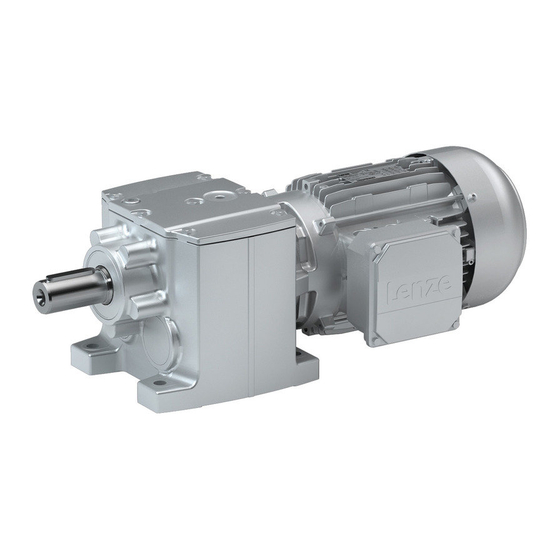

Lenze g500 Series Mounting Instructions

Helical gearboxes / helical gearboxes with servomotors

Hide thumbs

Also See for g500 Series:

- Mounting instruction (132 pages) ,

- Mounting instructions (68 pages) ,

- Mounting and switch-on instructions (72 pages)

Summary of Contents for Lenze g500 Series

- Page 1 g500 H45 ... H450 | 45 Nm ... 450 Nm Helical gearboxes / helical gearboxes with servo Mounting Instructions motors...

- Page 2 Please read these instructions before you start working! Follow the enclosed safety instructions. 0Abb. 0Tab. 0...

-

Page 3: Table Of Contents

..........Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 4: About This Documentation

Qualified skilled personnel are persons who have the required qualifications to carry out all activities involved in installing, mounting, commissioning, and operating the product. Tip! Information and tools concerning the Lenze products can be found in the download area at www.lenze.com Document history... -

Page 5: Terminology Used

In the following text used for Gearboxes Gearboxes of the g500 product family Drive system Drive systems with g500 gearboxes and other Lenze drive components Notes used The following pictographs and signal words are used in this documentation to indicate... -

Page 6: Safety Instructions

This is vital for safe and trouble−free operation and for achieving the specified product features. ¯ Only qualified skilled personnel are permitted to work with or on Lenze drive and automation components. According to IEC 60364 or CENELEC HD 384, these are persons ... - Page 7 Corrosion protection Lenze offers paints with different resistance characteristics for drive systems. Since the resistance may be reduced when the paint coat is damaged, defects in paint work (e.g.

-

Page 8: Application As Directed

... in explosion−protected areas – ... in aggressive environments (acid, gas, vapour, dust, oil) – ... in water – ... in radiation environments Note! Increased surface and corrosion protection can be achieved by using adapted coating systems. Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 9: Residual Hazards

¯ Design with plug: – Never disconnect plug when energised! Otherwise, the plug can be destroyed. – Switch off power supply and inhibit controller prior to disconnecting the plug. Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 10: Disposal

Safety instructions Disposal Fire protection ¯ Fire hazard – Prevent contact with flammable substances. Disposal Sort individual parts according to their properties. Dispose of them as specified by the current national regulations. Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 11: Product Description

¯ The most important technical data is given on the nameplate. ¯ The product catalogues contain further technical data. Identification Mounting position (A−F) and position of system modules (1−6) Connector / terminal box: 2, 3, 4, 5 Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 12: Nameplate

Product description Nameplate 3.2.1 Nameplate Gearbox 10.2 10.3 10.1 20.1 Asynchronous and synchronous servo motors 16.6 5.10 14.2 14.3 14.1 10.2 10.3 Lenze ¯ MA 12.0017 ¯ 3.0... - Page 13 Year of manufacture / week of manufacture Customer data 20.1 Additional customer data UL category (e.g. inverter duty motor) C86 = motor code for inverter parameterisation (code 0086) Permissible ambient temperature (e.g. Ta £ 40°C) Load capacity (specified if c<1.0) Lenze ¯ MA 12.0017 ¯ 3.0...

-

Page 14: Transport Weights

< 15 < 20 < 25 < 40 G50BH132 g500−H320 < 15 < 20 < 30 < 45 G50BH145 g500−H450 < 25 < 25 < 30 < 50 Tab. 2 Weights in kg Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 15: Mechanical Installation

Use additional appropriate lifting aids, if required, to achieve a direction of loading which is as vertical as possible (highest payload). Secure lifting aids against shifting! Stop! Observe load carrying capacity! Standing beneath floating loads is prohibited! Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 16: Preparation

General information about the assembly of drive systems Stop! The lubricant fill quantity of the gearboxes is matched to the mounting position. The mounting position indicated on the nameplate must be observed to avoid damage to the gearbox. Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 17: Mounting The Gearboxes

DIN 42955 R (reference values for smooth running < 0.025 mm; axial runout and concentricity < 0.05 mm). Fig. 2 Measurement of the surfaces of smooth running, axial runout and concentricity Motor flange Centering Lenze ¯ MA 12.0017 ¯ 3.0... - Page 18 ¯ The drive system must have cooled down. ¯ The motor must be deenergised. Note! Lenze recommends the use of smooth motor shafts without slots! 1. Check: ¯ If the drill depth in the hollow drive shaft is sufficient for the motor shaft.

