Lenze g500-H Manual

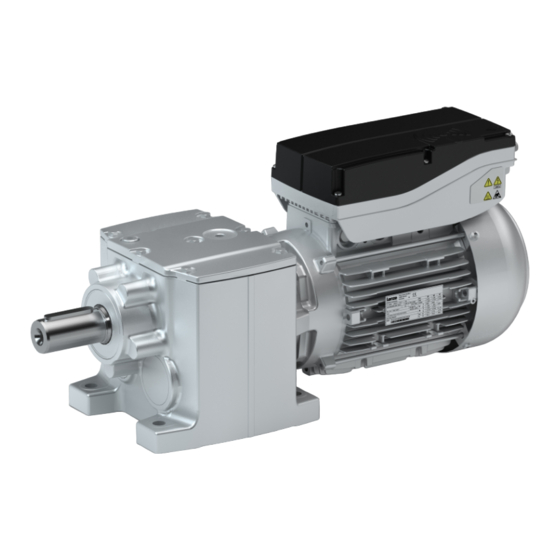

Mains-operated geared motors

Hide thumbs

Also See for g500-H:

- Manual (168 pages) ,

- Project planning (104 pages) ,

- Mounting and switch-on instructions (60 pages)

Summary of Contents for Lenze g500-H

- Page 1 Project planning EN Mains-operated geared motors g500-H helical geared motor / Smart Motor m300-E...

-

Page 3: Table Of Contents

Contents Contents About this document Document description Further documents Notations and conventions Product information Product description Identification of the products Features The modular system Designs Mounting positions Information on project planning Safety instructions Basic safety instructions Application as directed Residual hazards Drive dimensioning Final configuration Surface and corrosion protection... - Page 4 Contents Product extensions Motor connection Connection via terminal box Connection via QUICKON V2 connector Connection via M15 connector Connection via M12 connector Brakes Spring-applied holding brake Brake resistors Accessories NFC adapter QUICKON connector UMCLN_SGG_100181 Product codes Motor data Rated data Ecodesign Directive Environmental notes and recycling Appendix...

-

Page 5: About This Document

The documentation must always be complete and in a perfectly readable state. • Further documents Information and tools with regard to the Lenze products can be found on the Internet: www.Lenze.com à Downloads... -

Page 6: Notations And Conventions

About this document Notations and conventions Notations and conventions Conventions are used in this document to distinguish between different types of information. Numeric notation Decimal separator Point Generally shown as a decimal point. Example: 1 234.56 Warnings UL Warnings Are used in English and French. UR warnings Text Engineering Tools... -

Page 7: Product Information

Only an NFC-capable Android smartphone or the Lenze NFC adapter for PCs is needed as a tool. The data can therefore be read and written when the drive is in a de-energised state –... - Page 8 The Lenze Smart Products can be adjusted with an Android smartphone. The corresponding app in German and English can be obtained from www.Lenze.com or the Google Store. For convenience, the data records created can be archived on the smartphone and repeatedly transferred to the Lenze Smart Products for different applications.

- Page 9 Contactor and motor protection functions integrated The Lenze Smart Products can be started and stopped by mean of digital inputs. It is also possible to switch between different speeds and rotating directions. Up to 5 different speed modes (e.

-

Page 10: Identification Of The Products

Product information Identification of the products Application examples Roller conveyors with belt ejector Belt conveyors Identification of the products Gearbox product name Gearbox type Product series Type Rated torque Nm Gearbox g500-H45 g500-H100 g500-H140 g500-H210 g500-H320 Helical gearbox g500 g500-H450 g500-H600 g500-H850 1500... -

Page 11: Features

Product information Features Features The following figure provides an overview of the elements and connections on the product. Their position, size and appearance may vary. Ventilation (depending on the mounting position) Oil filler plug (depending on the mounting position) Remove oil control plug (depending on the mounting position) Output flange Output shaft... -

Page 12: The Modular System

Product information The modular system The modular system Values printed in bold are standard designs. Values that are not printed in bold are potential extensions, some of them including a surcharge. - Page 13 Product information The modular system Geared motors up to 450 Nm Gearboxes g500-H45 g500-H100 g500-H140 g500-H210 g500-H320 g500-H450 Min. motor assignment MSEMA□□ 063-42 063-42 063-42 063-42 063-42 063-42 Max. motor assignment MSEMA□□ 063-42 080-32 080-32 080-32 080-32 080-32 Technical data Max.

