to 10 1CIG Reports integral gain term (*CIG10) TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 72 This command defines the maximum allowable position or following error. If the actual position error ever exceeds the allowable position error, the TQ10X will generate a fault condition and shut down power output to the motor. If the maximum allowable position error is set to Ø, the function is disabled and no amount of position error will generate the...

- Page 73 In general, a longer derivative sampling period gives a more constant derivative term and improves stability. Many systems require a low CTG value to prevent oscillations, TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 74 however. Therefore, start with a low value and increase it incrementally. Refer to Chapter —Tuning for more information. Command Description CTG0 Set the derivative sampling period to 266 µsec CTG1 Set the derivative sampling period to 532 µsec CTG2 Set the derivative sampling period to 798 µsec CTG3 Set the derivative sampling period to 1064 µsec 1CTG...

- Page 75 Never Saved The Enable Communications (E) command allows the controller to accept commands over the serial communications interface. You can re-enable the communications interface with TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 76 this command if you had previously disabled the RS-232C interface with the Disable Communications Interface (F) command. If several units are using the same communications interface, the E and F commands can help streamline programming. Command Description Disables all units (axes) on the communications interface Enables serial interface on Device 1 Enables serial interface on Device 4 A1Ø...

- Page 77 The final approach to home switch is always form the CW direction. OSC—Define active state of home allows the use of a normally closed or normally open limit switch. TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 78 OSD—Enable Z Channel for home uses the Z channel of the encoder, in conjunction with a home switch, to determine the final home position. The Z channel is a more accurate home position than the edge of a switch. OSH—Reference edge of home switch allows either edge of the home switch to be used as the final edge position.

- Page 79 (dumps the sequence or command buffer if configured by SSHØ). Same as Stop (S) command. Active state (stop initiated) is high. Up to one input can be configured as a stop input. Function E—Home Input TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 80 Defines the motor home or origin position as executed by the GH command and configures with the Homing Function (OS) commands. OSC determines the active state of the input. Up to one input can be configured as a home input. Function F—Go Input Accelerates the motor to a velocity and distance specified in the Acceleration (A), Velocity (V), and Distance (D) commands.

- Page 81 D1ØØØØ Sets distance to 10,000 encoder counts Executes the move (Go) End of loop The commands in the loop will be executed 5 times. TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 82 LD—Limit Disable Command Type: Set-Up Valid Software Version: A Syntax: <a>LDn Units: See Below Range: n = 0 - 3 Default Value: Ø Attributes: Buffered See Also: RA Savable in Sequence The Limit Disable (LD) command allows you to enable/disable the end-of-travel limit switch protection.

- Page 83 Set velocity to 5 revs/sec D1ØØØ Set distance to 1,000 encoder counts Executes the move (Go) Motor turns 1,000 encoder counts CW after the G command is issued. TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 84 MPA—Mode Position Absolute Command Type: Set-Up Valid Software Version: A Syntax: <a>MPA Units: N/A Range: N/A Default Status: Inactive Attributes: Buffered See Also: D, MN, MPI, PZ Savable in Sequence This command sets the positioning mode to absolute. In this mode all move distances are referenced to absolute zero.

- Page 85 This command is functionally identical to the ST0 command. For details on the enable output see Chapter Installation. Command Description Energize the drive *00000000 (fault bit inactive) TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 86 O—Output Command Type: Programming Valid Software Version: A Syntax: <a>Onn Units: on, off, or unchanged Range: Ø, 1 or X (See Below) Default Value: ØØ Attributes: Buffered See Also: OS, S, TR Savable in Sequence The Output (O) command turns the programmable output bits on and off. This is used for signaling remote controllers, turning on LEDs, or sounding whistles.

- Page 87 Sets active state of home input closed (low) OSH1 Selects the CCW side of the home signal as the edge on which the final approach will stop TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 88 OSC—Define Active State of Home Switch Command Type: Set-Up Valid Software Version: A Syntax: <a>OSCn Units: NA Range: n = Ø, 1 Default Value: Ø Attributes: Buffered, See Also: GH, OSB, OSD, OSH Savable in Sequence OSCØ: Active state of home input is n = Ø (closed) OSC1: Active state of home input is n=1 (open) OSCØ...

