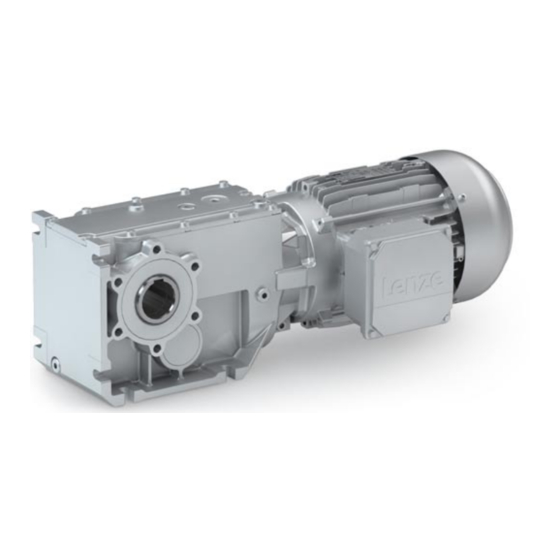

Lenze g500 Mounting Instruction

Shaft-mounted helical gearboxes / shaft-mounted helical gearboxes with three-phase ac motors

Hide thumbs

Also See for g500:

- Mounting instructions (68 pages) ,

- Mounting instruction (25 pages) ,

- Mounting and switch-on instructions (72 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Lenze g500

- Page 1 G50BS113 ... G50BS319 | 130 Nm ... 19000 Nm Shaft−mounted helical gearboxes / Shaft−mounted Mounting Instruction helical gearboxes with three−phase AC motors...

- Page 2 Please read these instructions before you start working! Follow the enclosed safety instructions. 0Abb. 0Tab. 0...

- Page 3 ............Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 4 ..........Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 5 Qualified skilled personnel are persons who have the required qualifications to carry out all activities involved in installing, mounting, commissioning, and operating the product. Tip! Information and tools concerning the Lenze products can be found in the download area at www.lenze.com Document history...

- Page 6 In the following text used for Gearboxes Gearboxes of the g500 product family Drive system Drive systems with g500 gearboxes and other Lenze drive components Notes used The following pictographs and signal words are used in this documentation to indicate...

- Page 7 About this documentation Notes used Application notes Pictograph and signal word Meaning Important note to ensure trouble−free operation Note! Useful tip for easy handling Tip! Reference to another document Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 8 ... must not be actuated if the drive system shows vibration accelerations > 2g (20m/s ... must not be actuated in the resonance range of a system or the Lenze drive system. ¯ All specifications of the corresponding enclosed documentation must be observed.

- Page 9 ¯ check that all component parts with a loose fastening are secured or removed; ¯ tighten all transport aids (eye bolts or support plates). Use an appropriate means of transport and lifting equipment! (¶ 19) Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 10 Corrosion protection Lenze offers paints with different resistance characteristics for drive systems. Since the resistance may be reduced when the paint coat is damaged, defects in paint work (e.g. through transport or assembly) must be removed professionally to reach the required corrosion resistance.

- Page 11 ¯ We recommend loading the gearbox with a maximum of 50 % of the rated output torque if it is outside the specified temperature range during commissioning. Disposal Sort individual parts according to their properties. Dispose of them as specified by the current national regulations. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 12 Connections must only be made when the equipment is deenergised and the motor is at standstill. – Installed brakes are no fail−safe brakes. ¯ Dangerous voltages at the power terminals, even if the plug is removed: residual voltage >60 V! Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 13 Never disconnect plug when energised! Otherwise, the plug can be destroyed. – Switch off power supply and inhibit controller prior to disconnecting the plug. Fire protection ¯ Fire hazard – Prevent contact with flammable substances. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 14 Product description Important notes Product description Important notes ¯ The most important technical data is given on the nameplate. ¯ The product catalogues contain further technical data. Identification Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 15 20.1 16.7 cos j 16.6 10.2 10.3 Three−phase AC motor with a standard output flange 14.2 14.1 16.1 16.2 14.3 r/min 16.3 16.4 16.4 16.5 20.1 16.5 cos j 10.2 10.3 16.6 16.7 Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 16 Product description Identification Nameplate N version gearbox 5.2+5.3+5.4 7.1+7.2 10.2+10.3 20.1 Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 17 Partial load efficiencies for 50Hz operation at a rated power of 50% and 75% CC number Department of Energy (optional) Permissible ambient temperature (e.g. Ta £ 40°C) Weight Encoder data 33.1 Encoder type 33.2 Encoder voltage Internal key: QR code Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 18 <320 < 400 <540 G50BS280 g500−S8000 <360 <360 <420 <500 <620 <760 <880 G50BS314 g500−S14000 <540 <600 <680 <800 <920 <1050 G50BS319 g500−S19000 <800 <860 <940 <1080 <1200 <1320 Tab. 1 Weights in kg Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 19 They are exclusively determined for mounting/dismounting the motor to the gearbox and must not be used for the complete geared motor! Fig. 1 Ear for transporting the complete drive system Stop! Observe load carrying capacity! Standing beneath floating loads is prohibited! Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 20 ¯ In some cases, due to lack of space, stud bolts with nuts must be used instead of head screws. In these cases, contact Lenze, if necessary. Tighten all screw connections with the torques given and lock them with standard...

