Summary of Contents for Signode TENSION-WELD VFX-9/13

- Page 1 VFX-9/13 TENSION-WELD® STRAPPING TOOL ! ! ! ! ! ! ! ! SIGNODE 3620 WEST LAKE AVENUE GLENVIEW, ILLINOIS 60026 U.S.A.

-

Page 2: General Safety Considerations

Use the correct Signode products for your application. 2. TRAINING. This tool must not be used by persons not properly trained in its use. Be certain that you receive proper training from your employer. If you have any questions contact your Signode Representative. 3. EYE INJURY HAZARD. -

Page 3: Tool Care

7. WORK AREA. Keep work areas uncluttered and well lighted. Several types of strap can be used with this tool. Use the correct Signode products for your application. If you need help contact your Signode Representative. SAFETY PROCEDURES FOR TOOL OPERATION 1. -

Page 4: Specifications

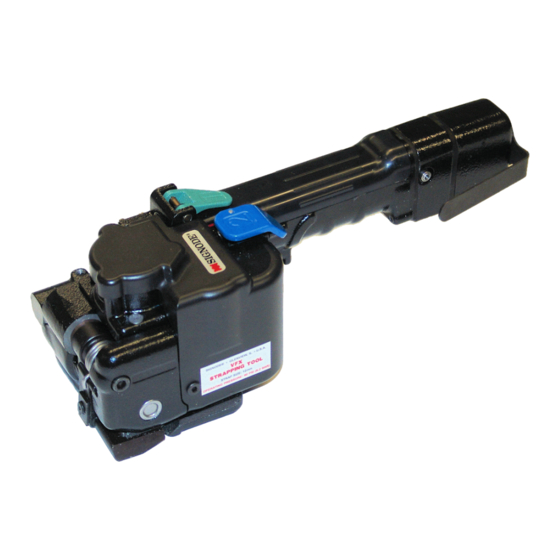

TABLE OF CONTENTS Page Page Parts List, Air Motors General Safety Instructions Parts List, Tool Specifications Troubleshooting Pneumatic Information Maintenance Operating Instructions Tool Options Adjustments Declaration of Conformity Parts Removal and Replacement Air Logic and Diagram VFX-9/13 Part No. 429276 SPECIFICATIONS STRAP MODEL... - Page 5 VFX MAJOR COMPONENTS...

-

Page 6: Pneumatic Information

Clean only with warm water. A cut-off valve placed ahead of the filter will be useful when cleaning the filter or replenishing the lubricator. Signode Pneumatic Accessories: ITEM PART NO. FRL W/ 10' HOSE 429141... - Page 7 The remaining moisture is removed at the water leg in the piping system or in the filter (Part No. 008559). NOTE: Additional information is available in the Signode publication, "Air Supply Manual" (Part No. 186038). If you have any questions, contact your local Signode Representative.

-

Page 8: Strap Tension

Air pressure is assumed to be 90 psig (6.2 Bar) with recommended size and length of air hose. Volume of air is at room temperature and sea level pressure, or so-called "free air" conditions. For more detailed information about air supply systems refer to Signode manual Part No. 186038. - Page 9 An air line dryer adjacent to the compressor. b. Use lubricant recommended by Signode. Signode has tested the use of anti-freezes, none work well in air tool; the tool will gum up when anti-freezes are introduced and will not function properly.

- Page 10 OPERATING INSTRUCTIONS Wear safety glasses. Stand to one side of the strap when tensioning. Make sure all bystanders are clear before proceeding. 1. With the dispenser placed behind you, bring the strap over the top and around the package, pulling out excess slack. NOTE: Do not operate tool without strap, as damage to the tool may occur.

- Page 11 5. When the motor stalls, indicating completion of tension, press the Weld Button (Blue) to weld and join the straps together. NOTE: The Weld Button only need to be pressed once. The button will stay down on it’s own. The internal weld timer is energized. The strap is welded and the supply end of the strap is cut-off.

- Page 12 4. If you are unable to produce an acceptable joint or if you have any questions as to whether your tool is producing good weld strength, contact -your Signode Sales Representative.

- Page 13 TOOL ADJUSTMENT - STRAP CUTTER The VFX strap cutter has two serrated cutting edges. After the first edge has become dull or strap cut-off becomes difficult the blade can be remounted to use the second cutting edge. Once both edges have become worn the blade should be replaced. Use the instructions below to remount, install and adjust a new cutter blade.

