SMC Networks EX600 Series Opration Manual

Fieldbus system ethernet/ip compatible si unit

Hide thumbs

Also See for EX600 Series:

- Operation manual (138 pages) ,

- Operation manuals (1 page) ,

- Operation manual (81 pages)

Advertisement

Quick Links

No.EX※※-OMR1012

PRODUCT NAME

Fieldbus system

TM

EtherNet/IP

compatible SI Unit

MODEL / Series / Product Number

EX600-SEN5-X22

EX600-ED#

This manual is for Ford Motor Company.

Any IP address within the 136.129.0.1 to 136.129.7.254 range can be set with a switch.

This IP address range can only be used with the permission of Ford Motor Company.

EX※※-OMR1012

Advertisement

Summary of Contents for SMC Networks EX600 Series

- Page 1 No.EX※※-OMR1012 PRODUCT NAME Fieldbus system EtherNet/IP compatible SI Unit MODEL / Series / Product Number EX600-SEN5-X22 EX600-ED# This manual is for Ford Motor Company. Any IP address within the 136.129.0.1 to 136.129.7.254 range can be set with a switch. This IP address range can only be used with the permission of Ford Motor Company. EX※※-OMR1012...

- Page 2 Table of Contents Safety Instructions System Outline Definition and terminology Assembly Mounting and Installation Installation Wiring SI Unit Model Indication and How to Order Summary of Product parts Mounting and Installation Wiring Setting and Adjustment LED Display Specification Specifications Dimensions End Plate Model Indication and How to Order Summary of Product parts...

- Page 3 Safety Instructions These safety instructions are intended to prevent hazardous situations and/or equipment damage. These instructions indicate the level of potential hazard with the labels of "Caution", "Warning" or "Danger". They are all important notes for safety and must be followed in addition to International 1) standards (ISO/IEC) and other safety regulations.

- Page 4 Caution The product is provided for use in manufacturing industries. The product herein described is basically provided for peaceful use in manufacturing industries. If considering using the product in other industries, consult SMC beforehand and exchange specifications or a contract if necessary. If anything is unclear, contact your nearest sales branch.

- Page 5 Operator This operation manual is intended for those who have knowledge of machinery using pneumatic equipment, and have sufficient knowledge of assembly, operation and maintenance of such equipment. Only those persons are allowed to perform assembly, operation and maintenance. Read and understand this operation manual carefully before assembling, operating or providing maintenance to the product.

- Page 6 Caution ■When handling the unit or assembling/replacing units: •Do not touch the sharp metal parts of the connector or plug for connecting units. •Take care not to hit your hand when disassembling the unit. The connecting portions of the unit are firmly joined with seals. •When joining units, take care not to get fingers caught between units.

- Page 7 ●Product handling Installation •Do not drop, hit or apply excessive shock to the SI unit. Otherwise damage to the product can result, causing malfunction. •Tighten to the specified tightening torque. If the tightening torque is exceeded the mounting screws may be broken. IP67 protection cannot be guaranteed if the screws are not tightened to the specified torque.

- Page 8 •When a surge-generating load such as a relay, valve or lamp is driven directly, use a product with a built-in surge absorbing element. Direct drive of a load generating surge voltage can damage the unit. •The product is CE marked, but not immune to lightning strikes. Take measures against lightning strikes in the system.

- Page 9 System Outline System configuration The EX600 range of units can be connected to various types of fieldbus to realize the reduction of input or output device wiring and the distributed control system. The unit communicates with the fieldbus through the SI unit.

- Page 10 ■ Definition and terminology Terminology Definition 100BASE-TX Standard of LAN transmission line with communication speed of 100 Mbps. Current consumption The current necessary to operate each unit. The protocol which automatically set the information such as IP address which needs to DHCP be registered in order to use the network.

- Page 11 Assembly Composing the unit as a manifold : If the unit was purchased as a manifold, the work described in this section is not necessary. (1) Connect the unit to the end plate. The Digital unit, Analogue unit can be connected in any order. (Tightening torque: 1.5 to 1.6Nm) (2) Add more units.

- Page 12 (4) Mounting the valve plate. Mount the valve plate (EX600-ZMV□) to the valve manifold using the valve set screws. (M3 x 8) (Tightening torque: 0.6 to 0.7 Nm) Screw mounting place : 2 places S0700 : 2 places VQC1000: 2 places VQC2000: 3 places VQC4000: 4 places : 2 places...

