Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Atlas FM9SL

- Page 2 Read this entire manual before operation begins. Record below the following information which is located on the serial number data plate. Serial No. Model No. Date of Installation...

-

Page 3: Table Of Contents

Contents General Information..5 Product Identifi cation ..8 Packing; Transport; Storage ..10 Product Description ..12 Technical Specifi... - Page 4 Indicates the direction of access for motor vehicles to the lift BOLD Important information TYPE WARNING: before operating the lift and carrying out any adjustment, read carefully chapter 7 “Installation” where all proper operations for a better functioning of the lift are shown. FM9SL...

-

Page 5: General Information

• keep the manual in an area protected from the damp. • use this manual properly without damaging it. • any use of the machine made by operators who are not familiar with the instructions and procedures contained herein shall be forbidden. General Information FM9SL... - Page 6 Any other use which differs from that provided for by the manufacturer of the machine is strictly forbidden. The use of non genuine parts may cause damage to people or objects General Information FM9SL...

- Page 7 The manufacturer is not liable for any mistakes made when drawing up this manual and reserves the right to make any changes due the development of the product, at any time. General Information FM9SL...

-

Page 8: Product Identifi Cation

Machines may be updated or slightly modifi ed from an aesthetic point of view and, as a consequence, they may present different features from these shown, this without prejudicing what has been described herein. Product Identification FM9SL... - Page 9 Dealer where the machine has been bought or the Manufacturer’s Commercial Department. Only skilled personnel who are familiar with the lift and this manual shall be allowed to carry out packing, lifting, handling, transport and unpacking operations. Product Identification FM9SL...

-

Page 10: Packing; Transport; Storage

Packages must be stored in a covered place, out of direct sunlight and in low humidity, at a temperature between -10°C and +40°C. Stacking is not recommended: the package’s narrow base, as well as its considerable weight and size make it diffi cult and hazardous. Packing; Transport; Storage FM9SL... - Page 11 Packages must be opened paying attention not to cause damage to people (keep a safe distance when opening straps) and parts of the lift (be careful the objects do not drop from the package when opening). Packing; Transport; Storage FM9SL...

-

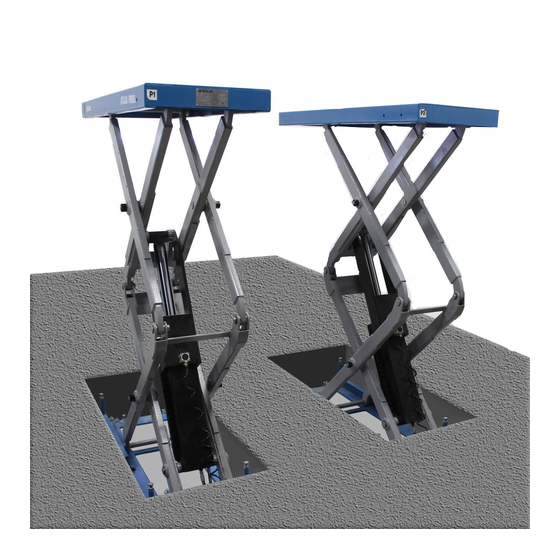

Page 12: Product Description

(7) placed next to the lift. The mechanical safety operating by a pneumatic cylinder is installed under each runway. Two limit switches are installed in the P2 base: for top position limit and for the safety height limit. Product Description FM9SL... - Page 13 In this way, the operator must verify that neither persons nor objects are within the safety area. If so, the fi nal lowering button can be pressed and the lift be lowered. A beeping sound is heard during the last travel. Product Description FM9SL...

-

Page 14: Technical Specifi Cation

The motor direction of rotation is shown in the label placed on the motor. Before use of the lift, make sure to check if the motor specifi cation shown in the nameplate of the motor conforms to the local electric supply. Technical Specification FM9SL... - Page 15 If there is over 10% fl uctuation on the electrical power supply, it is suggested to use the voltage stabilizer to protect the electrical components and system from overloading. Pump Type Gear Flow rate 2.1 cm 4.8 cm Continuous working pressure 240 bar Peak pressure 250 bar Technical Specification FM9SL...

- Page 16 Figure 2 - Layout Technical Specification FM9SL...