- Page 14 Product information The modular system Geared motors 600 Nm to 3000 Nm Gearboxes g500-H600 g500-H850 g500-H1500 g500-H3000 Min. motor assignment MSEMA□□ 063-42 063-42 063-42 063-42 Max. motor assignment MSEMA□□ 080-32 080-32 080-32 080-32 Technical data Max. output torque 1500 3000 Min.

-

Page 15: Designs

Product information The modular system Designs Designs Gearbox designs Observe the available gearbox designs! 4The modular system ^ 12 The VCP design (reinforced flange) is suitable for absorbing high radial and axial forces ^ 45 Solid shaft, with foot Without centring (VBR) With centring (VAR) Flange with through holes (VAK) Solid shaft, without foot... -

Page 16: Mounting Positions

Product information The modular system Mounting positions Mounting positions Details of the mounting position are needed to ensure the corresponding lubricant amount, position of the ventilation, oil checks and oil drain plug on the gearbox. To reduce the number of different versions, the following gearboxes can also be ordered with combined mounting positions: g500-H45 in mounting position M1-M6 (A-F) •... - Page 17 Product information The modular system Mounting positions Position of the terminal boxes Positions of the connections Mains connection Control terminal Cable gland for terminal box M12 connector QUICKON V2 connector M15 connector Position of the manual release lever...

-

Page 18: Information On Project Planning

Information on project planning Safety instructions Basic safety instructions Information on project planning Safety instructions Basic safety instructions Disregarding the following basic safety instructions and safety information may lead to severe personal injury and damage to property! Only use the product as directed. •... -

Page 19: Residual Hazards

Information on project planning Safety instructions Residual hazards Residual hazards Even if notes given are taken into consideration and protective measures are implemented, the occurrence of residual risks cannot be fully prevented. The user must take the residual hazards mentioned into consideration in the risk assessment for his/her machine/system. - Page 20 Information on project planning Safety instructions Residual hazards Gearbox protection Excessive vibration accelerations and resonances will damage the gearbox. • Do not operate the gearbox at vibration accelerations > 2 g (20 m/s ) of the machine. Do not operate the gearbox in the resonance range of the machine. Excessive torques will damage the gearboxes.

-

Page 21: Drive Dimensioning

With the «Drive Solution Designer«, you can design the drive both quickly and to a high quality. The software contains profound and proven expertise with regard to drive applications and mechatronic drive components. Please get in touch with your Lenze representative. Mains operation Check operating conditions... - Page 22 Information on project planning Drive dimensioning Determine correction factor Ambient temperature °C ≤ 40 Correction factor Installation height amsl ≤ 1000 m ≤ 2000 m ≤ 3000 m ≤ 4000 m Correction factor 0.95 Determine product on the basis of the forces Transmission element Gear wheels Sprockets...

-

Page 23: Final Configuration

STOP: 0 rpm Output speed 2 [500/i ... 2600/i] rpm CW rotation: > 0 rpm Output speed 3 Lenze Smart Motor with gearbox: The ratio i is Output speed 4 taken into account when calculating the output Output speed 5 speed. -

Page 24: Surface And Corrosion Protection

Information on project planning Final configuration Surface and corrosion protection Direction of rotation of the output shaft The direction of rotation of the output shaft is defined by the setpoint of the output speed. The direction of rotation is changed when a positive (n > 0) or negative (n < 0) speed is specified. -