- Page 13 Mounting and Installation ■ Installation •Direct mounting (1) Direct mounting When joining six or more units, fix the middle part of the complete EX600 unit with an intermediate reinforcing brace (EX600-ZMB1) before mounting using 2-M4 x 5 screws. (Tightening torque: 0.7 to 0.8 Nm) Intermediate reinforcing brace (EX600-ZMB1) (2) Fix and tighten the end plates at one end of the unit.

- Page 14 •DIN rail mounting (Not available for SY series valves. Refer to the SY catalog.) (1) When joining six or more units, fix the middle part of the complete EX600 unit with an intermediate reinforcing brace (EX600-ZMB2) before mounting, using 2-M4 x 6 screws. (Tightening torque: 0.7 to 0.8 Nm) (2) Mount the end plate bracket (EX600-ZMA2) to the end plate at the opposite end to the valves, using 2-M4 x 14 screws.

- Page 15 ■ Wiring •Connect the M12 or M8 connector cable. M12 connector is applicable for SPEEDCON connector. SPEEDCON connector wiring method is explained below. (1) Align the mark B on the metal bracket of the cable side connector (plug/socket) with the mark A. (2) Align the mark C on the unit and insert the connector into the unit vertically.

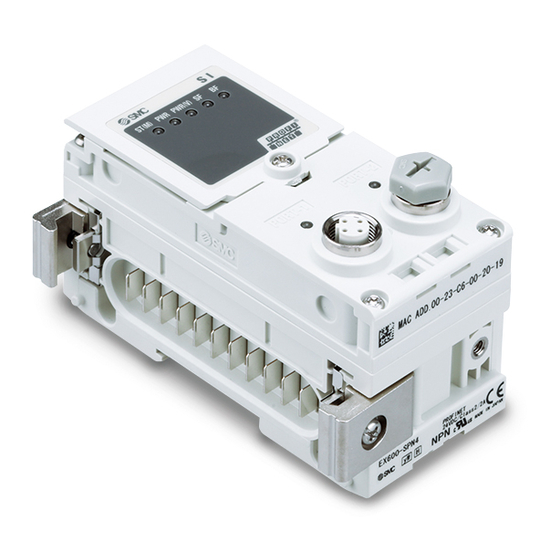

- Page 16 SI Unit Model Indication and How to Order EX600- S EN 5 - X22 SI Unit Output type Symbol Content Protocol PNP (negative common) Symbol Content EtherNet/IP Summary of Product parts Description Function Status display LED Displays the status of the unit. Display cover Open for the setting of switch.

- Page 17 Mounting and Installation ■ Wiring Connector pin assignment Configuration Pin No. Signal name BUS IN/BUS OUT ●Precautions for handling Be sure to fit a seal cap on any unused connectors. Proper use of the seal cap enables the enclosure to achieve IP67 specification. -16- EX※※-OMR1012...

- Page 18 Setting and Adjustment Switch operation (1) Loosen the display cover screw (indicated by arrow). (2) Open the display cover using a flat head screwdriver, etc. (3) Set the switch using a small watchmaker's screwdriver with a thin blade, referring to the setting of switch on the following pages.

- Page 19 Switch setting The range of IP address that can be set changes by 5 of the settings1. (1) 5 of the settings1 is OFF IP address range: 192.168.0.1 to 192.168.1.254. Subnet mask: 255.255.255.0 Settings1 Settings2 Hold/Clear setting Diagnostics setting Reserved •IP address byte 4 setting •DHCP mode setting...

- Page 20 •IP address setting switch (5 of the settings1 is OFF) Settings1 Settings2 IP address Subnet mask 192.168.0.1 192.168.0.2 255.255.255.0 192.168.0.253 192.168.0.254 192.168.1.1 192.168.1.2 255.255.255.0 192.168.1.253 192.168.1.254 1 ON/OFF DHCP mode 2 ON/OFF Remote Control mode 1: The mode to obtain IP address from DHCP server. Obtained IP address etc. is lost when the power supply is cut. 2: The mode to respond to the commands below of BOOTP/DHCP Server provided by Rockwell Automation.

- Page 21 (2) 5 of the settings1 is ON IP address range: 136.129.0.1 to 136.129.7.254. Subnet mask: 255.255.248.0 Settings 1 Settings 2 IP address byte 3 setting Hold/Clear setting •IP address byte 4 setting •DHCP mode setting Reserved Diagnostics setting ●Precautions for handling •Handle the switch with care.