- Page 89 PR equals the value of PX. Command Description Commanded position report. (*+ØØØØØØ2ØØØ) Encoder position report (*+ØØØØØØ2ØØ5) The actual motor position is 5 encoder counts from the commanded position. TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 90 PS—Pause Command Type: Programming Valid Software Version: A Syntax: <a>PS Units: N/A Range: N/A Default Value: N/A Attributes: Buffered, See Also: C, U Savable in Sequence This command pauses execution of a command string or sequence until the controller receives a Continue (C) command. PS lets you enter a complete command string before running other commands.

- Page 91 Set distance to 2,000 encoder counts Executes the move (Go) “MOVE_DONE Transmits message Continue move After the move, the TQ10X will send the message MOVE_DONE via the RS-232C port TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 92 See Also: Q1, RM Never Saved The QØ command exits the Velocity Profiling mode. The motor will stop when QØ is issued. Entering this command will cause the TQ10X to enter Normal mode (MN). Q1—Enter Velocity Profiling Mode Command Type: Set-Up Valid Software Version: A Syntax: <a>Q1...

- Page 93 (CR or LF) command or a programmable output to indicate move completion. Command Response *R (Controller ready to accept a command, and no error conditions exist.) TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 94 RA—Limit Switch Status Request Command Type: Status Valid Software Version: A Syntax: aRA Units: N/A Range: N/A Default Value: N/A Attributes: Immediate, See Also: R, RB Never Saved Response to aRA is *x The RA command responds with the status of the end-of-travel limits during the last move as well as the present condition.

- Page 95 See Also: R, RA, RB, FS, GH The RC command has the same response format of RA and RB. The condition for which status is indicated is: TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 96 Homing Function Failure: In this condition, the controller has encountered both End-of-Travel limits or one of several possible Stop commands or conditions. Go Home motion was concluded, but not at Home. Response Character Go Home Successful? Command Description *B Go home was unsuccessful. RFS—Return Servo Gains to Factory Settings Command Type: Status Valid Software Version: A...

- Page 97 A limit switch closure will stop movement in Velocity Profiling mode, but does not cause the TQ10X to exit Velocity Streaming mode. To recover from a limit stop in RM mode, QØ must be issued and the direction must be changed. Velocity Profiling mode is uni-directional.

- Page 98 The revision level identifies when the software was written. You may want to record this information in your own records for future use. This type of information is useful when you consult Parker Compumotor’s Applications Department.

- Page 99 This command allows you to select the best possible trade-off between noise immunity and speed for a given application. If you make your scan time too short, the TQ10X may respond to an electrical glitch. If you issue the Scan command with only a device address (1SN), the controller will respond with the current debounce time (*SNn).

- Page 100 commands. Status commands do not echo the command sent, but transmit the requested status report. Command Description SSA1 Turns echo off (Characters sent to the controller are not echoed back to the host.) SSC—Output #1 on In Position Command Type: Set-up Valid Software Version: A Syntax: aSSCn Units: N/A...

- Page 101 This command is functionally identical to the ON command. For details on the enable output see Chapter Installation. Command Description Disable the drive Enable the drive TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 102 T—Time Delay Command Type: Programming Valid Software Version: A Syntax: <a>Tn Units: seconds Range: n = 0.01 - 99999.99 Default Value: None Attributes: Buffered, Savable in Sequence The Time (T) command causes the controller to wait the number of seconds that you specify before it executes the next command in the buffer.

- Page 103 In Mode Continuous (MC), when a Go (G) command is issued the controller moves to the next command in the buffer. TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 104 DC power, or issue a Z (Reset) command. If the value specified for the V command is not valid, the TQ10X ignores that value and defaults to the value specified in the last V command. If V is issued with only a device address (1V), the controller will respond with the current velocity value (*Vn).

- Page 105 = 8: Sequence select inputs are read (single run) on power-up n = 9: Sequence select inputs are read (continuous run) on power-up In XP9 mode, you can use the XQ1 command to stop the TQ10X from selecting the next sequence until all the sequence select inputs are first opened.

- Page 106 This command can be used only when the TQ10X is stand-alone power-up sequencing in XP9 mode. In XP9 mode, if XQ1 is executed, the TQ10X will not accept a sequence select input until all sequence select inputs are OFF (closed). After all lines have simultaneously been brought to a low state (OFF), the controller will then read the sequence select lines and execute the sequence whose number appears there.

