Table of Contents

Advertisement

Quick Links

It is important that the installation of the oil burner,

piping and fittings, safety devices, controls, electrical

wiring and equipment be done in accordance with

national and/or local regulations of the authorities

having jurisdiction over such installation.

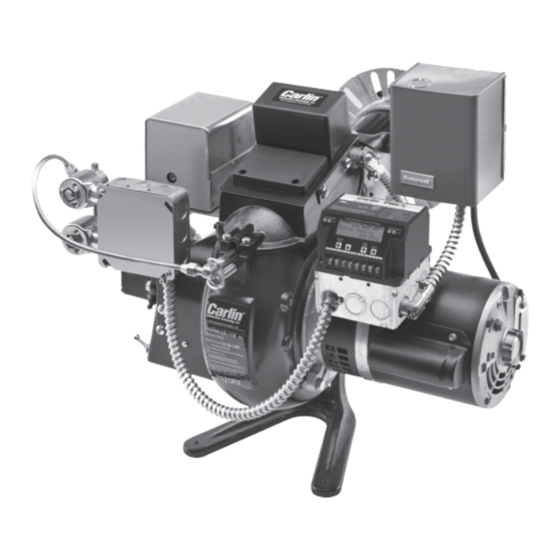

Model 702CRD

Oil Burner

Installation and

Operating Instructions

For Use By Qualified Service Technicians Only

The model 702CRD burner is designed

to fire No. 2 fuel oil and is a low-high-low-off

(step modulating) high-speed flame retention

burner. Oil flow-rate is step-modulated by

the use of two oil valves with a dual pressure

fuel unit. Combustion air is controlled by

a damper motor. Its end-switch energizes

the second stage valve as the air shutter

approaches the open position.

Model 702CRD is currently for use on

H.B. Smith "18" series, Weil-McLain "88"

series and Burnham "V9" series boilers. Other

applications should be reviewed with Carlin

factory support personnel if questionable.

Carlin Combustion Te chnology, Inc.

126 Bailey Rd

Ph 203-680-9401

Tech Support 800-989-2275

North Haven, CT 06473

Fx 203-680-9403

carlincombustion.com

Advertisement

Table of Contents

Summary of Contents for Carlin 702CRD

-

Page 1: Operating Instructions

Its end-switch energizes the second stage valve as the air shutter approaches the open position. Model 702CRD is currently for use on H.B. Smith “18” series, Weil-McLain “88” It is important that the installation of the oil burner, piping and fittings, safety devices, controls, electrical series and Burnham “V9”... - Page 2 ASSEMBLING THE BURNER (TWO-PAK) VENTILATION 1. Remove the air tube and nozzle line assembly from Boiler room areas of commercial buildings of normal the smaller carton. If nozzles are not installed, see construction generally do not allow for sufficient air instructions under (4).

- Page 3 FIRING BOILERS WITH COMBUSTION CHAMBERS FIRING BOILERS WITHOUT REFRACTORY CHAMBERS The 702CRD burner operates with superior efficiency Depending upon the geometry of the combustion and cleanliness in properly designed refractory-type space, some units perform better than others without combustion chambers (Figure 4). Very wide tolerance to refractory (Figures 5 and 6).

- Page 4 Refer to “A” dimension (Table 3) for corresponding imum firing rate of a burner is reduced. The greater the nozzle selection. Example: 702CRD burner firing at 6.80 pressure, the lower the maximum GPH capability GPH high-lire setting, Column “A” reads 1/8-inch.

- Page 5 In order to take full advantage of the energy savings when attempting to change retention ring setting (“A” potential of the 702CRD burner, it should be wired to dimension) otherwise scale will be torn or distorted. This operate with low-high-low cycles. Hence, the firing cy-...

- Page 6 Check all connections and joints. Flared fittings FUEL UNIT AND OIL LINES are recommended. Do not use compression fittings. The 702CRD burner is provided with a two-stage Open the air-bleed valve and start the burner. For clean dual pressure fuel unit. Low-fire operating pressure is bleed, slip a 3/16"...

- Page 7 For different boiler applications, it is sometimes nec- To adjust the damper end switch, remove the damper essary to have the high-fire pull in earlier or later than motor cover. This will expose a white plastic gear with normal during the swing to achieve a smooth, cleaner notches.

- Page 8 Carlin Combustion Technology, Inc. 126 Bailey Road North Haven, CT 06473 Phone 203–680–9401 Fax 203–764–1714 info@carlincombustion.com www.carlincombustion.com e-mail us at: © Copyright 2019 — Carlin Combustion Technology, Inc. 71761 110519...

Need help?

Do you have a question about the 702CRD and is the answer not in the manual?

Questions and answers