- Page 22 •IP address setting switch (5 of the settings1 is ON) Settings1 Settings2 IP address Subnet mask OFF OFF OFF OFF OFF OFF OFF 136.129.0.1 255.255.248.0 ON 136.129.0.254 OFF OFF OFF OFF OFF OFF OFF 136.129.1.1 255.255.248.0 ON 136.129.1.254 OFF OFF OFF OFF OFF OFF OFF 136.129.6.1 255.255.248.0 ON 136.129.6.254...

- Page 23 Setting method of IP address by BOOTP/DHCP Server •When BOOTP/DHCP Server starts up, the Server scans the devices connected to the network. •After selecting the MAC address of EX600, IP address is set. •IP address is set and added to the list. -22- EX※※-OMR1012...

- Page 24 LED Display The status display LED displays the power supply and communication status. Various kinds of status can be checked as follows: Display Content ST(M) Displays the diagnosis status of the unit. Displays the status of the power supply voltage for control and input.

- Page 25 •Module status LED display Content The power supply for control and input is OFF. MS LED is OFF Either of the following conditions: •The unit has not been configured correctly. •Fieldbus is idling. Green MS LED is flashing The unit is in normal operation. Green MS LED is ON Recoverable error.

- Page 26 •Communication status LED display Content Bus IN side :No Link, No Activity Green ON Bus IN side : Link, No Activity (100 Mbps) Green flashing Bus IN side : Link, Activity (100 Mbps) Yellow ON Bus IN side : Link, No Activity (10 Mbps) Yellow flashing Bus IN side : Link,...

- Page 27 Specification ■ Specifications Model EX600-SEN5-X22 Protocol EtherNet/IP (IEEE802.3) Standard EtherNet cable Transmission medium (CAT5 or more, 100BASE-TX) Transmission speed 10/100 Mbps (Auto negotiation) Transmission type Full duplex/Half duplex (Auto negotiation) Setting by SI unit switch IP address setting range Via DHCP server : Arbitrary address Vendor ID: 7 (SMC Corporation) Device information Product type: 12 (Communication Adapter)

- Page 28 ■ Dimensions -27- EX※※-OMR1012...

- Page 29 End plate Model Indication and How to Order EX600-ED - End plate at D side Mounting method Symbol Content Connector No DIN rail bracket Symbol Content With DIN rail bracket (Except SY series) M12 (5 pin) With DIN rail bracket (Specified for SY series) 7/8 inch (5 pin) Summary of Product parts •EX600-ED2-...

- Page 30 Mounting and Installation ■ Wiring ○Connector pin assignment (1) EX600-ED2- Configuration Pin No. Signal name 24 V (Output) 0 V (Output) 24 V (Control and input) 0 V (Control and input) F.E. (2) EX600-ED3- Configuration Pin No. Signal name 0 V (Output) 0 V (Control and input) F.E.

- Page 31 Specification ■ Specifications Model EX600-ED2- EX600-ED3- Power connector M12 (5 pin) Plug 7/8 inch (5 pin) Plug Power supply 24 VDC ±10% Class2, 2 A 24 VDC ±10%, 8 A (Control and input) Power supply (Output) 24 VDC +10/-5% Class2, 2 A 24 VDC +10/-5%, 8 A ...

- Page 32 •EX600-ED3- -31- EX※※-OMR1012...

- Page 33 Maintenance Turn OFF the power supply, stop the supplied air, exhaust the residual pressure and verify the release of air before performing maintenance. Cleaning method Use a soft cloth to remove stains. For heavy stains, use a cloth soaked with diluted neutral detergent and fully squeezed, then wipe up the stains again with a dry cloth.

- Page 34 W.S.). ■ Parameter definition and setting With EX600 series, parameters can be set for each unit. The table below shows settable parameters for the SI unit and input/output units. Note It is shown “○” of the parameter setting is to set it, and shows “...

- Page 35 •SI unit parameters (1) Parameter setting Default Parameter Definition Item Content setting E.O. W.S. Generated error ○ per unit when Enable Generates an error. Power supply control and input for control and ○ ○ power supply input voltage voltage goes over Does not generate an monitor Disable...

- Page 36 •SI unit parameters (2) Parameter setting Default Parameter Definition Item Content setting E.O. W.S. Memorizes the Generates an error. number of times Enable 4 Val: 1 to 65000 the valve is ON. Valve Generates error ○ ○ ON/OFF per channel when counter the operation count Does not generate an...

- Page 37 •Digital input unit parameters Parameter setting Default Parameter Definition Item Content setting E.O. W.S. The power Generates error ○ Enable Generates an error. supply short per unit when the circuit short circuit of the ○ ○ detection for power supply for Does not generate an control and the input device is...