- Page 21 10.9 with correspondingly high tightening torques. – Secure screwed connections using screw locking adhesive. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 22 Note! With unfavourable combinations of a small ratio and a high input speed, the use of a compensation reservoir may also be advisable in other mounting positions. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 23 Gearbox with output flange ¯ Especially with regard to applications with an alternating load, Lenze recommends...: – the use of anaerobic adhesive between the gearbox flange and mounting area in order to increase the friction fit;...

- Page 24 Maximum permissible force F M Tab 1A / 2B −−−−− −−−−− −−−−− −−−−− −−−−− 1500 1500 1500 1500 1500 1500 1500 1500 1500 1500 1500 1500 1500 1700 1700 1700 1700 −−−−− 2600 3500 3500 Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 25 Tab. 3 Attachment of motors to gearboxes with mounting flanges * Use original featherkey of the motor 1) Featherkey for standard hub and clamping hub 2) Measured from the seating face of the motor flange Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 26 4. Lay spider in the coupling claw on the gearbox side. 5. Align claws of the motor−side coupling hub with its counterpart. 6. Slowly push on motor, and bolt on to the gearbox flange. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 27 5. Lay spider in the coupling claw on the gearbox side. 6. Align claws of the motor−side coupling hub with its counterpart. 7. Slowly push on motor, and bolt on to the gearbox flange. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 28 3. Tighten the screws in the forcing threads crosswise and step−by−step so that the clamping ring is loosened. 4. Clean and grease all contact surfaces including threads and head of the clamping screws before reassembly. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 29 Take up forces only via the hollow shaft, and not via gearbox housing. 5. Secure the gearbox axially: – The hollow shaft has snap ring grooves for axial securing. Parts used to fix the shaft are not included in the scope of supply. K12.0611 Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 30 1. Undo axial gearbox locking in the hollow shaft. 2. Remove/extract the gearbox from the motor shaft using an appropriate auxiliary tool (LEERER MERKER). Fig. 5 Disassembly of gearboxes with hollow shaft, with auxiliary tool Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 31 ¯ During operation, the shrink disc has to be covered so that it is safe against contact by implementing suitable measures (e.g. cover). ¯ Degrease hollow shaft bore and machine shaft! Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 32 6. Slightly tighten clamping screws manually. 7. Tighten clamping screws (2) one after the other (see Fig. 7) in several passes, with rising torque, evenly until the indicated screw−tightening torque (see Tab. 7 ) is reached at all screws. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 33 If a different tightening torque is indicated on the shrink disc, this tightening torque has priority over the value indicated in the table. 8. Push protective cap (1, Fig. 6) onto the shrink disc. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 34 ¯ the connection is spinning due to overload or a too low friction factor and fretting corrosion has occurred, ¯ the shrink disc has been tightened too much leading to a plastic deformation of components, ¯ the components are corroded. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 35 1. Screw reducing bushes (3) into the flange so that they are flush using a screwdriver. 2. Fasten the protective cap (1) over the reducing bushes (3) on the flange using cheese head screws (2). Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 36 4.3.11 Foot mounting The foot on the g500−S130 … S660 gearboxes can be mounted in three positions (3, 4, 5) using the supplied screws. It is mounted on side 6 using 4 screws and additionally on side 1 using 2 screws. The screws must be mounted according to the hole pattern on the foot (see figure) depending on the foot position.

- Page 37 G50BS221 g500−S2100 2x12 G50BS231 g500−S3100 2x12 G50BS245 g500−S4500 2x12 G50BS280 g500−S8000 G50BS314 g500−S14000 G50BS319 g500−S19000 Note! Solvents, oils, greases, and fuels damage the rubber elements. Be absolutely sure to prevent contact with these substances! Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 38 To correctly connect the motor options, e. g. brakes or feedback systems, please observe: ¯ the notes in the corresponding terminal box ¯ the notes in the corresponding operating instructions ¯ the technical data on the corresponding motor nameplate. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 39 Has the transport locking device been removed? Stop! At input speeds below 200 rpm the amount of lubricant may need to be increased. Consultation with Lenze is required. Initial commissioning In order to ensure trouble−free operation, carry out checks during initial commissioning.

- Page 40 ¯ In the event of faults: – shut down the drive, – check the troubleshooting table. If the fault cannot be remedied, please contact the Lenze customer service. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 41 – The service life depends on the operating conditions. – Replace seals in case of leakage to avoid consequential damage. Stop! For drive systems: Also observe the maintenance intervals for the other drive components! Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 42 ^ 55 Maintenance operations Gearboxes and geared motors are ready to use on delivery and filled by Lenze with the lubricant type and lubricant quantity indicated on the nameplate. The first filling corresponds to the mounting position and design indicated on the nameplate.

