Subscribe to Our Youtube Channel

Summary of Contents for Aerotech AGS15000HL Series

- Page 1 AGS15000HL Series Stage User’s Manual Dedicated to the Science of Motion Aerotech, Inc. 101 Zeta Drive, Pittsburgh, PA, 15238 Phone: 412-963-7470 Fax: 412-963-7459 www.aerotech.com...

- Page 2 Email: service@aerotechkk.com.jp China: Phone: +852-3793-3488 Email: saleschina@aerotech.com Revision History Revision 1.01.00 February 21, 2011 Revision 1.00.00 October 31, 2008 Product names mentioned herein are used for identification purposes only and may be trademarks of their respective companies. © Aerotech, Inc. 2011...

-

Page 3: Table Of Contents

4.2. Cleaning and Lubrication 4.3. Linear Lubrication and Cleaning Procedure 4.4. Linear Encoder Cleaning and Maintenance Procedure 4.5. System Calibration Procedure Appendix A: Warranty and Field Service Appendix B: Technical Changes Appendix C: Payload and Performance Plots Index Reader's Comments www.aerotech.com... - Page 4 Table of Contents AGS15000HL Hardware Manual www.aerotech.com...

-

Page 5: List Of Figures

AGS15000HL Hardware Manual List Of Figures List of Figures Figure 2-1: Compliant Mounting, With and Without Mounting Bolt Figure 4-1: Location of Grease Nipples (approximate) Figure 4-2: Removing Upper Axis Encoder Cover www.aerotech.com... - Page 6 List of Figures AGS15000HL Hardware Manual www.aerotech.com...

-

Page 7: List Of Tables

AGS15000HL Hardware Manual List of Tables List of Tables Table 1-1: Model Numbering System Table 3-1: Environmental Specifications Table 3-2: AGS15000HL Series Specifications Table 3-3: AGS15000HL Motor Specifications Table B-1: Current Changes (1.01.00) Table B-2: Archived Changes www.aerotech.com... - Page 8 List of Tables AGS15000HL Hardware Manual viii www.aerotech.com...

-

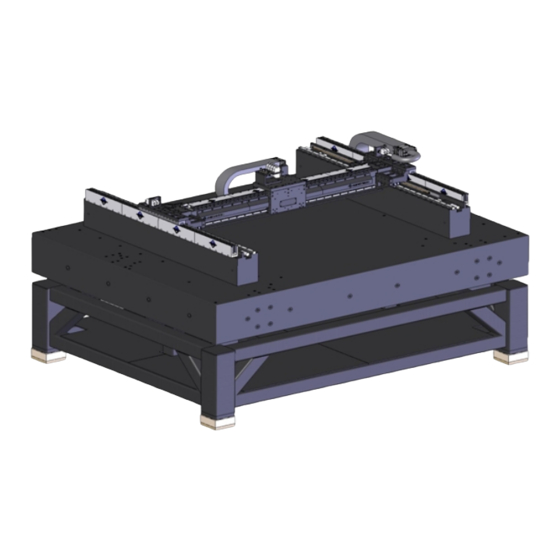

Page 9: Chapter 1: Overview

Overview Chapter 1: Overview The AGS15000HL series of Cartesian gantry systems is designed for ultra-precision contouring capabilities, providing outstanding performance and versatility in a wide range of automation platforms. To ensure high contouring accuracy, the bridge’s center of gravity is kept in line with the lower axis bearings and forcers to minimize pitch and roll errors at the work point. -

Page 10: Standard Features

1.1.1. Linear Motor / Linear Encoder Aerotech’s high-performance brushless linear servomotors drive the AGS15000HL to speeds up to 3 m/s and accelerations up to 5 g. Dual linear motors and encoders are included on the lower axis for the highest level of performance and precision. -