- Page 38 •Digital output unit parameters Parameter setting Default Parameter Definition Item Content setting E.O. W.S. Generates error ○ Enable Generates an error. Output load per unit when the ○ ○ short circuit short circuit of the Does not generate an detection output device is Disable ...

- Page 39 •Digital I/O unit parameters (1) Parameter setting Default Parameter Definition Item Content setting E.O. W.S. The power Generates error ○ Enable Generates an error. supply short per unit when the circuit short circuit of the ○ ○ detection for control or input Does not generate an control and power supply is...

- Page 40 •Digital I/O unit parameters (2) Parameter setting Default Parameter Definition Item Content setting E.O. W.S. Memorizes the number of times Generates an error. Enable the input or output 5 Val: 1 to 65000 Input or device is ON. Output ○...

- Page 41 •Analogue input unit parameters Parameter setting Default Parameter Definition Item Content setting E.O. W.S. The power Generates error ○ Enable Generates an error. supply short per unit when the circuit short circuit of the ○ ○ detection for power supply for Does not generate an the input the input device is...

- Page 42 Table. Settable range of user set value Settable value range Range Lower limit Upper limit -10..+10 V -10.50 to +10.45 V -10.45 to +10.50 V -5..+5 V -5.25 to +5.22 V -5.22 to +5.25 V -20..+20 mA -21.00 to +20.90 mA -20.90 to +21.00 mA 0..10 V 0.00 to +10.45 V...

- Page 43 •Analogue output unit parameters (1) Parameter setting Default Parameter Definition Item Content setting E.O. W.S. The power Generates error ○ Enable Generates an error. supply short per unit when the circuit ○ ○ short circuit of the detection for output device is Does not generate an the output Disable...

- Page 44 •Analogue output unit parameters (2) Parameter setting Default Parameter Definition Item Content setting E.O. W.S. Output will be user idle Output setting Set output per Enable value. channel during ○ ○ communication communication Output will be held last ○ Disable ...

- Page 45 Output value during communication error (Fault Value) Refer to the tables below for setting the Fault value via PLC. •Set in decimal number. •Conversion value varies depending on the assigned analogue data format and the analogue output range. (1) Offset binary data format •Range: 0 to 10 V, 0 to 5 V, 0 to 20 mA •Range: 1 to 5V, 4 to 20 mA Settable value...

- Page 46 (2) Signed binary data format & 2's complement data format •Range: 0 to 10 V, 0 to 5 V, 0 to 20 mA •Range: 1 to 5 V, 4 to 20 mA Settable value Settable value Output signal range Output signal range by PLC by PLC (0 to b)

- Page 47 (3) Scaled data format Function to set any value between "-32767 to 32767" as the AD value for output signal range. Resolution is determined by specifying the upper and lower scale limit. Upper limit value of the range - Lower limit value of the range Resolution = Upper limit value of the scale - Lower limit value of the scale Example: when the range is 1 to 5 V...

- Page 48 •Analogue I/O unit parameters (1) Parameter setting Default Parameter Definition Item Content setting E.O. W.S. The power Generates error ○ Enable Generates an error. supply short per unit when the circuit short circuit of the ○ ○ detection for input device power Does not generate an the input or supply or output...

- Page 49 •Analogue I/O unit parameters (2) Parameter setting Default Parameter Definition Item Content setting E.O. W.S. Generates error 1 Enable Generates an error. User’s set per channel when value lower the input or output Does not generate an limit error value falls below ○...

- Page 50 Table. Settable range for user set upper or lower limit and Fault Value User set output value Fault Value Settable range Range Settable range Lower limit Upper limit 0..10 V 0.00 to +10.45 V +0.05 to +10.50 V 0.00 to +10.50 V 0..5 V 0.00 to +5.22 V +0.03 to +5.25 V...

- Page 51 Output value during communication error (Fault Value) Refer to the tables below for setting the Fault value via PLC. •Set as a decimal number. •Conversion value varies depending on the assigned analogue data format and the analogue output range. (1) Offset binary data format •Range: 0 to 10 V, 0 to 5 V, 0 to 20 mA •Range: 1 to 5 V, 4 to 20 mA Settable value...