- Page 43 7.3.1 Position of the lubricant monitoring elements G50BS113 ... G50BS166 Mounting position A Mounting position B Mounting position C G50BS113 G50BS140+ G50BS166 G50BS122 G50BS122 G50BS122 G50BS140 G50BS113 G50BS113 G50BS113 G50BS122 Filling Drain Breathing Control Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 44 Maintenance Maintenance operations Position of the lubricant monitoring elements Mounting position D Mounting position E Mounting position F G50BS113 G50BS113 G50BS113 Filling Drain Breathing Control Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 45 Maintenance Maintenance operations Position of the lubricant monitoring elements G50BS195 ... G50BS245 Mounting position A Mounting position B Mounting position C Filling Drain Breathing Control Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 46 Maintenance Maintenance operations Position of the lubricant monitoring elements Mounting position D Mounting position E Mounting position F G50BS231 Filling Drain Breathing Control Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 47 Maintenance Maintenance operations Position of the lubricant monitoring elements G50BS280 ... G50BS319 Mounting position A Mounting position B Mounting position C Filling Drain 2−stage Breathing Control 3−stage Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 48 Maintenance Maintenance operations Position of the lubricant monitoring elements Mounting position D Mounting position E Mounting position F Filling Drain Breathing Control Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 49 Note! In case of ambient temperatures < −20°C or > +40°C, please contact Lenze! Observe increased starting torques at low temperatures! 7.3.3 Checking the oil level Note! Check the oil level in cold condition! Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 50 Checking the oil level Geared motor G50BS113 ... G50BS166 Check the oil level by means of the displayed dipsticks. Manufacture them according to the mounting position. Form template: dipsticks for G50BS113 A, C, F Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 51 Maintenance Maintenance operations Checking the oil level Form template: dipsticks for G50BS122 Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 52 Maintenance Maintenance operations Checking the oil level Form template: dipsticks for G50BS140 Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 53 Maintenance Maintenance operations Checking the oil level Form template: dipsticks for G50BS166 A, E Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 54 4. Reinsert drain plug (if necessary, replace seal). 5. Fill in lubricant through filler hole (quantities see nameplate). 6. Screw in breathing / oil filler plug. 7. Dispose of waste oil according to the applicable regulations. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 55 Maintenance Maintenance operations Lubricate roller bearings 7.3.5 Lubricate roller bearings The roller bearings on motors and gearboxes from Lenze are filled with the greases listed below: Ambient temperature Manufacturer Type Gearbox roller bearing −30 °C ... +50 °C Fuchs Renolit H 443 −30 °C ...

- Page 56 For horinzontal motor shafts to IP23 and for vertical motor shafts to IP20. Fig. 13 Motor with condensation drain holes Condensation drain holes Repair ¯ We recommend having all repairs carried out by the Lenze Service department. Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 57 If any malfunctions should occur during operation of the drive system, please check the possible causes using the following table. If the fault cannot be eliminated by one of the listed measures, please contact the Lenze Service. Fault Possible cause...

- Page 58 Notes Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 59 Notes Lenze ¯ MA 12.0013 ¯ 3.0...

- Page 60 © 06/2017 | MA 12.0013 | .VZ+ | 3.0 | TD09 Lenze Drives GmbH Postfach 10 13 52, 31763 Hameln Breslauer Straße 3, 32699 Extertal GERMANY Ü +49 5154 82−0 Ø +49 5154 82−2800 Ù lenze@lenze.com Ú www.lenze.com Û Lenze Service GmbH Breslauer Straße 3, D−32699 Extertal...

- Page 61 Montage- und Einschaltanleitung | Montage- und Einschaltanleitung | Mounting and switch-on instructions | Mounting and switch-on instructions Drehstrommotoren Lenze Smart Motor m300 Three-phase AC motors Lenze Smart Motor m300...

- Page 63 Montage- und Einschaltanleitung | Montage- und Einschaltanleitung | Mounting and switch-on instructions | Mounting and switch-on instructions DE - Lenze Smart Motor m300 EN - Lenze Smart Motor m300...

- Page 65 Inhalt Inhalt Über dieses Dokument Dokumentbeschreibung Weiterführende Dokumente Schreibweisen und Konventionen Sicherheitshinweise Grundlegende Sicherheitshinweise Bestimmungsgemäße Verwendung Vorhersehbarer Fehlgebrauch Handhabung Restgefahren Produktinformation Identifizierung der Produkte Typenschilder Produktcodes Ausstattung Mechanische Installation Wichtige Hinweise Transport Vorbereitung Aufstellung Abmessungen Gewichte Montage Elektrische Installation Wichtige Hinweise Netzanschluss Anschluss nach EN Anschluss nach UL...

-

Page 66: Table Of Contents

Inhalt Technische Daten Normen und Einsatzbedingungen Konformitäten/Approbationen Personenschutz und Geräteschutz Angaben zur EMV Umweltbedingungen Netzbedingungen Bemessungsdaten... - Page 67 Dokumentbeschreibung Weiterführende Dokumente Über dieses Dokument WARNUNG! Lesen Sie diese Dokumentation sorgfältig, bevor Sie mit den Arbeiten beginnen. ▶ Beachten Sie die Sicherheitshinweise! Dokumentbeschreibung Weiterführende Dokumente Informationen und Hilfsmittel rund um die Lenze-Produkte finden Sie im Internet: http://www.lenze.com à Download...

