Table of Contents

Advertisement

Quick Links

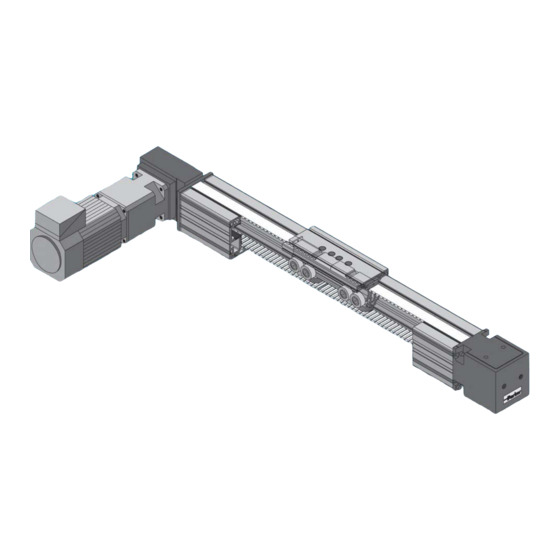

HPLA

HPLA Linear actuator - User Guide

PLEASE NOTE THIS IS FOR MAINTENANCE REFERENCE ONLY.

PART#'S NOMENCLATURE IS HAUSER GERMANY OFFERING.

PLEASE REFER TO WWW.PARKERMOTION.COM FOR USA

PART# NOMENCLATURE

Mounting, start-up, maintenance, repair

PLEASE NOTE THIS IS FOR MAINTENANCE REFERENCEONLY.

PART#'S NOMENCLATURE IS HAUSER GERMANY OFFERING.

PLEASE REFER TO

W e a u t o m a t e m o t i o n

The right to make technical changes is reserved. Data correspond to the technical-state at the time of going to press July/2003

WWW.PARKERMOTION.COM

FOR USA PART# NOMENCLATURE

Parker Hannifin GmbH

EMD HAUSER

DIN EN ISO 9001

Postfach: 77607-1720

Robert-Bosch-Str. 22

D-77656 Offenburg

Tel.: +49 (0)781 509-0

Fax: +49 (0)781 509-176

Reg. Nr. 36 38

http://www.parker-emd.com

P/N102-0004 REV2

No: 192-580050N5

Advertisement

Table of Contents

Need help?

Do you have a question about the HAUSER HPLA Series and is the answer not in the manual?

Questions and answers