SATO CL4NX Plus Operator's Manual

Hide thumbs

Also See for CL4NX Plus:

- Quick start manual ,

- Operator's manual (889 pages) ,

- Programming reference manual (759 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for SATO CL4NX Plus

- Page 1 CL4NX-J/CL6NX-J...

-

Page 2: Table Of Contents

Table of Contents Before You Start......................8 About This Manual..........................8 Features of the Product........................9 Safety Precautions........................... 10 Precautions for Installation and Handling..................16 Select a Safe Location........................16 Power Supply..........................17 Printing............................18 Regulatory Approval......................... 19 Environmentally Hazardous Materials....................22 Copyrights/Limitation of Liability/Trademarks...................23 Copyrights............................23 Limitation of Liability........................24 Trademarks.......................... - Page 3 Connecting the Power Cord......................65 Powering On the Product......................67 Powering Off the Product......................68 Initial Setup (Startup Guide)......................70 Overview of the Startup Guide....................71 Startup Screen..........................75 Language Selection........................76 Region Setting with Optional RTC Kit..................77 City Setting with Optional RTC Kit....................78 Date Setting with Optional RTC Kit.................... 79 Time Setting with Optional RTC Kit....................

- Page 4 Loading the Media........................168 Precautions for Loading the Media..................168 Loading the Media Roll......................168 Loading the Fan-fold Media....................172 Loading the Media with the Optional Cutter Unit..............173 Loading the Media with the Optional Dispenser Unit and Liner Discharge Outlet....179 Loading the Media with the Optional Dispenser Unit and Liner Discharge Rewinder..183 Removing the Liner from the Rewinder................188 Loading Ribbon..........................

- Page 5 [AEP].............................436 [System] Menu...........................439 [Regional]..........................440 [Notifications]........................446 [Sound]..........................453 [Energy Saving]........................455 [LCD Brightness]........................456 [Show Total Count].......................456 [Password]..........................457 [Start on AC]........................461 [Tools] Menu..........................462 [Test Print]..........................463 [HEX-Dump]..........................474 [Reset]..........................482 [Profiles]..........................486 [Certificates]..........................489 [Barcode Checker]........................491 [Clone]..........................503 [Support Info]........................504 [Logging Function]........................505 [Startup Guide]........................

- Page 6 Replacing Consumable Parts......................688 Replacing the Print Head......................688 Replacing the Platen Roller...................... 690 Operating the Notification Screen of SOS (SATO Online Services) (SOS users only)....693 Operating the Notification Screen of the SOS (SATO Online Services) On-Demand Mode (SOS users only)..........................693...

- Page 7 Operating the Date and Time Settings Notification Screen of SOS (SATO Online Services) (SOS users only)..........................695 SOS (SATO Online Services) Application (SOS users only)............697 When You Are in Trouble..................698 When an Error Message Appears....................698 Error Message Indication and Operating Procedure When the SOS (SATO Online Services) Is Enabled (SOS users only)......................

-

Page 8: Before You Start

Thank you for purchasing the SATO CL4NX Plus (hereafter referred to as "the product"). This manual supplies basic information on how to operate the CL4NX Plus. Read the manual carefully to understand each function of the CL4NX Plus before operation. -

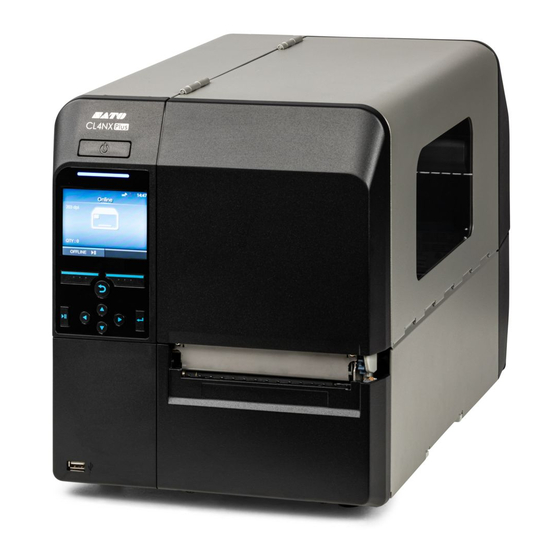

Page 9: Features Of The Product

Features of the Product CL4NX Plus is a high-performance labeling printer with engineered with a robust die-cast metal and equipped with versatile features for ZERO downtime. The main features of CL4NX Plus are as follows: • High accuracy and high quality printing, with resolutions of 203, 305 and 609 dpi •... -

Page 10: Safety Precautions

Safety Precautions Safety Precautions This topic describes how to use the product safely. Be sure to read the following information carefully before using the product. Pictographic Symbols This operator manual and the product labels use a variety of pictographic symbols. These symbols emphasize the safe and correct use of the product and to prevent injury to others and property damage. - Page 11 • If the product is dropped or breaks, immediately power it off, unplug the power cord from the outlet, and contact your SATO reseller or technical support. Using the product in one of these conditions could result in a fire or electric shock.

- Page 12 Doing so could result in a fire or electric shock. Immediately power off the product, unplug the power cord from the outlet, and contact your SATO reseller or technical support for repairs. Do not use the product...

- Page 13 Do not operate with wet hands • Do not disassemble or modify the product. Doing so could result in a fire or electric shock. Ask your SATO reseller or technical support to conduct internal inspections, adjustments, and repairs. Do not disassemble the product •...

- Page 14 • To replace the print head, follow the procedure in the Operator Manual. If the Operator Manual does not contain this procedure, avoid trying to replace it on your own terms, and contact your SATO reseller or technical support. •...

- Page 15 Print head • When opening and closing the print head, make sure that objects other than media do not get caught. Otherwise, it could result in injury or damage. • When opening and closing the cover, be careful not to get your fingers trapped in between.

-

Page 16: Precautions For Installation And Handling

Select a Safe Location Precautions for Installation and Handling Select a Safe Location Product operations can be affected by the product's environment. Refer to the following instructions regarding how to install and handle the product. • Place the product on a surface that is flat and level. If the surface is not flat and level, this may cause bad print quality. -

Page 17: Power Supply

Power Supply Product operations can be affected by the product's environment. Refer to the following instructions regarding how to install and handle the product. The product requires an AC power supply. • Be sure to connect the product to an AC power supply. •... -

Page 18: Printing

(the combination of media and ribbon), and the product settings (the print speed, the print darkness, etc.). Please sufficiently test the product in your usage environment, and use it with the optimal combination. If anything is unclear, or if you have any questions, contact your SATO sales representative or reseller. -

Page 19: Regulatory Approval

Regulatory Approval FCC Warning You are cautioned that changes or modifications not expressly approved by the party responsible for compliance could void your authority to operate the equipment. This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. - Page 20 Regulatory Approval installed and operated keeping the radiator at least 20 cm or more away from person’s body (excluding extremities: hands, wrists, feet and ankles). Le présent appareil est conforme aux CNR d’Industrie Canada applicables aux appareils radio exempts de licence. L’exploitation est autorisée aux deux conditions suivantes : •...

- Page 21 Disposal of Old Electrical & Electronic Equipment (Applicable in the European Union and other European countries with separate collection systems) A product marked with this symbol on itself or on its packaging shall not be treated as household waste. Instead it shall be handed over to an appropriate collection point for the recycling of electrical and electronic equipment in accordance with local regulations.