- Page 17 Hydrualic Power Unit Leveling cock N.C Motor (normally close) Emergency hand pump Leveling cock N.O (normally open) Lowering solenoid valve Pressure Emergency gauge lowering screw Figure 3 – Hydraulic Power Unit Technical Specification FM9SL...

- Page 18 ASTM D 2270 Viscosity index 104 N° ASTM D 97 Pour point ~ 30 °C ASTM D 92 Flash point 215 °C ASTM D 644 Neutralization number 0.5 mg KOH/g Change hydraulic oil at 1 year intervals Technical Specification FM9SL...

- Page 19 Slave platform cylinder P2 Emergency hand pump Leveling cock N.O (normally open) Gear pump Leveling cock N.C (normally close) Motor Pressure gauge Lowering speed control Non return valve Oil fi lter Pressure overload valve Parachute valve (optional) Technical Specification FM9SL...

- Page 20 Figure 5a – Electric Diagram (380V/400V - 3PH) Technical Specification FM9SL...

- Page 21 Lowering/fi nal lowering button Thermal relay Safety engaging button Transformer 63VA Override button Contactor DC Top limit switch Lowering solenoid valve Safety height limit switch Safety air valve Beeper Figure 5a – Electric Diagram (380V/400V - 3PH) (continued) Technical Specification FM9SL...

- Page 22 Figure 5b – Electric Diagram (220V/230V - 1PH) Technical Specification FM9SL...

- Page 23 Lowering/fi nal lowering button Thermal relay Safety engaging button Transformer 63VA Override button Contactor DC Top limit switch Lowering solenoid valve Safety height limit switch Safety air valve Beeper Figure 5b – Electric Diagram (220V/230V - 1PH) (continued) Technical Specification FM9SL...

- Page 24 Figure 6 – Pneumatic Plan Lubricator/pressure regulator can be supplied by the manufacturer on request. The pressure in the pneumatic line must be kept around 6bar – 8 bar. Technical Specification FM9SL...

-

Page 25: Safety

They also must carry out the following: • neither remove nor disconnect hydraulic, electric or other safety devices; • carefully follow the safety indications applied on the machine and included in the manual; • observe the safety area during lifting; Safety FM9SL... - Page 26 The operator must be sure no one is in danger before operating the lift. Bumping Risk When the lift is stopped at relatively low height for working, the risk of bumping against projecting parts occurs. Safety FM9SL...

- Page 27 Materials and procedures, suitable for the designed parameters of the lift, have been used by the manufacturer to build a safe and reliable product. Operate the lift only for the use it has been designed for and follow the maintenance schedule shown in the chapter “Maintenance”. Safety FM9SL...

- Page 28 The presence of unauthorized persons next to the lift and on the platforms is strictly forbidden during lifting as well as when the vehicle has been already lifted Any use of the lift other than that herein specifi ed can cause serious accidents to people in close proximity of the machine. Safety FM9SL...

-

Page 29: Installation

The surface where the lift has to be installed must be even and leveled in all directions. An inclination not higher than 2 cm in drive-on lift direction and 1 cm cross-wise can be balanced with leveling wedges. Installation FM9SL... - Page 30 • Place the control unit in the position provided for (the control unit can be place in either right side or left side). Installation FM9SL...

- Page 31 • Open the front cover of the control unit. • Referring to Figure 14 route hydraulic lines through the hole in the prepared pit. • Connect hydraulic hoses to the fi ttings referring to the letters shown on them. • Tighten thoroughly. Installation FM9SL...

- Page 32 fi ttings clean from dust. Failure to do so may result in hydraulic line failure which may result in damage or personal harm. Figure 14 – Hydraulic Connections Installation FM9SL...

- Page 33 The control unit must be kept dry. • Make the electric hookup to the hydraulic power unit referring to the attached wiring diagram (Figure 5) using the included cables; • Make sure the connection of the phases is right and the lift is grounded. Installation FM9SL...

- Page 34 • Feed the lift by Power Switch • Verify that the motor direction of rotation is that shown on the label by pushing the lifting button. IF MOTOR GETS HOT OR SOUNDS PECULIAR, STOP IMMEDIATELY AND RECHECK THE ELECTRIC CONNECTIONS Installation FM9SL...

- Page 35 • Raise the lift by pressing the lifting button until the lift is raised at the top limit position; • Open the top cover of the control panel to locate the override button (2); • Keep press the override button for a few seconds until two platforms are in the same height; Installation FM9SL...