- Page 68 Über dieses Dokument Schreibweisen und Konventionen Schreibweisen und Konventionen Zur Unterscheidung verschiedener Arten von Informationen werden in diesem Dokument Konventionen ver- wendet. Zahlenschreibweise Dezimaltrennzeichen Punkt Es wird generell der Dezimalpunkt verwendet. Beispiel: 1 234.56 Warnhinweise UL-Warnhinweise Werden in englischer und französischer Sprache verwendet. UR-Warnhinweise Textauszeichnung Engineering Tools...

- Page 69 Sicherheitshinweise Bestimmungsgemäße Verwendung Sicherheitshinweise Wenn Sie die folgenden grundlegenden Sicherheitsmaßnahmen und Sicherheitshinweise missachten, kann dies zu schweren Personenschäden und Sachschäden führen! Beachten Sie die Vorgaben der beiliegenden und zugehörigen Dokumentation. Dies ist Voraussetzung für einen sicheren und störungsfreien Betrieb, sowie für das Erreichen der angegebenen Produkteigenschaften. Beachten Sie die spezifischen Sicherheitshinweise in den anderen Abschnitten! Grundlegende Sicherheitshinweise Personal...

- Page 70 Sicherheitshinweise Handhabung Vorhersehbarer Fehlgebrauch • Direkt am Inverter betreiben • In Ex.-Bereichen verwenden • In agressiven Umgebungen • Unter Wasser • Unter Strahlung • Dauerhafter Generatorbetrieb Handhabung • Das Produkt niemals trotz erkennbarer Schäden in Betrieb nehmen. • Das Produkt niemals technisch verändern. •...

- Page 71 Sicherheitshinweise Restgefahren Restgefahren Auch wenn gegebene Hinweise beachtet und Schutzmaßnahmen angewendet werden, können Restrisiken verbleiben. Die genannten Restgefahren muss der Anwender in der Risikobeurteilung für seine Maschine/Anlage berück- sichtigen. Nichtbeachtung kann zu schweren Personenschäden und Sachschäden führen! Produkt Beachten Sie die Warnschilder auf dem Produkt! Symbol Beschreibung Elektrostatisch gefährdete Bauelemente:...

- Page 72 Produktinformation Produktinformation Identifizierung der Produkte Typenschilder 16.1 16.2 16.4 16.5 14.1 r/min 16.3 14.2 cos j 16.6 16.10 10.2 10.3 20.1 Pos. Inhalt Hersteller / Produktionsstandort Motorart / Norm Motortyp Technische Daten Bemessungsdrehmoment M2 Bemessungsdrehzahl Bemessungsfrequenz Bremsendaten Bremse Bremsmoment Fertigungsdaten 10.2 Materialnummer 10.3...

- Page 73 Produktinformation Identifizierung der Produkte Produktcodes Inhalt Bemessungsdaten für verschiedene Frequenzen 16.1 Hz= Frequenz 16.2 kW= Motorleistung 16.3 r/min.= Motordrehzahl 16.4 V= Motorspannung 16.5 A= Motorstrom 16.6 cos ϕ= Motorleistungsfaktor 16.10 M1= Bemessungsdrehmoment Fertigungsjahr / Fertigungswoche UL File−Nummer Kundendaten 20.1 Kundenzusatzdaten Zulässige Umgebungstemperatur (z.

- Page 74 Produktinformation Ausstattung Ausstattung Anschluss Bremswiderstand Extern Interner Bremswiderstand Steueranschluss X1, X2 Einstellen der Drehzahlen M12-Steckverbinder per Smartphone per PC über NFC-Adapter Netzanschluss Im Klemmenkasten oder über Externer Bremswiderstand QUICKON-Steckverbinder Ausführung Anschluss Federkraftbremse Fuß (B3) (bei Auslieferung fertig verdrahtet) Flansch (B5) mit Durchgangsbohrungen Flansch (B14) mit Gewindebohrungen Kühlung Eigenlüfter...

- Page 75 Dokumentation. • Beachten Sie die Angaben zum Oberflächen‐ und Korrosionsschutz. • Umgebungsmedien − insbesondere chemisch aggressive − können Wellendichtringe, Lacke und Kunst- stoffe angreifen. Halten Sie bei Bedarf Rücksprache mit Ihrer zuständigen Lenze-Niederlassung. Transport • Für einen sachgemäßen Umgang sorgen.

- Page 76 Mechanische Installation Montage Gewichte Transport Die Transportgewichte entnehmen Sie den Lieferpapieren! Montage Übertragungselemente • Nur mit geeigneten Vorrichtungen auf- oder abziehen. • Zum Aufziehen die Zentrierbohrung in der Welle verwenden. • Stöße und Schläge vermeiden. • Bei Riementrieb, den Riemen nach Herstellerangaben kontrolliert spannen. •...

