Lenze m850 Series Project Planning

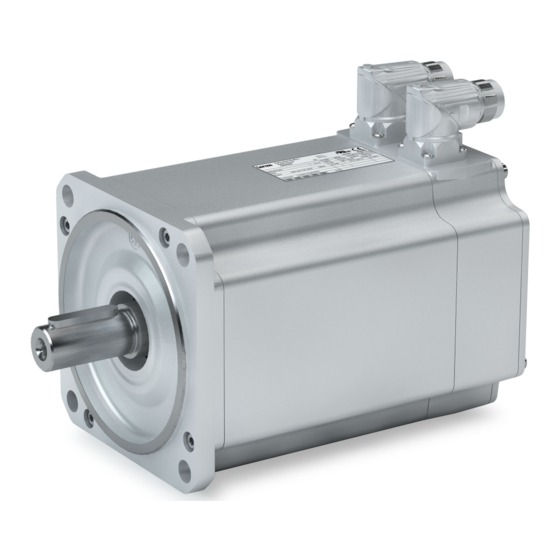

Synchronous servo motor

Hide thumbs

Also See for m850 Series:

- Planning manual (60 pages) ,

- Mounting and switch-on instructions (60 pages) ,

- Manual (160 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Lenze m850 Series

- Page 1 Project planning EN Servo motors m850 synchronous servo motor...

-

Page 3: Table Of Contents

Contents Contents About this document Document description Further documents Notations and conventions Product information Product description Identification of the products Features The modular system Information on project planning Safety instructions Basic safety instructions Application as directed Foreseeable misuse Residual hazards Drive dimensioning Final configuration Surface and corrosion protection... - Page 4 Contents Product extensions Motor connection Connection via ICN connector Brakes Spring-applied brakes Feedback Resolver Absolute value encoder Temperature monitoring Thermal detectors PT1000 Product codes Environmental notes and recycling Appendix Good to know Approvals and directives Operating modes of the motor Enclosures...

-

Page 5: About This Document

The documentation must always be complete and in a perfectly readable state. • Further documents Information and tools with regard to the Lenze products can be found on the Internet: www.Lenze.com à Downloads... -

Page 6: Notations And Conventions

About this document Notations and conventions Notations and conventions Conventions are used in this document to distinguish between different types of information. Numeric notation Decimal separator Point Generally shown as a decimal point. Example: 1 234.56 Warnings UL Warnings Are used in English and French. UR warnings Text Engineering Tools... -

Page 7: Product Information

Product information Product description Product information Product description The m850 servo motor for a medium dynamic performance in compact design. The compact synchronous servo motor for applications in the fields of positioning, robotics, and packaging technology as well as for handling systems. In connection with the i700 and i950 servo inverters, 9400 servo drives, and 8400 TopLine inverter drives, high-performance drive solutions in the torque range from 4.8 to 200 Nm can be obtained. -

Page 8: Features

Product information Features Features Motor connection Output flange Cooling Output shaft Feedback Spring-applied brake Temperature monitoring... -

Page 9: The Modular System

Product information The modular system The modular system Values printed in bold are standard designs. Values that are not printed in bold are potential extensions, some of them including a surcharge. Motor m850-S120/S3960 m850-S120/M3960 m850-S120/L3960 Technical data Rated power Rated torque Max. - Page 10 Product information The modular system Motor m850-S140/S3240 m850-S140/M3240 m850-S140/L3240 Technical data Rated power Rated torque 14.0 17.4 Max. torque 26.0 53.5 80.0 Rated speed 3240 3240 3240 Colour Unpainted Surface and corrosion protection Without Different types of OKS Output shaft Solid shaft without keyway 24 x 50 Solid shaft with featherkey...

