Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Steris Cmax

- Page 2 Operator Manual ......................P150830-685 Maintenance Instructions ................... P764333-268 Illustrated Parts Breakdown ..................P764333-269 Reference Drawings Schematic, Cmax Tables Hydraulic System ............. W755718-023 Schematic, Cmax Electrical System ................150832-407 Schematic, Cmax Floor Lock System ................150832-406 Schematic, Power Supply/Battery Charger (120 V; 542200902) ........5-536-4 D Schematic, Power Supply/Battery Charger (220 V;...

- Page 3 Live Document, Historical Table Live Document Figure Number/ Name Manual Development Historical Record Page Number (Front P: Stamp "12/09/2010 LIVE DOCUMENT" C: Document Manufacturing Front Cover changes/manual errors and clarifications A: Stamped to show Live Document Date Cover) P: Part numbers 542201-902 and 542200-902 are NLA C: Manufacturing changed the part A: The 542200-902 will be replaced by ·...

- Page 5 Complete instructions for uncrating have been furnished. If missing, contact STERIS for a replacement copy, giving the serial, equipment and model numbers of the unit. STERIS carries a complete line of accessories for use with this table. STERIS representatives will gladly review these with you. Advisory...

- Page 6 STERIS maintains a global staff of well equipped, factory-trained technicians to provide these services, as well as expert repair services.

- Page 7 STERIS House Jays Close Viables Basingstoke Hampshire RG22 4AX UNITED KINGDOM Manufactured by: STERIS Surgical Technologies SAS 645, rue des Châtaigniers BAT 405-B2-F 45774 Saran Cedex FRANCE + 33 2 38 74 54 00 Manufactured by: STERIS Corporation 2720 Gunter Park East Montgomery, AL 36109 •...

-

Page 8: Table Of Contents

TABLE OF CONTENTS Section Number Description Page Safety Precautions ........................1-1 Important User Information ......................2-1 Pinch Point Warnings ..........................2-1 Patient Positioning and Weight Limitation ..................... 2-3 Patient Safety Straps ..........................2-4 General Description ..........................2-4 Technical Specifications ........................2-5 2.5.1 Overall Size (W x L x H) ...................... - Page 9 TABLE OF CONTENTS (CONT’D) Section Number Description Page Cleaning Table............................5-2 5.2.1 General ............................5-2 5.2.2 After Each Usage ......................... 5-3 5.2.3 End-of-Day Cleaning Procedure ....................5-4 5.2.4 Weekly Cleaning Procedure......................5-4 Bi-Weekly Maintenance ......................... 5-4 Monthly Maintenance..........................5-4 Battery Charging Procedure ........................5-5 Preventive Maintenance Schedule ......................

- Page 10 Figure 2-1. Pinch Points............................2-1 Figure 2-2. Pinch Points............................2-2 Figure 2-3. Cmax Surgical Table Components (Typical) ..................2-6 Figure 2-4. Cmax Surgical Table Range of Motion (Typical) .................2-7 Figure 2-5. Cmax Tabletop Dimensions (Typical)....................2-8 Figure 2-6. Cmax Surgical Table Image Amplification Coverage ................2-9 Figure 3-1.

- Page 11 Definition of Symbols on Surgical Table..................1-5 Table 4-1. Cmax Surgical Table Specific Accessories ................... 4-16 Table 5-1 Recommended Cleaning Products....................5-2 Table 5-2 Preventive Maintenance Schedule for Cmax Surgical Table ............5-7 Table 5-3. Replacement Parts.......................... 5-9 Table 6-1 Troubleshooting Chart........................6-2 Table 6-2.

-

Page 12: Safety Precautions

SAFETY PRECAUTIONS ™ The following Safety Precautions must be observed when operating or servicing this Cmax Surgical Table. WARNING indicates the potential for personal injury and CAUTION indicates the potential for damage to equip- ment. For emphasis, certain Safety Precautions are repeated throughout the manual. It is important to review ALL Safety Precautions before operating or servicing the unit. - Page 13 WARNING – INSTABILITY HAZARD: Possible patient or user injury, as well as table or accessory failure, may result from using STERIS table accessories for other than their stated purpose – or from using, on STERIS tables, accessories manufactured and sold by other companies.

- Page 14 WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD: Repairs and adjustments to this equipment must be made only by STERIS or STERIS-trained service personnel. Maintenance performed by unqualified personnel or installation of unauthorized parts could cause personal injury, result in improper equipment performance, invalidate the warranty, or result in costly damage.

- Page 15 Route the hand control cord clear of any pinch points where cord could be damaged. Use of incorrect hydraulic oil may severely damage the table and/or cause malfunction. Contact STERIS for proper hydraulic oil. After performing cleaning procedures, ensure pads, tabletop and x-ray tops are completely dry before reinstalling.

-

Page 16: Table 1-1. Definition Of Symbols On Surgical Table

1.1 Symbols on Table The following is a key to symbols on the Cmax Surgical Table. Table 1-1. Definition of Symbols on Surgical Table Symbol Definition Type B Equipment Protective Earth Ground Equipotentiality Electric Shock Hazard Control Power ON Control Power OFF... - Page 17 Table 1-1. Definition of Symbols on Surgical Table (Cont’d) Symbol Definition Serial Number of the Unit IPX4 Splash-Proof Equipment ® INTELLIPOWER Dual Power System Power Panel (Battery Charge/Discharge Status) CHARGE BATTERY INTELLI POWER Powered By Battery 150830-685 Operating Manual Safety Precautions...

-

Page 18: Important User Information

(see Warnings Figure 2-1). All personnel involved in tabletop positioning should ™ examine and be aware of these points before operating the Cmax WARNING – PINCHING Surgical Table. HAZARD: Pinch points shown (circled) in Figure 2-1: •... -

Page 19: Figure 2-2. Pinch Points

FIG. 3.1 PINCH POINTS BATT -C.M Figure 2-2. Pinch Points 150830-685 Operator Manual Important User Information... -

Page 20: Patient Positioning And Weight Limitation

Weight Limitation accessory. WARNING – TIPPING The Cmax General Surgical Table is designed to safely support (with HAZARD: patient in normal orientation): 1100 lb (499 kg) without patient posturing or tabletop slide (except raise/lower); 1000 lb (454 kg) full •... -

Page 21: Patient Safety Straps

Electromagnetic Compatibility radiological access without patient reversing. (EMC). There is, however, a potential for electromagnetic The Cmax Surgical Table is powered by either internal battery or or other interference between ® facility electric through use of the patent-pending INTELLIPOWER this equipment and other dual power system. -

Page 22: Technical Specifications

• The Cmax Surgical Table should not be used adjacent to or IEC 60601-1-2:2001, Medical stacked with other equipment. If so, table should be observed to Electrical Equipment - Part 1;... -

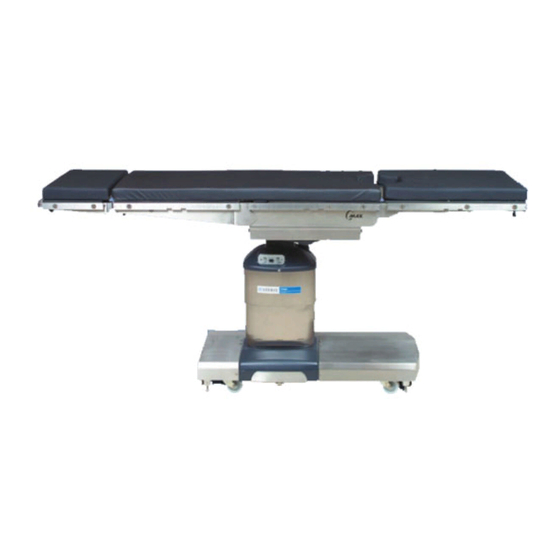

Page 23: Figure 2-3. Cmax Surgical Table Components (Typical)

16. Electrical Characteristics Label 7. Seat Section (Sliding) 17. Data Plate 8. Leg Section 18. Primary Fuses 9. Power Panel 19. Main Power Switch 10. Power Cord 20. AC Receptacle Figure 2-3. Cmax Surgical Table Components (Typical) 150830-685 Operator Manual Important User Information... -

Page 24: Figure 2-4. Cmax Surgical Table Range Of Motion (Typical)