- Page 107 = 2: Out of memory. The sequence buffer is full. XSD verifies that the last sequence definition was successful. Command Response 1XSD *1 (A sequence already exists as sequence 1) TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 108 XSP—Sequence Status Power-up Command Type: Status Valid Software Version: A Syntax: aXSP Units: N/A Range: N/A Default Value: N/A Attributes: Immediate, See Also: XP, XQ, XSR Never Saved Response to aXSP is *n The Sequence Status Power-up (XSP) determines which, if any, sequence will be executed on power-up.

- Page 109 BBRAM automatically by issuing this command. NOTE: In your communication program, use sufficient time delays after downloading a sequence before you send more commands to the TQ10X. In particular, after sending the XT command, wait at least 12.5 msec before sending a Z command.

- Page 110 This command sets the individual unit address for each TQ10X, allowing addresses up to 255. Upon receipt of the command, the TQ10X will assign itself the address in the command and will pass on the daisy chain the address plus one, thus enabling automatic addressing of all units on the daisy chain.

- Page 111 *0*0*0*1***** (First 5 Units report no error, 6th unit detected an overrun error, and the last 3 units turned communication off because of unit 6) TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 112: Summary Of Commands

Summary of Commands A—Acceleration OSD—Enable Encoder Z Channel for Home B—Buffer Status OSH—Reference Edge of Home Switch BCDG—Buffered Configure Derivative PR—Position Report Gain PS—Pause BCIG—Buffered Configure Integral Gain PX—Report Absolute Encoder Position BCIL—Buffered Configure Integral Limit PZ—Set Absolute Counter to Zero BCPE—Buffered Configure Position “—Quote Error... - Page 113 TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 114: Chapter Six-Troubleshooting

C H A P T E R S I X Troubleshooting IN THIS CHAPTER • Diagnostic LEDs • RS-232C Problems • Software Debugging Tips • Encoder Problems • Homing Diagrams • Non-Drive Related Problems • Protective Circuits • Product Return Procedure Troubleshooting Artisan Technology Group - Quality Instrumentation ... -

Page 115: Troubleshooting Basics

If the problem persists, contact your local technical support resource. Diagnostic LEDs The TQ10X Drive has five LEDs on its front panel. The following summary of LED functions may help you isolate problems. LED Name... -

Page 116: Rs-232C Problems

Use the following procedure to troubleshoot communication problems that you may have with the TQ10X. Be sure the host computer’s transmit (Tx) wire is wired to the TQ10X’s receive (Rx) connection, and the host computer’s receive (Rx) wire is wired to the TQ10X’s transmit (Tx) connection. -

Page 117: Encoder Problems

5. Rotate counterclockwise one revolution. 6. Enter PX command. It should read approximately 0. If your TQ10X did not respond with similar values, it is not receiving encoder information. Either the encoder is mis-wired or in need of repair. Homing Diagrams The following diagrams are examples of the many possible homing set-ups. - Page 118 OSB1 OSD1 GH-1 GH+1 OSHØ GH-1 OSB1 OSD1 GH+1 GH-1 OSH1 GH+1 OSB1 OSDØ GH+1 GH-1 OSHØ GH-1 GH+1 OSB1 OSDØ GH+1 GH-1 OSH1 GH+1 GH-1 Troubleshooting Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

-

Page 119: Troubleshooting Table

No LEDs are illuminated red • The fault output is LOW These conditions indicate that the TQ10X is probably not the source of the prob- lem. The next table summarizes other possible sources of problems. TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 120 TROUBLESHOOTING TABLE Possible Source SOLUTION of Problem Check for motor problems. Check motor coils for continuity, MOTOR shorts, proper resistance. Check Hall and Phase wiring. MECHANICAL Check for jams, binds, increased friction, etc. SYSTEM Uncouple motor from load to test motor separately. Check motor wiring: phases, Hall effects.

-

Page 121: Protective Circuits

This is a latched fault. Cycle power to resume operations. Undervoltage The TQ10X Drive monitors the voltage on its AC power input terminals. If the voltage falls below 80VAC, the drive will shut down and activate its fault output. When you apply power to the drive, the power-up event is indistinguishable from an undervoltage;... -

Page 122: Foldback

If it persists indefinitely, it may damage the motor’s windings. To help protect the motor from overheating, the TQ10X has a current foldback circuit. If high motor current persists for too long, the circuit can reduce the current to a lower level that decreases the rate of motor heating;... - Page 123 The default settings cause the timer to start when the current is approximately twice the motor’s continuous rating (2 times Ics). The thermal switches in Parker servo motors will protect a properly mounted motor in its specified ambient temperature, up to at least twice Ics, at which point foldback takes over.

