Summary of Contents for Krone Swadro 1000

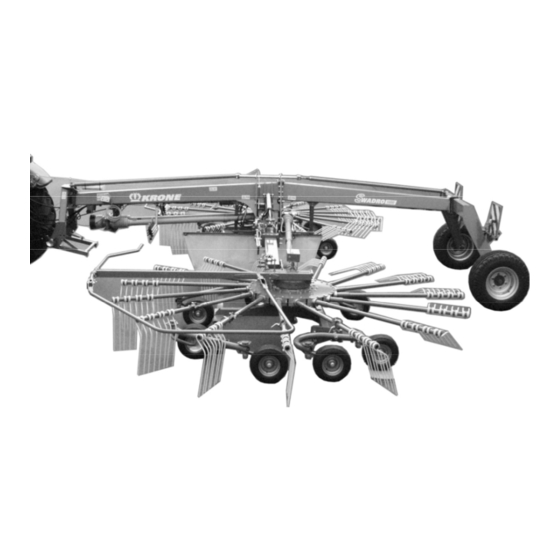

- Page 1 Rotary Swather Swadro 1000 (from serial no.: 864 760) Order no.: 150 000 116 04 en 22.11.2012...

- Page 2 Table of Contents Pos : 1 /BA/Konfor mitäts er kl ärungen/Schwader/N eu ab 2010/Swadro 1000 @ 40\mod_1268921153032_78.doc x @ 363090 @ @ 1 EC Declaration of Conformity Maschinenfabrik Bernard Krone GmbH Heinrich-Krone-Str. 10, D-48480 Spelle hereby declare as manufacturer of the product named below, on our sole responsibility,...

-

Page 3: Table Of Contents

Table of Contents Pos : 4 /BA/Inhalts verz eichnis @ 0\mod_1196861555655_78.doc x @ 15165 @ 1 @ 1 Table of Contents Table of Contents ...........................3 Foreword ..............................6 Introduction.............................7 Purpose of Use ..........................7 Validity ............................... 7 Identification Plate ..........................7 Information Required for Questions and Orders................ - Page 4 Table of Contents 6.6.1 Selecting the Rotors for a Function ..................... 34 Lowering the Rotors from Transport to Headland Position ............. 35 6.7.1 Lowering All Rotors to Headland Position ................... 35 Lowering the Rotors from Headland to Working Position..............36 6.8.1 Lowering All Rotors to Working Position ..................

- Page 5 Table of Contents Maintenance............................71 11.1 Special Safety Instructions ......................71 11.2 Compensation Spring(s) ........................71 11.3 Test run............................71 11.4 Tightening Torques .......................... 72 11.5 Tightening Torques (Countersunk Screws) ..................73 11.6 Testing the screws on the tines ....................... 73 11.7 Disc springs at collapsible tine arms outside...................

-

Page 6: Foreword

Pos : 6.2 /BA/Vor wort/Sc hwader/Ver ehrter Kunde Sc hwader @ 1\mod_1202129116819_78.doc x @ 57456 @ @ 1 Dear Customer, By purchasing your rotary rake, you have acquired a quality product from KRONE. We are grateful for the confidence you have invested in us in buying this machine. -

Page 7: Introduction

The rotary rake is designed to swathe cut crops. The installation is designed as a CAT II three- point frame at the tail. Pos : 8.4 /BA/Ei nleitung/Gültigkeit/Sc hwader/Gültig keit Swadro 1000 @ 2\mod_1202904913868_78.doc x @ 62439 @ 2 @ 1 Validity... -

Page 8: Information Required For Questions And Orders

Authentic KRONE spare parts and accessories authorised by the manufacturer help to ensure safety. The use of spare parts, accessories and other devices which are not manufactured, tested or approved by KRONE will result in the revoking of the liability for damages resulting thereof. -

Page 9: Intended Use

Introduction Pos : 8.10.1 /Übersc hriften/Übersc hriften 2/A-E/Besti mmungsgemäß er Gebrauch (alt) @ 0\mod_1196401545090_78.doc x @ 7728 @ 2 @ 1 Intended Use Pos : 8.10.2 /BA/Einl eitung/Besti mmungsgemäßer Gebrauc h/Sc hwader /Besti mmungsgemäß er Gebr auch Sc hwader @ 1\mod_1202215704310_78.doc x @ 57818 @ @ 1 The rotary rake is built exclusively for conventionaluse in agricultural work (intended use). - Page 10 Introduction Pos : 10 /BA/Einl eitung/T ec hnis che D aten/Sc hwader/Swadro 1000 @ 90\mod_1322810560248_78.doc x @ 766318 @ @ 1 Road travel is only permitted with the swivelled rotary arms in transport position. The max. height of 4 m must not be exceeded.

- Page 11 Introduction SW1000001 Figure 2: Pos : 12 /BA/---------------Seitenumbruc h---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ @ 1...

-

Page 12: Safety

Safety Pos : 13.1 /Übersc hriften/Übersc hriften 1/P-T/Sicher heit @ 0\mod_1195566748646_78.doc x @ 635 @ 1 @ 1 Safety Pos : 13.2 /BA/Sicher heit/Sc hwader/Sicherheit Einführung Schwader @ 1\mod_1202219372123_78.doc x @ 58050 @ 2 @ 1 Introduction The rotary rake is equipped with all safety devices (protective devices). However, it is not possible to eliminate all potential hazards on this machine as this would impair its full functional capability. -

Page 13: Re-Ordering The Adhesive Safety And Information Labels

Pos : 13.6 /Übersc hriften/Übersc hriften 3/A-E/Ans prec hpartner @ 0\mod_1195569394286_78.doc x @ 839 @ 3 @ 1 4.1.3 Contact Pos : 13.7 /Adressen/Adress e M asc hinenfabri k KRON E Spelle @ 0\mod_1195568531083_78.doc x @ 734 @ @ 1 Maschinenfabrik Bernard Krone GmbH Heinrich-Krone-Strasse 10 D-48480 Spelle (Germany) Telephone: + 49 (0) 59 77/935-0 (Head Office) Fax.: + 49 (0) 59 77/935-339 (Head Office) -

Page 14: Position Of The Adhesive Safety Stickers On The Machine

Safety Pos : 13.9 /Übersc hriften/Übersc hriften 2/K-O/Lage der Sic herheits aufkleber an der Mas chi ne @ 0\mod_1195634967326_78.doc x @ 1020 @ 2 @ 1 Position of the Adhesive Safety Stickers on the Machine Pos : 13.10 /BA/Sic herheit/Aufkleber/Schwader/Sicherheits aufkl eber Schwader 1000 @ 137\mod_1353579488180_78.doc x @ 1220425 @ @ 1 SW1000002_1 Fig. - Page 15 Safety Do not stay in the swivel range of the While parts are moving, never outrigger arms. Keep your distance! reach into areas where there is a risk of being crushed. Order no. 942 196-1 (4x) Order No. 939 414-2 (2x) Keep the stipulated safe distance from power The shut-off valve must transmission lines.