Page 25: Lubricants

Information on project planning Final configuration Lubricants Lubricants The following gearboxes are lubricated for life: g500-H45 • g500-H100 • g500-H140 • Recommended lubricants: Lubricant CLP 220 CLP 460 CLP HC 220 CLP HC 320 Ambient temperature 0 … +40 °C -30 …... -

Page 26: Ventilation

Information on project planning Final configuration Ventilation Ventilation No ventilation is required for the gearboxes g500-H45 …H210. The gearbox g500-H210 can optionally be fitted with ventilation units. From g500-H320onwards, the gearboxes are supplied with ventilation units as standard. To reduce the number of different versions, the following gearboxes can also be ordered with combined mounting positions: g500-H45 in mounting position M1-M6 (A-F) •... - Page 27 Information on project planning Final configuration Ventilation g500-H210 ... H450 Mounting position M1 (A) Mounting position M2 (D) Mounting position M3 (B) Filling and ventilation Control Drain...

- Page 28 Information on project planning Final configuration Ventilation Mounting position M4 (C) Mounting position M5 (F) Mounting position M6 (E) Filling and ventilation Control ① ② Drain g500-H210 ① g500-H320 ② g500-H450...

- Page 29 Information on project planning Final configuration Ventilation g500-H600 ... H3000 Mounting position M1 (A) Mounting position M2 (D) Mounting position M3 (B) Filling and ventilation Check Drain...

- Page 30 Information on project planning Final configuration Ventilation Mounting position M4 (C) Mounting position M5 (F) Mounting position M6 (E) Filling and ventilation Control Drain Gearbox with oil compensation reservoir for mounting position M4 (C) In order to guarantee a reliable lubrication of the toothed parts in mounting position M4 (C) (motor is on the gearbox vertical from the top), a high filling level is required in the gearbox.

- Page 31 Information on project planning Final configuration Ventilation Dimensions of the oil compensation reservoir For the following gearboxes in mounting position M4 (C), which exceed the specified min. input speed, an oil expansion reservoir is required depending on the specified gear ratio: g500-H1500 g500-H3000 Gearbox ratio...

-

Page 32: Information On Mechanical Installation

• nameplate and in this documentation. Ambient media − especially chemically aggressive ones − may damage shaft sealing rings, • lacquers and plastics. Lenze offers special surface and corrosion protection in this case. • Transport Ensure appropriate handling. • Make sure that all component parts are securely mounted. Secure or remove loose •... -

Page 33: Information On Electrical Installation

Information on electrical installation Important notes Information on electrical installation Important notes DANGER! Risk of injury and risk of burns from dangerous voltage Power terminals may also carry voltage in the switched-off state or when the motor is stopped and may cause life-threatening cardiac arrhythmia and serious burns. ▶... -

Page 34: Connection According To En

Information on electrical installation Connection according to EN Connection according to EN The following data is valid for a three-phase mains connection with 400 V. Mains connection with QUICKON connector Motor MSEMA☐☐063-42 MSEMA☐☐080-32 Connection Laying system Connection type QUICKON connector Cable type Flexible Cable cross-section... - Page 35 Information on electrical installation Connection according to EN Single drive connection according to EN IEC 60204−1 3/N/PE AC 400/480 V SELV/PELV F1 … F3 F1 … F3 DC 24 V (+19.2 … +28.8 V) max. 50 mA n. c. L2 L3 Rb1 Rb2 L2 L3 Rb1 Rb2...

- Page 36 Information on electrical installation Connection according to EN Group drive connection according to EN IEC 60204−1 F1 … F3 PE L1 L2 L3 PE L1 L2 L3 PE L1 L2 L3 PE L1 L2 L3 PE L1 L2 L3 Max. total rated mains currents at 40 °C for different cable cross-sections Cable installation in accordance EN IEC 60204−1...

