Subscribe to Our Youtube Channel

Summary of Contents for Lenze g500-B / m850

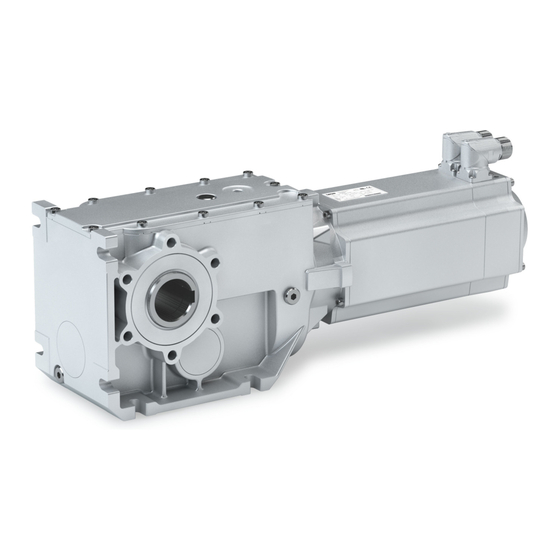

- Page 1 Mounting and switch-on instructions EN Geared servo motors g500-B / m850 bevel geared servo motor...

-

Page 3: Table Of Contents

Contents Contents About this document Document description Further documents Notations and conventions Safety instructions Basic safety instructions Application as directed Residual hazards Product information Identification of the products Nameplates Product codes Equipment Transport Storage Mechanical installation Important notes Preparation Installation Mounting positions Ventilation Dimensions... - Page 4 Contents Technical data Standards and operating conditions Conformities and approvals Protection of persons and device protection EMC data Environmental conditions Motor data Rated data Inverter power supply 400 V, self-ventilated motors Environmental notes and recycling...

-

Page 5: About This Document

The documentation must always be complete and in a perfectly readable state. • Further documents Information and tools with regard to the Lenze products can be found on the Internet: www.Lenze.com à Downloads... -

Page 6: Notations And Conventions

About this document Notations and conventions Notations and conventions Conventions are used in this document to distinguish between different types of information. Numeric notation Decimal separator Point Generally shown as a decimal point. Example: 1 234.56 Warnings UL Warnings Are used in English and French. UR warnings Text Engineering Tools... -

Page 7: Safety Instructions

Safety instructions Basic safety instructions Safety instructions Basic safety instructions Disregarding the following basic safety instructions and safety information may lead to severe personal injury and damage to property! Only use the product as directed. • Never commission the product in the event of visible damage. •... -

Page 8: Residual Hazards

Safety instructions Residual hazards Residual hazards Even if notes given are taken into consideration and protective measures are implemented, the occurrence of residual risks cannot be fully prevented. The user must take the residual hazards mentioned into consideration in the risk assessment for his/her machine/system. - Page 9 Safety instructions Residual hazards Gearbox protection Excessive vibration accelerations and resonances will damage the gearbox. • Do not operate the gearbox at vibration accelerations > 2 g (20 m/s ) of the machine. Do not operate the gearbox in the resonance range of the machine. Excessive torques will damage the gearboxes.

-

Page 10: Product Information

Product information Identification of the products Nameplates Product information Identification of the products Nameplates The nameplate is attached to the motor. 10.1 10.2 10.3 10.4 11.1 11.2 11.3 12.1 12.2 12.3 Pos. Contents Pos. Contents Manufacturer/production location Encoder type designation Motor type/standard Brake data Gearbox type... -

Page 11: Product Codes

Product information Identification of the products Product codes Product codes Gearbox product code Example Product type Gearboxes Product family Generation Gearbox type Bevel gearbox Output torque 45 Nm 110 Nm 240 Nm 450 Nm 600 Nm 820 Nm 1500 Nm 2700 Nm 4300 Nm 8000 Nm... - Page 12 40 x 100 rpm Degree of protection IP5x IP6x Cooling No cooling Brake attachment No brake Spring-applied brake Permanent magnet brake Encoder mounting Resolver Absolute value encoder Digital absolute value encoder Hiperface DSL® Product approval CE; cULus Manufacturer Lenze Internal key...

- Page 13 Product information Identification of the products Product codes Product code feedbacks Example 1024 Meaning Variant Product code Product family Resolver Resolver for safety function Incremental encoder Incremental encoder with commutation signal Absolute value encoder, singleturn Absolute value encoder, multiturn Number 2-pole Resolver for servo motors 2-pole Resolver for three-phase AC motors...