-

Page 22: Environmentally Hazardous Materials

Environmentally Hazardous Materials Environmentally Hazardous Materials RoHS Directive This product is in conformity with RoHS Directive 2011/65/EU on the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment. Compliance Status of REACH Regulation (1) Status of registered chemical substances No chemical substances are intentionally emitted, nor are there any chemical substances that are registered with the European Chemicals Agency. -

Page 23: Copyrights/Limitation Of Liability/Trademarks

Copyrights/Limitation of Liability/Trademarks Copyrights Any unauthorized reproduction of the contents of this document, in part or whole, is strictly prohibited. © 2019 SATO Corporation. All rights reserved. -

Page 24: Limitation Of Liability

Specifications and contents in this document are subject to change without notice. • Be sure to perform a virus check on the USB memory before connecting it to the product. SATO Corporation cannot be held responsible for any product malfunctions caused by a virus spread... -

Page 25: Trademarks

Trademarks • SATO is a registered trademark of SATO Holdings Corporation and its subsidiaries in Japan, the U.S. and other countries. • NiceLabel is a trademark or registered trademark of Euro Plus d.o.o. in the U.S.A and other countries. •... -

Page 26: Basic Information

Bundled Accessories After unpacking the product, make sure that you have all the bundled accessories. If there are any missing items, contact the SATO reseller where you purchased the product. • User documents (Quick Guide, Safety Instructions, and Global Warranty Program leaflet) •... -

Page 27: Optional Devices

Optional Devices The optional devices for the product are as follows. The optional devices can be factory installed or installed by the customer engineer. Contact your SATO reseller or technical support center. Optional Devices Description Available or Cutter unit Automatically cuts the media in the Available designated number of pages. -

Page 28: Parts Identification

Also, other devices like a barcode checker, barcode scanner or keyboard can be connected. • Be sure to perform a virus check on the USB memory before connecting it to the product. SATO Corporation cannot be held responsible for any product malfunctions caused by a virus spread via USB memory. -

Page 29: Rear View

Also, other devices like a barcode checker, barcode scanner or keyboard can be connected. • Be sure to perform a virus check on the USB memory before connecting it to the product. SATO Corporation cannot be held responsible for any product malfunctions caused by a virus spread via USB memory. (7) LAN connector... -

Page 30: Internal View

Internal View (8) AC input terminal Supplies power to the product through the inserted power cord. Before connecting, make sure that the AC voltage of your region is in the range of AC 100 to 240 V, 50 to 60 Hz. Internal View (1) Ribbon supply spindle (2) Ribbon rewind spindle... -

Page 31: Parts Identification For The Operator Panel

Parts Identification for the Operator Panel Power button To power on the product, press the power button until the LED lights up in blue. To power off the product, press the power button for more than two seconds. (2) LED indicator (3) Color LCD Soft buttons The functions change depending on the screen. - Page 32 Parts Identification for the Operator Panel Example 2: The numerical value input screen of the Settings menu left soft button: Delete one character, right soft button: Save Back button Returns to the previous screen. Line button Toggle between Online/Offline mode or playback/pause the video. Enter button Confirm the selected item or setting value.

-

Page 33: Using The Operator Panel

Using the Operator Panel Display and Operation of the Operator Panel LED Indicator The LED indicator lights up or flashes to show the current status of the product. The product statuses which the LED indicator shows are as follows: LED Indicator Color/Status Description Blue/Lights on... - Page 34 Operations in Online/Offline Mode In Online mode, you can execute the print job. (1) Change to Offline mode. Offline Mode In Offline mode, the print job will stop. You can adjust the print settings, cancel the print job or feed the media. After you complete or cancel the print job, you can show the Settings mode.

-

Page 35: Status Icon

Status Icon The icons on the status bar of the display show the product's status. (1) Status bar Communication Interface Status Icon Description Bluetooth is enabled but not connected. Bluetooth is enabled and connected. Network link is enabled but not connected. Network link is enabled and connected. - Page 36 Status Icon Icon Description NFC is enabled and connected. Not connected to the NTP time server. Wi-Fi is authenticated, but not connected. Wi-Fi is connected. Signal Level: 1 Wi-Fi is connected. Signal Level: 2 Wi-Fi is connected. Signal Level: 3 Wi-Fi is connected.

- Page 37 Product is connected to USB host. Waiting for external input/output signal. Standard code is disabled. The On-Demand mode of the SOS (SATO Online Services) is enabled. The Real Time mode of the SOS is enabled. The product is connected to the SOS cloud.

- Page 38 Status Icon Icon Description Time period set for periodic notification for On-Demand mode for SOS has been reached. Scan the QR code and send the information to the SOS cloud. IP address could not be acquired. Or a communication error has occurred. USB Memory Status Icon Description...

- Page 39 Print Job Status Icon Description Waiting for media removal. Remove the media. Ribbon is near the end. The rest of the ribbon is decreased. Prepare a new ribbon. Label is near the end. The rest of the media is decreased. Prepare new media. Command error detected.

-

Page 40: Operations When Errors Occur

Cancel the error. • Feed the media. • Change to Settings mode. • Change to guidance video. • Change to the SOS error screen on which the QR code and phone number are displayed if the SOS (SATO Online Services) is enabled. - Page 41 • The available operations vary, depending on the situation. (1) Error Icon (2) Error number (3) Clear the error if allowed for the active error. (4) Change to Offline mode if allowed for the active error. (5) The icon appears when the Settings mode or guidance video is available. The SOS icon appears when the SOS is enabled.

- Page 42 Operations When Errors Occur Icon Description Print data is larger than the media size. Sensor error is detected. Print head is unlocked. Print head error is detected. • Communication error is detected. • BCC error is detected. • CRC error is detected. Receive buffer overflow.

- Page 43 Icon Description • Wireless LAN setting error is detected. • Authentication with the server failed. • Authentication with the server timed out. • No print head installed or head resolution was changed. • Product error was detected. The temperature of the print head has exceeded the tolerance range. Bluetooth module is defective.

-

Page 44: Guidance Videos

Guidance Videos Guidance Videos The product contains guidance videos that are shown on the display for visual reference of the product's operations. List of the Guidance Videos The product contains the following guidance videos for visual reference of product operations. The onboard guidance videos are as follows: Guidance Videos Show video from... - Page 45 Guidance Videos Show video from Error screen Startup Guide [Information] Menu Fan-fold media Possible Possible replacement (Cutter) Ribbon replacement Possible Possible Print head replacement Possible Platen roller replacement Possible Cleaning Possible Playing the Guidance Video from the Error Screen Play the guidance video from the error screen and resolve the error by following the procedure of the video.

- Page 46 Guidance Videos 1. Press the button in Online mode. The product changes to Offline mode. 2. Press the button. The product changes to Settings mode. 3. Select [Information] using the buttons.

- Page 47 4. Press the button. The item list appears. 5. Select [Help] using the buttons. 6. Press the button. The guidance video list appears. 7. Select the video for playback using the buttons, and then press the button. The guidance video starts.

-

Page 48: Adjusting The Print Settings During Printing

Adjusting the Print Settings During Printing Operating the Guidance Video (1) Indication panel appears again when one of the buttons is pressed. (2) Stop the playback of the video and return to menu. (3) Playback the video from the start. (4) Playback or pause the video. -

Page 49: Canceling The Print Job

2. Press the button. The Adjustments mode appears. 3. Select an item and adjust the setting. 4. Press the button to return to Offline mode. 5. Press the button to change to Online mode. The print job resumes with the adjusted settings. •... - Page 50 Canceling the Print Job 1. Press the button to change the product to Offline mode. 2. Press the button. A message appears, confirming that you want to cancel the print job. 3. Press the button. The print job is canceled.

-

Page 51: Settings Mode

Settings Mode In the Settings mode, you can set the product's various settings. The topics here explain how to operate the Settings mode. Settings Mode Menus There are six main menus in the Settings mode and each menu contains many layers of submenus. Frequently used settings are also listed in the [Shortcut] menu so that you can directly access them. - Page 52 Changing to the Settings Mode 1. Press the button in Online mode. The product changes to Offline mode. 2. Press the button. The product changes to Settings mode.

-

Page 53: Logging In To/Logging Out Of The Settings Mode

• To exit the Settings mode, press the button. Logging In to/Logging Out of the Settings Mode The Settings mode logs in and logs out by the following procedure, if the password is enabled. • If the password is enabled, input the password after entering the Settings mode. When logged in to the Settings mode, [LOG OUT] appears on the bottom left of the screen. - Page 54 Item Selection 1. Select menu using the buttons. 2. Press the button. The item list appears. 3. Select an item using the buttons. 4. Press the button. If the selected item is a setting item, the setting screen appears. If the selected item is a handling item such as the auto calibration, copy, or delete, the starting screen or confirmation screen appears.

-

Page 55: Setting Value Input Or Selection

(1) There are more items in the next layer. (2) Return to the previous screen. Setting Value Input or Selection This topic describes the character and number input on the setting screen and how to select an item from the list. •... - Page 56 Setting Value Input or Selection • Character Input (1) Text box (2) Selection area (3) Delete the character displayed to the left of the cursor in the text box. (4) Select the character for input using the arrow buttons. The selected character will be highlighted in the selection area.

- Page 57 (2) Selection area (3) Delete the number displayed to the left of the cursor in the text box. (4) Select the number for input using the arrow buttons. The selected number will be highlighted in the selection area. (5) Change the input mode. (6) Save the number you enter in the text box and return to the item list.