Dimensions are inches (mm). SAE measurements are approximate based on metric dimensions. 9 (227) 9 (227) (1136) (675) 90° 90° 40° 105° 90° 20° 4 (110) 30° 20° 30° 90° (51) 140° Figure 2-4. Cmax Surgical Table Range of Motion (Typical) Important User Information Operator Manual 150830-685... -

Page 25: Weight

100-240 Vac, One-Phase, 50/60 Hz, 4.0 Amp NOTE: Each table is shipped from the factory configured to the electrical requirement specified on the factory order. If this electrical configuration needs to be changed in the field,consult STERIS for the needed procedure and required materials. 2.5.6 Environmental Temperature: 32-122°F (0-50°C) -

Page 26: Figure 2-6. Cmax Surgical Table Image Amplification Coverage

13” (635 mm) (1090mm) (635mm) (330mm) (1090 mm) (330 mm) Column 43” 13” 13” 25” 43” 25” (330 mm) (1088mm) (1088 mm) (330mm) (637 mm) (637mm) Figure 2-6. Cmax Surgical Table Image Amplification Coverage Important User Information Operator Manual 150830-685... -

Page 27: Installation Instructions

Any alteration of this equipment not authorized or performed • If the integrity of the by STERIS will void the warranty, could adversely affect proper table external protective ground functioning, could violate national, state and local regulations. -

Page 28: Figure 3-1. Install/Remove Battery Fuse

SERVE Figure 3-1. Install/Remove Battery Fuse NOTE: A green Main Power Switch indicates facility power is available to the Cmax table. A lighted plug symbol on the LED Display indicates the batteries are charging. Refer to S 5.5, B ECTION... -

Page 29: Figure 3-2. Connect Cmax Surgical Table To Facility Power

Ensure caps cover SERVE Foot End Head End Figure 3-2. Connect Cmax Surgical Table to Facility Power Install head section as follows: a. Fully loosen both locking thumbscrews located at bottom edge of back frame (see Figure 3-6). b. Insert both head section installation rods into back frame until fully engaged. -

Page 30: Figure 3-3. Connect Hand Control To Cmax Surgical Table

Install leg section as follows: NOTE: The Cmax Surgical Table is equipped with Hi-Lock™ locking mechanism enabling quick and easy removal/installation of the leg section with a safety lock feature. a. Using hand control, position table top seat section to horizontal by pressing LEG UP button (refer to S 4.2,... -

Page 31: Figure 3-4. Connect Panel

Figure 3-4. Connect Panel Protective Cover Control Ensure caps cover sockets when not in use. Panel SERVE Disconnect Foot Control Connect Foot Control Figure 3-5. Connect Optional Foot Control to Cmax Surgical Table Installation Instaructions Operator Manual 150830-685... -

Page 32: Figure 3-6. Install Head Section

Figure 3-6. Install Head Section Angle Value Figure 3-7. Hand Control LCD Display 150830-685 Operator Manual Installation Instaructions... -

Page 33: Figure 3-8. Attaching Leg Section

WARNING – PERSONAL «Click» INJURY HAZARD: The table leg section is designed to support the patient legs. Do not put body weight on the leg section. Figure 3-8. Attaching Leg Section Installation Instaructions Operator Manual 150830-685... -

Page 34: Operating Instructions

NOTE: If the Hand Control AND Foot Control are installed, Hand nerve pathways, or Control has priority. Also, the Cmax Table Head Section is manually circulation. adjusted as follows (if Head Section is not installed, refer to S ECTION •... -

Page 35: Figure 4-2. Head Section Operation (Typical)

NOTE: A patient grounding post/potential equalization terminal (male chest compressions. connector, DIN 42801) is provided. The mating female connector for WARNING – PERSONAL patient grounding is not furnished by STERIS. INJURY HAZARD: The Table Leg Section is designed to support the patient legs. Do not put body weight on the Leg Section. -

Page 36: Hand Control

The hand control is reactivated by depressing ANY button but OFF. The Cmax Surgical Table is equipped with a hand control (see Figure 4-3). This hand control contains easy-to-read icons and illuminates the key pad for easy articulation identification when room is dark. -

Page 37: Figure 4-3. Cmax Surgical Table Hand Control

HEIGHT UP: When depressed, the entire tabletop will rise. The LCD Display HEIGHT value will change accordingly. HEIGHT DOWN: When depressed, the entire tabletop will lower. The LCD Display HEIGHT value will change accordingly. Figure 4-3. Cmax Surgical Table Hand Control 150830-685 Operator Manual Operating Instructions... - Page 38 TREND: When depressed, the head end of the tabletop will lower; or, foot end will raise. The LCD Display TREND value will change accordingly. REV. TREND: When depressed, the head end of the tabletop will rise; or, foot end will lower. The LCD Display TREND value will change accordingly.

-

Page 39: Hand Control Lcd Display Description

NOTE: When table is in the UNLOCK configuration, NO tabletop functioning is active. If a tabletop function button is pressed while table is in the UNLOCK configuration, the LCD Display will show LOCK TABLE. OFF: When depressed, all hand control function buttons deactivate. All functions are stopped immediately. - Page 40 KIDNEY Elevator Mechanism (9): when T symbol is ON, Kidney Elevator Mechanism is UP; no T symbol, KIDNEY Elevator is at level WARNING – PERSONAL position. INJURY AND/OR EQUIPMENT Auto Limit Sensors (ALS) Warning (10): indicates the tabletop has DAMAGE HAZARD: The Auto been ordered into a configuration or has moved into a position that Limit Sensor (ALS) System may cause tabletop damage or patient injury.

-

Page 41: Figure 4-4. Hand Control Lcd Display

SENSORS 03" 20° 04° 00" TREND TILT 00° 00° SLIDE HEAD ! inches/46cm) rg angle value KEY: 1. LCD Display 2. LCD Status Indicators 3. Height Level 4. Trendelenburg/Reverse Trendelenburg Angle 5. Lateral Tilt Angle 6. Back Section Angle 7. Leg Section Angle 8. -

Page 42: Reverse Patient Orientation

Before any new positioning is attempted, ensure table patient configuration is correct. 3) The Cmax Table Head Section is manually adjusted and will not be affected by REV. ORIENT button operation. 4) FLEX and REFLEX functions are NOT available for patient safety. -

Page 43: Auxiliary System Operation

4.5.1 Auxiliary System To operate system, proceed as follows: Operation 1. Flip pedal down (see Figure 4-5). 2. Pull drawer out and remove auxiliary hand control. 3. Return drawer to table. 4. To operate table functions, pump pedal while pressing desired function button on auxiliary hand control (see Figure 4-6). -

Page 44: Auxiliary Hand Control Description

The auxiliary hand control pushbutton descriptions are as follows Description (Figure 4-6): NOTE: Simply release the auxiliary hand control pushbutton when desired Cmax Tabletop position has been reached and table will automatically stop and lock in position. Refer to S 2.5.2, ECTION... -

Page 45: Return Auxiliary Control System

5. Fold pedal back to original position. Pump Line Green LED Figure 4-6. Auxiliary Hand Control 4.6 Leg Section The Cmax Surgical Table leg section is designed to be easily Removal ™ removed (Hi-Lock locking mechanism) to enable procedures requiring optional leg supports. Remove the leg section as follows:... -

Page 46: Figure 4-7. Leg Section Removal

3. Safely store leg section to prevent damage. positioned. Patient's torso and NOTE: When leg section is removed from the Cmax Surgical Table, buttocks must be firmly held the LCD Display will show a blank display for angle value and LEG... -

Page 47: X-Ray Top Installation

Figure 4-8. Tabletop Pads 4.8 X-Ray Top The Cmax Surgical Table is designed to enable installation of an X- ray top to allow use of X-ray cassette film. Attach the four-part X-ray Installation top as follows (see Figure 4-9): 1. Carefully remove X-ray top sections from packing container. -

Page 48: Accessories/Side Rails

SERVE Figure 4-9. X-Ray Top Installation 4.9 Accessories/Side The standard STERIS permanently attached 3/8" wide x 1-1/8" tall side rails allow for the use of many standard surgery table Rails attachments and accessories. The rails consist of one rail mounted to each side of each tabletop main section. -