-

Page 11: Information On Project Planning

Information on project planning Safety instructions Information on project planning Safety instructions Disregarding the following basic safety measures and safety information may lead to severe personal injury and damage to property! Observe all specifications of the corresponding documentation supplied. This is the precondition for safe and trouble-free operation and for obtaining the product features specified. -

Page 12: Basic Safety Instructions

The procedural notes and circuit details described are only proposals. It is up to the user to check whether they can be adapted to the particular applications. Lenze does not take any responsibility for the suitability of the procedures and circuit proposals described. -

Page 13: Application As Directed

Information on project planning Safety instructions Application as directed Application as directed NOTICE Please observe the notes in the following chapters! ▶ Safety instructions ^ 11 ▶ Information on mechanical installation ^ 22 ▶ Information on electrical installation ^ 23 The product must only be actuated under the operating conditions and power limits •... -

Page 14: Residual Hazards

Information on project planning Safety instructions Residual hazards Residual hazards Even if notes given are taken into consideration and protective measures are implemented, the occurrence of residual risks cannot be fully prevented. The user must take the residual hazards mentioned into consideration in the risk assessment for his/her machine/system. - Page 15 Information on project planning Safety instructions Residual hazards Motor protection Version with plug: • Never disconnect the plug when energized. The plug could be destroyed. Switch off the voltage supply or disable the inverter prior to disconnecting the plug. Installed thermal detectors are no full protection for the machine. •...

-

Page 16: Drive Dimensioning

With the «Drive Solution Designer«, you can design the drive both quickly and to a high quality. The software contains profound and proven expertise with regard to drive applications and mechatronic drive components. Please get in touch with your Lenze representative. The dimensioning is suitable for: kinematic profiles •... - Page 17 Information on project planning Drive dimensioning Operation chart S1 operation S2,S3 and S6 operation Speed profiles Check operating conditions Define required input variables Determine correction factor Operating modes and operating time Operating modes and operating time Ambient temperature and installation height Ambient temperature and installation height Ambient temperature and installation height Determine motor on the basis of the forces acting...

- Page 18 Information on project planning Drive dimensioning Determine correction factor Operating modes S1, S2, S3, S6, and operating time Operating mode S1 Operating mode S2 Operating mode S3 Operating mode S6 1.4 - 1.5 1.4 - 1.5 1.5 - 1.6 1.15 - 1.2 1.3 - 1.4 1.4 - 1.5 1.07 - 1.1...

- Page 19 Information on project planning Drive dimensioning Operating modes S2, S3, and S6 Check and select servo motor/inverter combination Check Selection Unit Output torque ≥ M / ( k rated rated Output speed (recommendation) ≥ n rated rated Max. output torque. ≥...

- Page 20 Information on project planning Drive dimensioning Check and select servo motor/inverter combination Check Preselection Unit > M Output torque rated rated ≥ n Output speed rated rated Load-matching factor Requirement k = 0.5 ... 10 for an optimum dynamic performance/ / (J control properties Optimum k...

-

Page 21: Final Configuration

Information on project planning Final configuration Surface and corrosion protection Final configuration Check Connection dimensions Output shaft Output flange Product extensions Brake Feedback More information about the final configuration: 4The modular system 4Product extensions ^ 45 Surface and corrosion protection Depending on the ambient conditions, the surface and corrosion protection system (called OKS) offers tailor-made solutions for optimum protection. -

Page 22: Information On Mechanical Installation

Ambient media − especially chemically aggressive ones − may damage shaft sealing rings, • lacquers and plastics. Lenze offers special surface and corrosion protection in this case. • NOTICE Bearing damage caused by unbalance! Shafts with keyway are balanced with a half featherkey! ▶... -

Page 23: Information On Electrical Installation

The manufacturer of the system or machine is responsible for adherence to the limits • required in connection with EMC legislation. Preparation The notes for the electrical connection can be found in the enclosed mounting instructions. EMC-compliant wiring The EMC-compliant wiring is described in detail in the documentation of the Lenze inverters. -

Page 24: Technical Data

NOTICE In case of other operating conditions, the achievable values can differ for those mentioned. ▶ In case of extreme operating conditions, please get in touch with your Lenze representative. Cooling effect of mounting flange Mounting on a thermally conducting / insulating plate or machine chassis has an influence on heating up the motor, particularly when using naturally ventilated motors. -

Page 25: Standards And Operating Conditions

Eurasian conformity: electromagnetic compatibility of technical means Approval cULus UL 1004-1 for USA and Canada (requirements of the CSA 22.2 No.100) UL 1004-6 Servo motor, Lenze file no. E210321 Protection of persons and device protection Enclosure IP54 EN 60034-5 Self-ventilated IP65... -

