Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Kobold MIS

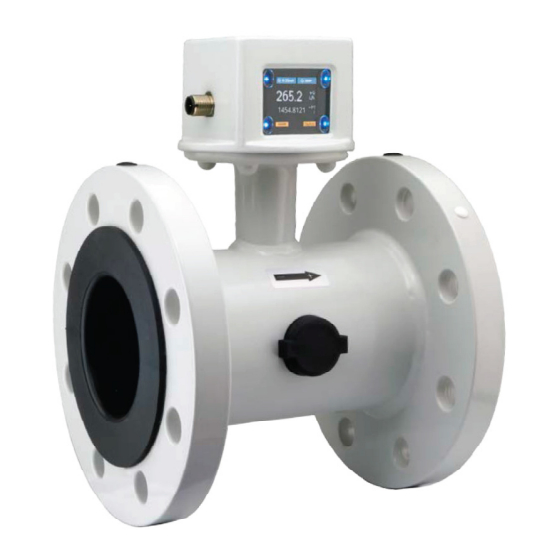

- Page 1 Operating Instructions Electromagnetic Flowmeter Model: MIS...

- Page 2 The document may contain technical inaccuracies and typographical errors. The content will be revised on a regular basis. These changes will be implemented in later versions. The described products can be improved and changed at any time without prior notice. © Copyright All rights reserved. page 2 MIS K01/0719...

-

Page 3: Table Of Contents

Dimensions ....................56 Annex ......................57 17.1 IO-Link process data structure ............57 17.2 IO-Link diagnostic information ............58 17.3 IO-Link device-specific system commands ........59 MIS K01/0719 page 3... - Page 4 IO-Link ISDU Parameter table ............60 Manufacturer’s Declaration ................. 71 EU Declaration of Conformance ..............72 Manufactured and sold by: Kobold Messring GmbH Nordring 22-24 D-65719 Hofheim Tel.: +49(0)6192-2990 Fax: +49(0)6192-23398 E-Mail: info.de@kobold.com Internet: www.kobold.com page 4 MIS K01/0719...

-

Page 5: Note

In acc. with Article 4 Paragraph (3), "Sound Engineering Practice", of the PED 2014/68/EU no CE mark. Overview of the device functionality Depending on the installed device firmware, the MIS device may have different functionalities. The functional extensions are shown in the following table. -

Page 6: Instrument Inspection

The user assumes all risk for such usage. 5. Environment The MIS device with stainless steel housing and stainless steel electrodes is weatherproof and conforms to protection class IP67. The meter is designed for harsh indoor or outdoor environments and complies with Directive 2014/30/EU (Electromagnetic Compatibility). -

Page 7: Operating Principle

For the correct function of the instrument, it is necessary that the flow channel is always completely filled with medium. From a minimum electrical conductivity of 20 μS / cm, the MIS operates within the specified error limits. The conductivity of the medium is constantly monitored by the device electronics. If the electronics detects that the minimum conductivity has fallen below min. -

Page 8: Mechanical Connection

Without the discs, the liner creeps back to its original shape and installation is more difficult to do. The sensor should be left for at most a few hours without the discs. Remove the discs immediately before installation. page 8 MIS K01/0719... -

Page 9: Installation Requirements

If the flow tube is lined with PTFE, the flowmeter must be installed with special care. The tube lining is bordered at the flanges (seal). This must not be damaged or removed as it prevents the fluid from penetrating between the flange and flow tube destroying the electrode insulation. MIS K01/0719 page 9... -

Page 10: Installation

DIN EN 1514-1. Mounted gaskets must not reach into the pipe cross-section. Caution! Do not use conductive sealing compounds such as graphite. This could result in a conductive layer building up on the inside of the flow tube, short-circuiting the measuring signal. page 10 MIS K01/0719... - Page 11 The installed position of the flowmeter is arbitrary, however the intended x-y electrode axis should run approximately horizontal. A vertical Electrode axis should be avoided, since gas pockets or solid particles carried along in the fluid could affect the accuracy of the device. MIS K01/0719 page 11...

- Page 12 Caution! There is the danger of accumulation of solids in the siphon. The installation of a cleaning aperture in the pipe is therefore advisable. page 12 MIS K01/0719...

- Page 13 However, when installed in vertical piping, especially when using sensors with PTFE-lining and high operating temperatures, the regulating and shut-off devices should be placed in front of the sensor (danger of vacuum). MIS K01/0719 page 13...

- Page 14 These establish the necessary conductive connection to the fluid and are made of a chemical-resistant material. The material used should be identical to that of the measuring electrodes page 14 MIS K01/0719...

- Page 15 The grounding cables are not included in the scope of your delivery and must be provided by the plant operator. The grounding rings can be ordered as accessories. 7.3.6.1 Examples of earthing the MIS 7.3.6.1.1 Metal piping electrically conductive Ground wire min. 4 mm...

- Page 16 The shield must be connected to the sensor end via a 1.5 μF capacitor. The shield must never be connected to both ends. For isolated installation: If the above connections are unacceptable, isolate the sensor from the piping. page 16 MIS K01/0719...

- Page 17 2) Sealing material of maximum 75 Shore A hardness will be used between the flow meter and the associated flanges 3) All bolts are galvanized and greased accordingly 4) The values are calculated for use with carbon steel flanges Flow meter and associated flanges are properly aligned MIS K01/0719 page 17...