- Page 77 Elektrische Installation Wichtige Hinweise Elektrische Installation Wichtige Hinweise GEFAHR! Lebensgefährliche Spannung! An den Leistungsanschlüssen, auch bei abgezogenem Stecker: Restspannung >60 V! ▶ Produkt vom Netz trennen und warten, bis der Motor still steht. ▶ Auf Spannungsfreiheit prüfen! • Beachten Sie bei Arbeiten an unter Spannung stehenden Produkten die geltenden nationalen Unfallver- hütungsvorschriften.

- Page 78 Elektrische Installation Netzanschluss Anschluss nach EN Netzanschluss Anschluss nach EN Die folgenden Daten sind für einen 3-phasigen Netzanschluss mit 400 V gültig. Netzanschluss QUICKON-Steckverbinder Motor MSEMA☐☐063-42 MSEMA☐☐080-32 Anschluss Verlegeart Anschlusstyp QUICKON-Steckverbinder Leitungsausführung flexibel Leitungsquerschnitt Typ. Min. Max. Netzanschluss Leitung L1, L2, L3, PE Motor MSEMA☐☐063-42 MSEMA☐☐080-32...

- Page 79 Elektrische Installation Netzanschluss Anschluss nach EN Anschluss Einzelantrieb nach EN 60204-1 3/N/PE AC 400/480 V SELV/PELV F1 … F3 F1 … F3 DC 24 V (+19.2 … +28.8 V) max. 50 mA n. c. L2 L3 Rb1 Rb2 L2 L3 Rb1 Rb2 ①...

- Page 80 Elektrische Installation Netzanschluss Anschluss nach EN Anschluss Gruppenantrieb nach EN 60204-1 F1 … F3 PE L1 L2 L3 PE L1 L2 L3 PE L1 L2 L3 PE L1 L2 L3 PE L1 L2 L3 Max. Summe der Netz-Bemessungsströme bei 40 °C Leitungsinstallation nach EN 60204-1 Verlegeart...

- Page 81 Elektrische Installation Netzanschluss Anschluss nach UL Anschluss nach UL Die folgenden Daten sind für einen 3-phasigen Netzanschluss mit 480 V gültig. Netzanschluss QUICKON-Steckverbinder Motor MSEMA☐☐063-42 MSEMA☐☐080-32 Anschluss Anschlusstyp QUICKON-Steckverbinder Leitungsquerschnitt Typ. Min. Max. Netzanschluss Leitung L1, L2, L3, PE Motor MSEMA☐☐063-42 MSEMA☐☐080-32 Anschluss...

- Page 82 Elektrische Installation Netzanschluss Anschluss nach UL Anschluss Einzelantrieb nach UL 61800-5-1 3/N/PE AC 400/480 V SELV/PELV F1 … F3 F1 … F3 DC 24 V (+19.2 … +28.8 V) max. 50 mA n. c. L2 L3 Rb1 Rb2 L2 L3 Rb1 Rb2 ①...

- Page 83 Elektrische Installation Netzanschluss Anschluss nach UL WARNUNG! ▶ UL marking ▶ Suitable for use on a circuit capable of delivering not more than 5k rms symmetrical amperes, 480 V maxi- mum. ▶ When protected by fuses rated, see table below. ▶...

- Page 84 Elektrische Installation Motoranschluss WARNUNG! ▶ UL marking ▶ Suitable for motor group installation on a circuit capable of delivering not more than 5k rms symmetrical amperes, 480 V maximum. ▶ When protected by fuses rated, see table below. ▶ When protected by a circuit breaker having an interrupting rating not less than 5k rms symmetrical ampe- res, 480/277 V Maximum, see table below.

- Page 85 Inbetriebnahme Inbetriebnahme Sie haben zwei Möglichkeiten, den Lenze Smart Motor an die Anwendungen anzupassen: Werkzeug Voraussetzungen NFC-fähiges Smartphone • Android-Version ab V3.0 oder Tablet • Lenze-App "Lenze Smart Motor" - Download von www.Lenze.com oder aus dem Google-Store • Motor spannungsfrei schalten •...

- Page 86 0 r/min STOP: 0 r/min Abtriebsdrehzahl 2 500 ... 2600 r/min Rechtslauf: > 0 r/min Abtriebsdrehzahl 3 Lenze Smart Motor mit Getriebe: Die Über- Abtriebsdrehzahl 4 setzung i wird bei der Berechnung der Abtriebsdrehzahl 5 Abtriebsdrehzahl berücksichtigt. Hochlaufzeit [0.0 ... 20.0] s...