-

Page 14: Equipment

Product information Equipment Equipment The following figure provides an overview of the elements and connections on the product. Their position, size and appearance may vary. Ventilation Temperature monitoring (depending on the mounting position) Oil filler plug (depending on the mounting position) Motor connection Remove oil control plug (depending on the mounting position) -

Page 15: Transport

Transport Transport Ensure appropriate handling. • Make sure that all component parts are securely mounted. Secure or remove loose • component parts. Only use safely fixed transport aids (e.g., eye bolts or support plates). • Do not damage any components during transport. •... - Page 16 Transport Position of the eye bolt G50AB045...G50BB124 from G50BB145 Thread Load carrying 1200 1800 capacity...

-

Page 17: Storage

Storage Storage Storage up to one year: Observe the climatic conditions according to the technical data • 4Environmental conditions ^ 52 Store in a dry, low-vibration environment (V < 0.2 mm/s) without aggressive atmosphere • in the interior Protect from dust, shocks and sunlight •... -

Page 18: Mechanical Installation

Ambient media − especially chemically aggressive ones − may damage shaft sealing rings, • lacquers and plastics. Lenze offers special surface and corrosion protection in this case. • Only install the gearbox in the mounting position shown. •... -

Page 19: Installation

Mechanical installation Installation Mounting positions Installation The mounting surfaces must be plane, torsionally rigid and free from vibrations. • The mounting areas must be suited to absorb the forces and torques generated during • operation. Ensure an unhindered ventilation. • For versions with a fan, keep a minimum distance of 10 % from the outside diameter of the •... -

Page 20: Ventilation

Mechanical installation Installation Ventilation Ventilation No venting measures are required for the G50AB045 … BB124 gearboxes. The G50BB124 gearbox can optionally be equipped with breather elements. From G50BB145 onwards, the gearboxes are supplied with breather elements as standard. Gearboxes that are delivered with a ventilation unit are provided with a label. Remove the transport locking device on the vent valve before initial commissioning. - Page 21 Mechanical installation Installation Ventilation Mounting position M4 (C) Mounting position M5 (E) Mounting position M6 (F) Filling and ventilation Control Drain...

- Page 22 Mechanical installation Installation Ventilation G50BB145 Mounting position M1 (A) Mounting position M2 (D) Mounting position M3 (B) Filling and ventilation Check Drain...

- Page 23 Mechanical installation Installation Ventilation Mounting position M4 (C) Mounting position M5 (E) Mounting position M6 (F) Filling and ventilation Control Drain...

- Page 24 Mechanical installation Installation Ventilation G50BB160 ... BB243 Mounting position M1 (A) Mounting position M2 (D) Mounting position M3 (B) Filling and ventilation Check Drain ① ② ④ ⑤ ③ G50BB160 ① G50BB182 ② G50BB215 ③ G50BB227 ④ G50BB243 ⑤...

- Page 25 Mechanical installation Installation Ventilation Mounting position M4 (C) Mounting position M5 (E) Mounting position M6 (F) Filling and ventilation ④ ③ ⑤ ④ ① ⑤ ② ① ③ ② ③ Check ③ Drain G50BB160 ① G50BB182 ② G50BB215 ③ G50BB227 ④...

-

Page 26: Dimensions

Mechanical installation Dimensions Ventilation Gearbox with oil compensation reservoir for mounting position M4 (C) In order to guarantee a reliable lubrication of the toothed parts in mounting position M4 (C) (motor is on the gearbox vertical from the top), a high filling level is required in the gearbox. As a result of the reduced volume of air in the gearbox, this may lead to oil escaping from the ventilation at higher input speeds. -

Page 27: Mounting

Mechanical installation Mounting Mounting Transmission elements Fit or remove transmission elements only using suitable equipment. • For fitting the transmission elements use the center hole in the shaft. • Avoid impacts and shocks. • In case of a belt drive, tension the belt in a controlled manner according to manufacturer •... - Page 28 Mechanical installation Mounting Gearbox with hollow shaft and shrink disc NOTICE ▶ Never disassemble the new shrink disc. ▶ Thoroughly clean and degrease hollow shaft bore and machine shaft! ▶ Do not tighten clamping screws before the machine shaft has been inserted, the hollow shaft may undergo plastic deformation.

- Page 29 Mechanical installation Mounting NOTICE ▶ The shrink disc is mounted correctly and fixed when the faces of the outer ring and the inner ring are aligned. Minimum misalignments are permissible. Outer ring Inner ring Free of grease NOTICE ▶ If a different tightening torque is indicated on the shrink disc, this tightening torque has priority over the value indicated in the table.