Page 49: Table 4-1. Cmax Surgical Table Specific Accessories

WARNING – PERSONAL Table 4-1. Cmax Surgical Table Specific Accessories* INJURY HAZARD: When installing any table accessory, Accessory Equipment Number check for correct attachment and tighten securely (if Foot Control BF58-600 appropriate). Do not use a Hand Control BF61-000 worn or damaged accessory. -

Page 50: Routine Maintenance

Contact STERIS for details. performed by unqualified Maintain a record of all maintenance procedures performed on this personnel or installation of Cmax Surgical Table. If a problem occurs, refer to S ECTION unauthorized parts could , or contact STERIS. -

Page 51: Cleaning Table

Disinfecting/Deoderizing/ INJURY HAZARD: When Cleaning Wipes cleaning/disinfecting table, do not use phenolics, which may cause patient skin burns if * Contact STERIS for ordering information. inadequately rinsed off, or alcohol, which does not have sufficient cleaning/ disinfection properties. 5.2.1 General... -

Page 52: After Each Usage

5.2.2 After Each Usage After each use of the Cmax Surgical Table, clean/disinfect as follows: WARNING – INFECTION NOTE: Ensure all protective covers are installed over any open HAZARD: To protect against receptacles. aerosols being reflected from potentially contaminated 1. Remove gross soil with a disposable cloth and place used cloth surfaces, wear rubber or in an appropriate biohazardous waste disposal container. -

Page 53: End-Of-Day Cleaning Procedure

At the end of each day, perform the cleaning procedures as outlined in S 5.2.2, A Procedure ECTION FTER SAGE 5.2.4 Weekly Cleaning After each weekly use of the Cmax Surgical Table, clean/disinfect table as follows: Procedure 1. Perform Steps 1 through 4 of S 5.2.2, A ECTION FTER SAGE 2. -

Page 54: Battery Charging Procedure

Main Power Switch is set to ON (lighted green) and the ac power is and adjustments to this connected to the Cmax Surgical Table. The PLUG icon appears on equipment must be made only Power Panel LED Display (see Figure 5-1) indicating ac power and by STERIS or STERIS-trained diode bar indicates battery condition. -

Page 55: Figure 5-1. Intellipower Panel Led Display

table operation without damaging the batteries. However, when the last green diode bar is OFF, batteries must be recharged without further delay or battery damage will occur. If all diodes are OFF, batteries are completely drained and the table can only operate on main facility power. -

Page 56: Preventive Maintenance Schedule

ECTION be performed regularly at the indicated intervals. Use the Preventive Maintenance Schedule Maintenance Schedule in Table 5-2 as a guide for further Cmax Surgical Table maintenance. Table usage may require more frequent WARNING – PERSONAL maintenance than indicated. See S 5.7 for R... -

Page 57: Replacement Parts

Table 5-2. Preventive Maintenance Schedule for Cmax Surgical Table (Cont’d) Service Required Minimum Frequency Verify condition of batteries and battery charger status. 1 x per year Verify Auto Limit Sensor status. 1 x per year 6.0 TABLETOP OPERATION Check operation of Level function. -

Page 58: Als Check

542200240 Pad, Leg Section 542200241 5.8 ALS Check The Cmax Surgical Table is equipped with the Auto Limit Sensor system. This system provides instant user feedback on any WARNING – PERSONAL conflicting tabletop articulations. An Auto Limit Sensors (ALS) Warning (refer to Fig. 4-4, Item 10) on the hand control indicates the... -

Page 59: Level Check

Trendelenburg and back. c. Leg. NOTE: The LCD Display values will change accordingly. 4. Use a level and ensure tabletop is level. If not, call STERIS. 5.10 Auxiliary Control Check the Cmax Surgical Table auxiliary control system as follows: Check 1. -

Page 60: Troubleshooting

• Failure to perform periodic STERIS. Service charges may be incurred, consult your warranty for inspections of the table ™ details. A trained service technician will promptly place your Cmax could result in serious Surgical Table in proper working order. personal injury or table damage. -

Page 61: Table 6-1 Troubleshooting Chart

Faulty power cord – replace. is pressed . Hand control not plugged in properly – correct. Faulty hand control** – replace. Call STERIS.* Table remains on battery power even when main Incorrect power cord connection – correct. power cord is plugged into facility power. -

Page 62: Table 6-2. Troubleshooting Chart (Lcd Message)

Table 6-2. Troubleshooting Chart (LCD Message) FAULT DISPLAYED FAULT DESCRIPTION FAULT ACTION 1 KEY ONLY Two pushbuttons are pressed at the same Press one button only time DUAL COMMAND Commands are sent from the optional foot Hand control has priority pedal and the hand control at the same time. - Page 63 542200240 Pad, Leg Section 542200241 5.8 ALS Check The Cmax Surgical Table is equipped with the Auto Limit Sensor system. This system provides instant user feedback on any WARNING – PERSONAL conflicting tabletop articulations. An Auto Limit Sensors (ALS) Warning (refer to Fig. 4-4, Item 10) on the hand control indicates the...

- Page 64 Live Document, Historical Table Live Document Figure Number/ Name Manual Development Historical Record Page Number (Front P: Stamp "11/09/2011 LIVE DOCUMENT" Document Manufacturing Front Cover changes/manual errors and clarifications A: Stamped to show Live Document Date Cover) P: Hand Control Assembly P150832-500 subs to a new number Table 5-3 Replacement Parts R: P150832-632...

- Page 66 , for a list of terminology used in this document. EFINITIONS Thank you for choosing this fine STERIS product. INDICATIONS FOR USE STERIS is committed to ensuring your continued The Cmax Surgical Table is designed for most surgical satisfaction. This manual contains...

- Page 67 EC Authorized Representative STERIS Limited STERIS House Jays Close Viables Basingstoke Hampshire RG22 4AX UNITED KINGDOM Manufactured by: STERIS Corporation 2720 Gunter Park East Montgomery, AL 36109 • USA Class 1 Equipment Type B Equipment Classified as IPX4 (Splash-proof) Equipment not suitable for use...

- Page 68 TABLE OF CONTENTS Section Number Description Page Safety Precautions ........................1-1 Terms, Definitions, Symbols and Special Tools................. 2-1 Terms and Definitions ..........................2-1 Symbols ..............................2-1 Special Tools/Materials Required for Maintenance ................2-1 Principles of Operation ......................... 3-1 General ..............................3-1 Table Overview .............................

- Page 69 TABLE OF CONTENTS (CONT’D) Section Number Description Page 4.10 Leg Section Checks ..........................4-8 4.11 Replacement Parts and Supplies ......................4-8 Troubleshooting ..........................5-1 General ..............................5-1 Electrical Troubleshooting ........................5-7 Field Test Procedure ........................6-1 General ..............................6-1 Test Instrumentation Needed ........................ 6-1 Table Level Calibration ..........................

- Page 70 TABLE OF CONTENTS (CONT’D) Section Number Description Page 7.13 Auxiliary (Backup) Hand Control Replacement..................7-8 7.14 Table Column Cover Cap Replacement ....................7-9 7.15 Height Sensor Replacement ........................7-9 7.16 Table Control (CPU) Board Replacement.................... 7-10 7.17 Tilt Cylinder Replacement........................7-10 7.18 Trendelenburg Cylinder Replacement ....................

-

Page 71: Description Page

LIST OF FIGURES Description Page Figure 4-1. INTELLIPOWER Panel LED Display (Typical) ................... 4-5 Figure 4-2. Install/Remove Battery Fuse (Typical)....................4-7 Figure 6-1. Table Sensor Calibration ........................6-2 Figure 6-2. Table Sensor Calibration ........................6-4 Figure 6-3. Lower Lift Column..........................6-5 Figure 6-4. - Page 72 LIST OF FIGURES (CONT’D) Description Page Figure 7-31. Properly Secure Tabletop ....................... 7-12 Figure 7-32. Disconnect Hydraulic Lines From Main Valve Block ..............7-12 Figure 7-33. Remove Tabletop Seat Section ...................... 7-13 Figure 7-34. Remove Tabletop Kidney Section ....................7-13 Figure 7-35.

- Page 73 Definition of Symbols on Hand Control ................... 2-3 Table 2-3 Tools for Cmax Surgical Table Maintenance .................. 2-5 Table 3-1 Cmax 110 Master Control and Hand Control Assembly Compatibility Matrix ......... 3-7 Table 4-1 Preventive Maintenance Schedule for the Cmax Surgical Table ............ 4-2 Table 4-2 Cmax Surgical Table Replacement Parts ..................