- Page 36 P2 until two platforms are at the same height; • Turn off the leveling cock N.C and turn on the leveling cock N.O after the adjustment. After adjusting level of the lift, reset ordinary operating conditions. Installation FM9SL...

- Page 37 Limit switches must be adjusted during the installation of the lift Two limit switches are installed on the P2 base for the top position and the safety height. If limit switches were not functioning properly, it’s possible to adjust them in the following way: Installation FM9SL...

- Page 38 • the lift for reaching its maximum height • the top limit switch for proper operation, adjust if necessary • the safety limit switch for proper operation, adjust if necessary • the beeper for proper operation during the fi nal travel Installation FM9SL...

- Page 39 Carry out two or three complete cycles of lowering and lifting and check: • Repeat the 7.11 section • Check no strange noise during lifting and lowering • If the platforms weren’t leveled, repeat the 7.8 section Installation FM9SL...

-

Page 40: Operation And Use

If an anchor bolt becomes loose or any component of the lift is found to be defective, DO NOT USE THE LIFT until repairs are made. Do not permit the electric control unit to get wet! Controls Figure 18 - Control Panel Operation And Use FM9SL... - Page 41 • When pressed, at fi rst the lift takes 1-2 seconds to clear off the safety, and then descends to the safety height. • When pressed with the lift at the safety height, the lift is lowered to the ground. A beeping sound is heard during the last travel. Operation And Use FM9SL...

- Page 42 • Push the lifting button to raise the lift a little bit to clear off the safeties; • Press the lowering button to carry out lowering. The lift will take seconds to release the safeties then it will descend to a safety height; Operation And Use FM9SL...

- Page 43 Screwing or loosing the screw can reduce or increase the lowering speed. After manual lowering of the lift, reset ordinary operating conditions. Lift cannot be lifted if solenoid valves are opened. Operation And Use FM9SL...

-

Page 44: Maintenance

The use of water or infl ammable liquid is strictly forbidden. Be sure the rod of the hydraulic cylinders is always clean and not damaged since this may result in leakage from seals and, as a consequence, in possible malfunctions. Maintenance FM9SL... - Page 45 • a check of the electrical system to verify that Every 12 Electrical motor, limit switch, and control panel operate months system properly must be carried out by skilled electricians • empty the oil tank and change the hydraulic Maintenance FM9SL...

-

Page 46: Troubleshooting

The lowering solenoid valve does Check and clean, if dirty, or is pressed not close replace, if faulty The emergency screw of Retighten the screw lowering valve does not close The suction pump fi lter is dirty Check and clean if needed Troubleshooting FM9SL... - Page 47 The motor does not operate the safety properly and does not release Check the motor height the mechanical safeties Check the lowering button The lowering button is faulty and connection for proper operation. Replace, if needed Troubleshooting FM9SL...

- Page 48 Leakages or presences of air into Bleed the hydraulic system hydraulic circuit The lift does not The pump fi lter is dirty Check and clean if needed lift or lower smoothly Check the seal and replace if The pump suction is blown needed Troubleshooting FM9SL...

-

Page 49: Parts Breakdown

Parts Breakdown Lift Item Part No. Description J32T010000 Runway P1 J32T020000 Runway P2 7335D03000 Control unit Parts Breakdown FM9SL... - Page 50 Runway P1 Parts Breakdown FM9SL...

- Page 51 Self-lubricated bush 3024 0210018 Self-lubricated bush 3055 0210022 Self-lubricated bush 3525 0210028 Self-lubricated bush 3560 0203025 Nut M16 0201103 Screw M16X50- GB/T5781 J32AY12000 Master hydraulic cylinder GJ300-400008 Steel shim 1 GJ300-400009 Steel shim 2 0205023 Washer D.24- GB/T95 Parts Breakdown FM9SL...

- Page 52 Nylon head M8X10 GJ300-800002 Air divider 0201019 Screw M6X30- GB/T5781 0306033 90° union 8-1/8 J32A110101 Wheel limit 0202047 Screw M8X25 - GB/T70.1 0205008 Washer D.8 - GB/T97.1 J32T210000 Table J32A220000 Pull plate 0202030 Screw M6X10 - GB/T70.1 Parts Breakdown FM9SL...

