JUMO AQUIS touch P Interface Description

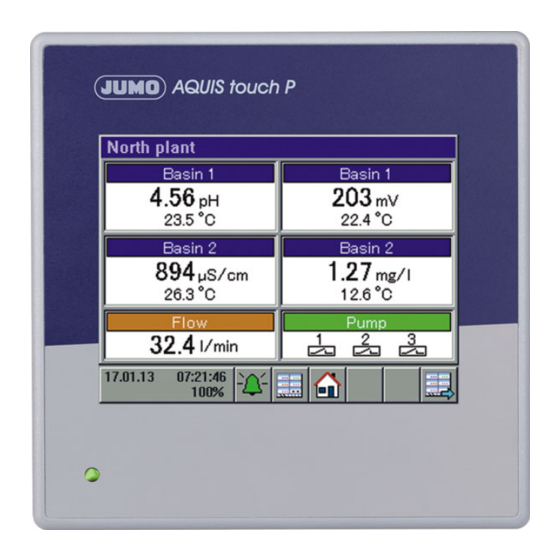

Modular multichannel measuring device for liquid analysis with integrated controller and paperless recorder

Hide thumbs

Also See for AQUIS touch P:

- Operating manual (404 pages) ,

- Operating manual (370 pages) ,

- Installation instructions manual (82 pages)

Summary of Contents for JUMO AQUIS touch P

- Page 1 JUMO AQUIS touch P Modular Multichannel Measuring Device for Liquid Analysis with Integrated Controller and Paperless Recorder Interface description PROFINET IO 20258007T92Z001K000 V3.00/EN/00661195...

-

Page 3: Table Of Contents

Project integration of JUMO IO devices ........ - Page 4 Contents...

-

Page 5: Safety Information

Safety information 1 Safety information Warning symbols DANGER! This symbol indicates that personal injury caused by electrical shock may occur if the respective pre- cautionary measures are not carried out. WARNING! This symbol in connection with the signal word indicates that personal injury may occur if the respective precautionary measures are not carried out. - Page 6 1 Safety information...

-

Page 7: Compatibility And System Requirements

Compatibility and system requirements 2 Compatibility and system requirements Certification JUMO IO devices are certified by the PNO to Conformance Class B (abbreviated to CC-B) and net load class "Netload Class III". PROFINET IO and Ethernet standard services The PROFINET interface supports all Ethernet standard services. Over this interface, the device can also be accessed via the JUMO PC setup program and the JUMP PCC/PCA software. - Page 8 2 Compatibility and system requirements...

-

Page 9: Electrical Connection

(3) free Ethernet port (e.g. for additional PROFINET IO devices) NOTE! The cyclical data exchange with JUMO PROFINET IO devices is based on the RT protocol (Confor- mance Class B). PROFINET RT communication cannot be routed. It is thus necessary that the PROF- INET IO controller and the IO devices be in a common broadcast domain (not connected via a router). - Page 10 3 Electrical connection...

-

Page 11: The Gsdml File

IO controller, the modules to be transferred via the PROFINET-IO have to be as- signed to the free slots of the JUMO IO device in the project structure of the IO controller. The IO items of the inserted modules are then available for the programming of the IO controller. The assignment of the JUMO field device data to the IO items of the individual modules is provided for the programmer in the printed module configuration list. - Page 12 Bit ad- Explanation dress Sub-module 1 Status bits 1 UINT Collective alarm Alarms and internal signals from the binary selection on the JUMO Collective alarm acknowl- AQUIS touch P edged Collective alarm for control ac- knowledged Memory alarm Login Fault USB inserted –...

- Page 13 Bit item Bit ad- Explanation dress Controller 1 actual value Real – – Analog input signals from the ana- log input selection on the JUMO Controller 1 setpoint val- Real – – AQUIS touch P Controller 1 output Real –...

- Page 14 Bit field for binary out- USINT Digital output 1 (OUT1) Digital output signals from the dig- puts/limit values ital output selection on the JUMO Digital output 2 (OUT2) AQUIS touch P – Digital output 4 (OUT6) Digital output 5 (OUT7)

- Page 15 4 The GSDML file Cyclical IO data, DeviceStatusBlock IO item Type Bit item Bit ad- Explanation dress Empty byte USINT – Not used...

- Page 16 The configurable modules are intended exclusively for transferring cyclical IO data. The assignment of the modules can be compiled and printed via the JUMO PC setup program of the AQUIS touch P. The printed list will help you maintain an overview of the configured modules of the JUMO IO device during the project planning and programming of the IO controller (PLC, host PC or similar).