-

Page 74: Safety Precautions

If an antistatic path is necessary, STERIS recommends antistatic pads (specifically developed for this table) be placed in direct contact with the patient. STERIS recommends that the table be positioned on antistatic floor or connected to equalization device (equipotential connector). - Page 75 Do not store items on table base. Doing so may result in equipment damage or inadvertent tabletop movement placing the patient and/or user at risk of injury. Repairs and adjustments to this equipment must be made only by STERIS or STERIS-trained service personnel. Maintenance performed by unqualified personnel or installation of unauthorized parts could cause personal injury, result in improper equipment performance, invalidate the warranty or result in costly damage.

- Page 76 Route the hand control cord clear of any pinch points where cord could be damaged. Use of incorrect hydraulic oil may severely damage the table and/or cause table malfunction. Contact STERIS for proper hydraulic oil. After performing cleaning procedures, ensure pads and tabletop are completely dry before reinstalling.

- Page 77 CAUTION – POSSIBLE EQUIPMENT DAMAGE (CONT’D): When the bearing assembly is removed from the table, the seat section side member becomes free- floating. Be careful not to damage the slide potentiometer pulley that sits freely in the groove in the seat section side member.

-

Page 78: Terms, Definitions, Symbols And Special Tools

LCD Display - Hand Control Liquid Crystal Display indicating table status, tabletop positioning and Table 2-1 and Table 2-3 contain symbols which may control system messages to user. appear on your Cmax Surgical Table and/or Hand LED - Light Emitting Diode. Control. 764333-268... -

Page 79: Special Tools/Materials Required For Maintenance

Table 2-3 shows tools and packs necessary to repair and maintain the Cmax Surgical Table. It is important Table 2-1. Definition of Symbols on Surgical Table Symbol... - Page 80 Table 2-1. Definition of Symbols on Surgical Table (Cont’d) Symbol Definition Alternating Current Frequency Rating of Unit Power Rating Serial Number of the Unit IPX4 Splash-Proof Equipment ® INTELLIPOWER Dual Power System Power Panel (Battery Charge/Discharge Status) CHARGE BATTERY INTELLI POWER Powered By Battery Table 2-2.

- Page 81 Table 2-2. Definition of Symbols on Hand Control (Cont’d) Symbol Definition Height Down (Tabletop Down; Lower) Move Tabletop into Trendelenburg Move Tabletop into Reverse Trendelenburg Floor Lock Function Floor Lock Locked Floor Lock Unlocked Kidney Up Kidney Down Leg Up Leg Down Back Up 764333-268...

- Page 82 Table 2-2. Definition of Symbols on Hand Control (Cont’d) Symbol Definition Back Down Slide Head Slide Foot Flex Reflex Table 2-3. Tools for Cmax Surgical Table Maintenance Part Number Tool Quantity P752911-091 Wrench - Socket Set, Inch and Metric, Deep Well P764324-655...

-

Page 83: Principles Of Operation

The Cmax Surgical Table is powered by either internal battery or facility electric power through use of the The following sections give a detailed description of the patent-pending INTELLIPOWER dual power system ®... -

Page 84: Optional Foot Control Operation

3) When any key is pressed on backup hand control, the green LED should light indicating system is The Cmax Surgical Table may be operated using the active. optional Foot Control as follows: 4) The ALS System is NOT active during Auxiliary 1. -

Page 85: Electrical System

Reverse Trendelenburg 3.4.1 Overview articulations involve the use of one hydraulic cylinder. The Cmax Surgical Table control system is designed for 3.3.2.6 Back Up/Down maximum reliability and includes adequate system redundancy for almost any circumstance. The control Refer to Hydraulic System Schematic (755718-023)behind system utilizes microprocessor technology to control the Tab. -

Page 86: System Function

Flash ROM. Solenoid (P150832-769) may be configured for either the outputs are generated by open-collector drivers. A Cmax 110 NA, the 4085 General, the 5085 watchdog timer and appropriate software monitor I/O General or the 5085 SRT Surgical Table by DIP signals to ensure graceful (instant) recovery should the switch settings. - Page 87 • Fuse F2 protects line input power from downloading to the table control board and also for transformer to table control at TB4, hydraulic using the Cmax Service 1.8 or later Power Screen pump and Tabletop slide motor. diagnostics utility (later version master control •...

-

Page 88: Intelli-Strip Description

movements and collisions with the table such LEDs ON Battery State as a person bumping into the table. 8. Backup Hand Control and Foot Pump: 4 Yellow and 2 Green 26 - 27 V The Backup Hand Control (sometimes referred 4 Yellow and 4 Green 28 - 29 V to as Override Hand Control) is used in... -

Page 89: Technical Drawings

Hand Control icon indicates (driving with PWM signal). the battery charge level in three stages: Full, Half and Empty. Table 3-1. Cmax 110 Master Control and Hand Control Assembly Compatibility Matrix Hand Control* Software Master Control Assembly... -

Page 90: Inspection And Maintenance

A preventive maintenance program is available from skin burns if inadequately rinsed off, or STERIS to help ensure peak performance and to avoid alcohol, which does not have sufficient unscheduled downtime. The program includes cleaning/disinfecting properties. - Page 91 Table 4-1. Preventive Maintenance Schedule for the Cmax Surgical Table Minimum Service Required Frequency 1.0 PREPARATION FOR PREVENTIVE MAINTENANCE Discuss equipment operation with department personnel. 1x per year Remove pads. Examine pad covers and fastening strips (pads and table). 1x per year Examine clamps and other Side Rail hardware.

- Page 92 Table 4-1. Preventive Maintenance Schedule for the Cmax Surgical Table (Cont’d) Minimum Service Required Frequency Check all cables for damage or fraying. 1x per year Inspect electrical cord and Hand Control cable. 1x per year Verify operation of Backup (Override) Hand Control.

-

Page 93: After Each Usage

5. Unplug hand control. Note hand control plug is locked, do not simply pull on plug. After each use of the Cmax Surgical Table, clean/ 6. Clean hand control as follows: disinfect as follows: NOTE: Do NOT immerse hand control in liquid. -

Page 94: Battery Charging Procedure

Main Power Switch is set to ON (lighted • When table is on battery power and primary hand green) and the ac power is connected to the Cmax control is active (on), diode bar shows battery charge Surgical Table. -

Page 95: Change Fuses

5. Insert fuse in cap. Therefore, to obtain the longest life and capacity from your Cmax Surgical Table batteries, always connect ac 6. Insert fuse (with cap) into fuse holder assembly in power cord to table base and plug into an appropriate table base. -

Page 96: Als Check

KIDNEY Elevator and lateral tilt. The Cmax Surgical Table is equipped with the Auto Trendelenburg and back. Limit Sensor (ALS) system. This system provides Leg and Slide. -

Page 97: Floor Lock Procedures

1. Include serial number of your equipment on your 4.9.2 Floor Lock Cylinder Inspection order. At any inspection or installation of a Cmax Surgical 2. Include model number and description as listed in Table, inspect the floor lock cylinders for leaks as Table 4-2 or Table 4-3. - Page 98 Table 4-2. Cmax Surgical Table Replacement Parts DESCRIPTION PART NUMBER RECOMMENDED SPARES Primary Hand Control Assembly Cord, Hand Control 542200420 Power Cord 093909-354 Fuse (Main), 4.0 Amp 150832-335 Fuse (Set) 342213555 Pad, Head Section 150832-695 Pad, Back/Seat Section 413724-464 Pad, Leg Section 413724-465 Table 4-3.

-

Page 99: Troubleshooting

STERIS. A trained service technician will promptly place warranty or result in costly damage. your Cmax Surgical Table in proper working condition. Contact STERIS regarding service Calling For Service: First, try to define the situation and options. - Page 100 Table 5-1. Troubleshooting Guide Situation Cause Service Instructions 1. No green light on Main Power • Main Power Switch is • Turn Main Power Switch to ON. Switch (if equipped with backlight). OFF. • Plug power cord into appropriate facility •...