- Page 52 (2) Signed binary data format & 2's complement data format •Range: 0 to 10 V, 0 to 5 V, 0 to 20 mA •Range: 1 to 5 V, 4 to 20 mA Settable value Settable value Output signal range Output signal range by PLC by PLC (0 to b)

- Page 53 I/O Map Allocated input and output bytes of each unit type Allocated input and output size is changable according to the diagnosis setting and connected EX600 unit type. The allocated input and output bytes for each EX600 unit are shown below. Allocated bytes Unit Unit part number...

- Page 54 When configuring the input and output data size, please ensure the following steps are taken; •The minimum value of both the input and output data size is 2 bytes. If the EX600 data size is 0 or 1byte, this must be set to 2 bytes. •If the input or output size is an odd number, add 1 byte, to make it an even number of bytes.

- Page 55 <Example 2> Unit 0 Unit 1 Unit 2 Unit 3 Unit 4 Unit 5 DY□B DY□B DX□B DX□D SEN5 Analogue Digital Digital Digital Digital SI unit input output output input input End plate Valve 4 byte 1 byte 2 byte Input Input Input...

- Page 56 •When Diagnostic mode 1 and byte order of analogue value LSB-MSB are selected. Input data Output data Byte0 Diagnostic data byte0 DY□B (Unit 1) Output 0 to 7 Byte1 Diagnostic data byte1 DY□B (Unit 2) Output 0 to 7 Byte2 Diagnostic data byte2 Output 0 to 7 Byte3...

- Page 57 Diagnosis By changing the diagnosis switch, the diagnostic data shown below is assigned to the head of input data of the I/O map. (Refer to “Setting and adjustment” for setting the switch.) Mode Diagnostic data Diagnostic size No diagnostic data. 0 byte System diagnosis + Unit diagnosis 4 bytes...

- Page 58 ■ Details of diagnostic data Diagnostic data Byte Bit No. Diagnostic content The analogue value has fallen below the user set value. The analogue value has exceeded the user set value. The analogue input value has fallen below the set range. The analogue input value has exceeded the set range.

- Page 59 EDS file: ex600_sen_2p_qc2_v10.eds Icon: ex600_1.ico ■ Setting using RSLogix5000 When connecting EX600 series, use RSLogix5000 software by Rockwell Automation. Refer to the manual of RSLogix5000 for a detailed manner of operation. : The screen data shown here is the English version of RSLogix5000 •Select [EtherNet/IP...

- Page 60 •[Select Module] window is displayed. Select [ETHERNET-MODULE Generic Ethernet Module], and click on [OK]. -59- EX※※-OMR1012...

- Page 61 •[Module Properties] window is displayed. Perform each setting. (1) Name: Input the description of specific unit. (2) Comm Format: Select the data format of Connection Parameters. (3) IP Address: Input IP Address which is set in SI unit. (4) Assembly Instance: Set as below. Description Decimal Common Format...

- Page 62 ■ Device Level Ring (DLR) function This SI unit can be used as an EtherNet/IP compliant node for network rings with the DLR function. To enable the DLR function, all of the ring nodes need to be applicable to the DLR function. Since all of the DLR function settings are performed by the Ring Supervisor, there is no need to perform any settings to the SI unit.

- Page 63 2. QuickConnect function setting Change the TCP/IP Object to the values shown below. Make sure the value is set to "0" when the QuickConnect function is not used. Class Instance Attribute Value QuickConnect setting 0: disabled (default setting) 0xF5 0x01 0X0C ○...

- Page 64 EtherNet/IP Object System diagnostic object (Class: 66h) Instance Attribute Access Name Type Value Input data length UINT I/O mapping input data length (Byte) Output data length UINT I/O mapping output data length (Byte) Number of units USINT Number of units connected connected 0: switch Get/Set...

- Page 65 Unit/Channel diagnosis object (Class: 67h) Instance Attribute Access Name Type Value 0: No error, 1: Error Bit0: The analogue value has fallen below the user set value. Bit1: The analogue value has exceeded the user set value. Bit2: The analogue input value has fallen below the set range. Bit3: The analogue input value has exceeded the set range.

- Page 66 Details of channel diagnosis object (Class: 77h) Instance Attribute Access Name Type Value 0: No error, 1: Error Bit0: The analogue value has fallen below the user set value. Bit1: The analogue value has exceeded the user set value. Bit2: The analogue input value has fallen below the set range. 01h to 64h to Bit3: The analogue input value has exceeded the set range.

- Page 67 Unit parameter object (Class: 78h) Instance Attribute Access Name Type Value Short circuit detection (Power supply for input device) 0: Disable BOOL 1: Enable •Digital input, I/O •Analogue input, output, I/O Short circuit detection (Output) 0: Disable BOOL •SI 1: Enable •Digital output, I/O Analogue over range detection 0: Disable...