-

Page 16: Identifying Symbols In The Operating Instructions

Safety Pos : 13.12 /BA/Sic herheit/Ü berarbeitete Warnhinweise/Kennz eic hnung von Hi nweis en i n der Betriebsanl eitung Ei nführungstext ( 2012-07-27 09:59:06) @ 0\mod_1195637804826_78.doc x @ 1098 @ 2 @ 1 Identifying Symbols in the Operating Instructions The safety instructions contained in this manual which could result in personal injury if not followed are identified by the general danger sign: Pos : 13.13 /BA/Sic herheit/Ü... -

Page 17: Personnel Qualification And Training

Safety Pos : 15.1 /BA/Sicher heit/Personalqualifi kati on und -sc hul ung @ 0\mod_1195639383185_78.doc x @ 1136 @ @ 1 4.4.1 Personnel Qualification and Training The machine may be used, maintained and repaired only by persons who are familiar with it and have been instructed about the dangers connected with it. -

Page 18: Safety Instructions And Accident Prevention Regulations

Safety Pos : 15.5 /BA/Sicher heit/Sic her heits- und U nfall ver hütungs-Vorschriften Swadr o_Ladewag en_Eas yC ut @ 73\mod_1308298589597_78.doc x @ 655493 @ 2 @ 1 Safety Instructions and Accident Prevention Regulations Please follow all generally applicable safety and accident prevention regulations in addition to the safety instructions contained in these operating instructions! The attached warning and safety signs provide important information for safe operation. -

Page 19: Hitched Implements

Safety Parts operated by external power (e.g. hydraulically) can cause crushing and shearing injuries! Before leaving the tractor, lower the implement onto the ground, apply the parking brake, switch off the engine and remove the ignition key! Pos : 15.6 /BA/Sicher heit/Angehängte Geräte/Geräte angehängt @ 0\mod_1199699679381_78.doc x @ 33245 @ 2 @ 1 Hitched Implements 1... -

Page 20: Pto Operation

Safety Pos : 15.8 /BA/Sicher heit/Zapfwellenbetrieb Traktor @ 0\mod_1199699899350_78.doc x @ 33264 @ 2 @ 1 PTO operation 1 Use only PTO shafts specified by the manufacturer! 2 The guard tube and guard cone of the PTO shaft and the PTO guard must be attached and in good working condition (on the implement side, too)! 3... -

Page 21: Hydraulic System

Safety Pos : 15.11 /BA/Sic herheit/H ydr auli kanl age @ 2\mod_1203503691986_78.doc x @ 66225 @ 2 @ 1 Hydraulic system 1 The hydraulic system is pressurised! 2 When connecting hydraulic cylinders and motors, make sure the hydraulic hoses are connected as specified! 3... -

Page 22: Maintenance

8 Replacement parts must at least comply with the technical requirements set by the manufacturer of the implements! This is guaranteed by original KRONE spare parts! Pos : 15.16 /BA/---------------Seitenumbr uc h---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ @ 1... -

Page 23: Working In The Vicinity Of Power Transmission Lines

Safety Pos : 15.17 /BA/Sic herheit/Arbeiten im Bereic h von H oc hspannungsleitung en @ 11\mod_1223357468516_78.doc x @ 145505 @ 2 @ 1 4.11 Working in the vicinity of power transmission lines 1 Always take great care when working under or in the vicinity of power transmission lines. 2... - Page 24 Safety Pos : 17 /BA/Di es e Seite is t bewusst fr eigelass en worden. @ 1\mod_1201783680373_78.doc x @ 54443 @ @ 1 This page has been left blank deliberately!! Pos : 18 /BA/---------------Seitenumbruc h---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ @ 1...

-

Page 25: Commissioning

Commissioning Pos : 19.1 /Übersc hriften/Übersc hriften 1/A-E/Ers tinbetriebnahme @ 0\mod_1196314201498_78.doc x @ 5855 @ 1 @ 1 Commissioning Pos : 19.2 /BA/Sicher heit/Gefahr enhi nweis e/Gefahr - F ehl erhafter Z us ammenbau @ 1\mod_1202224212591_78.doc x @ 58171 @ @ 1 Danger! - Incorrect assembly Effect: Danger to life, serious injuries or serious damage to the machine. -

Page 26: First Installation

Commissioning Pos : 19.5 /Übersc hriften/Übersc hriften 2/A-E/Ers tmontage @ 1\mod_1202226261982_78.doc x @ 58270 @ 2 @ 1 First installation Pos : 19.6 /BA/Inbetriebnahme/Ersti nbetri ebnahme/Erstmontage @ 1\mod_1202224111998_78.doc x @ 58190 @ @ 1 The document "Assembly Instructions" describes how to install the device for the first time. Pos : 19.7.1 /Übersc hriften/Übersc hriften 2/U-Z/Vorberei tungen am Traktor @ 2\mod_1202363643678_78.doc x @ 58694 @ 2 @ 1 Preparations on tractor Pos : 19.7.2 /Übersc hriften/Übersc hriften 3/A-E/Aus hubhöhe ei nstellen @ 0\mod_1196675396916_78.doc x @ 10668 @ 3 @ 1... -

Page 27: Pto Shaft

Commissioning Pos : 19.9.1 /Übersc hriften/Übersc hriften 2/F-J/Gelenkwelle @ 0\mod_1199781879794_78.doc x @ 34542 @ 2 @ 1 PTO shaft Pos : 19.9.2 /Übersc hriften/Übersc hriften 3/K-O/Längenanpass ung @ 1\mod_1201687632810_78.doc x @ 53589 @ 3 @ 1 5.3.1 Length adjustment Pos : 19.9.3 /BA/Inbetriebnahme/Ersti nbetri ebnahme/Gel enkwelle/Sc hwader/Längenanpassung Bild Sc hwader @ 2\mod_1202364902991_78.doc x @ 58848 @ @ 1 SW9070007 Fig. -

Page 28: Height Of Tractor Lower Suspension Arms

Commissioning Pos : 19.11 /Ü bersc hriften/Ü berschriften 2/F-J /Höhe der Tr aktorunterlenker @ 35\mod_1257862892625_78.doc x @ 332062 @ 2 @ 1 Height of tractor lower suspension arms Pos : 19.12 /BA/Inbetri ebnahme/Erstinbetriebnahme/Sc hwader/Swadro 807_810_907/H öhe der Traktor unterlenker @ 2\mod_1202734685720_78.doc x @ 60755 @ @ 1 SW9070025 Figure 6 Perform basic setting on a level surface. -