- Page 58 Setting Value Input or Selection • Selection from the Box (1) Change the value in the selection box using the buttons. (2) Selection box (3) Perform the function as shown on the screen above. (4) Return to the previous screen. (5) Select an item using the buttons.

- Page 59 (4) Cancel the IP address you enter in the text box and return to the item list. (5) Select the number to input using the buttons.

-

Page 60: Product Memory And Usb Memory

Get the support information • Be sure to perform a virus check on the USB memory before connecting it to the product. SATO Corporation cannot be held responsible for any product malfunctions caused by a virus spread via USB memory. •... -

Page 61: Getting Started

Getting Started Installation Installation Precautions Install the product in a location as follows: • A location that is horizontal and stable. • A location that has sufficient space for operating the product. Do not install the product in a location as follows. Doing so could cause the product to malfunction. •... - Page 62 Installation Precautions • A location with a lot of electrical noise. • A location with a large fluctuation in power. • A location with an explosive atmosphere (flammable gas or vapor).

-

Page 63: Installation Space

Make sure that there is sufficient space around the product so that the top cover can be fully opened when operating or cleaning the product, or replacing consumables. The dimensions of the front view of the product are as follows: CL4NX Plus • The image above is the standard model. -

Page 64: Bottom View

The dimensions of the side view of the product are as follows: • The arrow indicates the front of the product. Bottom View The bottom surface dimensions of the product are as follows: CL4NX Plus • The arrow indicates the front of the product. -

Page 65: Powering On/Off The Product

Make sure that the AC voltage of your region is in the range of AC 100 - 240 V, 50 - 60 Hz. If your local voltage is not in the stated range, contact your SATO reseller or technical support center. - Page 66 Connecting the Power Cord • This product is also designed for IT power distribution system with phase-to-phase voltage 230 V.

-

Page 67: Powering On The Product

Powering On the Product • Do not power on or off the product, connect or disconnect the power cord while your hands are wet. Doing so could cause an electric shock. • You can power on/off the product from the main power source by enabling [Start on AC] under the [System] menu. -

Page 68: Powering Off The Product

Powering Off the Product Powering Off the Product • Do not power on or off the product, connect or disconnect the power cord while your hands are wet. Doing so could cause an electric shock. • Do not power off the product during operation, such as when printing or updating. Doing so could cause a malfunction of the product. - Page 69 2. Press the power button for more than two seconds to power off the product.

-

Page 70: Initial Setup (Startup Guide)

Initial Setup (Startup Guide) Initial Setup (Startup Guide) The topics here explain how to complete the startup guide that appears when you power on the product for the first time after purchase. -

Page 71: Overview Of The Startup Guide

Overview of the Startup Guide When you power on the product for the first time after purchase, the display shows the startup guide. The startup guide is a function to help you through the initial product settings, such as setting date and time, and loading the ribbon and media. - Page 72 Overview of the Startup Guide 4. City Setting with Optional RTC Kit Set the city (time zone). 5. Date Setting with Optional RTC Kit Set the date. 6. Time Setting with Optional RTC Kit Set the time. 7. Print Method Setting Set whether to use the ribbon or direct thermal media to print.

- Page 73 8. Ribbon Setting Load the ribbon. Appears if you have selected [Use Ribbon] in the print method setting. 9. Media Sensor Type Setting Set the sensor type for detecting the media. 10. Media Setting Load the media. 11. Completion of Initial Setup Screen Finish the startup guide.

- Page 74 Overview of the Startup Guide Select whether or not to show the startup guide during the next startup, and press the button to confirm.

-

Page 75: Startup Screen

Startup Screen When you power on the product for the first time after purchase, the display shows the startup guide. 1. Press the power button of the operator panel until the LED lights blue to power on the product. The startup screen appears. -

Page 76: Language Selection

Language Selection Language Selection Select the display language. 1. Select the language name using the buttons. 2. Press the button or button to confirm. -

Page 77: Region Setting With Optional Rtc Kit

Region Setting with Optional RTC Kit Set the region (time zone). 1. Select the region using the buttons. 2. Press the button or button to confirm. -

Page 78: City Setting With Optional Rtc Kit

City Setting with Optional RTC Kit City Setting with Optional RTC Kit Set the city (time zone). 1. Select the city using the buttons. 2. Press the button or button to confirm. -

Page 79: Date Setting With Optional Rtc Kit

Date Setting with Optional RTC Kit Set the date. 1. Select the current value using the buttons, and move the cursor using the buttons. 2. When you have completed the date setting, press the button or button. The confirmation screen appears. 3. -

Page 80: Time Setting With Optional Rtc Kit

Time Setting with Optional RTC Kit Time Setting with Optional RTC Kit Set the time. 1. Select the current value using the buttons, and move the cursor using the buttons. 2. When you have completed the time setting, press the button or button. -

Page 81: Print Method Setting

Print Method Setting Set whether to use the ribbon or direct thermal media to print. 1. Select the print method using the buttons. [Use Ribbon] Print using a ribbon. [Direct Thermal] Print using direct thermal media. 2. Press the button or button to confirm. -

Page 82: Ribbon Setting

Ribbon Setting Ribbon Setting Load the ribbon. You can check the loading method of the ribbon through the video. • Appears if you have selected [Use Ribbon] in the print method setting. 1. Press the button to play the video. The video starts. -

Page 83: Media Sensor Type Setting

Media Sensor Type Setting Set the sensor type for detecting the media. 1. Select the media sensor type using the buttons. [None] Disable the media sensor. [Gap] Select this option when using gap type media. Use the transmissive type sensor. [I-Mark] Select this option when using I-mark type media. -

Page 84: Media Setting

Load the media. You can check the loading method of the media through the video. 1. Press the button. For the models other than the CL4NX Plus linerless model, the selection screen of the video for playback appears. Proceed to step 2. For the CL4NX Plus linerless model, the video appears immediately after the button is pressed. - Page 85 For Dispenser Model [Dispenser] Shows the video on how to eject the liner out of the product. [Rewinder] Shows the video on how to rewind the liner in the product. 3. Press the button or button. The video starts. 4. Load the media while checking the video. 5.

-

Page 86: Completion Of Initial Setup Screen

Completion of Initial Setup Screen Completion of Initial Setup Screen When the startup guide completes, the completion of initial setup screen appears. 1. If you want the startup guide to show the next time you start up, press the button. If not, press the button. -

Page 87: Startup Guide Cancelation

Startup Guide Cancelation You can cancel the startup guide at any time. 1. Press the button while configuring the startup guide. The screen to confirm whether or not to show the startup guide again appears. 2. Select whether or not to show the startup guide during the next startup using the buttons, and press the button to confirm. -

Page 88: Configuring The Product According To Media And Options

Configuring the Product According to Media and Options Configuring the Product According to Media and Options Before starting to print with the product, configure the product according to the media to be used and the installed options. -

Page 89: Print Method

Print Method The product supports two types of print methods, thermal transfer and direct thermal. Thermal transfer Prints using a ribbon. Direct thermal Prints using direct thermal media. • Ribbon is not necessary if you are using direct thermal media. Change the print method according to the following procedure: 1. - Page 90 Print Method 2. Press the button. The product changes to Settings mode. 3. Select [Printing] using the buttons. 4. Press the button. The item list appears.

- Page 91 5. Select [Printing Mode] using the buttons. 6. Press the button. The [Printing Mode] screen appears. 7. Select the print method using the buttons. [Use Ribbon] Prints using a ribbon. [Direct Thermal] Prints using direct thermal media. 8. Press the button to confirm.

-

Page 92: Media Sensor Type

Media Sensor Type Media Sensor Type The product adjusts the print position precisely by detecting I-marks or gaps on the media (label) using media sensors. The I-marks or gaps on each type of media are as follows: I-mark label Gap label I-mark journal paper/ linerless label (1) Media feed direction... - Page 93 2. Press the button. The product changes to Settings mode. 3. Select [Printing] using the buttons. 4. Press the button. The item list appears.

- Page 94 Media Sensor Type 5. Select [Sensor Type] using the buttons. 6. Press the button. The [Sensor Type] screen appears. 7. Select the sensor type to detect the print position using the buttons. [None] Disables the media sensor. [Gap] Select when using gap type media. Use the transmissive type sensor. [I-Mark] Select when using I-mark type media.

- Page 95 8. Press the button to confirm.