- Page 101 Table 5-1. Troubleshooting Guide (Cont’d) Situation Cause Service Instructions 6. Table does not function on facility • Control power fuse F2 • Replace control power fuse F2. power (power cord plugged into open. appropriate facility power and battery fuse F8 removed, or battery charge too low) but table does function on battery power.

- Page 102 Table 5-1. Troubleshooting Guide (Cont’d) Situation Cause Service Instructions 12. Hand Control displays SENSOR • Bad or loss of sensor • Recalibrate table. FAIL. Level button may or may not calibration data. • Verify battery voltage level and recharge be responsive. as needed.

- Page 103 Table 5-1. Troubleshooting Guide (Cont’d) Situation Cause Service Instructions 19. Table has longitudial mechanical • Check lash in rack and • Replace slide motor assembly. play. pinion gear system. • Adjust table for minimum lash. • Check tension in pinion drive chain.

- Page 104 Table 5-1. Troubleshooting Guide (Cont’d) Situation Cause Service Instructions 25. Only tabletop slide function • Faulty hydraulic pump. • Verify backup hand control/foot pump operates. system function. • Faulty power supply at pump drive circuit. • Ensure voltage present at pump. •...

-

Page 105: Electrical Troubleshooting

Table 5-2 . Troubleshooting (LCD Message) Chart (Cont’d) FAULT DISPLAYED FAULT DESCRIPTION FAULT ACTION BATT FUSE No fuse or blown fuse. Check fuse; plug power cord into facility power. BATT DEF Battery voltages differ by more than Check voltage of each battery; 0.6 V. -

Page 106: Field Test Procedure

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD: Repairs and adjustments to this equipment must be made only by STERIS or STERIS-trained service personnel. Maintenance performed by unqualified personnel or installation of unauthorized parts could cause personal injury, result in improper equipment performance, invalidate the warranty or result in costly damage. - Page 107 Tabletop Tabletop Extend table Extend Tabletop top 3/16” 3/16" (4.8 mm) Beyond Foot beyond the End of Tilt Frame foot end of the tilt frame. Tilt Frame Tilt frame Figure 6-1. Table Sensor Calibration 8. Display shows ADJUST MODE. 13. Press REV. ORIENT button to save setting. NOTE: During table sensor calibration, note the 14.

-

Page 108: Newer Control Board (P542200-769)

22. Display shows BACK D MAX. Lower back NOTE: During table sensor calibration, note the section to maximum position and press REV. following: ORIENT button to save setting. 1) The REV. ORIENT LED must be OFF. 23. Display shows BACK U MAX. Raise back section 2) Do not press LEVEL button during procedure to maximum position and press REV. - Page 109 Tabletop Side Member Inner Face Tilt Frame Tilt frame Extend Tabletop 3/16" (4.8 mm) NOTE: Tabletop removed for clarity only. Beyond Foot Extend End of Tilt Frame Figure 6-2. Table Sensor Calibration 26. Press REV. ORIENT button to save setting. 38.

-

Page 110: Accessory Attachments

6.4 ACCESSORY ATTACHMENTS 3. Measure lash between inner and outer column tubes. Lash must be no more than 5/64" (2 mm). 6.4.1 Mayo Stand 4. Lower lift column until a small gap exists between outer tube and base plate (see Figure 6-3). Insufficient clearance between table base and floor to allow use of flat-bladed Mayo Stands. - Page 111 Table 6-1. Articulation Times Tabletop Moved in This Direction Articulation Times (Seconds) Loose Screws Articulation Minimum Target Maximum Trendelenburg 15.0 17.1 19.3 / Reverse Trendelenburg Loose Screws Tilt Right / 10.0 11.4 12.9 Left Back Up / 21.8 24.0 26.2 Tabletop Moved in This Direction Down Kidney Up...

- Page 112 Port P Port T Y11 – Kidney Up Y12 – Kidney Down Y21 – Back Up Y22 – Back Down Y32 – Leg Down Y31 – Leg Up Y42 – Height Down Y41 – Height Up Y52 – Rev Trend Y51 –...

-

Page 113: Component Repair And Replacement

WARNING – EXPLOSION HAZARD: Table must not be used in the presence of flammable anesthetics. WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD: • Repairs and adjustments to this equipment must be made only by STERIS or STERIS-trained service personnel. Maintenance performed by unqualified personnel or installation of unauthorized parts could cause personal injury, result in improper equipment performance, invalidate the warranty or result in costly damage. -

Page 114: Work Place

The less people- traffic around you, the better. Stay away from heating To gain access to most of the Cmax Surgical Table and cooling vents that also put particulates into the air. hydraulic and electrical components, the Table Column Cover (or shroud) and/or Table Base Cover 7.2.3 Tools... -

Page 115: Sealing Table Covers

RTV to prevent fluid intrusion. 7.4 TABLE BASE COVER ASSEMBLY To gain access to most of the Cmax Surgical Table hydraulic and electrical components, the stainless- steel Table Column Cover (or shroud) and/or Table Figure 7-5. Plastic Base Cover Screws Base Cover must be removed. -

Page 116: Three-Part Shrouds

7.5.1 Three-Part (Original) Shrouds 1. Seal area where power supply inlet is exposed through base (see Figure 7-6). Figure 7-9. Seal Between Plastic and Stainless-Steel Covers NOTE: To aid in loosening RTV between stainless- steel base covers and plastic base cover for future procedures, spray Dry Lubricant Spray NG 202 (P752870-091) along the perimeter. -

Page 117: Two-Part Shrouds

7. Seal along both seams of upper plastic column covers as shown in Figure 7-12. Figure 7-14. Apply RTV to V-Shaped Cut-Outs 3. Apply RTV over two base shroud holes where support bracket attaches (see Figure 7-15). Figure 7-12. Seal Along Both Seams of Upper Plastic Column Covers 8. -

Page 118: Power Supply Replacement

NOTE: Before removing battery cables, note position of cables on the batteries for reattachment. 5. Before replacing batteries, verify (see Figure 7-16): • Same engraved number (typically located on plastic top of each battery) on both batteries. Ensure both batteries are manufactured by same vendor. -

Page 119: Floor Lock Foot (Leveling Mount) Replacement

Return Floor Lock Cylinder assembly to table NOTE: Replace (do not reuse) hydraulic screws and sealing washers (see Figure 7-18). Ensure bolt and secure with three mounting screws. threads, manifold threads and hose connectors are Adjust foot or leveling mount as necessary and free of rubber seal particles. -

Page 120: Floor Lock Manifold Assembly Replacement

Replace sealing washers and torque hydraulic screws and sealing washers. hydraulic screws to 12 N•m (106 lbf•in). NOTE: Refer to Cmax Surgical Table Hydraulics NOTE: Replace (do not reuse) hydraulic screws and figure in the Illustrated Parts Breakdown section for sealing washers (see Figure 7-22). -

Page 121: Auxiliary (Backup) Hand Control Replacement

10. Remove Hand Control from drawer and replace. Cover 11. Reinstall drawer and Hand Control by reversing Support procedure. Bracket 12. Test table operation using Auxiliary (Backup) Mounting Hand Control before replacing covers. Screw Push Down End Stop Plate Electrical Pull Out Wiring Drawer... -

Page 122: Height Sensor Replacement

NOTE: On plastic column cover cap reinstallation, P75 Connector ensure distance between tilt cylinder shaft and nut is 1-1/8" (29 mm) when reconnecting tilt cylinder (as shown in Figure 7-26). P6 Connector 12. Restore RTV seal (see S 7.5.1, T ECTION HREE or S... -

Page 123: Tilt Cylinder Replacement

3) Ensure distance between cylinder shaft and nut is 1-1/8" (29 mm) - see Figure 7-26. Column 4) After reassembly, ensure all table functions operate Cover Cap properly. Upper Connections 5) Check hydraulic oil level with table completely lowered and tabletop level. Level should be 2-9/16" (65 mm). -

Page 124: Main Valve Block Replacement

10. Remove snap ring and cylinder pin from bottom 7.19 MAIN VALVE BLOCK mounting bracket (see Figure 7-30). REPLACEMENT 11. Remove and discard both hydraulic screws and Replace the main hydraulic valve block as follows: sealing washers. 12. Replace hydraulic cylinder and reassemble by 1. -

Page 125: Remove Tabletop Sections

Screws 3) Torque new screws to 14 ± 1.5 N•m (124 ± 13 lbf•in). 4) Follow Cmax Surgical Table Hydraulics figure in the IPB Section of this manual to ensure proper Figure 7-34. Remove Tabletop Kidney Section reconnection. -

