Samson 3271 Mounting And Operating Instructions

Pneumatic actuator

Hide thumbs

Also See for 3271:

- Mounting and operating instructions (76 pages) ,

- Original instructions manual (72 pages) ,

- Mounting and operating instruction (112 pages)

Summary of Contents for Samson 3271

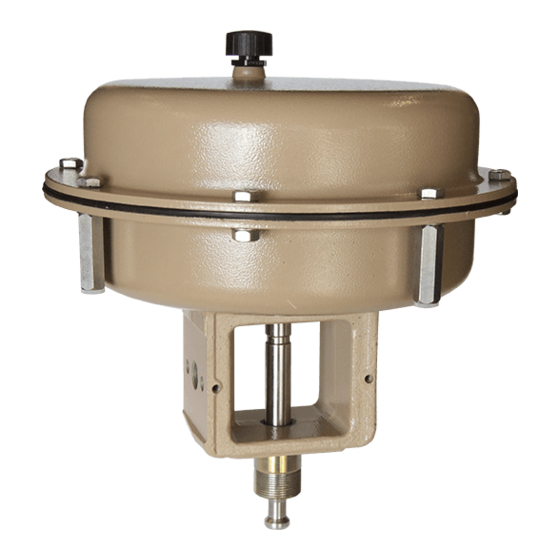

- Page 1 EB 8310-7 EN Translation of original instructions Type 3271, 2800 cm² Type 3271, 2 x 2800 cm² (tandem actuator) Type 3271 Pneumatic Actuator Actuator areas: 1400-120 cm² · 2800 cm² · 2 x 2800 cm² Edition April 2018...

- Page 2 Î For the safe and proper use of these instructions, read them carefully and keep them for later reference. Î If you have any questions about these instructions, contact SAMSON‘s After-sales Service Department (aftersalesservice@samson.de). The mounting and operating instructions for the devices are included in the scope of delivery.

-

Page 3: Table Of Contents

Contents Safety instructions and measures ..............5 Notes on possible severe personal injury ............7 Notes on possible personal injury ..............8 Notes on possible property damage ..............9 Markings on the device ................10 Actuator nameplate ..................10 Design and principle of operation ..............12 Direction of action ..................12 Signal pressure routing .................12 Fail-safe action ....................14 3.3.1... - Page 4 Contents Travel stop ....................30 6.4.1 Bottom travel stop (minimum travel) ...............30 6.4.2 Top travel stop (maximum travel) ..............30 Servicing.....................31 Preparation for return shipment ..............31 Ordering spare parts and operating supplies ..........31 Malfunctions ....................32 Decommissioning and removal ..............33 Decommissioning ..................33 Removing the actuator from the valve ............33 Relieving the spring compression in the actuator ..........33 Disposal ......................34 Appendix ....................34...

-

Page 5: Safety Instructions And Measures

SAM- SON. SAMSON does not assume any liability for damage resulting from the failure to use the de- vice for its intended purpose or for damage caused by external forces or any other external factors. - Page 6 Î Check with the plant operator for details on further protective equipment. Revisions and other modifications Revisions, conversions or other modifications of the product are not authorized by SAMSON. They are performed at the user's own risk and may lead to safety hazards, for example. Fur- thermore, the product may no longer meet the requirements for its intended use.

-

Page 7: Notes On Possible Severe Personal Injury

Safety instructions and measures Referenced standards and regulations According to the ignition risk assessment performed in accordance with EN 13463-1:2009, section 5.2, the non-electrical actuators do not have their own potential ignition source even in the rare incident of an operating fault. As a result, they do not fall within the scope of Di- rective 2014/34/EU. -

Page 8: Notes On Possible Personal Injury

Safety instructions and measures 1.2 Notes on possible personal injury WARNING Crush hazard arising from moving parts. The actuator contains moving parts (actuator stem), which can injure hands or fingers if inserted into the actuator. Î Do not insert hands or fingers into the yoke while the valve is in operation. Î... -

Page 9: Notes On Possible Property Damage

Risk of actuator damage due to the use of unsuitable tools. Certain tools are required to work on the actuator. Î Only use tools approved by SAMSON (u AB 0100). Risk of actuator damage due to the use of unsuitable lubricants. The lubricants to be used depend on the actuator material. Unsuitable lubricants may corrode and damage the surface. -

Page 10: Markings On The Device

12 Symbol indicating fail-safe action Actuator stem extends (FA) Actuator stem retracts (FE) Manual override 14 Connecting thread 15 Diaphragm material 16 Date of manufacture Made in Germany SAMSON 3271 Var-ID Serial no. Fig. 1: Nameplate EB 8310-7 EN... - Page 11 EB 8310-7 EN...