-

Page 96: Print Mode

Print Mode Print Mode You can change the print mode of the product according to its usage and installed options. The product has the following print modes: [Continuous] Prints the specified number of media. The media remains in position for printing at all times. [Tear-Off] (Feeding media to the position for manual cutting) After printing the specified number of media, the product feeds the last printed media so that it is fully extended out of the product’s front for removal. - Page 97 1. Press the button in Online mode. The product changes to Offline mode. 2. Press the button. The product changes to Settings mode. 3. Select [Printing] using the buttons.

- Page 98 Print Mode 4. Press the button. The item list appears. 5. Select [Print Mode] using the buttons. 6. Press the button. The [Print Mode] screen appears.

- Page 99 7. Select the print mode using the buttons. • If no option is installed, [Continuous] and [Tear-Off] are available. • If the optional cutter unit is installed, [Continuous], [Tear-Off], [Cutter], and [Cut & Print] are available. • If the optional dispenser unit is installed, [Continuous], [Tear-Off], and [Dispenser] are available.

-

Page 100: Connecting The Product To A Computer

Connecting the Product to a Computer Connecting the Product to a Computer This section explains how to connect the product to a computer, and how to install the printer driver and the All-In-One Tool. -

Page 101: Procedure For Connecting The Product To A Computer

Procedure for Connecting the Product to a Computer The product supports various interfaces and can be connected to a computer in an optimum way for your environment. When you have installed the printer driver to the computer, the data created with the computer (documents and illustrations) can be printed to a label through easy operations. -

Page 102: Connecting Interfaces

Available Interfaces Connecting Interfaces Available Interfaces The product supports the following interfaces. • A product connected with multiple interface cables can continue to operate when receiving data. However, you cannot receive data from more than one interface at a time. Normally, do not use multiple interfaces at a time. •... -

Page 103: Usb Interface Connection (Standard)

• Do not connect or disconnect the interface cables (or use a switch box) while power is supplied to either the product or computer. This may cause damage to the interface circuitry in the product or computer and is not covered by warranty. USB Interface Connection (Standard) Connect the interface cable when the product is powered off. -

Page 104: Bluetooth Interface Connection (Standard)

NFC Interface Connection (Standard) The communication condition settings must be configured according to your network environment. Set the IP address of the product. The IP address of the product can be set through the product's [Interface] menu or the All-In-One Tool. •... -

Page 105: Rs-232C Interface Connection (Standard)

• If it does not communicate well, shift the Android device to the front, back, left and right, and then hold it up again. • For the operation of the NFC for the Android device, refer to the user manual for the Android device. -

Page 106: Ieee1284 Interface Connection (Standard)

IEEE1284 Interface Connection (Standard) • To use the RS-232C interface to connect with the computer, the product's [Tools] > [Barcode Checker] > [Test] > [Interface] menu must be set to [RS-232C]. • The interface settings of the computer can be confirmed by the following. In the Device Manager, right-click [Ports] >... -

Page 107: Wireless Lan Interface Connection (Optional)

• If the product is powered on without installing the printer driver, Windows' Plug & Play runs. When you use the printer driver, do not power on the product while the cable is connected, until instructed in the procedure for installing the printer driver. •... - Page 108 Wireless LAN Interface Connection (Optional) The printer driver performs data communication using the dedicated SOCKET interfaces. The communication condition settings must be configured according to your network environment. Set the IP address of the product. The IP address of the product can be set through the product's [Interface] menu or the All-In-One Tool. •...

-

Page 109: Configuring The Interface Settings

Configuring the Interface Settings Interface Setting Methods Configure the interface settings of the product according to the communication conditions of the connected network and computer. You can set the interface settings of the product doing either of the following. • Set from the [Interface] menu of the product •... - Page 110 Configuring the Interface Settings from the Interface Menu of the Product 2. Press the button. The product changes to Settings mode. 3. Select [Interface] using the buttons. 4. Press the button. The item list appears.

- Page 111 5. Select the interface using the buttons. [Network] Sets the LAN connection and wireless LAN connection. [IEEE1284] Sets the IEEE1284 connection. Appears only if the combo interface board is installed. [RS-232C] Sets the RS-232C connection. Appears only if the combo interface board is installed. [USB] Sets the USB connection.

-

Page 112: Configuring The Interface Settings Using The All-In-One Tool

Installing the All-In-One Tool When you use the All-In-One Tool, you can easily set and manage the product. Download the All-In-One Tool and All-In-One Tool Manual from the SATO All-In-One Tool download site http://www.satoworldwide.com/software/all-in-one-tool.aspx, and install the software to a computer. -

Page 113: Installing The Printer Driver

The printer driver is software that can send data created on the computer (documents and illustrations) to the product and print it to a label. For information about the printer driver, refer to "CL4NX Plus Printer Driver Manual". Installing the Printer Driver (USB) When the computer is connected to the Internet, the printer driver is automatically installed after connecting the USB cable between the computer and the product and powering on the product. - Page 114 Installing the Printer Driver (USB) 7. Click [Next]. 8. Click [Install Printer Driver].

- Page 115 9. Click [USB Port]. 10. Follow the instructions on the screen to power on the product. Windows' Plug & Play runs, and the [Printer Options] screen appears.

- Page 116 Installing the Printer Driver (USB) 11. Click [Install]. 12. When the security warning screen appears, click [Install]. The printer driver is installed. • The warning screen above may not appear, depending on the version of the printer driver or your computer environment. •...

-

Page 117: Installing The Printer Driver (Lan/Wireless Lan)

13. Click [Exit] to complete the installation. 14. In [Devices and Printers], confirm that the product is added to [Printers]. • The settings of the printer driver should be performed by the Administrator Privilege. Installing the Printer Driver (LAN/Wireless LAN) Do the following procedures to install the printer driver using a LAN/Wireless LAN. - Page 118 1. Power on the product, and confirm that the product is connected to the network. 2. Start Windows. 3. Download the printer driver from the SATO printer driver download site. http:// www.satoworldwide.com/software/gallerydriver.aspx 4. Extract the downloaded compressed file of the printer driver.

- Page 119 8. Click [Install Printer Driver]. 9. Click [Network Port]. A list of the printers found on the network appears.

- Page 120 Installing the Printer Driver (LAN/Wireless LAN) 10. Select the printer to add and click [Add]. If the product is not shown on the list, click [Refresh]. If the product is still not shown on the list, add the product using the following procedures. a.

- Page 121 b. Select the model of the product and click [Next]. • Select the model which is compatible with the resolution of the product. The resolution of the product is displayed on the upper left of the Online/Offline screen.

- Page 122 Installing the Printer Driver (LAN/Wireless LAN) c. Select the network port, and click [Next]. If you have selected [Create a new network port], proceed to step d. If you have selected [Use an existing port] and then selected a port from the list, proceed to step 11.

- Page 123 11. Click [Install]. 12. When the security warning screen appears, click [Install]. The printer driver is installed. • The warning screen above may not appear, depending on the version of the printer driver or your computer environment. • If a security warning screen indicating that another process is blocking access appears, follow the steps on the screen, and click [Next].

-

Page 124: Installing The Printer Driver (Bluetooth)

Installing the Printer Driver (Bluetooth) 13. Click [Exit] to complete the installation. 14. Open [Devices and Printers] and confirm that the printer driver is installed. • The settings of the printer driver should be performed by the Administrator Privilege. Installing the Printer Driver (Bluetooth) To use the printer driver with the Bluetooth interface connection, add the product to the computer as a Bluetooth device, and then install the printer driver. - Page 125 The procedure for adding (pairing) the Bluetooth device varies depending on the environment of your computer. The following procedure is an example of Windows 10. For details, refer to the user manual of your computer. • Before starting the installation, close all applications. •...

- Page 126 5. Select the product from the search device list and click [Pair]. • The initial value of the device name for the product is "SATO PRINTER_xxxxxxxxxxxx (BD address)". You can check and change it on the [Bluetooth] > [Name] on the [Interface] menu of the product.

- Page 127 The product is added as a Bluetooth device. 7. Open [Devices and Printers], right-click the product added as a Bluetooth device, and select [Properties].

- Page 128 8. Confirm the port assigned as the [Serial port (SPP)] in the [Services] tab, and click [OK]. Note down this information as it will be necessary for the printer driver installation. 9. Download the printer driver from the SATO printer driver download site. http:// www.satoworldwide.com/software/gallerydriver.aspx 10.