- Page 53 Runway P2 Parts Breakdown FM9SL...

- Page 54 Self-lubricated bush 3024 0210018 Self-lubricated bush 3055 0210022 Self-lubricated bush 3525 0210027 Self-lubricated bush 3550 0203025 Nut M16 0201103 Screw M16X50- GB/T5781 J32AY10000 Slave hydraulic cylinder GJ300-400008 Steel shim 1 0205023 Washer D.24- GB/T95 GJ300-400009 Steel shim 2 Parts Breakdown FM9SL...

- Page 55 Screw M6X30- GB/T5781 J32A800201 Switch support J32A800202 Limit plate 0206030 Screw M5X8 - GB/T818 J32A110101 Wheel limit 0202047 Screw M8X25 - GB/T70.1 0205008 Washer D.8 - GB/T97.1 J32T210000 Table J32A220000 Pull plate 0202030 Screw M6X10 - GB/T70.1 Parts Breakdown FM9SL...

- Page 56 Top cover 0206059 Screw M4X8 0508330 Guide DZ47- L=80mm 0508330 Guide DZ47- L=60mm 0507367 CPU board 102.1 0206058 Screw M5X10 0510380 Grounding decal 0206019 Screw M4X6 - GB/T818 0508017 Cable relief GM-2314 J04A110001 Support 0508018 Holder HC-1(Φ4) Parts Breakdown FM9SL...

- Page 57 Washer D.3 - GB/T97.1/3 0208001 Washer D.3 - GB/T93/3 0203001 Nut M3 - GB52 J04A031000 Lower box J04A030003 Front cover 0206028 Screw M5X25 0207019 Screw M8X20 - GB/T819.1 3032084008 Rubber pad 3002005001 Support BZ-W4LY Hydraulic power unit Parts Breakdown FM9SL...

- Page 58 Hydraulic Power Unit Parts Breakdown FM9SL...

- Page 59 90° union 1/4 1T9-04SP 0305001 Plug ZBJ22 007-QD07 BZ-W-YL Interface block 0203004 Nut M6-GB52 0213045 Double-screw bolt M6X120-GB/T901 0309019 O-ring 18X2.4 - GB1235 0307006 Lowering speed control valve BLF06-02-00/Φ2.5 0307049 Lowering solenoid valve (AC220V) 0301034 Manual pump QTHB-14 Parts Breakdown FM9SL...

- Page 60 Seal Φ16XΦ9X2.5 (For 1PH motor) 44.2 BZ-HC2-1 Valve body (For 1PH motor) 44.3 BZ-HC-2 Valve piston (For 1PH motor) 44.4 BZ-HC2-3 Valve pin (For 1PH motor) 44.5 BZ-HC2-4 Spring (For 1PH motor) 44.6 BZ-HC2-5 Valve back cover (For 1PH motor) Parts Breakdown FM9SL...

- Page 61 Slave hydraulic cylinder 7330-ZW4900 Hydraulic hose L=4900 7330-ZZ3160 Hydraulic hose L=3160 7330-ZZ320 Hydraulic hose L=320 7335-ZZ2320 Hydraulic hose L=2320 0303021 Tee union 1/4(AB-04) 0303065 Union 1/4 (1B-04) 0313001 Washer 1/4 0303002 90° union 1/4(1BT9-04SP) 0306067 90° union 10-1/4 Parts Breakdown FM9SL...

- Page 62 J32AY12803 Sealing ring J32AY10100 Slave cylinder liner 0312032 Gasket 100X86X22.5 YF658003 Piston J32AY10802 Cylinder shaft J32AY10801 Cylinder guiding cover 0305006 Guide ring 50X25X2.5 0311010 Scraper 50X58X5 0310015 Seal 50X50X6 0309080 O-ring 92.5X5.3 – GB3452.1 J32AY10803 Sealing ring Parts Breakdown FM9SL...

-

Page 63: Warranty

RETURNS: Products may not be returned without prior written approval from the Manufacturer. DUE TO THE COMPETITIVENESS OF THE SELLING PRICE OF THESE LIFTS, THIS WARRANTY POLICY WILL BE STRICTLY ADMINISTERED AND ADHERED TO. Warranty FM9SL...

Need help?

Do you have a question about the FM9SL and is the answer not in the manual?

Questions and answers