Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Pentair Hydromatic HPG200

- Page 1 NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Item # E-03-407 | Part # 5625-407-1 | © 2017 Pentair plc | 02/17/17...

-

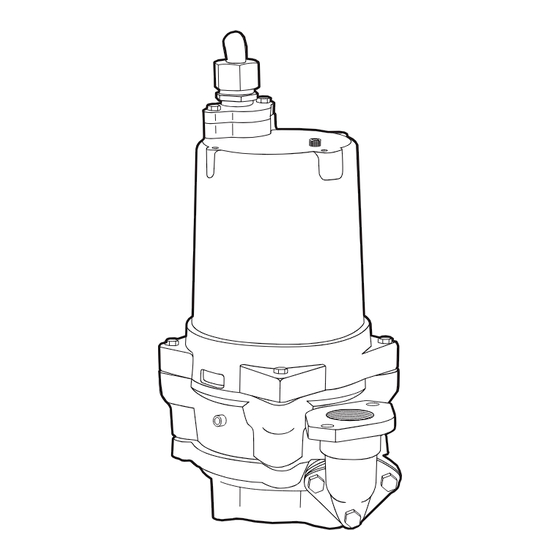

Page 2: General Information

exists. Installer(s) and/or service common. This specialized pump is General personnel must use proper personal designed to incorporate a grinding Information protective equipment and follow mechanism to remove wastewater handling procedures per OSHA particulate and pump the resulting Attention: 29 CFR 1910.1030 when handling slurry from a residential structure to This manual contains important equipment after wastewater source... -

Page 3: Pump Installation

can be fur nished for mounting to seal cham ber are com pletely sealed ELECTRICAL CONNECTIONS walls of basin. In either case, be with O-rings located at mating part 1 Phase 3 Phase sure that the Hydromatic solids faces. ® Green Ground Ground... -

Page 4: Pump Maintenance

NOT OVERTIGHTEN) the 2. Remove the volute and 6. If problems occur, check power source. Allen head screw. It is good cutters per the instrutions Make sure a separate supply practice to add a light coat of listed under the Pump Disas- line is available. - Page 5 using the same method as used plate, re place the cap screws, 2. Remove the shaft rotor for the lower seal, remove the and evenly tighten. assembly from the motor carbon seal assembly. housing, making note that a 13. Using a pressure gauge with a wave washer is used on the top 7.

-

Page 6: Pump Troubleshooting

Pump overloads motor 8. Examine the bearings on Pump the shaft/rotor assembly. If 1. Wrong rotation Troubleshooting when rotated they feel rough, 2. Specific gravity or vis cos i ty of replace. When reinstalling Below is a list of troubles and their liquid too high new bearings, press only on probable causes:... - Page 7 HPG200 Parts List ORDERING REPLACEMENT PARTS: Product improvements are made from time to time. The latest part design will be fur- nished as long as it is in ter change able with the old part.When ordering re place ment parts, always furnish the fol low ing information: (1) pump serial num ber, (2) pump model and size, (3) part description, (4) part number, (5) im pel ler diameter (if ordering impeller), (6) quan ti ty required and (7) shipping instructions.

-

Page 8: Standard Limited Warranty

Pentair Hydromatic will cover only the lower seal and labor thereof for all dual seal pumps. Under no circumstance will Pentair Hydromatic be responsible for the cost of field labor, travel expenses, rented equipment, removal/reinstallation costs or freight expenses to and from the factory or an authorized Pentair Hydromatic service facility.

Need help?

Do you have a question about the Hydromatic HPG200 and is the answer not in the manual?

Questions and answers