- Page 129 13. Click [Next]. 14. Click [Install Printer Driver].

- Page 130 Installing the Printer Driver (Bluetooth) 15. Click [Other]. 16. Select the model of the product and click [Next].

- Page 131 • Select the model which is compatible with the resolution of the product. The resolution of the product is displayed on the upper left of the Online/Offline screen. 17. Click [Add] and add a port manually. 18. Select [SERIAL (COM)] from the [Select port type] drop down list and click [OK].

- Page 132 Installing the Printer Driver (Bluetooth) 19. Configure the port setting. a. Enter the port name. b. In [Serial port], select the port of the Bluetooth device checked in step 8. c. In [Flow control], select [None]. d. Click [OK]. 20. Click [Next].

- Page 133 21. Click [Install]. 22. When the security warning screen appears, click [Install]. The printer driver is installed. • The warning screen above may not appear, depending on the version of the printer driver or your computer environment. • If a security warning screen indicating that another process is blocking access appears, follow the steps on the screen, and click [Next].

- Page 134 Installing the Printer Driver (Bluetooth) 23. Click [Exit] to complete the installation. 24. Open [Devices and Printers] and confirm that the printer driver is installed. The printer driver can be used with the Bluetooth interface connection. When printing, use the product added when the printer driver was installed, not the product added as the Bluetooth device.

-

Page 135: Installing The Printer Driver (Rs-232C)

1. Connect the product and computer with the RS-232C cable, and power on the product. 2. Start Windows. 3. Download the printer driver from the SATO printer driver download site. http:// www.satoworldwide.com/software/gallerydriver.aspx 4. Extract the downloaded compressed file of the printer driver. - Page 136 Installing the Printer Driver (RS-232C) 7. Click [Next]. 8. Click [Install Printer Driver].

- Page 137 9. Click [Local Port]. 10. Select the model of the product and click [Next].

- Page 138 Installing the Printer Driver (RS-232C) • Select the model which is compatible with the resolution of the product. The resolution of the product is displayed on the upper left of the Online/Offline screen. 11. Select a serial (COM) port and click [Next].

- Page 139 12. Click [Install]. 13. When the security warning screen appears, click [Install]. The printer driver is installed. • The warning screen above may not appear, depending on the version of the printer driver or your computer environment. • If a security warning screen indicating that another process is blocking access appears, follow the steps on the screen, and click [Next].

-

Page 140: Installing The Printer Driver (Ieee1284)

Installing the Printer Driver (IEEE1284) 14. Click [Exit] to complete the installation. 15. Open [Devices and Printers] and confirm that the printer driver is installed. • The settings of the printer driver should be performed by the Administrator Privilege. Installing the Printer Driver (IEEE1284) When the computer is connected to the Internet, the printer driver is automatically installed after connecting the IEEE1284 compliant cable between the computer and the product and powering on the product. - Page 141 [General] tab. 1. Power off the product and connect the IEEE1284 compliant cable to a computer. 2. Start Windows. 3. Download the printer driver from the SATO printer driver download site. http:// www.satoworldwide.com/software/gallerydriver.aspx 4. Extract the downloaded compressed file of the printer driver.

- Page 142 Installing the Printer Driver (IEEE1284) 7. Click [Next]. 8. Click [Install Printer Driver].

- Page 143 9. Click [Local Port]. 10. Select the model of the product and click [Next].

- Page 144 Installing the Printer Driver (IEEE1284) • Select the model which is compatible with the resolution of the product. The resolution of the product is displayed on the upper left of the Online/Offline screen. 11. Select a printer port (LPT) and click [Next].

- Page 145 12. Click [Install]. 13. When the security warning screen appears, click [Install]. The printer driver is installed. • The warning screen above may not appear, depending on the version of the printer driver or your computer environment. • If a security warning screen indicating that another process is blocking access appears, follow the steps on the screen, and click [Next].

- Page 146 Installing the Printer Driver (IEEE1284) 14. Click [Exit] to complete the installation. 15. Power on the product. Windows' Plug & Play runs. 16. Open [Devices and Printers] and confirm that the printer driver is installed. • The settings of the printer driver should be performed by the Administrator Privilege.

-

Page 147: Uninstalling The Printer Driver

When you do the printer driver setup, the properties settings, or the print settings, log in with Administrator Privilege. 1. Power off the product. 2. Start Windows. 3. Download the printer driver from the SATO printer driver download site. http:// www.satoworldwide.com/software/gallerydriver.aspx 4. Extract the downloaded compressed file of the printer driver. - Page 148 Uninstalling the Printer Driver 8. Click [Uninstall Printer Drivers]. 9. Check the check box of the printer you want to uninstall and click [Next]. You can select multiple printers. The printer driver is uninstalled. • When the multiple printers are shown, as long as you do not remove all of the printers, the files related to the installed printer drivers are not removed.

- Page 149 10. Click [Exit].

-

Page 150: Printer Driver Features

Configuring the Printer Driver Settings as an Administrator Printer Driver Features The topics here explain how to open the printer driver setting screens and provide an overview of the printer driver features. Configuring the Printer Driver Settings as an Administrator Configuring the Printer Driver Settings as an Administrator (Windows 7 or Later) When printing a layout created by an application software, configure the printer driver settings first. - Page 151 3. Open the [Sharing] tab.

- Page 152 Configuring the Printer Driver Settings as an Administrator 4. Click [Change Sharing Options].

- Page 153 If [Change Sharing Options] is not shown, do the following procedures. a. Open the [Control Panel] and select [Network and Sharing Center].

- Page 154 Configuring the Printer Driver Settings as an Administrator b. Select [Change advanced sharing settings]. c. In [File and printer sharing], select [Turn off file and printer sharing] and click the [Save changes] button. Configuring the Printer Driver Settings as an Administrator (Windows Server 2008) When printing a layout created by an application software, configure the printer driver settings first.

-

Page 155: Configuring The Driver Settings

The settings of the printer driver should be done by the administrator. If you change a setting value or add a printer port through someone other than the administrator, an error screen appears and the processes you operated are not reflected. In Windows Server 2008, open the properties screen of the printer driver as an administrator with the following procedures. - Page 156 Outputs the current driver settings to a file and reads the settings. (7) [International] Sets the display language of the printer driver. • Be sure to manage the master data for fonts by customer. SATO do not take responsibility for data stored on the product.

-

Page 157: Configuring The Printer Settings

Configuring the Printer Settings [Printing Defaults] and [Printing Preferences] These functions can configure the media settings and printing modes of the product from the printer driver and send them to the product. Use [Printing Defaults] or [Printing Preferences] from the properties screen of the product's printer driver. - Page 158 Configuring the Printer Settings • When you right-click the product in [Devices and Printers] and select [Printing preferences], the same screen as the settings screen for the [Printing Preferences] appears. Overview of the Printer Settings The product settings can be configured from the printer settings screen of [Printing Defaults] or [Printing Preferences].

-

Page 159: Outputting A Label From An Application Software

Selects the unit to be used. (9) [About] Shows the version of the printer driver and provides access to the SATO homepage. Outputting a Label from an Application Software The method for starting a print job varies depending on application software. In general, print jobs begin when you click [Print] button in the dialog that is displayed after selecting [Print] from the [File] menu. - Page 160 Outputting a Label from an Application Software Before starting the print job, confirm that the printer driver to be used in the application software is set to the appropriate printer driver for the product you are using. The method for setting the printer driver varies depending on the application software. In general, select the item you want from the list that is displayed when you select [Print] from the [File] menu, or when you click [▼] in [Printer Name] in the dialog.

-

Page 161: Printer Driver Sharing Function

The following shows how to set the printer driver when using the printer driver with sharing settings. 1. In both the print server and clients, download and install the printer driver from the SATO printer driver download site. http://www.satoworldwide.com/software/ gallerydriver.aspx •... - Page 162 Printer Driver Sharing Function Environment Setting Method Windows Server 2008 In the printer driver, open [Properties] > [Ports], and uncheck [Enable bidirectional support]. Windows 7 or later In the printer driver, open [Printer properties] > [Ports], and uncheck [Enable bidirectional support]. Restrictions When Using the Printer Driver with Sharing Settings When you use the printer driver with sharing settings, the following restrictions occur because bi- directional communication is disabled in the client.