- Page 68 Channel parameter object (1) (Class: 79h to 7Fh) Class Instance Attribute Access Name Type Value Open circuit detection 0: Disable 1: Enable •SI BOOL □ •Digital input (DX •Digital output, I/O ON/OFF count upper limit detection 0: Disable BOOL 1: Enable •SI •Digital input, output, I/O ON/OFF count upper limit value...

- Page 69 Channel parameter object (2) (Class: 83h to 8Ah) Class Instance Attribute Access Name Type Value Output setting at communication error 0: Disable (Hold) BOOL 1: Enable •SI (Clear or Force ON) •Digital output, I/O •Analogue output, I/O Output setting at communication error (Digital) 0: Off (Clear) BOOL...

- Page 70 Web Server EX600 Web server functional overview The Web server function is provided by the EX600-SEN5-X22. The functions available vary depending on the mode. Function Admin mode Monitor only mode I/O Monitor Available Available Diagnostic status monitor Available Available Parameter setting Available Not available Force I/O setting...

- Page 71 (4) When the [Start] button is selected in the EX600 webpage, the following screen will be displayed. Factory default setting: User name: admin Password: admin When using only the monitor function, If the [log in] button is selected after the username and select the [monitor only] button.

- Page 72 (5) When the [Login] or [Monitor only] button is selected, the following screen will be displayed. -71- EX※※-OMR1012...

- Page 73 (6) When the [Next] button is selected, the [SYSTEM CONFIGURATION STATUS screen] will be displayed. This screen is TOP. When a Unit Name is selected, the I/O Monitor screen will be displayed (page 74). Total I/O size is displayed. Select here to change the Username & Password, and clear Error Log. Select here to log out.

- Page 74 If the error of each unit occurs, diagnostic information is displayed on the [SYSTEM CONFIGURATION STATUS screen]. Indicates which unit the diagnostics was generated for. The diagnostic log data previously generated is displayed. -73- EX※※-OMR1012...

- Page 75 (7) When the [Unit Name] is selected on the [SYSTEM CONFIGURATION STATUS screen], the [I/O monitor screen] will be displayed. (Ex. EX600-DX D) Fig. I/O MONITOR -74- EX※※-OMR1012...

- Page 76 [I/O monitor screen] indicates which channel generated the error. Indicates which channel the diagnostics was generated for. -75- EX※※-OMR1012...

- Page 77 (8) When the [UNIT PARAMETER tab] is selected, the [UNIT PARAMETER screen] will be displayed. (Ex. EX600-DX D) When the [SET] button is selected after the set value has been changed, the parameter will be changed. -76- EX※※-OMR1012...

- Page 78 (9) When the [CHANNEL PARAMETER tab] is selected, the [CHANNEL PARAMETER screen] will be displayed. (Ex. EX600-DX D) When the [SET] button is selected after the set value has been changed, the parameter will be changed. <Clear method of ON/OFF Counter> Input “0”...

- Page 79 (10) When the [FORCE MODE tab] is selected, the following screen will be displayed. (Ex. EX600-DX B) (11) When [YES] button is selected, the [FORCE MODE screen] will be displayed. (Ex. EX600-DX B) Note Please do not select the [×] button to log out. Malfunction can result. -78- EX※※-OMR1012...

- Page 80 Accessories For the selection of accessories, refer to the catalog. (1)Valve plate EX600-ZMV1 Enclosed parts: Round head screw (M4 x 6), 2 pcs. Round head screw (M3 x 8), 4 pcs. EX600-ZMV2 (Specified for SY series) Enclosed parts: Round head screw (M4 x 6), 2 pcs. Round head screw (M3 x 8), 4 pcs.

- Page 81 (4)Seal cap (10 pcs.) EX9-AWES: For M8 EX9-AWTS: For M12 (5)Marker (1 sheet, 88 pcs.) EX600-ZT1 (6)Assembled type connector PCA-1446553: For EtherNet/IP communication, M12 (4 pin) Plug, D code PCA-1578078: For power supply, 7/8 inch, Plug, Cable O.D. 12 to 14 mm PCA-1578081: For power supply, 7/8 inch, Socket, Cable O.D.

- Page 82 Revision history Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer. EtherNet/IP™ is a trademark of ODVA The descriptions of products shown in this document may be used by the other companies as their trademarks. ©...

Need help?

Do you have a question about the EX600 Series and is the answer not in the manual?

Questions and answers