- Page 87 Inbetriebnahme Gerätedaten Parameter Wert Bemerkung Name Auslieferung Einstellbereich Materialnummer auftragsabhängig [Zahl] Identifizierung des Antriebs Gerätetype [Text] Firmeware Version [Text] Hardware Version [Text] Motor [Text] Getriebe [Text] Übersetzung [Zahl] Bremse [Text] Seriennummer [Text] Drehzahlen aktivieren Abtriebsdrehzahl Abtriebsdrehzahl aktivieren Statusmeldung Werte Drehrichtung X1.4 (DI1) X1.2 (DI2) X2.2 (DI3)

- Page 88 Inbetriebnahme Erweiterte Einstellungen Parameter Wert Bemerkung Name Auslieferung Einstellbereich Anhebung 0.0 % [0.0 ... 100.0] % Wirksam nur bei Energiesparfunktion = Ein: • Anhebung der Motorspannung im Bereich kleiner Dreh- zahlen. • Bei fördertechnischen Anwendungen mit Steiganteil kann damit das Zurückdrehen beim Anlaufen verhindert wer- den.

- Page 89 Inbetriebnahme Funktionsprüfung Vor dem ersten Einschalten • Ist der Antrieb äußerlich unbeschädigt? • Ist die mechanische Befestigung in Ordnung? • Ist der elektrische Anschluss ordnungsgemäß? • Sind die umlaufenden Teile und die Oberflächen, die hohe Temperaturen erreichen können, vor Berüh- rung geschützt? •...

- Page 90 Die Störung wird in den Historienspeicher eingetragen. • Lenze Smart Motor ohne Bremse: Der Motor wird abgeschaltet und trudelt aus. • Lenze Smart Motor mit Bremse: Der Motor wird abgeschaltet, die Bremse fällt ein. Warnung Die Störung wird in den Historienspeicher eingetragen.

- Page 91 NFC‐Kommunikation gestört 1. Netz einschalten und ausschalten. 2. Aktion wiederholen. RFID Schreibfehler (RFIW) 3. Tritt der Fehler erneut auf, wen- den Sie sich an den Lenze-Service. RFID Daten CRC ungültig (PS02) NFC‐Kommunikation gestört 1. Werkseinstellung laden. 2. Netz einschalten und ausschalten.

- Page 92 Lagerung Lagerung Lagerung bis zu einem Jahr: • Möglichst in der Herstellerverpackung • In trockener, schwingungsarmer Umgebung ohne aggressive Atmosphäre • Vor Staub und Stößen schützen • Klimatische Bedingungen gemäß den Technischen Daten einhalten 4Umweltbedingungen ^ 37...

- Page 93 Wartung Wartung • Oberflächen regelmäßig reinigen • Bei Ausführung mit Lüfter: Luftansaugwege regelmäßig reinigen Bremse • Wartungsarbeiten an der Bremse dürfen nur durch den Lenze Service durchgeführt werden!

- Page 94 • Überprüfen Sie die möglichen Störungsursachen zuerst anhand der 4Diagnose und Störungsbeseiti‐ gung ^ 30 • Lässt sich die Störung nicht durch eine der aufgeführten Maßnahmen beseitigen, verständigen Sie bitte den Lenze-Service. Die Kontaktdaten finden Sie auf der Rückseite dieser Dokumentation.

- Page 95 Entsorgung Entsorgung Die Produkte enthalten wiederverwertbare Rohstoffe. Tragen Sie zum Umweltschutz bei, indem Sie wert- volle Rohstoffe in die Wiederverwertung geben. Beachten Sie die aktuellen nationalen Bestimmungen! Was? Material Wohin? Paletten Holz Rückgabe an Hersteller, Spediteur oder Wert- stofferfassungssystem Verpackungsmaterial Papier, Karton, Pappe Wertstofferfassungssystem Kunststoffe...

-

Page 96: Technische Daten

Eurasische Konformität: Elektromagnetische Verträglichkeit von technischen Erzeugnissen Approbation GB Standard 12350-2009 cULus UL 61800-5-1 für USA und Kanada (Anforderungen der CSA 22.2 No.14) Industrial Control Equipment, Lenze File No. E132659 Personenschutz und Geräteschutz Schutzart IP55 EN 60529 Type 4 Indoor only NEMA 250... -

Page 97: Angaben Zur Emv

Technische Daten Normen und Einsatzbedingungen Netzbedingungen Angaben zur EMV Betrieb an öffentlichen Netzen Maßnahmen treffen, um die zu erwarten- Die Einhaltung der Anforderungen für die Maschine/Anlage den Funkstörungen zu begrenzen: liegt in der Verantwortung des Maschinen-/Anlagenherstel- lers! < 1 kW: mit Netzdrossel EN 61000-3-2 >... -

Page 98: Bemessungsdaten

Technische Daten Bemessungsdaten Bemessungsdaten Motor MSEMA☐☐063-42 MSEMA☐☐080-32 Netzspannung 3 AC 400 ... 480 3 AC 400 ... 480 1.75 Bemessungsdrehmoment Anlaufmoment -2600 ... -500 / 0 / 500 ... 2600 Verstellbereich r/min Bemessungsstrom 400 V 480 V 0.47 1.36 Bemessungsleistung Leistungsfaktor cos ϕ... - Page 99 Contents Contents About this document Document description Further documents Notations and conventions Safety instructions Basic safety instructions Application as directed Foreseeable misuse Handling Residual hazards Product information Identification of the products Nameplates Product codes Features Mechanical installation Important notes Transport Preparation Installation Dimensions...