-

Page 163: All-In-One Tool Features

When you add the product to the All-In-One Tool, you can easily set and manage the product. • For details of the All-In-One Tool, download and read the All-In-One Tool Manual from the SATO All-In-One Tool download site. http://www.satoworldwide.com/software/all-in- one-tool.aspx... -

Page 164: Loading Media And Ribbon

Media, Ribbon and Print Methods Loading Media and Ribbon Media, Ribbon and Print Methods The product supports two types of print methods, thermal transfer and direct thermal. The media or ribbon to be used varies depending on the print method. Thermal transfer Prints using a ribbon. -

Page 165: Loading Media

Loading Media The topics here explain how to load the media. -

Page 166: Usable Media

Usable Media Usable Media The product can print on the following two types of media. • Media roll • Fan-fold media The product uses media sensors to detect I-marks or gaps on the media in order to precisely print the content. -

Page 167: Adjusting The Position Of The Media Sensor

Adjusting the Position of the Media Sensor When you use nonstandard media (for example, media with printing on the underside, or media with a special shape), the media sensor cannot detect the I-mark or gap of the media correctly. In such a case, adjust the position of the media sensor to detect the I-mark or gap correctly. -

Page 168: Loading The Media

Loading the Media Roll Loading the Media Precautions for Loading the Media Use genuine SATO media and ribbons for the product, for optimum print quality. • The print head and its surroundings are hot after printing. Be careful not to touch it, to avoid being burned. - Page 169 • Open the top cover fully to prevent accidental drop of the cover. 2. Push the head lock lever (2) towards the rear.

- Page 170 Loading the Media Roll 3. Pull the media holder guide (3) and media guide (4) away from the product. Turn the knob (5) counterclockwise to release the media guide. 4. Load the media in the media holder (6). Make sure that the media roll is all the way in towards the inside of the product. 5.

- Page 171 6. Pass the media below the media damper (7) and the media sensor guide (8) while pushing the media to inside of the product. Make sure that the end of the media extends out the front of the product. 7. Press the print head down until the head lock lever is locked. 8.

-

Page 172: Loading The Fan-Fold Media

Loading the Fan-fold Media • When closing the top cover, be careful not to pinch your fingers. 10. Perform a test print to make sure that the media is loaded correctly. • You need to load the ribbon when printing using thermal transfer. Loading the Fan-fold Media 1. -

Page 173: Loading The Media With The Optional Cutter Unit

3. Place the fan-fold media on a flat location, and load the media from the media slot on the rear or the bottom of the product. The routing path of the media is shown in the below picture. Load the media from the rear of the product Load the media from the bottom of the product. - Page 174 Loading the Media with the Optional Cutter Unit • Open the top cover fully to prevent accidental drop of the cover. 2. Push the head lock lever (2) towards the rear.

- Page 175 3. Pull the media holder guide (3) and media guide (4) away from the product. Turn the knob (5) counterclockwise to release the media guide. 4. Load the media roll or the fan-fold media. For Media Roll The routing path of the media is shown in the below picture. Face-in media Face-out media...

- Page 176 Loading the Media with the Optional Cutter Unit a. Load the media in the media holder (6). Make sure that the media roll is all the way in towards the inside of the product. b. Push the media holder guide (3) lightly against the media roll. For Fan-fold Media a.

- Page 177 Load the media from the rear of the product Load the media from the bottom of the product. • When loading the media, make sure that the print side faces up. 5. Pull the tab (7) of the cutter unit in the direction A, and then open up the cutter- open lever to (B).

- Page 178 Loading the Media with the Optional Cutter Unit 7. Press the print head down until the head lock lever is locked. 8. Close the cutter and then push the tab (7) in the reverse direction to lock it. 9. Press the media guide (4) lightly against the end of the media, and then turn the knob (5) to lock the media guide.

-

Page 179: Loading The Media With The Optional Dispenser Unit And Liner Discharge Outlet

• You need to load the ribbon when printing using thermal transfer. Loading the Media with the Optional Dispenser Unit and Liner Discharge Outlet The below topic describes the procedure to dispense the label and eject the liner out of the product. 1. - Page 180 Loading the Media with the Optional Dispenser Unit and Liner Discharge Outlet 3. Pull the media holder guide (3) and media guide (4) away from the product. Turn the knob (5) counterclockwise to release the media guide. 4. Load the media in the media holder (6). Make sure that the media roll is all the way in to inside of the product.

- Page 181 6. Pass the media below the media damper (7) and the media sensor guide (8) while pushing the media to inside of the product. Make sure that the end of the media extends out the front of the product. 7. Press the tab (9) at the front of the product to open the dispenser unit (10). 8.

- Page 182 Loading the Media with the Optional Dispenser Unit and Liner Discharge Outlet 9. Pass the liner (12) through the gap of the dispenser unit to the outside of the product. 10. Adjust the dispenser roller (13) to the center of the label. 11.

-

Page 183: Loading The Media With The Optional Dispenser Unit And Liner Discharge Rewinder

Loading the Media with the Optional Dispenser Unit and Liner Discharge Rewinder The below topic describes the procedure to dispense the label and rewind the liner in the product. • The maximum diameter of the liner that can be rewound in the product is φ120 mm (4.72"). - Page 184 Loading the Media with the Optional Dispenser Unit and Liner Discharge Rewinder • Open the top cover fully to prevent accidental drop of the cover. 2. Push the head lock lever (2) towards the rear.

- Page 185 3. Pull the media holder guide (3) and media guide (4) away from the product. Turn the knob (5) counterclockwise to release the media guide. 4. Load the media in the media holder (6). Make sure that the media roll is all the way in to inside of the product. 5.

- Page 186 Loading the Media with the Optional Dispenser Unit and Liner Discharge Rewinder 6. Pass the media below the media damper (7) and the media sensor guide (8) while pushing the media to inside of the product. Make sure that the end of the media extends out the front of the product. 7.

- Page 187 9. Pass the liner (12) through the gap of the dispenser unit to the inside of the product. 10. Adjust the dispenser roller (13) to the center of the label. 11. Pass the liner (12) below the liner rewinder (14), and attach it with the clip (15). 12.

-

Page 188: Removing The Liner From The Rewinder

Removing the Liner from the Rewinder 13. Close the print head. 14. Close the dispenser unit. 15. Press the media guide lightly against the end of the media, and then turn the knob to lock the media guide. 16. Close the top cover. •... -

Page 189: Loading Ribbon

Loading Ribbon You need to load the ribbon when printing using thermal transfer. The topics here explain how to load and replace the ribbon. -

Page 190: Checking The Ink Side Of The Ribbon

Checking the Ink Side of the Ribbon Checking the Ink Side of the Ribbon There are two wind directions for the ribbon. Face-out means the ink is on the outer side and Face-in means the ink is on the inner side. The product supports both wind directions. You can examine the ink side of the ribbon using the following procedure. -

Page 191: Loading The Ribbon

Touching the edge of the print head with your bare hand could cause injury. • Use genuine SATO media and ribbons for the product, for optimum print quality. • The routing path of the ribbon is shown in the below picture. - Page 192 Loading the Ribbon • Open the top cover fully to prevent accidental drop of the cover. 2. Push the ribbon rewind spindle (2) all the way in. If there is any ribbon on the ribbon rewind spindle, remove it from the spindle before installing new ribbon.

- Page 193 4. Load the ribbon (4) onto the ribbon supply spindle (5). While taking note of the wind direction, insert the ribbon all the way in. 5. From the ribbon supply spindle (5), pass the ribbon below the print head (6). 6.

- Page 194 Loading the Ribbon 7. If the media is already loaded, press the print head down until the head lock lever is locked. If the media is not loaded, load the media. 8. Close the top cover. • When closing the top cover, be careful not to pinch your fingers.

-

Page 195: Replacing The Ribbon

Replacing the Ribbon 1. Open the top cover (1). • Open the top cover fully to prevent accidental drop of the cover. 2. Push the head lock lever (2) towards the rear. - Page 196 Replacing the Ribbon 3. Press the tab (3) on the tip of the ribbon rewind spindle to pull it out. 4. Pull to remove the used ribbon from the ribbon rewind spindle. 5. Push the ribbon rewind spindle (4) all the way in. 6.

- Page 197 7. Load the ribbon (5) onto the ribbon supply spindle (6). While taking note of the wind direction, insert the ribbon all the way in. 8. From the ribbon supply spindle (6), pass the ribbon below the print head (7). 9.