-

Page 14: Parts List - Tool

PARTS LIST - TOOL Part No. Description 429538 Weld Plate Assembly 429479 Cylinder Housing 429469 Cutter Insert Holder 429429 Lower Weld Gripper 429280 Contact Plate 273842 425120 Slider Link 429540 Upper Gripper 427724 Pivot Pin 429507 Torrington HK-1010 Needle Bearing 429189 Cylinder Cap 427734... - Page 15 Part No. Description 010036 M6 X 16 SFHCS 429107 Signode Sticker 429281 Lift Tab 429284 Spring Lc-032b-08-m 429287 Piston Rod 004238 #10 Lockwasher 429288 Spring LC-036g 03 M 429312 Cylinder Gasket 429313 Cylinder Cover 429315 Opening Lever (Casting) 428435 Barb Fitting...

- Page 16 Part No. Description 429591 Gear Housing Assembly 274104 Gripper Plug 429187 Side Plate 429590 Thrust Washer 429594 M3 X 10 SSS Cup 429411 ET-20 Air Fitting 429436 Signal Air Line (7.608) White 429497 Airline #1 (1.75") Black 429487 Airline #2 (.625") Dark Green 429446 Airline #3 (.75") Gray 429494...

- Page 19 PARTS LIST - MOTOR Part No. Description 428746 M5 X 16 SHCS (extra Low) 280851 M4 X 12 SHCS 429100 Ø1.5 X 12 Dowel Pin 429160 Timer Plate 424377 Check Valve 425310 Flow Control 428543 Valve Cap 428455 Timing Chamber 428435 Barb Fitting 428432...

- Page 21 AIR LINE ROUTING...

-

Page 22: Troubleshooting

TROUBLESHOOTING The following items are the most common types of tool malfunctions. For symptoms or remedies not shown, contact your Signode service representative for additional information and details. The following tool conditions are shown in this manual: AIR SUPPLY #1 - The air motor is frozen. - Page 23 #3 CONDITION: The tool runs sluggishly. CAUSE REMEDY The air filter-regulator-lubricator is malfunctioning 1A. Check the regulator to see that the correct air or is not properly maintained. pressure is getting to the tool. 1B. Check to see the filter unit is clean and functioning properly.

- Page 24 TROUBLESHOOTING, Continued #6 CONDITION: The tool will not tension strap (air motor continues to run). CAUSE REMEDY Worn tension drive belt. Replace as required. #7 CONDITION: A poor weld identified by an incomplete area of weld. CAUSE REMEDY The grippers have become clogged with strap residue Dismantle and clean the weld mechanism by brushing or the bearings in the weld mechanism are extremely away the strap residue or washing the entire unit in a...

- Page 25 #11 CONDITION: Strap weld time is erratic. CAUSE REMEDY Dirty or very dry valve in air motor valve housing. Add a several drops of airline oil into the air inlet of the tool and cycle several times to lubricate. If the problem persists, review the air motor valve housing maintenance instructions found in this manual.

-

Page 26: Maintenance

MAINTENANCE TOOL 1. Always be sure the tensioner foot is free and periodically lubricate the support pin. 2. Clean the teeth on the feedwheel and the gripper plug with the special brush provided, (Part No. 023963). 3. Periodically clean the tool with an air hose. 4. -

Page 27: Tool Options

TOOL OPTIONS BELT HOOK - Part No. 428462 PIGTAIL ASSEMBLY - Part No. 429596 STRAP GUIDE - Part No. 014565 SUSPENSION BRACKET - Part No. 429610 STANDARD EQUIPMENT KIT - Part No. 429607... - Page 29 It is hereby declared that the undermentioned machinery has been designed and constructed to comply with the health and safety requirements defined in EC Directive 89/392/EEC Machine Supplier: Signode, Division of ITW Ltd. Queensway, Fforestfach Swansea SA5 4ED Machine Description:...

- Page 30 Glenview, Illinois plant, any tool which proves to not operate per functional specifications within the stated period. Signode reserves the right to replace any tool which proves not to operate per functional specifications with a new or like-new tool of the same model if in Signode's judgement such replacement is appropriate.

Need help?

Do you have a question about the TENSION-WELD VFX-9/13 and is the answer not in the manual?

Questions and answers

IN YOUR TROUBLESHOOT SHEET I AM NOT SEEING ..WHAT IF THE CUTTER BLADE AND WELD BLADE DOES NOT RAISE UP AFTER WELDING.