Page 29: Medium Control Unit

Medium Control Unit Pos : 21.1 /Übersc hriften/Übersc hriften 1/A-E/Bedienei nheit - Medium @ 2\mod_1203070410463_78.doc x @ 64992 @ 1 @ 1 Medium Control Unit Pos : 21.2 /BA/Sicher heit/Gefahr enhi nweis e/Ac htung - Bedieneinhei t sc hütz en @ 0\mod_1200308247867_78.doc x @ 39598 @ @ 1 Caution! - Protect Control Unit. -

Page 30: Mounting

Medium Control Unit Pos : 21.5 /BA/Info-C enter/Sc hwader/Bedi enei nheit - Medium/Anbau @ 36\mod_1260880356866_78.doc x @ 337134 @ 2 @ 1 Mounting Figure. 8 • Fasten the support (1) using the drill holes (2) already present. • The control unit (3) is fixed by the magnetic plate (4) on the support (1). Pos : 21.6 /BA/Info-C enter/Sc hwader/Bedi enei nheit - Medium/Spannungs vers orgung @ 2\mod_1203072066010_78.doc x @ 65050 @ 2 @ 1 Electrical power supply Danger! - Failure of the control unit... -

Page 31: Control Unit

Medium Control Unit Pos : 21.8 /BA/Info-C enter/Sc hwader/Bedi enei nheit - Medium/Anbau Bedieneinheit @ 2\mod_1203072184463_78.doc x @ 65070 @ 2 @ 1 Control unit SW1000028 Figure 10 • Connect the connecting cable to the socket (3) of the control unit (2). •... -

Page 32: Control Unit Overview

Medium Control Unit Pos : 21.10 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Übersicht Bedieneinhei t @ 2\mod_1203073630166_78.doc x @ 65110 @ 2 @ 1 Control unit overview SW1000027 Figure 11 Pos : 21.11 /BA/---------------Seitenumbr uc h---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ @ 1... - Page 33 Medium Control Unit Pos : 21.12 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Übersicht Bes chr eibung der Tasten und Kontrolll euc hten @ 2\mod_1203076914291_78.doc x @ 65129 @ @ 1 Keys Pilot lights ON/OFF key ON/OFF and messages / alarms "-"...

-

Page 34: Operational Readiness

LED off: No iron in front of the sensor LED flashing: Sensor has broken cable or short circuit Pos : 21.18 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Kr eisel für ei ne Funkti on vorwählen @ 2\mod_1203313671715_78.doc x @ 65322 @ 23 @ 1 Settings 6.6.1... -

Page 35: Lowering The Rotors From Transport To Headland Position

Medium Control Unit Pos : 21.20 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Abs enken aller Kreis el in di e Vorgewendestellung @ 2\mod_1203316033918_78.doc x @ 65400 @ 23 @ 1 Lowering the Rotors from Transport to Headland Position 6.7.1 Lowering All Rotors to Headland Position... -

Page 36: Lowering The Rotors From Headland To Working Position

Pos : 21.23 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Abs enken einz elner Kreis el in di e Arbeitss tell ung @ 2\mod_1203318076668_78.doc x @ 65457 @ 3 @ 1 6.8.2 Lowering individual rotors to working position (optional) •... -

Page 37: Lowering The Rotors From Working To Headland Position

Pos : 21.26 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Anheben einzel ner Kreis el i n die Vorgewendes tell ung @ 2\mod_1203320380652_78.doc x @ 65495 @ 3 @ 1 6.9.2 Raising individual rotors to headland position (optional) •... -

Page 38: Raising Rotors To Transport Position

Medium Control Unit Pos : 21.28 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Anheben aller Kreis el @ 2\mod_1203317574324_78.doc x @ 65438 @ 23 @ 1 6.10 Raising Rotors to Transport Position 6.10.1 Raising All Rotors to transport Position SW1000030 Figure 16... -

Page 39: Adjusting The Swath Width

Medium Control Unit Pos : 21.30 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Sc hwadbreite ei nstellen @ 2\mod_1203322610449_78.doc x @ 65553 @ 2 @ 1 6.11 Adjusting the Swath Width SW1000031 Figure 17: • Press the key. Pilot lamp (10) flashes. -

Page 40: Adjusting The Working Height Of The Rotors (Optional)

Medium Control Unit Pos : 21.32 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Ar beitshöhe der Kr eisel ei nstellen @ 2\mod_1203323104340_78.doc x @ 65592 @ 2 @ 1 6.12 Adjusting the Working Height of the Rotors (optional) SW1000032 Figure 18 •... -

Page 41: Sensor Test

Medium Control Unit Pos : 21.34 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Sensortest @ 3\mod_1206001376370_78.doc x @ 74265 @ 2 @ 1 6.13 Sensor test SW1000039 Fig. 19 In the sensor test the sensors installed on the machine are checked for faults. -

Page 42: Alarm Messages

The buzzer also sounds the same error code for 5 cycles. Pos : 21.37 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Beispi el Sens orfehl er @ 2\mod_1203324866121_78.doc x @ 65650 @ @ 1 Example: Sensor error (11) (Error code "21") = 21"... -

Page 43: Malfunctions - Causes And Remedies

Pos : 21.39 /Ü bersc hriften/Ü berschriften 2/P-T/Stör ung en - Ursachen und Behebung @ 2\mod_1203325826011_78.doc x @ 65688 @ 2 @ 1 6.15 Malfunctions - Causes and Remedies Pos : 21.40 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Stör ungen_Ursac he_Behebung @ 2\mod_1203325023621_78.doc x @ 65669 @ @ 1 Description Possible cause... -

Page 44: Eliminating Alarm Messages

SW1000034 Figure 21 Pos : 21.45 /BA/Info-Center/Schwader/Bedi eneinheit - M edi um/Swadro 1000/Anz eigen der Softwar e-Version T ext @ 2\mod_1203326012074_78.doc x @ 65727 @ @ 1 To display the software version of the machine, press the key 10 times. -

Page 45: Start-Up

Start-up Pos : 23.1 /Übersc hriften/Übersc hriften 1/F-J/Inbetri ebnahme @ 0\mod_1196327075811_78.doc x @ 6375 @ 1 @ 1 Start-up Pos : 23.2 /BA/Sicher heit/Gefahr enhi nweis e/Sc hwader /Gefahr - An-/ Abbau der Maschi ne gez ogene Sc hwader @ 2\mod_1202363265522_78.doc x @ 58675 @ @ 1 Danger! - Assembling / dismantling the machine Effect: Danger to life or serious injuries. -