- Page 198 Replacing the Ribbon 10. Press the print head down until the head lock lever is locked. 11. Close the top cover. • When closing the top cover, be careful not to pinch your fingers. 12. Press the button (FEED) to feed the media. 13.

-

Page 199: When To Replace Media And Ribbon

When to Replace Media and Ribbon Checking the Remaining Amount of Media and Ribbon You can check the remaining amount of media and ribbon according to the following procedure. • Checking through the window on the right side of the product You can visually check the remaining amount of media and ribbon in the product through the window on the right side of the product (1). -

Page 200: Conditions That Trigger Paper End, Label Near End, Ribbon End And Ribbon Near End

Conditions That Trigger Paper End Conditions That Trigger Paper End, Label Near End, Ribbon End and Ribbon Near End Conditions That Trigger Paper End The conditions that trigger paper end vary depending on the operation of the product. Conditions That Trigger Paper End in the Feeding Operation A paper-end occurs if the no-paper condition persists even after the paper-end sensor detects the no- paper condition when 15 mm (0.59") continues to be fed. - Page 201 2. If the amount of printing remaining is less than the distance between the print head position and paper end sensor -15 mm (-0.59"), a paper end error occurs after completing the output of 1. If the amount of media remaining is more than the distance between the print head position and paper end sensor -15 mm (-0.59"), a paper end error occurs right after detecting the paper end, and the product will reprint after clearing the paper end error.

- Page 202 Conditions That Trigger Paper End • When the Amount of Printing Remaining Is More Than the Amount of Media Remaining If the amount of printing remaining is more than the amount of media remaining when a paper end error is detected, the product cannot finish the print job. Printing stops immediately and a paper end error occurs.

-

Page 203: Conditions That Trigger Label Near End

If there are multiple sheets between the print head and paper end sensor when a paper end error is detected, a paper end error will occur only after finishing the label currently being printed. (1) Print head position (2) Paper end sensor (3) Amount of media remaining (4) Amount of printing remaining Conditions That Trigger Label Near End... -

Page 204: Various Settings Of The Product

[Shortcut] Menu Various Settings of the Product The Product's [Settings] Menu [Shortcut] Menu Frequently used settings are listed in the [Shortcut] menu. -

Page 205: [Printing] Menu

[Printing] Menu The following settings are available in the [Printing] menu: Label Length Set the length of the media. Label Width Set the width of the media. Auto Measure Automatically measure the length of the media. Printing Mode Set whether to print using a ribbon or direct thermal media. Ribbon Near End Enable or disable the warning when the ribbon is about to run out. -

Page 206: [Label Length]

Set the length of the media. The setting range varies depending on the print resolution of the product. The setting range of the label length is as follows: Resolution CL4NX Plus 203 dpi 1 to 20000 dots (1 dot = 0.125 mm (0.0049")) -

Page 207: [Label Width]

Resolution CL4NX Plus (1 dot = 0.042 mm (0.0017")) • Set the label size to a value that includes the liner. [Label Width] Set the width of the media. The setting range varies depending on the print resolution of the product. -

Page 208: [Auto Measure]

[Auto Measure] [Auto Measure] The product automatically measures the length of the media. The measured length of the media will be automatically saved in [Label Length]. The Auto Measure function can be performed when [Sensor Type] is set to [Gap] or [I-Mark]. The setting procedure of the label length using the Auto Measure function is as follows: 1. -

Page 209: [Printing Mode]

[Printing Mode] Set whether to print using a ribbon or direct thermal media. The options are as follows: Use Ribbon Print using a ribbon. Direct Thermal Print using direct thermal media. [Ribbon Near End] Shows or does not show the warning icon when the ribbon is about to run out. Printing does not stop even if the warning icon shows up. -

Page 210: [Speed]

609 dpi (24 dots/mm) 2 to 6 ips (inches/sec) (50.8 to 152 mm/sec) • If the optional linerless cutter kit is installed to CL4NX Plus, the setting range is as follows: ◦ The setting range is 2 to 6 ips (inches/sec) (50.8 to 152 mm/sec) regardless of the printing resolution. -

Page 211: [Sensor Type]

[Sensor Type] Set the sensor type for detecting the media. The options are as follows: None Disable the media sensor. Select when using gap type media. Use the transmissive type sensor. I-Mark Select when using I-mark type media. Use the reflective type sensor. •... - Page 212 [Micro Label Print Mode] Set the micro label print mode operation. Micro Label Print Mode is a mode to provide high accuracy printing for small sized labels. • The improved accuracy provided by micro label print mode is for labels sizes of less than 53 mm (incl.

- Page 213 Enable or disable the use of Micro Label Print Mode. The options are as follows: Enabled Enable Micro Label Print Mode. Disabled Disable Micro Label Print Mode. [Auto Label Length Detection] Enable or disable automatic measurement of label length when the [Micro Label Print Mode] is set to [Enabled].

- Page 214 Label Length Detection] is set to [Disabled]. The setting range varies depending on the print resolution of the product. The setting range of the label length is as follows: Resolution CL4NX Plus 203 dpi 72 to 424 dots (1 dot = 0.125 mm (0.0049"))

-

Page 215: [Auto-Mode]

Resolution CL4NX Plus (1 dot = 0.042 mm (0.0017")) • Set the label size to a value that includes the liner. [Auto-mode] When using [Auto-mode], the print mode changes automatically according to the status of the installed option unit. The options are as follows: Enabled The print mode changes automatically. -

Page 216: [Print Mode]

[Print Mode] [Print Mode] Set the print mode. The options are as follows: Continuous Continuously print the specified number of the media. The media remains in position for printing at all times. Tear-Off (Feeding media to the position for manual cutting) After continuously printing the specified number of the media, feed the media to the point to remove the media. -

Page 217: [Backfeed]

• If no option is installed, [Continuous] and [Tear-Off] are available. • If the optional cutter unit is installed, [Continuous], [Tear-Off], [Cutter], and [Cut & Print] are available. • If the optional dispenser unit is installed, [Continuous], [Tear-Off], and [Dispenser] are available. -

Page 218: [Eject Cut]

[Darkness Range] [Eject Cut] Set the Eject cut motion for the last printed media. Cut the last media after the specified timing. Appears if you have selected [Cut & Print] in the [Print Mode] menu. The setting range is Off, or from 1 to 5 (sec). [Darkness Range] Set the range of the print darkness. -

Page 219: [Darkness]

[Darkness] Specify the print darkness from 10 steps. The setting range is from 1 to 10. 1 is the lightest and 10 is the darkest. • To further fine tune the print darkness, set [Printing] > [Advanced] > [Adjustments] > [Darkness Adjust]. - Page 220 [Imaging] Adjusting direction of the print reference position and base reference point (1) Feed direction (2) Liner (3) Label (4) Gap between labels (5) Adjustment of vertical base reference point (6) Base reference point after adjustment (7) Adjustment of horizontal base reference point (8) Print reference position [Vertical] Set the print position in the vertical direction.

- Page 221 (1) Feed direction The setting range varies depending on the print resolution of the product. The setting range is as follows: Resolution CL4NX Plus 203 dpi -19999 to 0 to 19999 dots (1 dot = 0.125 mm (0.0049")) 305 dpi -17999 to 0 to 17999 dots (1 dot = 0.083 mm (0.0033"))

-

Page 222: [Advanced]

(1) Feed direction The setting range varies depending on the print resolution of the product. The setting range is as follows: Resolution CL4NX Plus 203 dpi -831 to 0 to 831 dots (1 dot = 0.125 mm (0.0049")) 305 dpi -1247 to 0 to 1247 dots (1 dot = 0.083 mm (0.0033")) - Page 223 The setting items are as follows: Calibrate Adjust the media sensor. Head Check Check if there is a broken element of the print head. Head Check Mode Set the mode for head check. ◦ Appears if you have selected [All] or [Barcode] in the [Head Check] menu. Every Page Set the interval for head check.

- Page 224 [Advanced] Label Near End Enable or disable the warning when the media is about to run out. [Calibrate] Adjust the media sensor level. In instances of media detection malfunction, adjust the media sensor level (Gap and I-mark sensors). The setting items are as follows: Auto-calibration Automatically adjust the sensor level.

- Page 225 7. The result of the sensor adjustment is shown. To exit the adjustment, press the button. 8. Set to Offline mode. Press the button to confirm that the media is fed correctly. • If the media is not fed correctly after doing [Auto-calibration], contact your SATO reseller or technical support center.