- Page 19 (7) and leave it there (Fig. 6). The terminal screw (8) must only be tightened to such a degree that the clamping ring (7) does not move but the shaft is not tightened yet! Lenze ¯ MA 12.0017 ¯ 3.0...

- Page 20 Note! Lenze recommends the use of smooth motor shafts without slots! 5. Position the motor shaft vertically and centrically to the hollow drive shaft and insert it carefully into the hollow drive shaft. Exert only little force in order to prevent damage to the ball bearing in the bell housing and the motor.

-

Page 21: Mounting Of Motors On Gearboxes With Mounting Flange And Flexible Coupling (Drive−End Version N)

B8 x 7 x 18 B6 x 6 x 18 Tab. 4 Attachment of motors to gearboxes with mounting flange * Use original key for the motor Key for standard hub and clamping hub Lenze ¯ MA 12.0017 ¯ 3.0... - Page 22 5. Lay spider in the coupling claw on the gearbox side. 6. Align claws of the motor−side coupling hub with its counterpart. 7. Slowly push on motor, and bolt on to the gearbox flange. Lenze ¯ MA 12.0017 ¯ 3.0...

-

Page 23: Gearboxes With Breathers

Gearboxes that are delivered with a ventilation unit are provided with a label. Remove the transport locking device on the vent valve before initial commissioning. GT−GNG−13285760.iso/dms Note! Loosely enclosed vent valves must be mounted in accordance with the mounting position, (¶ 27). Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 24: Electrical Connection

The notes for the electrical connection can be found in... ¯ in the terminal box (in the case of motors with terminal box). ¯ in the connection plan (in the case of motors with plugs). Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 25: Commissioning And Operation

¯ For gearboxes with breathing elements: – Has the transport locking device been removed? Stop! At drive speeds below 200 rpm the amount of lubricant may need to be increased. Consultation with Lenze is required. Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 26: During Operation

¯ In the event of faults: – shut down the drive, – check the troubleshooting table. If the fault cannot be remedied, please contact the Lenze customer service. Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 27: Maintenance

Oil sump temperature [°C] Synthetic oil CLP HC/CLP PG Oil life/changing intervals [operating Mineral oil CLP hours h] Stop! Irrespective of the operating hours, an oil change must be carried out every three years at the latest! Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 28: Maintenance Operations

Maintenance operations Maintenance operations The gearboxes are ready to use on delivery and filled by Lenze with the lubricant type and lubricant quantity indicated on the nameplate. The initial filling corresponds to the mounting position and design indicated on the nameplate. - Page 29 Maintenance Maintenance operations Form template: dipsticks for G50BH121 Lenze ¯ MA 12.0017 ¯ 3.0...

- Page 30 Maintenance Maintenance operations Form template: dipsticks for G50BH132 Lenze ¯ MA 12.0017 ¯ 3.0...

- Page 31 Maintenance Maintenance operations Form template: dipsticks for G50BH145 Lenze ¯ MA 12.0017 ¯ 3.0...

-

Page 32: Repair

5. Fill in lubricant through filler hole (quantities see nameplate). 6. Screw in breathing / oil filler plug. 7. Dispose of waste oil according to the applicable regulations. Repair ¯ We recommend having all repairs carried out by the Lenze Service department. Lenze ¯ MA 12.0017 ¯ 3.0... -

Page 33: Troubleshooting And Fault Elimination

If any malfunctions should occur during operation of the drive system, please check the possible causes using the following table. If the fault cannot be eliminated by one of the listed measures, please contact the Lenze Service. Fault Possible cause... - Page 34 Notes Lenze ¯ MA 12.0017 ¯ 3.0...

- Page 35 Notes Lenze ¯ MA 12.0017 ¯ 3.0...

- Page 36 © 04/2017 | MA 12.0017 | .V8> | 3.0 | TD09 Lenze Drives GmbH Postfach 10 13 52 D−31763 Hameln Germany Ü +49 5154 82−0 Ø +49 5154 82−2800 Ù Lenze@Lenze.com Ú www.Lenze.com Û Lenze Service GmbH Breslauer Straße 3 D−32699 Extertal...

Need help?

Do you have a question about the g500 Series and is the answer not in the manual?

Questions and answers