- Page 100 Contents Technical data Standards and operating conditions Conformities/approvals Protection of persons and device protection EMC data Environmental conditions Electrical supply conditions Rated data...

-

Page 101: About This Document

▶ Please observe the safety instructions! Document description Further documents Information and tools with regard to the Lenze products can be found on the Internet: http://www.lenze.com à Download Notations and conventions This document uses the following conventions to distinguish different types of information:... -

Page 102: Safety Instructions

The procedural notes and circuit details described are only proposals. It is up to the user to check whether they can be adapted to the particular applications. Lenze does not take any responsibility for the suitability of the procedures and circuit proposals described. -

Page 103: Foreseeable Misuse

Safety instructions Handling Foreseeable misuse • Connect directly to the inverter • Use in potentially explosive areas • In aggressive environments • Under water • Under radiation • Permanent operation in generator mode Handling • Never commission the product in the event of visible damage. •... -

Page 104: Residual Hazards

Safety instructions Residual hazards Residual hazards Even if notes given are taken into consideration and protective measures are implemented, the occurrence of residual risks cannot be fully prevented. The user must take the residual hazards mentioned into consideration in the risk assessment for his/her machine/system. -

Page 105: Product Information

Product information Product information Identification of the products Nameplates 16.1 16.2 16.4 16.5 14.1 r/min 16.3 14.2 cos j 16.6 16.10 10.2 10.3 20.1 Pos. Contents Manufacturer / production location Type of motor / standard Motor type Technical data Rated torque M2 Rated speed Rated frequency Brake data... -

Page 106: Product Codes

Product information Identification of the products Product codes Contents Rated data for various frequencies 16.1 Hz = frequency 16.2 kW = motor power 16.3 r/min. = motor speed 16.4 V = motor voltage 16.5 A = motor current 16.6 cos ϕ= motor power factor 16.10 M1= rated torque Year of manufacture / week of manufacture UL file number... -

Page 107: Features

Product information Features Features Brake resistor connection External Internal brake resistor Control terminal X1, X2 Adjustment of speeds M12 connector by means of smartphone by means of PC via NFC adapter Mains connection In the terminal box or via External brake resistor QUICKON connector Type Connection of spring-applied brake... -

Page 108: Mechanical Installation

• Observe the information relating to the surface and corrosion protection. • Ambient media − especially chemically aggressive ones − may damage shaft sealing rings, lacquers and plastics. If required, contact your responsible Lenze subsidiary. Transport • Ensure appropriate handling. -

Page 109: Weights

Mechanical installation Mounting Weights Transport The transport weights can be found in the shipping documents! Mounting Transmission elements • Fit or remove transmission elements only using suitable equipment. • For fitting the transmission elements use the center hole in the shaft. •... -

Page 110: Electrical Installation

Electrical installation Important notes Electrical installation Important notes DANGER! Hazardous voltage! On the power connections even when disconnected from the mains: residual voltage >60 V! ▶ Disconnect the product from the mains and wait until the motor is at a standstill. ▶... -

Page 111: Mains Connection

Electrical installation Mains connection Connection according to EN Mains connection Connection according to EN The following data is valid for a three-phase mains connection with 400 V. Mains connection with QUICKON connector Motor MSEMA☐☐063-42 MSEMA☐☐080-32 Connection Installation method Connection type QUICKON connector Cable type Flexible... - Page 112 Electrical installation Mains connection Connection according to EN Single drive connection according to EN 60204-1 3/N/PE AC 400/480 V SELV/PELV F1 … F3 F1 … F3 DC 24 V (+19.2 … +28.8 V) max. 50 mA n. c. L2 L3 Rb1 Rb2 L2 L3 Rb1 Rb2...

- Page 113 Electrical installation Mains connection Connection according to EN Connection for group drive according to EN 60204-1 F1 … F3 PE L1 L2 L3 PE L1 L2 L3 PE L1 L2 L3 PE L1 L2 L3 PE L1 L2 L3 Max. total rated mains currents at 40 °C Cable installation in compli- EN 60204-1 ance with...

-

Page 114: Connection According To Ul

Electrical installation Mains connection Connection according to UL Connection according to UL The following data is valid for a three-phase mains connection with 480 V. Mains connection with QUICKON connector Motor MSEMA☐☐063-42 MSEMA☐☐080-32 Connection Connection type QUICKON connector cable cross‐section Typ. - Page 115 Electrical installation Mains connection Connection according to UL Single drive connection according to UL 61800-5-1 3/N/PE AC 400/480 V SELV/PELV F1 … F3 F1 … F3 DC 24 V (+19.2 … +28.8 V) max. 50 mA n. c. L2 L3 Rb1 Rb2 L2 L3 Rb1 Rb2...