Page 46: Mounting Onto The Tractor

Start-up Pos : 23.4 /Übersc hriften/Übersc hriften 2/A-E/Anbau an den Traktor @ 0\mod_1199717845194_78.doc x @ 34039 @ 2 @ 1 Mounting onto the Tractor Pos : 23.5 /BA/Sicher heit/Gefahr enhi nweis e/Ladewag en/Gefahr - Stütz- und Anhängel asten des Traktors nic ht beac htet @ 0\mod_1199720048038_78.doc x @ 34118 @ @ 1 Danger! - Support and hitching loads of tractor not observed! Effect: Danger to life, injuries or damage to the machine. -

Page 47: Hydraulics

Start-up Pos : 23.9 /Übersc hriften/Übersc hriften 2/F-J/H ydrauli k @ 0\mod_1199776034950_78.doc x @ 34205 @ 2 @ 1 Hydraulics Pos : 23.10 /Ü bersc hriften/Ü berschriften 3/P-T/Speziell e Sicherheits hinweis e @ 0\mod_1197301069931_78.doc x @ 17662 @ 3 @ 1 7.2.1 Special Safety Instructions Pos : 23.11 /BA/Sic herheit/H ydr auli k/Warnung - Ansc hlus s der H ydrauli klei tungen @ 0\mod_1199776548685_78.doc x @ 34225 @ @ 1... -

Page 48: Connecting The Hydraulic Lines

Pos : 23.14 /Ü bersc hriften/Ü berschriften 3/A-E/Ansc hluss der H ydrauli kleitungen @ 0\mod_1199777037794_78.doc x @ 34244 @ 3 @ 1 7.2.2 Connecting the hydraulic lines Pos : 23.15 /BA/Inbetri ebnahme/Sc hwader /H ydr auli kanschl uss /H ydr auli kansc hluss Swadro 1000 @ 2\mod_1202916724602_78.doc x @ 62953 @ @ 1 SW1000021 SW1000005... -

Page 49: Lighting Connection

Start-up Pos : 23.19 /Ü bersc hriften/Ü berschriften 2/A-E/Ansc hluss Beleuc htung @ 33\mod_1254385308979_78.doc x @ 319105 @ 2 @ 1 Lighting connection Pos : 23.20 /BA/Inbetri ebnahme/Sc hwader /Ansc hluss Beleuc htung/Ansc hluss Beleuc htung SW 1000 @ 2\mod_1202919289524_78.doc x @ 63013 @ @ 1 SW1000006 Figure 24 The connection for the lighting system is performed via the 7-pin connecting cable (1) provided. -

Page 50: Connecting The Electrical Controls

Start-up Pos : 23.23 /Ü bersc hriften/Ü berschriften 2/A-E/Ansc hluss der elektrischen Bedienung @ 2\mod_1202396974288_78.doc x @ 59195 @ 2 @ 1 Connecting the electrical controls Pos : 23.24 /BA/Inbetri ebnahme/Sc hwader /Ansc hluss el ektrisc he Bedienung/Ans chl uss el ektrisc he Bedienung SW 1000 @ 2\mod_1202919455696_78.doc x @ 63053 @ @ 1 SW1000007 Figure 25 The connection of the electrical controls is performed by means of the power supply cable (1). -

Page 51: Install The Pto Shaft

Start-up Pos : 23.27 /Ü bersc hriften/Ü berschriften 2/F-J /Gelenkwelle montier en @ 2\mod_1202398342788_78.doc x @ 59253 @ 2 @ 1 Install the PTO shaft Pos : 23.28 /BA/Sic herheit/Gel enkwell e/Gefahr - Sic h drehende Gel enkwelle_2 @ 0\mod_1199781692950_78.doc x @ 34523 @ @ 1 Danger! - Rotating PTO shaft Effect: Danger to life or serious injuries •... -

Page 52: Driving And Transport

Driving and Transport Pos : 25.1 /Übersc hriften/Übersc hriften 1/F-J/F ahr en und Trans port @ 0\mod_1196330049217_78.doc x @ 6553 @ 1 @ 1 Driving and Transport Pos : 25.2 /BA/Sicher heit/Fahren und Trans port/Mitfahr en Straß enfahrt/Gefahr Straß enfahrt, Mitfahren Swadros gez ogen @ 2\mod_1202456315526_78.doc x @ 59426 @ @ 1 Danger! - Road travel, carrying passengers, driving conduct Effect: Danger to life, injuries or damage to the machine. - Page 53 Driving and Transport Pos : 25.5 /BA/F ahren und Tr ansport/Sc hwader /Vorbereitung für den Trans por t Swadro 1000 @ 2\mod_1202921348196_78.doc x @ 63153 @ @ 1 SW1000008 Figure 27 • Revolve the collapsible tine arms (right and left side of machine) (see Chaper on Operation "Rotating tine arms to transport position").

-

Page 54: Operation

Operation Pos : 27.1 /Übersc hriften/Übersc hriften 1/A-E/Bedienung @ 0\mod_1199789505403_78.doc x @ 34825 @ 1 @ 1 Operation Pos : 27.2 /BA/Bedi enung /Sc hwader/M asc hine ist für Vor wär tsfahrt konzi piert. @ 66\mod_1302175087311_78.doc x @ 615098 @ @ 1 WARNING! –... -

Page 55: From Transport Into Working Position

Operation Pos : 27.5 /Übersc hriften/Übersc hriften 2/U-Z/Von Trans por t in Ar beitsstellung @ 2\mod_1202466185276_78.doc x @ 59662 @ 2 @ 1 From transport into working position Pos : 27.6 /BA/Sicher heit/Gefahr enhi nweis e/Sc hwader /Gefahr M asc hine absenken @ 5\mod_1213694805078_78.doc x @ 88774 @ @ 1 Danger! –... -

Page 56: Swivel Tine Arms To Working Position

Operation Pos : 27.10 /Ü bersc hriften/Ü berschriften 2/U-Z/Zi nkenar me in Arbeits tell ung s chwenken @ 2\mod_1202709358751_78.doc x @ 59873 @ 2 @ 1 Swivel tine arms to working position. Pos : 27.11 /BA/Sic herheit/Gefahrenhinweise/Ei nstellar beiten / Ei nstellungenGefahr - Ei nstellar beiten gez ogene Maschi nen @ 0\mod_1199717011038_78.doc x @ 33980 @ @ 1 Danger! - Unexpected movements of the machine Effect: Danger to life or serious injuries. - Page 57 Operation Pos : 27.14 /BA/Bedienung /Sc hwader/Zinken / Zinkenar me/Zi nkenarme i n die Ar beitsstellung sc hwenken @ 2\mod_1202711544751_78.doc x @ 59954 @ @ 1 SW9070017 Figure 31 • Pull out the linch pin (1). • Remove the bolts (2). •...