-

Page 37: Connection According To Culus

Information on electrical installation Connection according to cULus Connection according to cULus The following data is valid for a three-phase mains connection with 480 V. Mains connection with QUICKON connector Motor MSEMA☐☐063-42 MSEMA☐☐080-32 Connection Connection type QUICKON connector Cable cross-section Typ. - Page 38 Information on electrical installation Connection according to cULus WARNING! ▶ UL marking ▶ Use 75 °C copper wire only, except for control circuits. ▶ Maximum conductor size is AWG14. ▶ Cord connected drives are for use only in NFPA 79 applications. ▶...

- Page 39 Information on electrical installation Connection according to cULus Fuse data (F1 ... F3) Motor MSEMA☐☐063-42 MSEMA☐☐080-32 Cable installation in accordance NFPA 70, NFPA 79 with Fuse Standard UL 248 Typ. Rated current Max. rated current Semiconductor fuse Standard UL 248 Typ.

- Page 40 Information on electrical installation Connection according to cULus Max. total rated mains currents at 40 °C for different cable cross-sections Cable installation in accordance NFPA 70, NFPA 79 with Main cable Cable cross-section Stub Cable cross-section Fuse Typ. Rated current Max.

-

Page 41: Technical Data

The ratings apply to the operating mode S1 (acc. to EN 60034-1). • NOTICE In case of other operating conditions, the achievable values can differ for those mentioned. ▶ In case of extreme operating conditions, please get in touch with your Lenze representative. -

Page 42: Standards And Operating Conditions

The Electrical Equipment (Safety) Regulations 2016 S.I. 2021/745 The Ecodesign for Energy-Related Products and Energy Information Regulations 2021 Approvals GB Standard 12350-2009 For USA and Canada (requirements of the CSA 22.2 No.14) Industrial Control Equipment, Lenze File cULus UL 61800-5-1 No. E132659... -

Page 43: Protection Of Persons And Device Protection

Technical data Standards and operating conditions Protection of persons and device protection Protection of persons and device protection Degree of protection EN IEC 60529,EN IEC Information applies to the mounted and ready- IP55 60034-5 for-use state Type 12 NEMA NEMA 250 Type 4 indoor only Depending on the configuration Insulation resistance... -

Page 44: Environmental Conditions

Technical data Standards and operating conditions Environmental conditions Environmental conditions Climate 1K3 (-30 ... +60°C) <3 months Storage EN 60721-3-1:1997 1K3 (-30 ... +40 °C) >3 months Transport EN 60721-3-2:1997 2K3 (-30 ...+70 °C) EN 60721-3-3:1995 + Operation 3K3 (-30 ...+40 °C) Operation A2:1997 Site altitude... -

Page 45: Radial Forces And Axial Forces

Technical data Radial forces and axial forces Radial forces and axial forces Permissible radial force The calculation of the permissible radial force must take account of the additional load factor rad, perm rad,max If the direction of action α and the direction of rotation (R/L) at the output shaft are known, the following can be calculated taking into account the direction of action factor f (see α... - Page 46 1.3 and an input speed of 1400 rpm. In case of different operating conditions, considerably higher forces can be transmitted. Please get in touch with your Lenze representative Max. radial force, gearbox with foot (VBR) Output speed n...

- Page 47 Technical data Radial forces and axial forces Max. radial force, gearbox with/without foot with threaded pitch circle (V□R/V□K) Output speed n [rpm] Getriebe 1000 Max. radial force F rad,max g500-H45 1100 1400 1500 1500 g500-H100 1000 1200 1500 1700 1700 1700 1700 1700...

- Page 48 Technical data Radial forces and axial forces Effective direction factor f on the output shaft α g500-H45 1.45 1.40 1.35 1.30 1.25 1.20 1.15 1.10 1.05 1.00 30 60 90 120 150 180 210 240 270 300 330 360 α 2-stage: Direction of rotation R 2-stage: Direction of rotation L g500-H100...

- Page 49 Technical data Radial forces and axial forces g500-H850 g500-H1500 1.25 1.35 1.30 1.20 1.25 1.15 1.20 1.15 1.10 1.10 1.05 1.05 1.00 1.00 30 60 90 120 150 180 210 240 270 300 330 360 30 60 90 120 150 180 210 240 270 300 330 360 α...