Page 26: Radial Forces And Axial Forces

Technical data Radial forces and axial forces Radial forces and axial forces The values of the bearing service life L refer to the rated motor speed specified. Depending on the ambient temperatures, they are additionally limited by the grease lifetime. 4Rated data ^ 28 Application of forces... - Page 27 Technical data Radial forces and axial forces Application of force at l Bearing service life L Motor m850-S120/S3960 m850-S140/S3240 m850-S190/S3000 m850-S120/M3960 m850-S140/M3240 m850-S190/M3000 m850-S120/L3960 m850-S140/L3240 m850-S190/L2520 5000 h Radial force 1030 2170 Axial tensile force -800 -1080 -1290 ax, - Axial compression force ax, + 10000 h...

-

Page 28: Rated Data

Technical data Rated data Inverter mains connection 400 V, Self-ventilated motors Rated data Inverter mains connection 400 V, Self-ventilated motors Product name m850-S120/S3960 m850-S120/M3960 m850-S120/L3960 Standstill torque 6.50 11.0 15.0 Rated torque 4.80 7.40 9.00 Rated Max. torque 14.5 29.0 44.0 max. Rated speed 3960 3960... - Page 29 Technical data Rated data Inverter mains connection 400 V, Self-ventilated motors Product name m850-S190/S3000 m850-S190/M3000 m850-S190/L2520 Standstill torque 27.0 46.0 67.0 Rated torque 16.0 24.0 35.0 Rated Max. torque 71.0 max. Rated speed 3000 3000 2520 Rated Max. speed 4500 4500 4500 max.

-

Page 30: Selection Tables

Technical data Selection tables Selection tables Notes on the selection tables The selection tables represent the combinations of servo motors and servo inverters. The serve as a rough overview. In the case of the servo inverters, the overload capacity depending on the switching frequency in the default setting is taken into consideration. - Page 31 Technical data Selection tables 8400 TopLine inverter drives The data apply to a mains voltage of 3x 400 V and a switching frequency of 8 kHz of the inverter. Motor Inverter E84AVTC□ 1524 2224 3024 4024 5524 7524 1134 1534 1834 2234 3034 3734 4534 m850-S120/S3960 Rated torque rated...

- Page 32 Technical data Selection tables Motor Inverter E84AVTC□ 1524 2224 3024 4024 5524 7524 1134 1534 1834 2234 3034 3734 4534 m850-S190/S3000 Rated torque 14.8 16.0 16.0 16.0 16.0 16.0 16.0 rated Standstill torque 16.0 21.9 27.0 27.0 27.0 27.0 27.0 Max.

- Page 33 Technical data Selection tables i700 servo inverter The data apply to a mains voltage of 3x 400 V and a switching frequency of 4 kHz of the inverter. Motor Inverter E70ACMS□ 0104 0204 0324 0484 0644 m850-S120/S3960 Rated torque rated Standstill torque Max.

- Page 34 Technical data Selection tables Motor Inverter E70ACMS□ 0104 0204 0324 0484 0644 m850-S190/S3000 Rated torque 15.5 16.0 16.0 16.0 rated Standstill torque 16.9 27.0 27.0 27.0 Max. standstill torque 32.8 47.8 62.5 71.0 0,max Max. torque 32.8 47.8 62.5 71.0 Transition speed 2620 2180...

- Page 35 Technical data Selection tables 9400 HighLine servo drives The data apply to a mains voltage of 3x 400 V and a switching frequency of 4 kHz of the inverter. Motor Inverter E94A□□ E0044 E0074 E0094 E0134 E0174 E0244 E0324 E0474 E0594 m850-S120/S3960 Rated torque...

- Page 36 Technical data Selection tables Motor Inverter E94A□□ E0044 E0074 E0094 E0134 E0174 E0244 E0324 E0474 E0594 m850-S190/S3000 Rated torque 13.7 16.0 16.0 16.0 16.0 16.0 rated Standstill torque 14.9 19.7 27.0 27.0 27.0 27.0 Max. standstill torque 34.2 43.2 55.0 63.6 68.9 71.0...