Page 11: Optional Features

Cleanroom grease – refer to section 4.2 for grease specification. 1.2.3. Electronics / Controller The AGS15000HL is typically part of a complete Aerotech motion control system, which is adjusted at the factory for optimum performance. Setup usually involves connecting a stage to the appropriate drives with the cables provided. -

Page 12: Model Numbers

Granite baseplate for AGS151000-1000 -GRR500-500 Granite baseplate for AGS15500-500 with 150 mm (6 in) risers -GRR750-750 Granite baseplate for AGS15750-750 with 150 mm (6 in) risers -GRR1000-1000 Granite baseplate for AGS151000-1000 with 150 mm (6 in) risers Chapter 1 www.aerotech.com... - Page 13 100 mm (4 in) travel z-stage Z150 150 mm (6 in) travel z-stage THETA 360° travel theta axis MB500-500 Steel weldment machine base for AGS15500-500 MB750-750 Steel weldment machine base for AGS15750-750 MB1000-1000 Steel weldment machine base for AGS1000-10000 www.aerotech.com Chapter 1...

-

Page 14: Safety Procedures And Warnings

If the stage is used in a manner not specified by the manufacturer, the protection provided by the stage can be impaired. Stage cables can pose a tripping hazard. Securely mount and position all stage cables to avoid potential hazards. Chapter 1 www.aerotech.com... - Page 15 This stage is intended for light industrial manufacturing or laboratory use. Use of the stage for unintended applications can result in injury and damage to the equipment. Before using this stage, perform an operator risk assessment to determine the needed safety requirements. www.aerotech.com Chapter 1...

-

Page 16: Ec Declaration Of Incorporation

101 Zeta Drive Pittsburgh, PA 15238 herewith declares that the product: Aerotech, Inc. AGS15000HL Stage is intended to be incorporated into machinery to constitute machinery covered by the Directive 2006/42/EC as amended; does therefore not in every respect comply with the provisions of this directive;... -

Page 17: Chapter 2: Installation

Installation Chapter 2: Installation This chapter describes the installation procedure for the AGS15000HL series gantry, including handling the stage properly, preparing the mounting surface to accept the stage, securing the stage to the mounting sur- face, attaching the payload, and making the electrical connections. -

Page 18: Mounting The System To A Machine Base

It should be supported in three or four places unless otherwise specified during the system approval process. A compliant mounting scheme (shown in Figure 2-1) is recommended for most cases. Consult with Aerotech to ensure that this method is acceptable for a specific application. - Page 19 AGS15000HL Hardware Manual Installation The stage must be mounted securely. Improper mounting can result in injury and damage to the equipment. www.aerotech.com Chapter 2...

-

Page 20: Attaching The Payload To The Stage

2.4. Electrical Installation Aerotech motion control systems are adjusted at the factory for optimum performance. The AGS15000HL stage is typically part of a complete Aerotech motion control system; setup involves connecting a stage to the appropriate drives with the cables provided. -

Page 21: Chapter 3: Operating Specifications

40 kg. This weight of all additional axes integrated onto the system as well as all customer fixturing and/or test equipment contributes to this load. The load capacity is reduced if the load must be cantilevered away from the face of the upper axis. Contact Aerotech to determine acceptable loading limits for offset pay- loads. -

Page 22: Basic Specifications

(4) Maximum load based on bearing capability; maximum application load may be limited by acceleration and dynamic requirements. (5) Measured at center of travel, single axis under static conditions. (6) Available with Aerotech controllers with HALAR. Chapter 3 www.aerotech.com... -

Page 23: Table 3-3: Ags15000Hl Motor Specifications

(6) Maximum winding temperature is 125 °C (7) Ambient operating temperature range: 0 °C - 25 °C, consult Aerotech for performance in elevated ambient temperatures (8) All Aerotech amplifiers are rated Apk; use torque constant in N-m / Apk when sizing www.aerotech.com... -