Page 126: Leg Section

4) Tighten bolt from beneath table before returning cylinder mounting plate. 5) Hand tighten all bolts first. 6) Follow Cmax Surgical Table Hydraulics figure in the IPB Section of this manual to ensure proper reconnection. 7) Ensure all screws are secured with Loctite 242. -

Page 127: Kidney Cylinder Replacement

7.22 KIDNEY CYLINDER REPLACEMENT 5) After reassembly, move kidney section up and down several times to ensure proper operation of kidney Replace kidney hydraulic cylinder as follows: bridge and limit switch and no hydraulic oil leakage. 1. Position tabletop to level. 6) Verify kidney assembly status on the hand control. -

Page 128: Leg Sensor Replacement

13. Push hydraulic cylinder toward table foot end and 7. Remove wire protection cover. lift from table. 8. Disconnect sensor from main CPU board (P73 14. Reassemble in reverse order. connector). NOTE: When reassembling the leg hydraulic cylinder, 9. Remove and replace sensor. note the following: 10. -

Page 129: Leg Support Locking Device Replacement

7.26 LEG SUPPORT LOCKING DEVICE 11. Reassemble in reverse order. Adjust as needed for proper operation. REPLACEMENT 12. Verify switch status on hand control. Replace leg support locking device as follows: 1. Position tabletop to level. 2. Turn Main Power Switch to OFF and remove battery fuse (refer to supplied Operator Manual for more information). -

Page 130: Tilt Sensor Replacement

2. Turn Main Power Switch to OFF and remove Trendelenburg battery fuse (refer to supplied Operator Manual for Sensor more information). 3. Remove tabletop seat section per S 7.20.1, ECTION Screws ECTION 4. Remove seat plastic cover as follows: Remove four top and four side screws from both head-side and foot-side seat cover Connector (see Figure 7-37). -

Page 131: Slide (Translation) Motor Replacement

5. Remove chain plastic cover. 6. Remove cover bracket above motor Sliding (see Figure 7-53). Connectors Power Board Connector Cover Mounting Screw Support Motor Figure 7-51. Disconnect Sliding Motor And Screw Support Power Board Screw 6. Loosen both mounting screws. Figure 7-53. -

Page 132: Back Section Sensor Replacement

5. Remove side cover. 13. Disconnect back hydraulic cylinder connection. Discard hydraulic screw and sealing washers (see 6. Raise back section to 75°. Properly support back Figure 7-58). section as it is free to move once cylinder is disconnected. 7. Remove tabletop back section per S 7.20.3, ECTION ECTION... -

Page 133: Hydraulic Fluid Contamination

8. Remove six lower screws from table column plastic Replace manifold(s) (per S 7.19, M ECTION cap (see Figure 7-25) and allow table column cover ) and/or pump and ALVE LOCK EPLACEMENT to lower to base cover. motor assembly. 10. Remove block and tie-down. 9. - Page 134 7. Manually slide bearing assembly support to NOTE: Each bearing cartridge appears to have at opposite end of table seat section (until it reaches least one ball bearing missing in the track. This is physical stop) to expose remaining eight bearing normal as the balls must be able to migrate freely rail mounting screws (four on upper rail and four around the turns in the track.

- Page 135 P: There is no “P” prefix on p/n. 3.4.2 System Function C: Error A: the correct p/n is 542200-903. Table 3.1 Cmax 110 Master P: There is no “P” prefix on p/n. Control and Hand Control C: Error Assembly Compatibility Matrix A: the correct p/n is 542200-903.

- Page 136 Maintenance Manual Updates Revision History Date Added Maintenance Manual Update Maintenance Manual Update Subject to Manual Number and Date 3/16/2011 11003-MMU 3/01/2011 Primary Hand Control Obsolescence 3/22/2011 11004-MMU 03/01/2011 Backup Hand Control Obsolescence 7/20/2011 11014-MMU 7/19/2011 Trendelenburg and Tilt Sensor Replacement *REMOVED/replace with 11026-MMU 7/20/2011 11015-MMU 7/19/2011 Universal Hand Control...

- Page 137 CLASSIFICATION JUSTIFICATION: This service improvement update is to introduce the replacement Hand Control for the Cmax 110 NA table. The existing Cmax 110 Hand Control is obsolete and Hand Control P150832-632 is the available replacement. This improvement does not affect safety and efficacy, nor does it affect the intended use of the device. This has been deemed not to be a significant modification to the device.

- Page 138 Hand Control for the first time. If so, contact the Account Manager to request an In-Service visit and to provide an updated Cmax Operator Manual P150830-685 which gives full details of the operation of the new device. If questions arise regarding operation or reasons why this device was chosen to be the replacement, refer the Customer to the Account Manager.

- Page 139 CLASSIFICATION JUSTIFICATION: This service improvement update is to introduce the replacement backup Hand Control for the Cmax 110 NA table. The existing Cmax 110 backup Hand Control is obsolete and a new Hand Control is available for replacement. This improvement does not affect safety and efficacy, nor does it affect the intended use of the device.

- Page 140 The purpose of this document is to provide a description of the functionality of the Universal Hand Control. The term “Universal” refers to the range of surgical tables that consists of the Cmax, 4085, and 5085 non-transport tables. The 5085 SRT transport table is not supported by the universal hand control. The universal hand control will identify a 5085 SRT if connected but will not provide a control interface to the surgical table.

- Page 141 4085 General and STERIS 5085 General Surgical Tables unless noted otherwise. The Universal Hand Control is not to be used with the STERIS 5085 SRT Surgical Tables. Failure to comply with the safety information contained within this publication could result in injuries, damage to the equipment or damage to other property.

- Page 142 Page 3 of 14...

- Page 143 NOTE: Refer to the appropriate Operator Manual for specific instructions on operating the surgical table: 1)Cmax (P150830-685). 2) STERIS 4085 General (P150832-639). 3) STERIS 5085 General (413724-246). Table 1. Symbol Definition Symbol Color Definition Green POWER: Table is connected to facility power...

- Page 144 Blue POINTER: Indicates button user needs to push when selecting compatibility mode Page 5 of 14...

- Page 145 Figure 4. Surgical Table Running Software Version 1.48 5. Figure 5 shows display appearance when Universal Hand Control is connected to Cmax Surgical Table equipped with version 1 table control chassis running table control software version less than 1.47. Figure 5. Surgical Table Running Software Version Less Than 1.47 After a brief time, display clears and shows symbols representing state of table.

- Page 146 This is normal selection to be made when Universal Hand Control detects a table type that differs from existing compatibility mode. Figure 6 shows display when a Cmax/4085 Surgical Table is detected while Universal Hand Control is configured for a 5085 Surgical Table or when a 5085 Surgical Table is detected while Universal Hand Control is configured for a Cmax/4085 Surgical Table.

- Page 147 Universal Hand Control displays BEACH CHAIR MODE ERROR (see BEACH CHAIR MODE for 5085 Section and Figure 10). 5085 Cmax/4085 With Universal Hand Control and Surgical Table Power table off by Version 2 Table function correctly. Refer to Operator’s pressing STOP button.

- Page 148 Page 9 of 14...

- Page 149 Page 10 of 14...

- Page 150 SEE OPERATOR’S MANUAL and BEACH CHAIR MODE ERROR messages on the display. Using the Universal Hand Control configured for a Cmax/4085 also causes this error. A symbol appears in the lower right corner of the display instructing the user to refer to the operator’s manual...

- Page 151 Pressing any key while the BEACH CHAIR MODE ERROR message (see Figure 10) is displayed returns the Universal Hand Control to normal operation (see Figure 1) with the following exceptions: NOTE: The table should be serviced by a STERIS technician to resolve an issue preventing cancellation of the Beach Chair Mode.

- Page 152 Feature Matrix Table 4 shows the functionality available for each compatible Surgical Table Page 13 of 14...

- Page 153 1.20 or greater or Cmax hand control software version 1.10. Legacy Cmax control chassis 542200-903 will work with any software version or any of the Cmax/4085 hand controls but not the 5085 hand control. 5085 table control chassis 413724-263 running software V2.13 requires 1) Universal Hand Control 150832-632 running V1.22 or 2) 5085 hand control 542804-999M running software V4.12.