- Page 116 Electrical installation Mains connection Connection according to UL WARNING! ▶ UL marking ▶ Suitable for use on a circuit capable of delivering not more than 5k rms symmetrical amperes, 480 V maxi- mum. ▶ When protected by fuses rated, see table below. ▶...

-

Page 117: Motor Connection

Electrical installation Motor connection WARNING! ▶ UL marking ▶ Suitable for motor group installation on a circuit capable of delivering not more than 5k rms symmetrical amperes, 480 V maximum. ▶ When protected by fuses rated, see table below. ▶ When protected by a circuit breaker having an interrupting rating not less than 5k rms symmetrical amperes, 480/277 V Maximum, see table below. - Page 118 Commissioning Commissioning You have two options to adapt the Lenze Smart Motor to the applications: Tool Preconditions NFC-capable smartphone or • Android version from V3.0 tablet • Lenze app "Lenze Smart Motor" - Download from www.Lenze.com or from the Google store •...

- Page 119 Output speed 2 500 ... 2600 rpm CW rotation: > 0 rpm Output speed 3 Lenze Smart motor with gearbox: The ratio i Output speed 4 is taken into account in the calculation of the Output speed 5 output speed.

- Page 120 Commissioning Device data Parameter Value Comment Designation Delivery Setting range Material number depending on the [number] Drive identification order Device types [Text] Firmware version [Text] Hardware Version [Text] Motor [Text] Gearbox [Text] Ratio [number] Brake [Text] Serial number [Text] Activating speeds Output speed Activate output speed Status message...

-

Page 121: Before Initial Switch-On

Commissioning Before initial switch-on Advanced settings Parameter Value Comment Designation Delivery Setting range boost 0.0 % [0.0 ... 100.0] % Effective only if Energy saving function = On: • Boost of the motor voltage in the range of low speeds. •... -

Page 122: Functional Test

Commissioning Functional test Functional test After commissioning, check all individual functions of the drive: • Rotating direction in decoupled state. • Torque behaviour and current consumption • Brake function During operation, carry out inspections on a regular basis. Pay special attention to: •... -

Page 123: Diagnostics And Fault Elimination

The fault is entered in the history buffer. • Lenze Smart Motor without brake: The motor is switched off and coasts down. • Lenze Smart motor with brake: The motor is switched off; the brake is applied. Warning The fault is entered in the history buffer. -

Page 124: Malfunctions

2. Connect and disconnect mains. 3. Rewrite parameter set. RFID data version invalid (PS04) Incompatible software version Update Lenze App or EASY Starter. Missing mains phase (SU02) A mains phase of a three-phase sup- • Check mains connection. ply has failed. Reliable detection from •... -

Page 125: Storage

Storage Storage Storage up to one year: • If possible, in the manufacturer's packaging • In dry, low‐vibration environment without aggressive atmosphere • Protect against dust and impacts • Observe the climatic conditions according to the technical data 4Environmental conditions ^ 70... -

Page 126: Maintenance

Maintenance Maintenance • Clean surfaces regularly • If equipped with blower: clean the air inlets regularly Brake • Maintenance work of the brake must only be carried out by Lenze Service personnel! -

Page 127: Repair

• First check the possible causes of malfunction according to the 4Diagnostics and fault elimination ^ 63 • If the fault cannot be remedied using one of the measures listed, please contact the Lenze Service depart- ment. The contact data can be found on the back cover of this documentation. -

Page 128: Disposal

Disposal Disposal The products contain recyclable raw materials. Help protect the environment by recycling valuable raw materials. Please observe the current national regulations! What? Material Where? Pallets Wood Return to manufacturers, freight forwarders or reusable materials collection system Packaging material Paper, cardboard, pasteboard Reusable materials collection system Plastics... -

Page 129: Technical Data

Approval GB Standard 12350-2009 cULus UL 61800-5-1 for USA and Canada (requirements of the CSA 22.2 No. 14) Industrial Control Equipment, Lenze File No. E132659 Protection of persons and device protection Enclosure IP55 EN 60529 Type 4 indoor only... -

Page 130: Emc Data

Technical data Standards and operating conditions Electrical supply conditions EMC data Actuation on public supply systems Implement measures to limit the radio The machine or plant manufacturer is responsible for com- interference to be expected: pliance with the requirements for the machine/plant! <... -

Page 131: Rated Data

Technical data Rated data Rated data Motor MSEMA☐☐063-42 MSEMA☐☐080-32 Mains voltage 3 400 ... 480 AC 3 400 ... 480 AC rated 1.75 Rated torque rated Starting torque -2600 ... -500 / 0 / 500 ... 2600 Adjustment range Output current 400 V rated 480 V... - Page 132 © 06/2018 | 13554164 | 2.0 Lenze Drives GmbH Ö Postfach 10 13 52, D-31763 Hameln Breslauer Straße 3, D-32699 Extertal Germany HR Lemgo B 6478 +49 5154 82-0 Ü +49 5154 82-2800 Ø sales.de@lenze.com Ù www.lenze.com Ú Lenze Service GmbH Û...

Need help?

Do you have a question about the g500 and is the answer not in the manual?

Questions and answers