-

Page 58: Move The Hoop Guards To The Working Position

Operation Pos : 27.17.1 /Ü berschriften/Ü berschriften 2/P-T/Schutz bügel i n Ar bei tsstellung bri ngen @ 2\mod_1202972231499_78.doc x @ 63393 @ 2 @ 1 Move the hoop guards to the working position. Pos : 27.17.2 /BA/Sic herheit/Gefahrenhinweise/Wartnung - Quetschg efahr @ 2\mod_1202971999343_78.doc x @ 63374 @ @ 1 Warning - Crush hazard! Effect: Injury to hands Do not hold onto hoop guards to swivel within range of the rotating points. -

Page 59: Travelling On An Incline

Operation Pos : 27.19 /BA/Bedienung /Sc hwader/Fahr en i m Hangbereic h @ 2\mod_1202724671955_78.doc x @ 60415 @ 2 @ 1 Travelling on an incline Danger! - Travelling on an incline (danger of turning over!). Effect: Danger to life, injuries or damage to the machine. •... -

Page 60: Switching From Working Position To Transport Position

Operation Pos : 27.22 /Ü bersc hriften/Ü berschriften 2/U-Z/Von Arbeits stellung in Tr ansportstellung @ 2\mod_1202466246542_78.doc x @ 59681 @ 2 @ 1 Switching from working position to transport position Pos : 27.23 /BA/Sic herheit/Gefahrenhinweise/Ei nstellar beiten / Ei nstellungenGefahr - Ei nstellar beiten gez ogene Maschi nen @ 0\mod_1199717011038_78.doc x @ 33980 @ @ 1 Danger! - Unexpected movements of the machine Effect: Danger to life or serious injuries. -

Page 61: Swivelling Tine Arms Into Transport Position

Operation Pos : 27.27 /Ü bersc hriften/Ü berschriften 2/U-Z/Zi nkenar me in Transports tell ung @ 2\mod_1202719789158_78.doc x @ 60199 @ 2 @ 1 9.11 Swivelling tine arms into transport position Pos : 27.28 /BA/Sic herheit/Gefahrenhinweise/Ei nstellar beiten / Ei nstellungenGefahr - Ei nstellar beiten gez ogene Maschi nen @ 0\mod_1199717011038_78.doc x @ 33980 @ @ 1 Danger! - Unexpected movements of the machine Effect: Danger to life or serious injuries. - Page 62 Operation Pos : 27.30 /BA/Bedienung /Sc hwader/Zinken / Zinkenar me/Zi nkenarme i n Tr ans portstellung sc hwenken @ 2\mod_1202719970173_78.doc x @ 60219 @ @ 1 SW9070018 Figure 35 Firstly: • Turn the left rotor far enough so that the swivelling tine arms are extended outwardly. •...

- Page 63 Operation Pos : 27.32 /BA/Ei nstellungen/Sc hwader/Zinkenar me/Hinweis durch di e Vors pannkraft 20 kg H andkraft aufbringen um Bolz en ziehen zu können @ 39\mod_1268745020196_78.doc x @ 361246 @ @ 1 Note When swivelling the tine arms into transport position, a manual force of 20 kg has to be applied by the use of preload force (via assembled disc springs) in order to be able to remove the bolt (2) (see chapter Settings “Disc springs at collapsible tine arms).

-

Page 64: Lifting The Rotor Arms To Transport Position

Operation Pos : 27.34 /Ü bersc hriften/Ü berschriften 2/K-O/Kreis elar me i n die Tr ansportstellung anheben @ 37\mod_1263480684659_78.doc x @ 340021 @ 2 @ 1 9.12 Lifting the rotor arms to transport position Pos : 27.35 /BA/Bedienung /Sc hwader/Kr eisel ar me senken/heben/Kreis elar me heben SW 1000 @ 40\mod_1270115346763_78.doc x @ 366357 @ @ 1 SW1000008 Figure 36 •... -

Page 65: Parking

Operation Pos : 27.38 /Ü bersc hriften/Ü berschriften 2/A-E/Abstellen @ 0\mod_1199801980622_78.doc x @ 35320 @ 2 @ 1 9.14 Parking Pos : 27.39 /BA/Sic herheit/Gefahrenhinweise/Schwader/Gefahr - M asc hine abs tell en gez ogene Geräte @ 2\mod_1202726300830_78.doc x @ 60434 @ @ 1 Danger! –... -

Page 66: Settings

Pos : 30.1 /Übersc hriften/Übersc hriften 2/K-O/Kr eiselfahr wer k ei nstellen @ 2\mod_1202882031680_78.doc x @ 62105 @ 2 @ 1 10.1 To adjust the rotor running gear Pos : 30.2 /BA/Eins tell ung en/Sc hwader/Kreis elfahr wer k/Kr eisel fahr wer k Bild Swadro 1000 8 R ad @ 22\mod_1239864569081_78.doc x @ 234432 @ @ 1 SW1000040 Fig. 39 Pos : 30.3 /BA/Eins tell ung en/Sc hwader/Kreis elfahr wer k/Kr eisel fahr wer k Text allgemei n SW 1000 @ 22\mod_1239866403175_78.doc x @ 234457 @ @ 1... -

Page 67: Optional

10.1.1 Optional Pos : 32.2 /BA/Eins tell ung en/Sc hwader/Kreis elfahr wer k/Kr eisel fahr wer k Bild Swadro 1000 6 R ad @ 78\mod_1314254557717_78.doc x @ 695763 @ @ 1 Fig. 40 Pos : 32.3 /BA/Eins tell ung en/Sc hwader/Kreis elfahr wer k/Kr eisel fahr wer k Text allgemei n @ 2\mod_1202882266696_78.doc x @ 62162 @ @ 1... -

Page 68: Setting The Lifting Height In Headland Position

Settings Pos : 34 /BA/Einstell ung en/Sc hwader/Eins tell en der Aus hubhöhe in Vorgewendestellung SW 1000 @ 137\mod_1353506673040_78.doc x @ 1218936 @ 2 @ 1 10.2 Setting the Lifting Height in Headland Position SW1000024_2 Fig. 41 The lifting height of the rotors in headland position is determined by the position of the sensor plate (1) on the respective outrigger arm. -