- Page 154 MAINTENENANCE MANUAL UPDATE Product: Cmax and 4085 Surgical Tables No.: 11021-MMU Maintenance Manual No.: P764333-267 P764333-765 Subject: Second Spacer Added to Table Caster Date: 09-01-2011 Approved: Classification: Service Improvement CLASSIFICATION JUSTIFICATION: This service improvement describes the addition of a second washer to the table caster from the supplier.

- Page 155 Figure 1. Second Spacer Page 2 of 2...

- Page 156 Classification: Service Improvement CLASSIFICATION JUSTIFICATION: This service improvement supersedes 11410-MMU. This service improvement provides information needed to return a Cmax or 4085 Surgical Table to use after replacing either the Trendelenburg or Tilt sensors. SITUATION: The current Trendelenburg and Tilt sensors (688200019) used in the Cmax and 4085 surgical table are obsolete.

- Page 157 Both the Trend and the Tilt sensors will need to be removed. The new sensor is a dual axis sensor and functions as both the Trend/Tilt sensor. b. Follow the Maintenance Manual Instruction (Cmax – P764333-268 or 4085- P764333-765) for Trend/Tilt Sensor Replacement to gain access to the sensors.

- Page 158 c. Disconnect Slide Sensor cable from Slide Rail Mount d. Disconnect Energy Chain from bracket e. Remove bracket holding Trend and Slide Sensors. Keep (2) mounting screws as they will be needed with the new bracket. Page 3 of 8...

- Page 159 Remove Trend Sensor from bracket g. Remove Slide Sensor from the bracket. Keep (2) screws for mounting on the new bracket. h. At this point, the mounting bracket should be empty. Remove the Tilt Sensor from its mounts. Leave it to the side and it will be completely removed later.

- Page 160 2. Installing new Trend/Tilt Sensor a. Using the new mounting bracket from the kit P764334-451, mount the new sensor. Use the sensor cover (P150832-918) and the (2) M6 x 10 screws (P600990-068) to accomplish this. b. Mount Slide Sensor to the new bracket using the same screws from step Page 5 of 8...

- Page 161 c. Mount energy chain bracket (P150832-851) to the new bracket using (2) M4 x 10 stainless steel screws (P600990-077) provided in the kit. d. Mount bracket with sensors on column frame using (2) screws from step 1e. Page 6 of 8...

- Page 162 e. Reconnect the energy chain to the mounting bracket. Reconnect Slide Sensor Cable to slide rail mount. Page 7 of 8...

- Page 163 Reinstall seat plastic cover b. Reinstall Tabletop Seat Section c. Perform the Table Level Calibration for the particular table, section 6.3 of both the Cmax and 4085 Maintenance Manuals. (P764333-268 or P764333- 765 respectively) d. Reinstall shrouds. Page 8 of 8...

- Page 165 UNITS PER ASSEMBLY column is specific for the given assembly or subassembly level. Table 1 provides part numbers and figure references for the most commonly replaced items on a Cmax WARNING – PERSONAL INJURY AND/OR Surgical Table and Table 2 does the same for the EQUIPMENT DAMAGE HAZARD: Repairs hydraulics assembly.

- Page 166 FIG. & ITEM UNITS PER PART DESCRIPTION ASSEMBLY NUMBER 10-1 P 146667 035 Harmony LA Wall Control Assembly, Domestic......X P 146667 327 Harmony LA Wall Control Assembly, Global........P 146667 358 Harmony LA Wall Control Assembly, LA2 ........P 146667 278 ASSEMBLY, Cover/Membrane Replacement ........

- Page 167 List of Illustrations and Tables Figure 1. Cmax Surgical Table Shroud and Support Assembly ......8 Figure 2.

- Page 168 Figure 4 Power Supply, 220 V 542201-902 Figure 4 Electric Unit (PC Board) P150832-769 V542200-903 Figure 4 Cmax Hand Control Assembly (w/o Cable) 542200-904 Figure 6 Cmax Hand Control Cable Figure 1 Override Hand Control Assembly 542200-905 542200-905 Figure 6...

- Page 169 Table 2: Quick Reference Parts (Hydraulics) Cmax Surgical Table Cmax Surgical Table Cmax Surgical Table Hydraulic Assembly Hydraulic Assembly Hydraulic Assembly Reference Domestic, Before Domestic, After International S/N 0401209043 S/N 0401209043 Trendelenburg Cylinder 342223-555 Sub-Assembly Figure 5 Trendelenburg, Cylinder P755718-040...

- Page 170 P150832-186 Size: 11-5/16 x 5-5/32, Base: Foot End Label Label 542200-201 Hand/Foot Control, E-Serve Label Label, ID 542200-479 STERIS Cmax Label Label, Leg Position 542200-344 Used on Both Left and Right Leg Section Covers Label Label, No A/P P200050-371 Size: 2-1/4 x 1-3/4...

- Page 171 Table 4: Quick Reference Parts (Hardware Listing) Unit Of Quantity per TYPE NUMBER DESCRIPTION Measure Unit Cable Tie 084104-001 Cable Tie, 4 129360-598 Cable Tie Clamp 605130-003 Cable Clamp, 3M DIA 129361-169 Cable Clamp, Alum, 5/16 OD M x #8 Std 150830-770 Nylon Cable Clamp, 1/4 ID 150830-771...

- Page 172 Table 4: Quick Reference Parts (Hardware Listing) Unit Of Quantity per TYPE NUMBER DESCRIPTION Measure Unit Screw (Cont’d) 600411-035 Flat Head Cap Screw, M10 x 35 SS 600530-410 Socket Head Cap Screw, M4 x 10 SS 600530-412 Socket Head Cap Screw, M4 x 12 SS 600530-425 Socket Head Cap Screw, M4 x 25 SS 600530-508...

- Page 173 Table 4: Quick Reference Parts (Hardware Listing) Unit Of Quantity per TYPE NUMBER DESCRIPTION Measure Unit Screw (Cont’d) 600990-850 Screw, Lag, M8 x 50 (Pack of 4) 150832-652 Screw, Pan Head, M2 x 10 Sealant 764322-636 Hydraulic Oil Pack EA (1 gal) 005300-545 Loctite Sealant #222-31 005300-548...

- Page 174 Patient Head Patient Left Patient Right Patient Foot View at A NOTE: Not all labels are shown. See Quick Reference List for part numbers. Figure 1. Cmax Surgical Table Shroud and Support Assembly 764333-269...

- Page 175 FIG. & PART DESCRIPTION ASSEMBLY ITEM NUMBER Cmax Surgical Table Shroud and Support Assembly - Domestic ..............Cmax Surgical Table Shroud and Support Assembly - International............... Cmax Surgical Table Shroud and Support Assembly - Domestic After 0434408112 ........V 342210 555 ASSEMBLY, Base Cover..............

- Page 176 Cmax Surgical Table Shroud and Support Assembly - International............... Cmax Surgical Table Shroud and Support Assembly - Domestic After 04-34408112 ........P 150832 478 *** GASKET, Cmax Base Cover (Column to Base)........P 150832 525 SPACER, Base Cover................– –...

- Page 177 Patient Left Figure 2. Cmax Surgical Tabletop (1 of 3) 764333-269...

- Page 178 Back Section Headrest Section Seat Section Leg Section Figure 2. Cmax Surgical Tabletop (2 of 3) 764333-269...

- Page 179 Typical of Rail Assemblies See Figure 7 Patient Head Back Section Members, Patient Foot Not Covers Figure 2. Cmax Surgical Tabletop (3 of 3) 764333-269...

- Page 180 PART DESCRIPTION ASSEMBLY ITEM NUMBER Cmax Surgical Tabletop - Domestic - Before C424207101 ... Cmax Surgical Tabletop - Domestic - After C424207101 ....Cmax Surgical Tabletop - International .......... P 755717 643 ** ASSEMBLY, Back Rail-Left ..............– V 542200 154 ASSEMBLY, Back Rail-Left ..............

- Page 181 Standoff P/N 542200-324 is current production Internationally and was used on some Domestic Tables. Standoff uses Item #12, Flat Head Cap Screw, P600411-016. If tabletop sections are equipped with metal inserts in receptacles for X-Ray tops, refer to STERIS 4085 General Surgical Table Maintenance Manual (P764333-765) for replacement.