-

Page 50: Selection Tables

Technical data Selection tables Selection tables Notes on the selection tables The selection tables represent the available combinations of gearbox, number of stages, ratio and motor for the mounting position M1. They only serve as a rough overview. The following legend shows the layout of the selection tables: Example Explanation = 7.0 Nm... - Page 51 Technical data Selection tables 7 Nm Mains operation Geared motor Min. output speed Max. output speed Starting torque a, 1 a, 2 kgcm² 1001 18.0 17.6 3.960 2.597 g500-H45 MSEMA□□063-42 22.0 22.2 4.602 3.267 g500-H140 MSEMA□□063-42 23.0 22.8 4.225 3.354 g500-H100 MSEMA□□063-42 19.0...

- Page 52 Technical data Selection tables Mains operation Geared motor Min. output speed Max. output speed Starting torque a, 1 a, 2 kgcm² 23.5 36.0 36.0 44.0 55.0 3.727 21.350 g500-H45 MSEMA□□063-42 23.0 37.0 37.0 3.811 21.808 g500-H140 MSEMA□□063-42 23.0 37.0 37.0 3.882 21.802 g500-H210...

- Page 53 Technical data Selection tables Mains operation Geared motor Min. output speed Max. output speed Starting torque a, 1 a, 2 kgcm² 93.0 46.6 93.0 4.164 55.710 g500-H600 MSEMA□□063-42 94.0 47.0 94.0 3.887 55.307 g500-H600 MSEMA□□063-42 94.0 46.0 94.0 3.951 56.469 g500-H450 MSEMA□□063-42 95.0...

- Page 54 Technical data Selection tables Mains operation Geared motor Min. output speed Max. output speed Starting torque a, 1 a, 2 kgcm² 15.6 3.721 166.541 g500-H320 MSEMA□□063-42 14.9 3.772 173.536 g500-H600 MSEMA□□063-42 14.7 3.754 176.611 g500-H450 MSEMA□□063-42 14.1 3.885 183.577 g500-H850 MSEMA□□063-42 13.7 3.720...

- Page 55 Technical data Selection tables Mains operation Geared motor Min. output speed Max. output speed Starting torque a, 1 a, 2 kgcm² 1299 1299 3000 3300 3.871 788.632 g500-H3000 MSEMA□□063-42 1300 1300 1500 1650 3.872 788.863 g500-H1500 MSEMA□□063-42 1427 1427 3000 3300 3.871 866.202...

- Page 56 Technical data Selection tables 20 Nm Mains operation Geared motor Min. output speed Max. output speed Starting torque a, 1 a, 2 kgcm² 10.0 1233 10.0 41.0 40.9 26.600 2.108 g500-H100 MSEMA□□080-32 16.0 16.0 63.0 63.4 26.902 3.267 g500-H140 MSEMA□□080-32 16.0 16.0 62.0...

- Page 57 Technical data Selection tables Mains operation Geared motor Min. output speed Max. output speed Starting torque a, 1 a, 2 kgcm² 26.7 91.0 91.0 26.285 18.750 g500-H210 MSEMA□□080-32 25.7 95.0 95.0 26.069 19.486 g500-H100 MSEMA□□080-32 25.4 96.0 96.0 26.114 19.750 g500-H140 MSEMA□□080-32 24.2...

- Page 58 Technical data Selection tables Mains operation Geared motor Min. output speed Max. output speed Starting torque a, 1 a, 2 kgcm² 49.3 26.067 52.715 g500-H320 MSEMA□□080-32 48.4 26.131 53.703 g500-H320 MSEMA□□080-32 47.4 26.116 54.750 g500-H450 MSEMA□□080-32 46.6 26.464 55.710 g500-H600 MSEMA□□080-32 47.0 26.187...