Page 24: Overtravel Safety

The gantry is designed to prevent damage to itself and injury to the operator when used as specified upon system approval. If any combination of payloads, speeds, and accelerations are to be used other than those originally approved, contact Aerotech. Do not attempt to modify the system in any way that would affect overtravels or hard stops. -

Page 25: Chapter 4: Maintenance

The bearings of the AGS15000HL are generally greased with BR2-Plus grease (supplier is Dow Corning). http://www.dowcorning.com/applications/search/default.aspx?R=3178EN. Other greases may be used for cleanroom or other special applications. Contact Aerotech for confirmation on what grease is used in a par- ticular system. -

Page 26: Linear Lubrication And Cleaning Procedure

6. Repeat steps 3 through 5 for any areas covered by the original table position. 7. Restore power to the stage and drive the stage table back to its original position to redistribute lubri- cants. Figure 4-1: Location of Grease Nipples (approximate) Chapter 4 www.aerotech.com... -

Page 27: Linear Encoder Cleaning And Maintenance Procedure

4. Re-assemble any covers that were removed in Step 3. 5. Restore power to the stage and drive the system through travel to ensure proper encoder signal feed- back. www.aerotech.com Chapter 4... -

Page 28: System Calibration Procedure

AGS15000HL Hardware Manual 4.5. System Calibration Procedure If the HALAR option was purchased with the system, then the system was calibrated at the Aerotech fac- tory to meet catalog accuracy and repeatability specifications. The parameter file provided with the system includes the calibration data for the axes and should be enabled in the controller in order to achieve the spec- ified system accuracy. -

Page 29: Appendix A: Warranty And Field Service

Aerotech makes no warranty that its products are fit for the use or purpose to which they may be put by the buyer, where or not such use or purpose... - Page 30 Aerotech will provide an on-site field service representative in a reasonable amount of time, provided that the customer issues a valid purchase order to Aerotech cov- ering all transportation and subsistence costs. For warranty field repairs, the cus- tomer will not be charged for the cost of labor and material.

-

Page 31: Appendix B: Technical Changes

Current Changes (1.01.00) Section(s) Affected General Information Section 1.5. Section added Section 3.1. Section added Chapter 2: Installation, Section 2.1. , Section 2.2. , Safety information and warnings added and Section 1.4. Section 3.3. Specifications tables added www.aerotech.com Appendix B... -

Page 32: Table B-2: Archived Changes

Technical Changes AGS15000HL Hardware Manual Table B-2: Archived Changes Revision Section(s) Affected General Information 1.00.00 New manual Appendix B www.aerotech.com... -

Page 33: Appendix C: Payload And Performance Plots

AGS15000HL Hardware Manual Payload and Performance Plots Appendix C: Payload and Performance Plots Upper Axis Acceleration Plot: www.aerotech.com Appendix D... - Page 34 Payload and Performance Plots AGS15000HL Hardware Manual Lower Axis Acceleration Plots: AGS15000HL with BLM motors: AGS15000HL with BLMH motors: Appendix D www.aerotech.com...

-

Page 35: Index

Cleaning Declaration of Incorporation Electrical Installation Environmental Specifications Load Capability Lubrication lubrication schedule Model Numbers 4, 9 Mounting the System to a Machine Base Optional Features Overtravel Safety safety procedures Specifications Standard Features Unpacking and Handling the Stage www.aerotech.com Index... - Page 36 AGS15000HL Hardware Manual Index Index www.aerotech.com...

-

Page 37: Reader's Comments

Reader's Comments AGS15000HL Series Stage Manual P/N: EDS138, February 21, 2011 Revision 1.01.00 Please answer the questions below and add any suggestions for improving this doc- ument. Is the manual: Adequate to the subject Well organized Clearly presented Well illustrated How do you use this document in your job? Does it meet your needs? What improvements, if any, would you like to see? Please be specific or cite examples.

Need help?

Do you have a question about the AGS15000HL Series and is the answer not in the manual?

Questions and answers