-

Page 30: Product Extensions

Mechanical installation Mounting Product extensions Product extensions Mounting instructions for shrink disc cover NOTICE ▶ The loosely enclosed cover is mounted as a protection against accidental contact with the shrink disc. Gearboxes G50AB45 ... G50BB182 Press the cover with integrated mounting pins into the bore holes on the housing flange Gearboxes G50BB215 ... - Page 31 Mechanical installation Mounting Product extensions Hollow shaft cover Cheese head screw Flat gasket 1. Place flat gasket (4) between the housing flange and the hollow shaft cover (1). 2. Fasten the hollow shaft cover (1) with cheese head screws (2) to the housing flange. Torque plate mounting NOTICE Impermissible load caused by incorrect mounting...

- Page 32 Mechanical installation Mounting Product extensions At threaded pitch circle 1. Clean the contact surfaces between the housing and torque plate. 2. Align the torque plate to the gearbox flange according to the pitch of the bore belt. 3. Fasten torque plate with screws. Observe prescribed torques! 4Preparation ^ 18 On the housing foot...

-

Page 33: Electrical Installation

Use of filters, chokes • Use of special motor cables • Preparation The notes for the electrical connection can be found in the enclosed mounting instructions. EMC-compliant wiring The EMC-compliant wiring is described in detail in the documentation of the Lenze inverters. -

Page 34: Motor Connection

Electrical installation Motor connection Connection via ICN connector Motor connection Connection via ICN connector Position of the connections Standard connection One Cable Technology (OCT) Position Meaning Position Meaning ICN-M23 connector, 6-pole For One Cable Technology (OCT) ICN-M40 connector, 8-pole ICN-M23 connector, hybrid •... - Page 35 Electrical installation Motor connection Connection via ICN connector Standard connection Connection of power and brake ICN-M23 connector assignment 6-pole ICN M23 6-pole Contact Name Meaning PE conductor Brake DC +/AC Brake DC -/AC Power phase U Power phase V Power phase W ICN-M40 connector assignment 8-pole ICN M40 8-pole...

- Page 36 Electrical installation Motor connection Connection via ICN connector Feedback and temperature monitoring connection ICN-M23 connector assignment Resolver Code 0° ICN M23 for resolvers Contact Name Meaning +Ref Transformer windings -Ref Transformer windings Supply: Electronic nameplate (Only for motors and inverters that support +VCC ETS this function) +COS...

- Page 37 Electrical installation Motor connection Connection via ICN connector One Cable Technology (OCT) Connection of power, brake, feedback and temperature monitoring ICN-M23 connector assignment, hybrid For One Cable Technology (OCT) with digital absolute value encoder ICN M23 Hybrid for One Cable Technology (OCT) with digital absolute value encoder Contact Name Meaning...

- Page 38 Electrical installation Motor connection Connection via ICN connector ICN-M40 connector assignment, hybrid For One Cable Technology (OCT) with digital absolute value encoder DSL1 DSL2 ICN M40 Hybrid for One Cable Technology (OCT) with digital absolute value encoder Contact Name Meaning Power phase U Power phase V Power phase W...

- Page 39 Electrical installation Motor connection Connection via ICN connector Assembly of ICN connectors NOTICE Live cables! Possible destruction of the connector. ▶ Never remove connector when voltage is being applied! ▶ Disable inverter before removing the connector! NOTICE Loss of the protection class due to incorrect mounting! Malfunctions may occur.

-

Page 40: Commissioning

Commissioning Important notes Commissioning Important notes NOTICE Do not brake the motor by short-circuit operation. Short-circuit braking may damage the motor. Before initial switch-on That the drive does not show any visible signs of damage. • Is the mechanical fixing o.k.? •... -

Page 41: Functional Test

Commissioning Functional test Functional test After commissioning, check all individual functions of the drive: Rotating direction in decoupled state • Torque behavior and current consumption • Function of the feedback system • Brake function • During operation, carry out inspections on a regular basis. Pay special attention to: Unusual noises •... -

Page 42: Maintenance

Regulations 2008] . Any work on the safety encoder which has not been executed professionally will cause a loss of the safety functions. ▶ The safety encoder may only be repaired or replaced by the Lenze service or its authorised persons. -

Page 43: Maintenance Intervals

Maintenance Maintenance intervals Maintenance intervals Geared motor/gearbox Time interval Measures Description of the operations After assembly and after 3 hours , check fastening. Check all fixing screws on the gearbox (foot, flange and shrink disc fixing ...) for tightness. On the first day, then every General check Pay attention to unusual operating noises, vibrations and impermissibly high month... - Page 44 Maintenance Maintenance intervals Determine change intervals for lubricants 1. Measure the lubricant temperature at the drain plug 2. Add 10 C 3. Determined the change interval from the diagram Position Of the drain plug 4Ventilation ^ 20 1000 50000 10000 Oil sump temperature [°C] Synthetic oil: CLP HC/CLP PG Change interval in operating hours [h]...