- Page 59 Technical data Selection tables Mains operation Geared motor Min. output speed Max. output speed Starting torque a, 1 a, 2 kgcm² 1490 1490 1500 1650 26.253 316.487 g500-H1500 MSEMA□□080-32 1512 1512 3000 3750 27.218 321.282 g500-H3000 MSEMA□□080-32 1648 1648 1500 1650 26.253 350.054...

-

Page 60: Dimensions

If the mounting area (foot support) towards the motor is longer than the gearbox foot, some motors collide with the mounting area! For an accurate check of the geometrical data, Lenze recommends the use of the »Product Finder« at www.Lenze.com. -

Page 61: Basic Dimensions

Technical data Dimensions Basic dimensions Basic dimensions g500-H45, 2-stage Gearbox design: Solid shaft with foot (VBR) Motor series MSEMA Motor 063-42 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96... - Page 62 Technical data Dimensions Basic dimensions g500-H45, 2-stage Gearbox design: Solid shaft and foot/centering (VCR) Motor series MSEMA Motor 063-42 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 63 Technical data Dimensions Basic dimensions g500-H45, 2-stage Gearbox design: Solid shaft and foot/flange (VCK) Motor series MSEMA Motor 063-42 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 64 Technical data Dimensions Basic dimensions g500-H100, 2-stage Gearbox version: Solid shaft with foot (VBR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 65 Technical data Dimensions Basic dimensions g500-H100, 2-stage Gearbox version: Solid shaft with foot/centering (VAR/VCR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 66 Technical data Dimensions Basic dimensions g500-H100, 2-stage Gearbox design: Solid shaft and foot/flange (VAK/VCK) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 67 Technical data Dimensions Basic dimensions g500-H100, 2-stage Gearbox design: Solid shaft and flange (VCP) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 68 Technical data Dimensions Basic dimensions g500-H140, 2-stage Gearbox design: Solid shaft with foot (VBR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 69 Technical data Dimensions Basic dimensions g500-H140, 2-stage Gearbox design: Solid shaft with foot/centering (VAR/VCR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 70 Technical data Dimensions Basic dimensions g500-H140, 2-stage Gearbox design: Solid shaft and foot/flange (VAK/VCK) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 71 Technical data Dimensions Basic dimensions g500-H140, 2-stage Gearbox design: Solid shaft and flange (VCP) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 72 Technical data Dimensions Basic dimensions g500-H210, 2-/3-stage Gearbox design: Solid shaft with foot (VBR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 73 Technical data Dimensions Basic dimensions g500-H210, 2-/3-stage Gearbox version: Solid shaft with foot/centering (VAR/VCR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 74 Technical data Dimensions Basic dimensions g500-H210, 2-/3-stage Gearbox design: Solid shaft and foot/flange (VAK/VCK) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 75 Technical data Dimensions Basic dimensions g500-H210, 2-/3-stage Gearbox design: Solid shaft and flange (VCP) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 76 Technical data Dimensions Basic dimensions g500-H320, 2-/3-stage Gearbox version: Solid shaft with foot (VBR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 77 Technical data Dimensions Basic dimensions g500-H320, 2-/3-stage Gearbox version: Solid shaft with foot/centering (VAR/VCR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 78 Technical data Dimensions Basic dimensions g500-H320, 2-/3-stage Gearbox design: Solid shaft and foot/flange (VAK/VCK) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 79 Technical data Dimensions Basic dimensions g500-H320, 2-/3-stage Gearbox design: Solid shaft and flange (VCP) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 80 Technical data Dimensions Basic dimensions g500-H450, 2-/3-stage Gearbox design: Solid shaft with foot (VBR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 81 Technical data Dimensions Basic dimensions g500-H450, 2-/3-stage Gearbox design: Solid shaft with foot/centering (VAR/VCR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 82 Technical data Dimensions Basic dimensions g500-H450, 2-/3-stage Gearbox design: Solid shaft and foot/flange (VAK/VCK) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 83 Technical data Dimensions Basic dimensions g500-H450, 2-/3-stage Gearbox design: Solid shaft and flange (VCP) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 84 Technical data Dimensions Basic dimensions g500-H600, 2-/3-stage Gearbox design: Solid shaft with foot (VBR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 85 Technical data Dimensions Basic dimensions g500-H600, 2-/3-stage Gearbox design: Solid shaft with foot/centering (VAR/VCR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 86 Technical data Dimensions Basic dimensions g500-H600, 2-/3-stage Gearbox design: Solid shaft and foot/flange (VAK/VCK) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 87 Technical data Dimensions Basic dimensions g500-H850, 2-/3-stage Gearbox design: Solid shaft with foot (VBR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 88 Technical data Dimensions Basic dimensions g500-H850, 2-/3-stage Gearbox design: Solid shaft with foot/centering (VAR/VCR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 89 Technical data Dimensions Basic dimensions g500-H850, 2-/3-stage Gearbox design: Solid shaft and foot/flange (VAK/VCK) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 90 Technical data Dimensions Basic dimensions g500-H1500, 2-/3-stage Gearbox design: Solid shaft with foot (VBR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 91 Technical data Dimensions Basic dimensions g500-H1500, 2-/3-stage Gearbox version: Solid shaft with foot/centering (VAR/VCR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 92 Technical data Dimensions Basic dimensions g500-H1500, 2-/3-stage Gearbox design: Solid shaft and foot/flange (VAK/VCK) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 93 Technical data Dimensions Basic dimensions g500-H3000, 2-/3-stage Gearbox version: Solid shaft with foot (VBR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 94 Technical data Dimensions Basic dimensions g500-H3000, 2-/3-stage Gearbox design: Solid shaft with foot/centering (VAR/VCR) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