-

Page 124: Hall Miswiring

LED is still illuminated, then one or more MOTOR FAULT Hall sensors in the motor may be damaged. Motor Overtemperature Protection The TQ10X Drive has a circuit that can protect the motor against overheating. Through its terminals, the drive checks for MOTOR TEMP+ MOTOR TEMP–... -

Page 125: Product Return Procedure

Product Return Procedure If you must return your TQ10X Drive for repairs, use the following steps: Get the serial number and the model number of the defective unit, and a purchase order number to cover repair costs in the event the unit is determined to be out of warranty. -

Page 126: Appendix A-Using Non-Compumotor Motors

Α A P P E N D I X Using Non-Compumotor Motors IN THIS APPENDIX • Configuring DIP Switches • Connecting Motor Phase Wires and Hall Effect Wires Appendix A Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 127 Configuring the TQ10X Drive’s Dip Switches Set the TQ10X’s 12 DIP switches located on top of the drive, and 2 DIP switches located on the bottom of the drive. The following drawing shows DIP switch settings for selected motors.

- Page 128 Hall wires to the TQ10X. Improper Wiring Can Result in Poor Performance Assume that you arbitrarily connect your motor’s three Hall wires to the TQ10X’s Hall inputs. For any particular Hall wiring pattern, there are six different ways you can connect wires to Phase A, Phase B, and Phase C.

- Page 129 Motor shaft rotation may be opposite than you expect. Do not connect a load to the shaft until you first determine the direction of shaft rotation. You can use a trial and error method to connect your motor to the TQ10X. Follow these steps: Arbitrarily assign numbers to your motor’s three Hall output wires, and connect them...

-

Page 130: Appendix B-Lvd Installation Instructions

A P P E N D I X Installation Instructions IN THIS APPENDIX • LVD Installation Instructions Appendix B Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... -

Page 131: Lvd Installation Instructions

You must reliably earth the TQ10X Drive’s protective earth connection. Attach or remove the TQ10X Drive’s power plug only while input power is OFF. Using an Isolation Transformer The TQ10X Drive’s mains voltage is limited to 120 VAC nominal. If your mains voltage is higher, use an isolation transformer located between the power mains and the TQ10X Drive. -

Page 132: Mechanical

Only skilled or trained personnel should change firmware. Do Not Replace Fuses The TQ10X Drive has no fuses designed to be replaced by the user. Fuse failure indicates that other components have also failed. Fuses and other components should only be replaced by Compumotor or its designated repair facilities. -

Page 133: Table Of Graphic Symbols And Warnings

Symbol Description Earth Terminal Protective Conductor Terminal Frame or ChassisTerminal Equipotentiality Caution, Risk of Electric Shock Caution, Refer to Accompanying Text Hot Surface TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com... - Page 134 Ι Index Symbols “—Quote 82 Cable Daisy chain 101 # 30, 101 power 31 Daisy chaining 30 ^H—Delete 69 Carriage return 64 Debugging 105 800-358-9070 Compumotor applica- CCW limit 30 Default setting 57, 87 tion support 115 CE iii, 121 Derivative gain 49, 58, 61 CE Marking Directive iii Derivative sampling period 49, 60,...

- Page 135 Home input 28, 70 Outputs 29, 77 Home limit 69, 70, 79, 80 Overtemperature Homing function set-ups 77, 108 drive 112 Humidity 13 motor 115 Overvoltage 112 TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 136 Return servo gains to factory settings Torque/Speed Curves 40, 41 Position error 53, 59, 63, 66 TQ-Regen-Kit 23 Position report 80 Revision level 89 TQ10X Controller/Drive—Descrip- Position reset 82 RMA 116 tion & Block Diagra 2 Power Bus 23 RS-232C 30, 90...

- Page 137 TQ10X User Guide Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com...

- Page 138 SW 2 SW 3 SW 1 SM231A N0703F TQ10X Status LEDs see page 104 1 2 3 4 5 6 1 2 3 4 5 6 1 2 3 1 2 3 4 5 6 1 2 3 4 5 6...

Need help?

Do you have a question about the TQ10X and is the answer not in the manual?

Questions and answers