-

Page 12: Design And Principle Of Operation

The direction of action is determined by how the springs and diaphragm plate are ar- The Type 3271 Pneumatic Actuators with ranged in the actuator. With direction of ac- 1400-120 cm², 2800 cm² and 2x 2800 cm² tion "actuator stem retracts", the compressed... - Page 13 Design and principle of operation Type 3271, 1400-120 cm² Actuator stem re- Actuator stem tracts (FE) extends (FA) Type 3271, 2 x 2800 cm² (tandem actuator) Diaphragm Actuator stem Ring nut A10 Springs A16 Vent plug A26 Stem connector clamps A88 Anti-rotation fixture Signal pressure connection...

-

Page 14: Fail-Safe Action

Design and principle of operation 3.4 Versions In the "actuator stem retracts" version, the signal pressure is routed through both top − Type 3271 as single actuator with signal pressure connections (S) to the top di- 1400-120 cm² actuator area aphragm chamber and moves the actuator stem (A7) downward opposing the spring −... - Page 15 Design and principle of operation Temperature range The permissible temperature range depends on the diaphragm material: Diaphragm material Temperature range –35 to +90 °C 1) –31 to +194 °F –60 to +90 °C PVMQ –76 to +194 °F In on/off service, lowest temperature restricted to –20 °C (–4 °F).

- Page 16 Design and principle of operation Table 1: Dimensions in mm and weights in kg Actuator Type 3271 Actuator area cm² 1400-120 2800 2 x 2800 H/H' 1085 1) rated Height 2) Travel limitation ØD Diameter ØD2 Ød (thread) M100x2 M100x2 Air connection G 1/1 NPT G 1/1 NPT...

- Page 17 Design and principle of operation Dimensional drawings ØD2 ØD2 Ød Ød ØD ØD Type 3271 with 1400-120 and 2800 cm² Type 3271 as tandem actuator with actuator areas 2 x 2800 cm² actuator areas EB 8310-7 EN...

-

Page 18: Measures For Preparation

2. Check the shipment for transportation WARNING damage. Report any damage to Risk of lifting equipment tipping over and SAMSON and the forwarding agent risk of damage to lifting accessories due to (refer to delivery note). exceeding the rated lifting capacity. -

Page 19: Transporting

Measures for preparation 4.2.1 Transporting − Prevent the actuator from tilting or tip- ping. The actuator can be transported using lifting − Do not leave loads suspended when in- equipment (e.g. crane or forklift). terrupting work for longer periods of Î... - Page 20 Measures for preparation 3. Move the actuator at an even pace to the mounting site. 4. Mount the actuator to the valve. See sec- tion 5.1. 5. Remove slings after mounting. We recommend using a hook with safety latch (see Fig. 3). The safety latch prevents the slings from slipping during lifting and transporting.

- Page 21 Measures for preparation Fig. 3: Lifting point on the actuator Fig. 4: Lifting points on the control valve (example) EB 8310-7 EN...

-

Page 22: Storage

− Do not place any objects on the actuator. − Avoid long storage times. Special storage instructions for elastomers − Contact SAMSON in case of different stor‑ Elastomer, e.g. actuator diaphragm age conditions or long storage periods. − To keep elastomers in shape and to pre-... -

Page 23: Preparation For Installation

Measures for preparation 4.4 Preparation for installation Proceed as follows: Î Check the actuator for damage. Î Check to make sure that the type desig- nation, material and temperature range of the actuator match the plant condi- tions. Î Check the pressure gauge installed on valve accessories to make sure it func- tions. -

Page 24: Mounting And Start-Up

Mounting and start-up 5 Mounting and start-up Note SAMSON control valves are delivered ready − Remove the mounted actuator before for use. In special cases, the valve and actu- mounting another actuator (see sec‑ ator are delivered separately and must be tion 9.3). - Page 25 Mounting and start-up Bonnet/flange Threaded bushing Stem connector nut Lock nut Travel indicator scale Actuator stem Ring nut Stem connector clamps Fig. 5: Type 3271 Pneumatic Actuator EB 8310-7 EN...