- Page 95 Technical data Dimensions Basic dimensions g500-H3000, 2-/3-stage Gearbox design: Solid shaft and foot/flange (VAK/VCK) Motor series MSEMA Motor 063-42 080-32 Total length Motor length Motor diameter Motor/connection distance Δ L 4Additional lengths ^ 96...

-

Page 96: Gearbox With Pre-Stage

Technical data Dimensions Gearbox with pre-stage Gearbox with pre-stage g500-H100 ... H140, 3-stage g500-H210 ... H3000, 4-stage The geared motor dimensions are taken from the basic dimensions except for the overall length "L" and the center distance "a". 4Basic dimensions ^ 61 The total length "L"... -

Page 97: Weights

Technical data Weights Basic weights Weights Basic weights The basic weights are listed in the selection tables. Weights with lubricant for mounting position M1, all data approximate values. The exact values can be found in the delivery documents tables 4Selection ^ 50 Observe weights ... -

Page 98: Product Extensions

Connection via terminal box Product extensions Motor connection The Lenze Smart Motor can be simply connected via connectors (QUICKON or M15 for power connection, M12 for control terminals). The power connection can alternatively be established in the terminal box via cable glands using spring terminals. -

Page 99: Connection Via M15 Connector

Product extensions Motor connection Connection via M15 connector Connection via M15 connector Mains connection X3 M15 power without temperature sensor Contact Name Meaning Not assigned Mains connection Phase L1 Mains connection Phase L2 Mains connection Phase L3 PE conductor... -

Page 100: Connection Via M12 Connector

Product extensions Motor connection Connection via M12 connector Connection via M12 connector Control connections with M12 connectors Via the digital inputs of the two M12 control connections, it is possible to switch between different speeds and directions of rotation. Up to 5 different speed settings (e. g. creep speed and normal speed in both directions, as well as stop) can thus be selected. -

Page 101: Brakes

Product extensions Brakes Brakes The motors can be ordered with a spring-applied brake to allow stopping or deceleration of the moving masses. The spring-applied brake operates according to the closed-circuit principle. In the deenergized state, the brake is closed, preventing possible movement of the motor shaft or the load after switching off or in the event of a power failure. -

Page 102: Spring-Applied Holding Brake

Product extensions Brakes Spring-applied holding brake Spring-applied holding brake LongLife version The application brake is available in a LongLife version for applications with very high switching frequencies. The standard design has a guaranteed service life for the brake mechanism of 1 million switching cycles. The LongLife version has a reinforced brake mechanism and up to 10 million repeating or 15 million reversing switching cycles possible. - Page 103 Product extensions Brakes Spring-applied holding brake Rated data, LongLife design, IP54/55 Holding brake Power input 180 V DC Moment of inertia kgcm² 0.15 0.61 Braking torque is static Min. static braking torque tolerance Max. static braking torque tolerance Reversing cycles 15x 10 15x 10 Repetitive cycles...