-

Page 37: Torque Characteristics

Torque characteristics Torque characteristics The torque/speed characteristic for your motor/inverter combination can be found on the Internet: http://www.lenze.com à Product Finder à M-n characteristics The following data apply to a mains voltage 3 x 400 V of the inverter. m850-S120/S3960... - Page 38 Technical data Torque characteristics m850-S120/L3960 = 4 V = 36 V = 3x I = 2x I 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 r/min m850-S140/S3240 = 4 V = 36 V = 2x I 1000 1500 2000...

- Page 39 Technical data Torque characteristics m850-S140/M3240 = 4 V = 36 V = 3x I = 2x I 1000 1500 2000 2500 3000 3500 4000 4500 5000 r/min m850-S140/L3240 = 4 V = 36 V = 3x I = 2x I 1000 1500 2000...

- Page 40 Technical data Torque characteristics m850-S190/S3000 = 4 V = 36 V = 3x I = 2x I 1000 1500 2000 2500 3000 3500 4000 r/min m850-S190/M3000 = 4 V = 36 V = 3x I = 2x I 1000 1500 2000 2500 3000...

- Page 41 Technical data Torque characteristics m850-S190/L2520 = 4 V = 36 V = 3x I = 2x I 1000 1500 2000 2500 3000 3500 4000 r/min...

-

Page 42: Dimensions

Technical data Dimensions Basic dimensions Dimensions Basic dimensions The dimensions also apply for motors with One Cable Technology (OCT). m850-S120, self-ventilated Output flange FF130 Motor m850-S120/S3960 m850-S120/M3960 m850-S120/L3960 Total length without brake Total length with brake Motor/connection distance... - Page 43 Technical data Dimensions Basic dimensions m850-S140, self-ventilated Output flange FF165 Motor m850-S140/S3240 m850-S140/M3240 m850-S140/L3240 Total length without brake Total length with brake Motor/connection distance...

- Page 44 Technical data Dimensions Basic dimensions m850-S190, self-ventilated Output flange FF215 Motor m850-S190/S3000 m850-S190/M3000 m850-S190/L2520 Total length without brake Total length with brake Motor/connection distance...

-

Page 45: Product Extensions

In order to provide for a quick and error-free connection of Lenze motors to Lenze inverters, we recommend using prefabricated Lenze system cables. - Page 46 Product extensions Motor connection Connection via ICN connector Position of the connections Standard connection One Cable Technology (OCT) Position Meaning Position Meaning ICN-M23 connector, 6-pole For One Cable Technology (OCT) ICN-M40 connector, 8-pole ICN-M23 connector, hybrid • Power connection ICN-M40 connector, hybrid •...

- Page 47 Product extensions Motor connection Connection via ICN connector ICN-M40 connector assignment 8-pole Contact Name Meaning Not assigned Not assigned Holding brake + Holding brake - PE conductor Power phase U Power phase V Power phase W Feedback and temperature monitoring connection ICN-M23 connector assignment Resolvers Contact...

- Page 48 Product extensions Motor connection Connection via ICN connector Motor/connector assignment NOTICE When making your selection, the motor data and permissible currents of the cables according to the system cable system manual must be observed. Power terminal connectors Motor code m850- S120/S3960 S120/M3960 S120/L3960...

- Page 49 Product extensions Motor connection Connection via ICN connector One Cable Technology (OCT) Connection of power, brake, feedback and temperature monitoring ICN-M23 connector assignment, hybrid for One Cable Technology (OCT) with digital absolute value encoder Contact Name Meaning Power phase U Power phase V Power phase W Holding brake +...

- Page 50 Product extensions Motor connection Connection via ICN connector Hybrid cables for One Cable Technology (OCT) Connector with bayonet lock ICN-M23 Hybrid Order code for hybrid cable 1.5 mm Cable length 2.0 m EYP0080A0020M11A00 Cable length 3.5 m EYP0080A0035M11A00 Cable length 5.0 m EYP0080A0050M11A00 Cable length 7.5 m EYP0080A0075M11A00...

-

Page 51: Brakes

If long motor supply cables are used, pay attention to the ohmic voltage drop along the cable and compensate for it with a higher voltage at the input end of the cable. The following applies to Lenze system cables: Resulting supply voltage ´... - Page 52 Product extensions Brakes To simplify matters, the friction energy per switching cycle can be calculated using the formula below and must not exceed the limit value for emergency stops, which depends on the switching rate: Friction energy Total mass inertia (motor + load) æ...