-

Page 26: Preloading The Springs

Mounting and start-up The upper signal pressure range value is − In combination with a SAMSON valve: the same as the maximum value of the the actuator travel range can be adapted bench range or operating range (with to a smaller valve travel range preloaded springs). -

Page 27: Increasing The Actuator Thrust

Mounting and start-up 5.2.2 Increasing the actuator 3. To tension the springs evenly, tighten the nuts (A23) gradually in a crisscross pat- thrust tern until the diaphragm cases (A1, A2) rest on the diaphragm (A4). Hold the The thrust can only be increased in actuators bold head stationary with a suitable tool with "stem extends"... -

Page 28: Additional Fittings

Direction of action: actuator stem retracts The springs of actuators with "stem retracts" action cannot be preloaded. When a SAMSON valve is combined with an oversized actuator (e.g. the rated travel of the actuator is larger than the rated travel of the valve), only the first half of the actuator's bench range can be used. -

Page 29: Operation

6.1 Throttling service tends" and travel stop, the supply pressure must not exceed the upper bench range val- The Type 3271 Pneumatic Actuator with ue by more than 1.5 bar. 1400-120 cm², 2800 cm² and 2x 2800 cm² Additional points that apply concerning op-... -

Page 30: Reversal Of The Direction Of Action

3. Retighten lock nut (A70). Î If necessary, contact SAMSON’s After- sales Service department. 6.4 Travel stop In the version of Type 3271 with travel stop, the maximum and minimum actuator travel can be limited as follows: Direction of Min. stop Max. -

Page 31: Servicing

− Do not perform service and repair work on Tools your own. − Contact SAMSON's After‑sales Service de‑ Details on suitable tools can be found in the partment for service and repair work. document u AB 0100. 7.1 Preparation for return ship-... -

Page 32: Malfunctions

Check the signal pressure line for leakage. Valve accessories incorrectly set. Check the actuator without valve accessories. Check the settings of the valve accessories. Note Contact SAMSON's After‑sales Service department for malfunctions not listed in the table. EB 8310-7 EN... -

Page 33: Decommissioning And Removal

Decommissioning and removal 9 Decommissioning and remov- 9.2 Removing the actuator from the valve 1. Put the control valve out of operation. DANGER See associated valve documentation. Risk of bursting in the actuator. 2. Undo the clamps of the stem connector Actuators are pressurized. -

Page 34: Disposal

You can reach the After-sales Service De- partment at aftersalesservice@samson.de. Addresses of SAMSON AG and its subsid- iaries The addresses of SAMSON AG, its subsid- iaries, representatives and service facilities worldwide can be found on our website (www.samson.de) or in all SAMSON prod- uct catalogs. -

Page 35: Spare Parts

Appendix 10.2 Spare parts Top diaphragm case Hex nut Bottom diaphragm case Washer Diaphragm Spacer Diaphragm plate Guide stem (anti-rotation fixture) Actuator stem Bushing Ring nut O-ring Spring (external) Cap screw Spring (internal) Slotted round nut Vent plug Nameplate O-ring Label (preloading) Screw fitting Crossbeam... - Page 36 Actuator (1400-120 cm²) EB 8310-7 EN...

- Page 37 82/83 82/83 82/83 25/84 2800 cm² actuator EB 8310-7 EN...

- Page 38 Tandem actuator (2 x 2800 cm²)

- Page 39 EB 8310-7 EN...

- Page 40 EB 8310-7 EN SAMSON AKTIENGESELLSCHAFT Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany Phone: +49 69 4009-0 · Fax: +49 69 4009-1507 samson@samson.de · www.samson.de...

Need help?

Do you have a question about the 3271 and is the answer not in the manual?

Questions and answers