Page 69: Adjustable Throttles

Settings Pos : 36.1 /Übersc hriften/Übersc hriften 2/A-E/Ei nstellbare Dross eln @ 0\mod_1197295892260_78.doc x @ 17199 @ 2 @ 1 10.3 Adjustable throttles Pos : 36.2 /BA/Eins tell ung en/Dross el/Dr oss eln ei nstellen allgemei ner T ext Schwadbr eite SW 1000 @ 137\mod_1353566025516_78.doc x @ 1219456 @ @ 1 The adjustable throttles can be used to set the speed when extending for the swath width adjustment on the machine. -

Page 70: Regulating Direction Of Travel

Settings Pos : 38 /Ü bersc hriften/Übersc hriften 2/F-J/F ahrtric htung r egulier en @ 36\mod_1263299717731_78.doc x @ 338702 @ 2 @ 1 10.4 Regulating direction of travel Pos : 39 /BA/Einstell ung en/Sc hwader/F ahr trichtung regulier en Bil d SW 1000 @ 37\mod_1263304466668_78.doc x @ 338752 @ @ 1 SW1000015 Figure 43 Pos : 40 /BA/Einstell ung en/Sc hwader/F ahr trichtung regulier en T ext @ 36\mod_1263302390731_78.doc x @ 338727 @ @ 1... -

Page 71: Maintenance

Effect: Danger to life, serious injuries or loss of warranty claims as well as exclusion of liability • Use only authentic KRONE spare parts and accessories authorised by the manufacturer. The use of spare parts, accessories or additional equipment not manufactured, tested or approved by KRONE will exclude any liability for consequential damage. -

Page 72: Tightening Torques

Maintenance Pos : 42.10 /BA/War tung/Muttern und Sc hrauben ( 50h) anzi ehen @ 0\mod_1196949864530_78.doc x @ 15293 @ @ 1 Note Regularly check that nuts and bolts are tightly in place (approx. every 50 hours) and tighten them if necessary. Pos : 42.11 /Ü... -

Page 73: Tightening Torques (Countersunk Screws)

Maintenance Pos : 42.14 /Ü bersc hriften/Ü berschriften 2/A-E/Anzugs drehmomente über Innens echs kant @ 45\mod_1277106415765_78.doc x @ 411230 @ 2 @ 1 11.5 Tightening Torques (Countersunk Screws) Pos : 42.15 /BA/War tung/Drehmomente / Anzugs momente/Dr ehmomente über Innens ec hs kant @ 45\mod_1277106232328_78.doc x @ 411205 @ @ 1 A = Thread size The tightening torque M is stated in Nm... -

Page 74: Disc Springs At Collapsible Tine Arms Outside

Maintenance Pos : 42.18 /BA/Ei nstellungen/Sc hwader/Zinkenar me/kl appbar e Zinkenarme @ 39\mod_1268733295884_78.doc x @ 361068 @ 2 @ 1 11.7 Disc springs at collapsible tine arms outside SW1400_169 Fig. 45 Disc springs (2) are assembled at collapsible tine arms outside (1). A preload force is generated by the disc springs. - Page 75 Maintenance Pos : 42.20 /BA/Diese Seite ist bewusst freigel ass en wor den. @ 1\mod_1201783680373_78.doc x @ 54443 @ @ 1 This page has been left blank deliberately!! Pos : 42.21 /BA/---------------Seitenumbr uc h---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ @ 1...

-

Page 76: Tyres

If tyres are not correctly fitted, it could explode when pumped up. This can cause serious injury. If you do not have sufficient experience of fitting tyres, have tyres fitted by the KRONE dealer or a qualified tyre specialist. •... -

Page 77: Torque Of Wheels On The Running Gear

Maintenance Pos : 42.22.6 /BA/Wartung/Reifen/Schwader/Anziehdrehmoment der R äder am F ahrwer k @ 2\mod_1202794844888_78.doc x @ 61315 @ 3 @ 1 11.8.2 Torque of wheels on the running gear SW700040 Figure 47 Pos : 42.22.7 /BA/Wartung/Reifen/R eifen- Luftdr uc k allgemein @ 0\mod_1199956852616_78.doc x @ 37365 @ 3 @ 1 11.8.3 Tyre air pressure Check the tyre pressure at regular intervals and refill if necessary. - Page 78 Maintenance Pos : 42.24 /BA/War tung/Sc hwader/Zi nken / Zi nkenarme/Austaus ch der Zi nkenarme (i m R epar atur fall) Bild SW 907_1000 @ 16\mod_1234940816459_78.doc x @ 197222 @ @ 1 SW9070032 Fig. 48 Pos : 42.25 /BA/---------------Seitenumbr uc h---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ @ 1...

- Page 79 Maintenance Pos : 42.26 /BA/War tung/Sc hwader/Zi nken / Zi nkenarme/Kleben der Zi nkenarme SW 907_1000 @ 16\mod_1234886359835_78.doc x @ 197162 @ @ 1 In the case of repair, the tine arms can be individually replaced by dismantling them. • Unscrew the bolts (1) of two tine arms.

-

Page 80: Replacing Tines

Maintenance Pos : 42.28 /BA/War tung/Sc hwader/Zi nken / Zi nkenarme/Zi nken taus chen (im Reparaturfall) @ 139\mod_1354699792713_78.doc x @ 1241518 @ 2 @ 1 11.9 Replacing Tines SWN1400036 Fig. 49 Hex bolt M12 x 110 -10.9 Detent edged washer SKB 12 Washer 13x35x8 Fastening clamp Support... - Page 81 Maintenance Pos : 42.30 /BA/Diese Seite ist bewusst freigel ass en wor den. @ 1\mod_1201783680373_78.doc x @ 54443 @ @ 1 This page has been left blank deliberately!! Pos : 42.31 /BA/---------------Seitenumbr uc h---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ @ 1...

-

Page 82: Position Of Sensors And Actuators

Maintenance Pos : 42.32 /BA/War tung/Sc hwader/Sens oren/Aktoren/Sens oren/Aktoren Aufstellung Swadro 1000 @ 15\mod_1232362547442_78.doc x @ 173660 @ 2 @ 1 11.10 Position of sensors and actuators SW1000023_1 Fig. 50: Item Sensor designation Tightening torque Job computer valve block Lift/lower the control valve on the lifting cylinder (right and left machine side) rotor. -

Page 83: Adjusting The Sensors

Maintenance Pos : 42.34 /Ü bersc hriften/Ü berschriften 3/A-E/Einstellung der Sensor en @ 0\mod_1199962173428_78.doc x @ 37635 @ 3 @ 1 11.10.1 Adjusting the Sensors Pos : 42.35 /BA/War tung/Sensor en/Namurs ens or d = 30 mm a= 5mm @ 0\mod_1199962520100_78.doc x @ 37673 @ 4 @ 1 11.10.1.1 Namur sensor d = 30 mm BPXC0172... -