- Page 226 [Advanced] [GAP Levels] Manually set the Gap sensor level. The setting procedure is as follows: First, adjust the "Low" level (voltage) of the Gap sensor. 1. Remove the label from the liner. 2. Pass the liner through the media sensor. Align it so that the media sensor does not detect the I- mark (black mark).

- Page 227 ◦ Low (with only liner) ≤ 0.5 (V) ◦ High (media attached with liner) - Low ≥ 1.0 (V) [GAP Slice Level] Set the Gap sensor slice level. The setting procedure is as follows: 1. Use the following formula to calculate the slice level: (High level - Low level) x 0.3 + Low level = slice level 2.

- Page 228 [Advanced] [I-Mark Levels] Manually set the I-mark sensor level. The setting procedure is as follows: First, adjust the "Low" level (voltage) of the I-mark sensor. 1. Pass the media (attached with liner) between the media sensors. Align it so that the media sensor does not detect the I-mark (black mark).

- Page 229 [I-Mark Slice Level] Set the I-mark sensor slice level. The setting procedure is as follows: 1. Use the following formula to calculate the slice level: (High level - Low level) x 0.7 + Low level = slice level 2. Select the [I-Mark Slice Level] in the [Calibrate] menu and press the button.

- Page 230 [Advanced] The options are as follows: Disable the Head Check. Check the entire print area. Barcode Check only the area for printing a barcode. Head check is not applicable for barcodes printed as graphic data. • Head check is a reference for checking for a broken element of the print head. This function does not guarantee barcode readability.

- Page 231 [Every Page] Perform the head check for each specified number of media. Appears if you have selected [Every Page] in the [Head Check Mode] menu. The setting range is from 1 to 999999. [Check Media Size] Enable or disable media size check. Appears if you have selected [Gap] or [I-Mark] in the [Sensor Type] menu.

- Page 232 [Advanced] Disabled Disable media size check. [Adjustments] Correct the offset position, print position and print darkness. The setting items are as follows: Offset Adjusts the backfeed/stop position for Tear-off/Cut/Dispense operation. Pitch Adjusts the print start position thus effects the vertical print position placement. Pitch Offset Adjusts the offset position and the pitch position at the same time.

- Page 233 The setting range varies depending on the print resolution of the product. The setting range is as follows: Resolution CL4NX Plus 203 dpi -30 to 0 to 30 dots (1 dot = 0.125 mm (0.0049"))

- Page 234 (1) Feed direction The setting range varies depending on the print resolution of the product. The setting range is as follows: Resolution CL4NX Plus 203 dpi -30 to 0 to 30 dots (1 dot = 0.125 mm (0.0049")) 305 dpi -45 to 0 to 45 dots (1 dot = 0.083 mm (0.0033"))

- Page 235 (3) Pitch position (leading edge of media position that decides the vertical print position) The setting range varies depending on the print resolution of the product. The setting range is as follows: Resolution CL4NX Plus 203 dpi -392 to 0 to 392 dots (1 dot = 0.125 mm (0.0049"))

- Page 236 [Advanced] Fine tune the print darkness. The setting range is from 0 to 99. 0 is the lightest and 99 is the darkest. [Start Online] Select default mode when the product is powered on. The options are as follows: Enabled The product powers on in Online mode.

- Page 237 Enabled Feed the media when changing to Online mode after recovering from an error. Disabled Do not feed the media when changing to Online mode after recovering from an error. However, if [Feed At Power On] is set to [Enabled], the product feeds the media when it is powered on and changes to Online mode.

- Page 238 The actual media feed amount is the value of [Offset] + [Finisher Feed]. The setting range varies depending on the print resolution of the product. The setting range is as follows: Resolution CL4NX Plus 203 dpi 0 to 2040 dots (1 dot = 0.125 mm (0.0049"))

- Page 239 [Head Base Position] Set the position used for the base reference point for printing. The options are as follows: Item CL4NX Plus [Standard] Print with a standard base reference point. [Left-justify] Move the base reference point 2 mm (0.08") to the left...

- Page 240 [Advanced] • A message prompting you to restart the product will appear on the Online/Offline screen if you have made any changes. In such a case, reboot the product to apply the settings. [Prioritize] For product settings, set whether to prioritize the settings that are done through the product or through commands.

- Page 241 The setting range varies depending on the print resolution of the product. The setting range is as follows: Resolution CL4NX Plus 203 dpi 0 to 20000 dots (1 dot = 0.125 mm (0.0049"))

- Page 242 [Advanced] [Label Near End] Shows or does not show the warning icon when the media is about to run out. Printing does not stop even if the warning icon shows up. The options are as follows: Enabled Shows the warning icon. Disabled Does not show the warning icon.

-

Page 243: [Interface] Menu

[Interface] Menu The following settings are available in the [Interface] menu: Network Set the LAN connection and wireless LAN connection. IEEE1284 Set the IEEE1284 connection. ◦ Appears only if the combo interface board is installed. RS-232C Set the RS-232C connection. ◦... -

Page 244: [Network]

The setting items are as follows: Settings Set LAN or wireless LAN, or select an interface. Services Set the TCP/IP port number, NTP, LPD, FTP, SNMP, or SOS (SATO Online Services). Advanced Set the advanced function for the interface. [Settings] Set the LAN or wireless LAN, or select the interface. - Page 245 Set the LAN. Wi-Fi Set the wireless LAN. ◦ Appears only if you have installed the optional wireless LAN. Interface Select the network interface. ◦ This item is to select the network interface from LAN or wireless LAN when you have installed the optional wireless LAN.

- Page 246 [Network] [IPv4] Set IPv4 for the LAN. The setting items are as follows: Mode Select the IP address assignment method. DHCP / Renew Lease Update the lease time and get the IP address from the DHCP server again. ◦ Appears only if you have selected [DHCP] in the [Mode] menu and LAN is the active interface. ◦...

- Page 247 Set and check DNS server addresses. If you have selected [Static] in the [Mode] menu, select this to set and check DNS server addresses. • After doing the settings, press the button to enable the new settings. Press button to cancel the new settings and return to the previous settings. •...

- Page 248 [Network] [IP Address] If you have selected [Static] in the [Mode] menu, set the IP address. The setting range is as follows: 000.000.000.000 to 255.255.255.255 [Netmask] If you have selected [Static] in the [Mode] menu, set the subnet mask address. Each group of the address can be set cyclically among 0, 128, 192, 224, 240, 248, 252, 254 and 255.

- Page 249 [Gateway] If you have selected [Static] in the [Mode] menu, set the default gateway address. The setting range is as follows: 000.000.000.000 to 255.255.255.255 [DNS] If you have selected [Static] in the [Mode] menu, set and check DNS server addresses. The setting range is as follows: 000.000.000.000 to 255.255.255.255 •...

- Page 250 [Network] [IPv6] Set the IPv6 for the LAN. The setting items are as follows: Mode Select the IP address assignment method or disable IPv6. DHCP / Renew Lease Update the lease time and get the IP address from the DHCP server again. ◦...

- Page 251 • After doing the settings, press the button to enable the new settings. Press button to cancel the new settings and return to the previous settings. • You cannot change [IP Address], [Prefix Length], [Gateway], or [DNS] if [Mode] is anything other than [Static].

- Page 252 [Network] [IP Address] If you have selected [Static] in the [Mode] menu, set the IP address. The setting range is as follows: 0:0:0:0:0:0:0:1 to ffff:ffff:ffff:ffff:ffff:ffff:ffff:ffff [Prefix Length] If you have selected [Static] in the [Mode] menu, set the prefix. The setting range is from 1 to 128.

- Page 253 [Gateway] If you have selected [Static] in the [Mode] menu, set the default gateway address. The setting range is as follows: 0:0:0:0:0:0:0:0 to ffff:ffff:ffff:ffff:ffff:ffff:ffff:ffff [DNS] If you have selected [Static] in the [Mode] menu, set the primary address of the DNS server. The setting range is as follows: 0:0:0:0:0:0:0:0 to ffff:ffff:ffff:ffff:ffff:ffff:ffff:ffff •...

- Page 254 [Network] [Proxy] Set the proxy for the LAN. The setting items are as follows: Enabled Enable or disable use of proxy. Server Set the proxy server address. Exclude Exclude the proxy from usage. [Enabled] Enable or disable use of proxy. The options are as follows: Enabled Enable proxy server usage.