-

Page 53: Spring-Applied Brakes

Product extensions Brakes Spring-applied brakes Spring-applied brakes Rated data NOTICE Engagement and disengagement times apply to rated voltage (± 0 %) and suppressor circuit of the brakes with a varistor with DC switching. Without a suppressor circuit, the times may be longer. - Page 54 Product extensions Brakes Spring-applied brakes Motor m850-S190/S3000 m850-S190/M3000 m850-S190/L2520 Supply voltage range 21.6 ... 25.2 in,DC Rated voltage rated,DC Rated torque At 20 °C rated At 120 °C rated Output current rated Engagement time Disengagement time Maximum switching energy 5700 Mass 6.70 Moment of inertia...

-

Page 55: Feedback

Motors can perform speed-dependent safety functions for safe speed and/or safe relative position monitoring in a drive system by Lenze inverters or Controllers. In case of inverters, these functions are implemented by integrable safety modules and in case of Controllers by the additionally required Safety Controller. -

Page 56: Resolver

Product extensions Feedback Resolver Resolver The stator-supplied, 2-pole resolver with two stator windings shifted by 90 degrees and a rotor winding with a transformer winding can record both the speed and the rotor position, just like a single-turn absolute value encoder. The rotor position can be determined within one mechanical motor revolution after a voltage failure. -

Page 57: Absolute Value Encoder

Product extensions Feedback Absolute value encoder Absolute value encoder Absolute value encoders can detect the speed, the rotor position, and the machine position with a very high resolution. They are used for the positioning of dynamic applications and do not require homing. With the aid of the open feedback protocol HIPERFACE DSL®... -

Page 58: Temperature Monitoring

Product extensions Temperature monitoring Thermal detectors PT1000 Temperature monitoring Thermal detectors PT1000 The thermal sensors used continuously monitor the motor temperature. The temperature information is transferred to the inverter using the system cable of the feedback system. This is not a full motor protection! The motors are monitored via three thermal sensors connected in series (1x PT1000 + 2x PTC 150 °C ). -

Page 59: Product Codes

32 x 100 rpm 40 x 100 rpm Degree of protection IP5x IP6x Cooling No cooling Brake attachment No brake Spring-applied brake Permanent magnet brake Encoder mounting Resolver Absolute value encoder Digital absolute value encoder Product approval CE; cULus Manufacturer Lenze Internal key... -

Page 60: Environmental Notes And Recycling

Lenze products and their packaging: Lenze products are subject in part to EU Directive 2011/65/EU on the restriction of the use of certain hazardous substances in electrical and electronic devices (RoHS). This is documented accordingly in the EU Declaration of Conformity and with the CE mark. -

Page 61: Appendix

Appendix Good to know Approvals and directives Appendix Good to know Approvals and directives China Compulsory Certification documents the compliance with the legal product safety requirements of the PR of China - in accordance with Guobiao standards. CSA certificate, tested according to US and Canada standards Union Européenne documents the declaration of the manufacturer that EU Directives are complied with. -

Page 62: Operating Modes Of The Motor

Appendix Good to know Operating modes of the motor Operating modes of the motor Operating modes S1 ... S10 as specified by EN 60034-1 describe the basic stress of an electrical machine. The most important operating modes Continuous operation S1 Short-time operation S2 Operation with a constant load until the motor reaches the thermal Operation with constant load;... -

Page 63: Enclosures

Appendix Good to know Enclosures Enclosures The degree of protection indicates the suitability of a motor for specific ambient conditions with regard to humidity as well as the protection against contact and the ingress of foreign particles. The degrees of protection are classified by EN 60529. The first code number after the code letters IP indicates the protection against the ingress of foreign particles and dust. - Page 64 © 09/2020 | | 4.0 Lenze Automation GmbH Postfach 101352, 31763 Hameln Hans-Lenze-Str. 1, 31855 Aerzen GERMANY HR Hannover B 205381 Phone +49 5154 82-0 Fax +49 5154 82-2800 sales.de@lenze.com www.Lenze.com...

Need help?

Do you have a question about the m850 Series and is the answer not in the manual?

Questions and answers