Page 84: Maintenance - Hydraulic System

• Repair work on the hydraulic system must only be performed by authorised KRONE professional workshops. Pos : 42.37.3 /BA/Sic herheit/H ydrauli k/Gefahr - H ydrauli ksc hlauc hleitungen unterlieg en ei ner Alterung @ 2\mod_1202746238361_78.doc x @ 61083 @ @ 1... -

Page 85: Load-Sensing Connection

Maintenance - hydraulic system Pos : 42.37.5 /Ü berschriften/Ü berschriften 2/K-O/Load-Sensing-Ansc hluss @ 1\mod_1201241225401_78.doc x @ 51955 @ 2 @ 1 12.1 Load-sensing connection Pos : 42.37.6 /BA/Wartung/Load- Sensing/SW 1000/Bild Load-Sensing Ans chl uss Swadr o 1000 @ 2\mod_1202997446983_78.doc x @ 64321 @ @ 1 SW1000020 Figure 52 Pos : 42.37.7 /BA/Wartung/Load- Sensing/SW 1000/Load-Sensi ng-Anschl uss SW 1000 @ 2\mod_1203509411392_78.doc x @ 66403 @ @ 1... -

Page 86: Adjusting The Hydraulic System

Maintenance - hydraulic system Pos : 42.37.9 /Ü berschriften/Ü berschriften 2/A-E/Anpass en des H ydr auli ks ystems @ 1\mod_1201241743588_78.doc x @ 52013 @ 2 @ 1 12.2 Adjusting the hydraulic system Pos : 42.37.10 /BA/Wartung/Load-Sensing/SW 1000/Anpass en des H ydrauli ks ystems Swadr o 1000 @ 2\mod_1202998620124_78.doc x @ 64361 @ @ 1 The Comfort hydraulic system of the machine must be adjusted on the tractor. -

Page 87: Examples Of Emergency Manual Activation

Maintenance - hydraulic system Pos : 42.37.13 /Ü bersc hriften/Ü bersc hriften 2/A- E/Beis piel e z ur N ot-Hand-Betätigung @ 0\mod_1199946148163_78.doc x @ 36985 @ 2 @ 1 12.4 Examples of Emergency Manual Activation Pos : 42.37.14 /BA/Sic her hei t/Gefahrenhi nweis e/Ladewagen/Gefahr Not-Hand- Betätig ung @ 0\mod_1199945455397_78.doc x @ 36965 @ @ 1 Danger! - Unexpected actions on the machine. - Page 88 Maintenance - hydraulic system Pos : 42.37.17 /BA/Wartung/Load-Sensing/SW 1000/Not-Hand- Betätigung Beis pi ele Swadr o 1000 @ 3\mod_1206011079992_78.doc x @ 74494 @ @ 1 In order to perform a function (e.g. moving the rotor arms from working to transport position), activate the appropriate valves. For the valves to be switched, see the table. Fkt.2 Fkt.1 SW1000022...

- Page 89 Maintenance - hydraulic system Retracting the rotor arms • Start engine and pressurise hydraulic system • Screw in the starwheel screw on valve (Y5/Y6). • Activate valve (Function 1) until the rotor arms are fully retracted. • Unscrew the starwheel screw again on valve (Y5/Y6) as far as it goes. Note After emergency manual activation has been performed, the starwheel screws for emergency manual activation must all be completely screwed out again!

-

Page 90: Hydraulic System Circuit Diagrams

Maintenance - hydraulic system Pos : 42.37.19 /BA/Wartung/Sc hwader/H ydraulik/H ydraulikschaltplan SW 1000 @ 2\mod_1203341843230_78.doc x @ 65855 @ 2 @ 1 12.5 Hydraulic System Circuit Diagrams Figure 54 1 Width adjustment left 2 Width adjustment right 3 Lifting cylinder left 4... -

Page 91: Maintenance - Lubrication Chart

Maintenance – lubrication chart Pos : 42.39.1 /Ü berschriften/Ü berschriften 1/U-Z/Wartung - Sc hmierpl an @ 0\mod_1197359304198_78.doc x @ 18232 @ 1 @ 1 Maintenance – lubrication chart Pos : 42.39.2 /Ü berschriften/Ü berschriften 2/P-T/Speziell e Sicherheits hinweis e @ 0\mod_1196660495760_78.doc x @ 9134 @ 2 @ 1 13.1 Special Safety Instructions Pos : 42.39.3 /BA/Sic herheit/Gefahrenhinweise/Ladewagen/Gefahr War tung allgemein @ 0\mod_1199884069862_78.doc x @ 36704 @ @ 1... -

Page 92: Lubrication Chart

Maintenance – lubrication chart Pos : 42.39.7 /Ü berschriften/Ü berschriften 2/P-T/Schmi erpl an @ 0\mod_1197361829026_78.doc x @ 18495 @ 2 @ 1 13.3 Lubrication Chart Pos : 42.39.8 /BA/Wartung/Hinweis aus Gr ünden der Ü bersic ht @ 2\mod_1202799283498_78.doc x @ 61453 @ @ 1 Note To make the illustration easier to read, the greasing points have only been shown on one side of the machine. - Page 93 Maintenance – lubrication chart Pos : 42.39.10 /BA/Wartung/Sc hwader/Sc hmier plan/Sc hmier plan Swadro 1000 @ 137\mod_1353578784793_78.doc x @ 1220255 @ @ 1 Fig. 56 Pos : 42.40 /BA/---------------Seitenumbr uc h---------------- @ 0\mod_1196175311226_0.doc x @ 4165 @ @ 1...

-

Page 94: Maintenance - Gearbox

Maintenance - Gearbox Pos : 42.41 /Ü bersc hriften/Ü berschriften 1/U-Z/Wartung - Getriebe @ 2\mod_1203058202823_78.doc x @ 64495 @ 1 @ 1 Maintenance - Gearbox Pos : 42.42 /Ü bersc hriften/Ü berschriften 2/F-J /Füll mengen und Sc hmier mittel bezeic hnungen der Getriebe @ 0\mod_1196951094046_78.doc x @ 15335 @ 2 @ 1 14.1 Filling Quantities and Lubrication Designations for Gearboxes Pos : 42.43 /BA/War tung/Tabellen_F üll mengen/Sc hwader /Tec hnisc he Daten Betriebsstoffe F üll mengen Sc hwader 1000 @ 2\mod_1202985310202_78.doc x @ 63942 @ @ 1... -