-

Page 17: Noncyclical Data Exchange

CAUTION! All temperature values of the JUMO IO device are transferred in the unit "°C". Misinterpretation of measured values of a JUMO IO device in the IO controller can cause errors in the system control. Respect the unit for the transferred temperature values! - Page 18 Waiting time 0.5 to 2 s RDREC.request Transfer of the data exchange packet RDREC.BUSY = TRUE with response data from the IO device to the IO controller JUMO IO device Unpacking and Transfer of processing of the RDREC.response response data:...

-

Page 19: Single-Id And Multi-Id

5 Noncyclical data exchange 5.1.1 Single-ID and Multi-ID To implement the exchange of single (Single-ID) or multiple (Multi-ID) noncyclical data points, you must take the following actions: • Declare 1 data structure for both the outgoing and the incoming direction. Select the "Single-ID" for- mat to transfer 1 data point within a data exchange sequence. - Page 20 Incoming: the data exchange packet of the query from the IO controller, ERROR and then controls the processing of data in the JUMO IO device. Encoding: Value= 1: Writing (from the IO controller to the IO device) Value= 2: Reading (from the IO device to the IO controller)

- Page 21 The "ID-PLC" value must be used by the IO controller for se- quentially numbering the outgoing data exchange packets. JUMO IO devices enter the same number in the ID-PLC in the data exchange packet of the ensuing response, so that re-...

- Page 22 IO con- troller. The "DIR" variables control the process- Any basic data type with a VALUE_1 ing of the single data points in the JUMO IO length of 32 bits device accordingly. Query/re-...

- Page 23 PROFINET IO function blocks. Instead, data exchange packets that are processed by the IO device are transferred. The IO controller has to write a data exchange packet to the JUMO IO device via query data (WRREC). JUMO IO devices accept the data from the data exchange packet and then prepare this pack- et with response data for the IO controller.

- Page 24 JUMO IO device. The data have to be copied from here to the target before they are overwritten by another read request.

-

Page 25: Data Tables Of Noncyclical Data

CAUTION! All temperature values of the JUMO IO device are transferred in the unit "°C". Misinterpretation of measured values of a JUMO IO device in the IO controller can cause errors in the system control. Respect the unit for the transferred temperature values! 5.2.1... - Page 26 5 Noncyclical data exchange Limit values of pH/redox/NH for analysis inputs IN7 and IN8 Index Signal designation Data type Access Limit value for analysis input IN7 alarm 1 REAL Read/Write Limit value for analysis input IN7 alarm 2 REAL Read/Write Limit value for analysis input IN8 alarm 1 REAL Read/Write...

- Page 27 5 Noncyclical data exchange Limit values of Ci (inductive conductivity) for analysis inputs IN7 and IN8 Index Signal designation Data type Access Limit value for analysis input IN7 measuring REAL Read/Write range 1 alarm 1 Limit value for analysis input IN7 measuring REAL Read/Write range 2 alarm 1...

- Page 28 5 Noncyclical data exchange Index Signal designation Data type Access Manual value 13 REAL Read/Write Manual value 14 REAL Read/Write Manual value 15 REAL Read/Write Manual value 16 REAL Read/Write Controller 1 parameter block 1 Index Signal designation Data type Access XP1 proportional band (P component) REAL...

- Page 29 5 Noncyclical data exchange Index Signal designation Data type Access Switch hyst. 1 REAL Read/Write Switch hyst. 2 REAL Read/Write TT actuator time UINT Read/Write Y0 working point Read/Write Y1 output value limit (max.) Read/Write Y2 output value limit (min.) Read/Write TK1 minimum pick-up time of 1st relay REAL...

- Page 30 5 Noncyclical data exchange Controller 2 parameter block 2 Index Signal designation Data type Access XP1 proportional band (P component) REAL Read/Write XP2 proportional band (P component) REAL Read/Write TV1 derivative time (D component) REAL Read/Write TV2 derivative time (D component) REAL Read/Write TN1 reset time (I component)

- Page 31 5 Noncyclical data exchange Index Signal designation Data type Read/ Write Y1 output value limit (max.) Read/Write Y2 output value limit (min.) Read/Write TK1 minimum pick-up time of 1st relay REAL Read/Write TK2 minimum pick-up time of 2nd relay REAL Read/Write Maximum pulse frequency 1 UINT...