- Page 182 See Detail E Patient Left See Detail D Patient Right See Detail A, B and C Detail A Detail B 11 12 13 Detail D Detail C Figure 3. Cmax Surgical Tabletop Slide and Section Assembly (1 of 3) 764333-269...

- Page 183 Patient Right Patient Left Slide Motor Figure 3. Cmax Surgical Tabletop Slide and Section Assembly (2 of 3) 764333-269...

- Page 184 Patient Left Right Section Head Rest Member (Shown For Clarity) Figure 3. Cmax Surgical Tabletop Slide and Section Assembly (3 of 3) 764333-269...

- Page 185 DESCRIPTION ASSEMBLY ITEM NUMBER Cmax Surgical Tabletop Slide and Section Assemblies - Domestic - Before S/N C423607106 ..........Cmax Surgical Tabletop Slide and Section Assemblies - Domestic - After S/N C423607106 ..........Cmax Surgical Tabletop Slide and Section Assemblies - International ..................

- Page 186 DESCRIPTION ASSEMBLY ITEM NUMBER Cmax Surgical Tabletop Slide and Section Assemblies - Domestic - Before S/N C423607106 ..........Cmax Surgical Tabletop Slide and Section Assemblies - Domestic - After S/N C423607106 ..........Cmax Surgical Tabletop Slide and Section Assemblies - International..................

- Page 187 Hardware Items #23, #24 and #67. + Individual part number not available. ++Item #42 and #43, the original Cmax Head Rest with release lever on patient right side member is No Longer Available (NLA). Repace Head Rest with P150832-381. See Figure 7.

- Page 188 23 24 AUXILIARY HAND CONTROL Compartment (†) Drawer (†) Figure 4. Cmax Table Base Assembly (1 of 2) 764333-269...

- Page 189 73 72 Figure 4. Cmax Table Base Assembly (2 of 2) 764333-269...

- Page 190 DESCRIPTION ITEM NUMBER ASSEMBLY Cmax Table Base Assembly (Domestic Before S/N C419908042) ........ Cmax Table Base Assembly (International)......Cmax Table Base Assembly (Domestic After S/N C419908042 )........Cmax Table Base Assembly (Domestic After S/N 0401209043) ........Cmax Table Base Assembly (Domestic After S/N 0434408112) ........

- Page 191 PACK, Auxiliary Drawer to Plastic Compartment....A/R A/R A/R A/R A/R – 694802 059 BUSHING, Strain Relief ............P 764332 813 HANDLE, Cmax Auxiliary Hand Control, Parts....... A/R A/R A/R A/R A/R – P 150832 235 • HANDLE, Rel Auxiliary Drawer ..........–...

- Page 192 DESCRIPTION ITEM NUMBER ASSEMBLY Cmax Table Base Assembly (Domestic Before S/N C419908042) ........ Cmax Table Base Assembly (International)......Cmax Table Base Assembly (Domestic After S/N C419908042 )........Cmax Table Base Assembly (Domestic After S/N 0401209043) ........Cmax Table Base Assembly (Domestic After S/N 0434408112) ........

- Page 193 Item #29 was revised to have a plug-in fuse holder. If table does not have the plug-in style, retrofit to the new style cable assembly. ++ The Cmax floor lock block was changed in production S/N C419908042 to the self-compensating style. ~ The 2-valve block is no longer available for units before S/N C419908042. Order Pack, Complete Retrofit Floor Lock, P/N P764333-432.

- Page 194 2-Valve Floor Lock Block, (See Parts List) Figure 5. Cmax Surgical Table Hydraulics (1 of 4) [Before S/N 0401209043] 764333-269...

- Page 195 Figure 5. Cmax Surgical Table Hydraulics (2 of 4) [Before S/N 0401209043] 764333-269...

- Page 196 See 4 of 4 Figure 5. Cmax Surgical Table Hydraulics (3 of 4) [After S/N 0401209043] 764333-269...

- Page 197 Figure 5. Cmax Surgical Table Hydraulics (4 of 4) [After S/N 0401209043] 764333-269...

- Page 198 + HOSE, Cmax, FLOOR Lock Hydraulic, Floor Lock Block Main Valve Block 1270 mm 10 P 764333 246 + HOSE, Cmax, Floor Lock Hydraulic, 1270 mm Floor Lock Block Main Valve Block 11 P 764333 247 + HOSE, Cmax, Height Hydraulic, 1040 mm Cylinder, Height Main Valve Block, Y42 –...

- Page 199 Domestic Before S/N 0401209043 Cmax Surgical Table Hydraulic Assembly- International Cmax Surgical Table Hydraulic Assembly- Domestic After S/N 0401209043 23 P 764333 255 + HOSE, Cmax, Kidney Hydraulic, 1400 mm Cylinder, Kidney, Main Valve Block, Y11 – Right (A) 24 P 764333 256...

- Page 200 Item #12 Hose Set includes - 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 13, 14, 17, 18 and 33. ‡ The Cmax 2-valve floor lock block was changed in production S/N C419908042 to the 6-valve self compensating style.

- Page 201 Sensor P/N 688200- 220V P/N 542201-902 Slide Sensor Power Entry Tilt Sensor P/N Module 688200-019 P/N 764332-972 Height Sensor Battery P/N Back Sensor 134469-361 PACK Baragraph Leg Sensor PACK Battery P/N Pump 134469-361 P/N 342211-555 Figure 6. Cmax Electrical Cables 764333-269...

- Page 202 Cable Item/ Part Number Description Postition Cable Position To Hose From Position Cmax Electrical Cables P 150832 ASSEMBLY, Hand Control Without Cable CABLE/CORD, Hand Control Coil P30, Hand Controller 542501 208 542200 CABLE, HC Harness Connector Plate P30,P31, P32 Assembly...

- Page 203 Pump P 150823 • HARNESS, Filter Assembly P 150823 HARNESS, Foot Control (Cmax) - Not Floor Lock Valve Box Shown NOTES: * Item #23 is not included with Item #19. ** Item #24 is not included with sliding motor assembly.

- Page 204 Figure 7. New Style Cmax Headrest Assembly 764333-269...

- Page 205 Loctite is a registered trademark of Henkel Corporation. * Not available at this time. **If tabletop sections are equipped with metal inserts in receptacles for X-Ray tops, refer to STERIS 4085 General Surgical Table Maintenance Manual (P764333-765) for replacement. 764333-269...

- Page 206 Patient Right Figure 8. Cmax Surgical Table Leg Section Assembly 764333-269...

- Page 207 UNITS PER FIG. & PART DESCRIPTION ASSEMBLY ITEM NUMBER 764333 996 Cmax Surgical Table Leg Section Assembly ......... PACK, Right Leg Member Assembly ........... PACK, Left Leg Member Assembly ............. 624900 014 BUSHING..................... 624900 015 BUSHING..................... 542200 143 WASHER, Friction Disk ...............

- Page 208 Front Cover Front Cover changes/manual errors and clarifications A: Stamped to show Live Document Date P: P150832-381 has additional notes at the bottom of the page 7 New Style Cmax Headrest C: Clarification Assembly A: Added ** to the Assembly...

- Page 209 Front Cover Front Cover changes/manual errors and clarifications R: Stamped to show Live Document Date Table 1: Quick Reference P: Cmax hand control part number P150832-500 subs to a new number Parts (Miscellaneous Parts) R: P150832-632 1 Cmax Surgical Table Shroud...

- Page 210 R: Part number for the Cmax Hand Control Cable is V542501-208 1 Cmax Surgical Table Shroud P: Item 24 P/N 542200-420 Cable, Cmax Hand Control is no longer available. and Support Assembly R: Part Number for item 24, is V542501-208 Cable, Cmax Hand Control P: Item 2 P/N 542200-420 Cable/Cord, Hand Control Coil is no longer available.

- Page 218 C: Manufacturing changed the part A: The 542200-902 will be replaced by · P764334-146 KIT, REPLACEMENT CONTROL & FILTER Table 1 Cmax Surgical Table The 542201-902 will be replaced by P764334-145, KIT, FILTER HARNESS and one Technical Drawings of the following, the customer will select by voltage: ·...

Need help?

Do you have a question about the Cmax and is the answer not in the manual?

Questions and answers