Page 95: Main Gearbox

Maintenance - Gearbox Pos : 42.44.3.1 /Ü berschriften/Ü berschriften 2/F-J/H auptgetri ebe @ 0\mod_1197005740033_78.doc x @ 15416 @ 2 @ 1 14.3 Main gearbox Pos : 42.44.3.2 /BA/Wartung/Öl kontrolle_Wechsel/Sc hwader/Hauptgetriebe/H auptgetriebe Bild SW 1000 @ 2\mod_1202991162608_78.doc x @ 64065 @ @ 1 SW1000017 Figure. -

Page 96: Transfer Gearbox

Maintenance - Gearbox Pos : 42.44.5.1 /Ü berschriften/Ü berschriften 2/U-Z/Ver teil ergetriebe @ 2\mod_1202991526780_78.doc x @ 64104 @ 2 @ 1 14.4 Transfer gearbox Pos : 42.44.5.2 /BA/Wartung/Öl kontrolle_Wechsel/Sc hwader/Verteilergetri ebe/Verteilerg etriebe Bil d SW 1000 @ 2\mod_1202992935108_78.doc x @ 64182 @ @ 1 SW1000019 Figure. -

Page 97: Special Equipment

Special equipment Pos : 44.1 /Übersc hriften/Übersc hriften 1/P-T/Sonder ausstattung @ 2\mod_1202808469779_78.doc x @ 61649 @ 1 @ 1 Special equipment Pos : 44.2 /BA/Sicher heit/Gefahr enhi nweis e/Eins tell arbeiten / Eins tell ungenGefahr - Eins tellar beiten g ezog ene M asc hinen @ 0\mod_1199717011038_78.doc x @ 33980 @ @ 1 Danger! - Unexpected movements of the machine Effect: Danger to life or serious injuries. -

Page 98: Chain For Height Restriction Of Suspension Arms

Special equipment Pos : 44.5 /BA/Sonder ausstatung/Sc hwader/Kette zur Ti efenbegrenzung der U nterlenker @ 2\mod_1202808127295_78.doc x @ 61611 @ 2 @ 1 15.2 Chain for height restriction of suspension arms Figure 61 • Secure chains (1) with a spring-type slotted straight pin (3) and a washer (2) at the suspension arm seats. -

Page 99: Placing In Storage

Placing in Storage Pos : 46.1 /Übersc hriften/Übersc hriften 1/A-E/Ei nlag erung @ 0\mod_1197385459120_78.doc x @ 19966 @ 1 @ 1 Placing in Storage Pos : 46.2 /Übersc hriften/Übersc hriften 2/P-T/Spezi elle Sic her heitshi nweis e @ 0\mod_1196660495760_78.doc x @ 9134 @ 2 @ 1 16.1 Special Safety Instructions Pos : 46.3 /BA/Sicher heit/Gefahr enhi nweis e/Ladewag en/Gefahr Wartung allgemei n @ 0\mod_1199884069862_78.doc x @ 36704 @ @ 1... -

Page 100: At The End Of The Harvest Season

Perform the necessary repair tasks during the time immediately after the harvest season. Draw up a list of all replacement parts you will need. This will make it easier for your KRONE dealer to process your orders and you will be certain that your machine will be ready for use at the beginning of the next season. -

Page 101: Before The Start Of The New Season

Placing in Storage Pos : 46.8 /Übersc hriften/Übersc hriften 2/U-Z/Vor Beginn der neuen Sais on @ 0\mod_1197386024448_78.doc x @ 20081 @ 2 @ 1 16.3 Before the Start of the New Season Pos : 46.9 /Übersc hriften/Übersc hriften 2/P-T/Spezi elle Sic her heitshi nweis e @ 0\mod_1196660495760_78.doc x @ 9134 @ 2 @ 1 16.4 Special Safety Instructions Pos : 46.10 /BA/Sic herheit/Gefahrenhinweise/Ladewagen/Gefahr War tung allgemein @ 0\mod_1199884069862_78.doc x @ 36704 @ @ 1... -

Page 102: Malfunctions - Causes And Remedies

Malfunctions - Causes and Remedies Pos : 48.1 /Übersc hriften/Übersc hriften 1/P-T/Störungen - Urs ac hen und Behebung @ 0\mod_1200296925180_78.doc x @ 39459 @ 1 @ 1 Malfunctions - Causes and Remedies Pos : 48.2 /Übersc hriften/Übersc hriften 2/P-T/Spezi elle Sic her heitshi nweis e @ 0\mod_1196660495760_78.doc x @ 9134 @ 2 @ 1 17.1 Special Safety Instructions Pos : 48.3 /BA/Sicher heit/Gefahr enhi nweis e/Ladewag en/Gefahr Wartung allgemei n @ 0\mod_1199884069862_78.doc x @ 36704 @ @ 1... - Page 103 Malfunctions - Causes and Remedies Pos : 48.5 /BA/Störungen - Urs ac hen und Behebung/Sc hwader/T abellarisc he Auflis tung Schwader 1000 @ 2\mod_1202993666593_78.doc x @ 64241 @ @ 1 Malfunction Possible cause Remedy Rotor does not operate smoothly Raking height set too high Set raking height lower Working speed is too high.

-

Page 104: Appendix

Appendix Pos : 50 /Ü bersc hriften/Übersc hriften 1/A-E/Anhang @ 1\mod_1202278612285_78.doc x @ 58360 @ 1 @ 1 Appendix Pos : 51 /BA/Anhang/Sc hwader/Im Anhang finden Sie den Schaltplan @ 2\mod_1202811415263_78.doc x @ 61821 @ @ 1 The circuit diagram can be found in the Appendix. === Ende der Liste für T extmar ke Inhalt ===... - Page 108 index index Adjustable throttles ..........69 Identification Plate..........7 Adjusting the hydraulic system ......86 Identifying Symbols in the Operating Instructions ................16 Adjusting the Lifting Height .........26 Inadmissible Modes of Operation ...... 23 Adjusting the Sensors.........83 Information Required for Questions and Orders.. 8 Adjusting the Swath Width........39 Install the PTO shaft ..........

- Page 109 Removing the tine protections from the tine tips 55 Swivel tine arms to working position....56 Re-Ordering the Adhesive Safety and Information Swivelling tine arms into transport position..61 Labels ..............13 Replacing Tines ..........80 Technical data............9 Rotor gearbox / rotor housing ......94 Test run..............

- Page 110 . . konsequent, kompetent Maschinenfabrik Bernard Krone GmbH Heinrich-Krone-Straße 10, D-48480 Spelle Postfach 11 63, D-48478 Spelle Phone +49 (0) 59 77/935-0 +49 (0) 59 77/935-339 Internet: http://www.krone.de eMail: info.ldm@krone.de...

Need help?

Do you have a question about the Swadro 1000 and is the answer not in the manual?

Questions and answers