- Page 32 5 Noncyclical data exchange Controller 4 parameter block 1 Index Signal designation Data type Access XP1 proportional band (P component) REAL Read/Write XP2 proportional band (P component) REAL Read/Write TV1 derivative time (D component) REAL Read/Write TV2 derivative time (D component) REAL Read/Write TN1 reset time (I component)

-

Page 33: Process Values

5 Noncyclical data exchange Index Signal designation Data type Access TK1 minimum pick-up time of 1st relay REAL Read/Write TK2 minimum pick-up time of 2nd relay REAL Read/Write Maximum pulse frequency 1 UINT Read/Write Maximum pulse frequency 2 UINT Read/Write Pick-up delay 1 REAL Read/Write... - Page 34 5 Noncyclical data exchange Index Signal designation Data type Access External analog input 5 REAL Read External analog input 6 REAL Read External analog input 7 REAL Read External analog input 8 REAL Read External binary signals Index Signal designation Data type Access External digital input 1...

-

Page 35: Project Planning

Project integration of JUMO IO devices For JUMO field devices to be integrated into the project structure of the IO controller as IO device, the GSDML file of the respective device must be imported into the engineering system of your IO controller. -

Page 36: Configuring Profinet Modules

JUMO field device with all IO data, which the field devices provisions for the PROFINET IO communication. In the engineering system, the modules must then be assigned to the slots in the JUMO IO device, so that they can be queried by the IO controller during the cyclical communication. - Page 37 6 Project planning Procedure for module configuration 1. Call up the module configuration dialog in the JUMO PC setup program: Double-click on: Setup only > PROFINET configuration 2. In the "App text" and "App Version" fields of the module configuration dialog, assign information about the application (e.g.

- Page 38 6 Project planning 3. The module configuration contains 1 tab for each activated module. Define the number of modules you want to configure. To add modules, press the "Slot +" button. To reduce the number of modules, click on the next module tab to activate it and press the "Slot -" button. 4.

- Page 39 6. Once you have completed the configuration for all the required modules, click the "OK" button in the module configuration window to confirm the configuration. 7. Transfer the configuration to the JUMO field device and save the configuration file on the PC if re- quired.

-

Page 40: Configuring The Jumo Io Device

Block diagram of a PROFINET optional board with its interfaces (4) (5) (1) Ethernet slot in a JUMO IO device (COM2) with its own MAC address (cf. chapter 6.3.3 "Device in- formation", page 43) (2) Internal interface (SMK socket) of the PROFINET optional board for the slot in the JUMO IO device with its own MAC address (PROFINET MAC address of the JUMO IO device, cf. - Page 41 Send clock and reduction ratio determine the frequency at which an IO device transfers cyclical data in a PROFINET IO network. The transfer cycle time of the JUMO IO device is calculated by dividing the send clock by the reduction ratio. With JUMO field devices, these parameters apply globally for all slots.

- Page 42 6 Project planning NOTE! The watchdog cycle time can be set up to a maximum of 1.92 s. This is defined by the PROFINET IO standard for RT communication.

-

Page 43: Device Information

Open the Ethernet configuration: Device Menu > Configuration > Ethernet 3. After a valid IP configuration has been saved in the JUMO IO device, the PROFINET IO interface connects to the JUMO IO device and is initialized. To test, check the following indicators: The front status LED on the PROFINET optional board must glow green and the MAC addresses of the PROFINET optional board must now display content (other than 00-00-00-00-00-00). - Page 44 6 Project planning Status: Data for connecting the JUMO IO device to the IO controller In addition to the essential IP configuration data for the JUMO IO device, additional important information is dis- played, e. g. the "App Version" from the module configura- tion of the device (see chapter 6.2 "Configuring PROFINET...

- Page 45 JUMO IO device via the Ethernet interface (COM2 slot). It is essential for communication that the Ethernet interface of the JUMO IO device be configured with a valid IP address (cf. chapter 6.3.2 "Communication parameters", page 40). For checking and for diag- nostic purposes, the IP configuration of the Ethernet interface can be viewed in Device info.

- Page 46 6 Project planning...

-

Page 47: Error Messages

Error messages 7 Error messages Error messages for invalid values For measured values in float format, the error number itself is displayed as a value, i.e. instead of the measured value, the error number is returned. Error code for Error float values 1.0 ×... - Page 48 7 Error messages...

-

Page 49: Annex

Annex 8 Annex PROFINET certificate... - Page 50 8 Annex...

- Page 52 JUMO GmbH & Co. KG JUMO Instrument Co. Ltd. JUMO Process Control, Inc. Street address: JUMO House 6733 Myers Road Moritz-Juchheim-Straße 1 Temple Bank, Riverway East Syracuse, NY 13057, USA 36039 Fulda, Germany Harlow, Essex CM 20 2DY, UK Delivery address:...

Need help?

Do you have a question about the AQUIS touch P and is the answer not in the manual?

Questions and answers