-

Page 104: Brake Resistors

Brake resistors Brake resistors The Lenze Smart Motor can be braked in a guided manner along a ramp. If large amounts of regenerative energy are produced during braking, they must be absorbed by a brake resistor. In addition to a brake resistor (10 W) mounted inside the terminal box, another brake resistor (20 W) can also be connected externally alongside the terminal box via the terminal X4. -

Page 105: Accessories

Accessories NFC adapter The settings of the Lenze Smart Products can be made with an NFC-capable Android smartphone or a PC. If a PC is used to make the settings, the »EASY Starter« engineering tool must be used to do this (»EASY Advanced« software licence). Communication takes place via the NFC adapter. -

Page 106: Quickon Connector

Accessories QUICKON connector QUICKON connector With the QUICKONconnectors, the mains connection is available in a pluggable version with a commonly used standard. Nuts for QUICKON connection For fast and easy QUICKON connection, the following nuts (counterparts) can be fitted to the connecting cable. -

Page 107: Umcln_Sgg_100181

Accessories UMCLN_SGG_100181 QUICKON V2 components for cable cross-section 2.5 ... 6 mm² Order code Type QUICKON V2 H-distributor • Number of poles: 5 • Connection cross-section: 6 mm² • Cable diameter: 9 ... 20 mm EWS0114 • Connection frequency: ≥ 50 •... -

Page 108: Product Codes

Product codes Product codes Gearbox product code Example Product type Gearboxes Product family Generation Gearbox type Helical gearbox Output torque 45 Nm 100 Nm 140 Nm 210 Nm 320 Nm 450 Nm 600 Nm 850 Nm 1500 Nm 3000 Nm 5000 Nm 8000 Nm 14000 Nm... - Page 109 Product codes Motor product code Example Meaning Variant Product code Product family Motor Product type Smart Motor Cooling Integral fan Internal key Built-on accessories Without built-on accessories Brake Size Overall length Number of pole pairs 4-pole motors Design types Internal key Approval CE;...

-

Page 110: Motor Data

Efficiency at 75 % rated load η Efficiency at 50 % rated load Efficiency level Name of the manufacturer Lenze SE · Hans-Lenze-Str. 1 · 31855 Aerzen · GERMANY Commercial register number Hannover HRB 204803 Model identifier of the MSEMA□□063-42 MSEMA□□080-32... -

Page 111: Environmental Notes And Recycling

Lenze products and their packaging: Lenze products are partly subject to the EU Directive on the restriction of certain hazardous substances in electrical and electronic equipment 2011/65/EU: RoHS Directive [UKCA: S.I. 2012/3032 - The Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 2012] . -

Page 112: Appendix

Appendix Good to know Operating modes of the motor Appendix Good to know Operating modes of the motor In continuous operation a motor reaches its permissible temperature limit if it outputs the rated power dimensioned for continuous operation. However, if the motor is only subjected to load for a short time, the power output by the motor may be greater without the motor reaching its permissible temperature limit. -

Page 113: Enclosures

Appendix Good to know Enclosures Intermittent operation S3 Non-intermittent periodic operation S6 Sequence of identical duty cycles comprising operation with a constant Sequence of identical duty cycles comprising operation with a constant load and subsequent standstill. Start-up and braking processes do not load and subsequent no-load operation. - Page 116 © 11/2021 · 2.0 · www.Lenze.com...

Need help?

Do you have a question about the g500-H and is the answer not in the manual?

Questions and answers