-

Page 45: Maintenance Work

Maintenance Maintenance work Maintenance work Check the oil level NOTICE ▶ Check the oil level in cold condition! Check the oil level by means of the displayed dipsticks. Depending on the gearbox type and the mounting position (M1 ... M6), make these according to the following templates. The gearbox type and mounting position are indicated on the nameplate. - Page 46 Maintenance Maintenance work Gearbox G50BB124 ... B145 Template: Dipsticks for G50BB124 M1 3 2-stage gearbox ② 3-stage gearbox ③ 4-stage gearbox ④...

- Page 47 Maintenance Maintenance work Template: Dipsticks for G50BB145 How to check the lubricant level: 1. Remove the control screw at the marked position.4Ventilation ^ 20 2. Insert the dipstick through the threaded hole. Observe the position of the dipstick in the template! 3.

- Page 48 Maintenance Maintenance work Gearbox G50BB160 ... G50BB320 How to check the lubricant level: 1. Remove the control screw at the marked position.4Ventilation ^ 20 2. Insert auxiliary tool through the threaded hole. 3. Carefully pull out the auxiliary tool and determine the lubricant level. The lubricant level may be between the threaded hole and dimension "x".

- Page 49 Maintenance Maintenance work Tightening torques for venting elements and screw plugs Threaded hole Tightening torque M10 x 1 M12 x 1.5 M16 x 1.5 M20 x 1.5 Change roller bearing lubricant Recommended lubricants: Ambient temperature Manufacturer Type Gearbox roller bearing −30 °C ...

-

Page 50: Repair

First check the possible causes of malfunction according to the 4Diagnostics and fault • elimination ^ 51 If the fault cannot be remedied using one of the measures listed, please contact the Lenze • service department. The contact data can be found on the rear of this documentation. -

Page 51: Diagnostics And Fault Elimination

If faults occur during the operation of the drive, the table below helps you to identify the causes. If it is not possible to remedy the fault using the measures listed, please contact the Lenze service department. Error Possible cause... - Page 52 Technical data Standards and operating conditions Conformities and approvals Technical data Standards and operating conditions Conformities and approvals More information and certificates of approval can be found under g500 + m850 bevel geared motors Europa Country Conformity/approval Product representation European Union CE mark Eurasian Economic Union (EAEU) EAC mark...

- Page 53 Technical data Motor data Rated data Motor data Rated data Inverter power supply 400 V, self-ventilated motors Motor M85AS120S40 M85AS120M4 M85AS120L40 M85AS140S32 M85AS140M3 M85AS140L32 Standstill torque 6.50 11.0 15.0 11.0 21.0 28.0 Rated torque 4.80 7.40 9.00 8.50 14.0 17.4 rated Max.

- Page 54 Technical data Motor data Rated data Motor M85AS190S30 M85AS190M30 M85AS190L25 Standstill torque 27.0 46.0 67.0 Rated torque 16.0 24.0 35.0 rated Max. torque 71.0 Rated speed 3000 3000 2520 rated Max. speed 4500 4500 4500 Rated power rated Standstill current 16.0 26.8 30.8...

- Page 55 Lenze products and their packaging: Lenze products are partly subject to the EU Directive on the restriction of certain hazardous substances in electrical and electronic equipment 2011/65/EU: RoHS Directive [UKCA: S.I. 2012/3032 - The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 2012] .

- Page 56 Lenze SE Postfach 101352 · 31763 Hameln Hans-Lenze-Straße 1 · 31855 Aerzen GERMANY Hannover HRB 204803 Phone +49 5154 82-0 Fax +49 5154 82-2800 sales.de@lenze.com www.Lenze.com © 03/2022 · · 1.0 · www.Lenze.com...

Need help?

Do you have a question about the g500-B / m850 and is the answer not in the manual?

Questions and answers