-

Page 18: Electrical Connection

We recommend the use of wires with cross sectional area of min. 0.25 mm². Attention! The measuring electrodes are galvanically connected with the reference potential of the supply voltage and the signal output. 8.2 Pin assignment page 18 MIS K01/0719... -

Page 19: Connection Example Outputs

2-10 V analogue output 0-10 V analogue output 0-10 V alarm output alarm output pulse output pulse output frequency output frequency output communication mode KofiCom communication mode IO Link control input control input dosing function dosing output MIS K01/0719 page 19... -

Page 20: Operation And Menu Structure

TFT display. function key symbol designation Measuring mode menu mode Activate menu menu mode mode hold 3-5 sec. opens the info info display menu Scroll down menu / decrease numeric down value when entering numeric value page 20 MIS K01/0719... -

Page 21: Measuring Mode

If the background color is green, the set threshold value is exceeded; if it is red, the current value is still under threshold. MIS K01/0719 page 21... - Page 22 The measured variables flow and volume counter can in principle be assigned to each output function. The assignment of the respective output is indicated by the display of the symbol of the measuring variable. The representation of the assignment is independent of the set display layout (single, dual). page 22 MIS K01/0719...

- Page 23 8 minus characters (--------). In this case, the meter reading can no longer be read. The user now has the option of bringing the counter reading back into the display area by changing the volume counter unit. MIS K01/0719 page 23...

-

Page 24: Menu Mode

This transition happens automatically Step 4 Step 2 Step 3 Parameter selection 1 Parameter selection 2 Apply selection Menu and save The orientation can be Step 1 Menu button selected with up and press for 3-5 seconds down buttons page 24 MIS K01/0719... - Page 25 , the editing point can be moved to the left again. If the editing point is on the far right, the set value is saved by pressing the key again and switched to the higher-level menu function. MIS K01/0719 page 25...

-

Page 26: Device Configuration

The flowmeter MIS is pre-configured in factory. Changing the parameters "Measuring range" and "Sensor constant" or "K factor" is therefore not permitted. The adjustment of these parameters is only possible on the part of Kobold- factory. In the event of subsequent changes to volume or throughput units, the dependent parameters are converted and adjusted accordingly. -

Page 27: Display

MIN/MAX / Reset Value display / Reset flow Yes / Yes Yes / No Temperature Yes / Yes Yes / No Partial quantity Not available Yes / Yes counter Totalizer Not available Yes / No MIS K01/0719 page 27... - Page 28 The menu timeout time defines the time after which the menu function is automatically exited without pressing a key. In the setting "0 s" this function is deactivated and the menu function can only be left by hand by pressing the back key several times. page 28 MIS K01/0719...

-

Page 29: Measurement

For magnetic inductive flowmeter, these are: • Flow • Volume (total volume counter) • Part volume Each measurement variable is still divided into its own submenu. In the submenu, all parameters relating to the respective measuring variables can be adjusted. MIS K01/0719 page 29... - Page 30 Depending on the flow direction, the calculated partial volume is added or subtracted to the counters. If the measured flow value is negative, the volume value goes down from measurement to measurement (possibly into the negative range). page 30 MIS K01/0719...

- Page 31 Each simulation started is automatically stopped after the time set in the "Sim Auto Stop Time" (user service) parameter (1 to 30 min) or after the programmed intervals have expired. The following measured values can be simulated: Volume flow, temperature and part quantity counter MIS K01/0719 page 31...

- Page 32 "increment value" after the start. When simulating the subset counter, note that in triangle mode, the submenu counter must be in bidirectional mode to achieve the expected effect. page 32 MIS K01/0719...

-

Page 33: Dosing Function

12 10.6 Outputs The MIS flowmeter provides a total of 2 outputs that are freely configurable. The configuration of the outputs (output 1 and output 2) is done via a wizard function. The wizard function guides the user step by step through all necessary settings. - Page 34 "lower threshold". The monitored window decreases in each case by the amount of the "hysteresis". If the switching output is to be active within the window, the parameter "switching function" must be changed from N/O to N/C. page 34 MIS K01/0719...

- Page 35 The hysteresis value should therefore always be greater than the real measured value fluctuations. As a result, a targeted suppression can be achieved. MIS K01/0719 page 35...

- Page 36 With this function sporadic limit value overruns can be safely suppressed. According to the value of the parameter "filter factor", the response time of the output generally increases. Examples of the effect of the switching delay for window and limit function page 36 MIS K01/0719...

- Page 37 Note 1: If the value is set smaller than the end of the measuring range, the resolution and accuracy of the output voltage value are reduced. Output behavior 4-20 mA and 2-10 V MIS K01/0719 page 37...

- Page 38 10.6.3 Pulse output MIS flowmeter provides a scalable pulse output. When the pulse output is activated, the cyclically incoming volume is available as a pulse train at the output. The pulse width of the pulse output is constant and can be set in a range of 1 ms up to 20 s.

- Page 39 22500 ∗ Pulse volume L If the condition is not met, there may be a time lag of the pulse output. This is particularly undesirable if dosing tasks are to be performed with the pulse signal. MIS K01/0719 page 39...

- Page 40 = 1/10 L = 0.1 L 10.6.3.2 Volume unit The volume unit to be set is the input unit for the "Pulse volume" parameter. The definition of a user-defined unit ("user") is also possible and can be programmed in "liters". page 40 MIS K01/0719...

- Page 41 10.6.4 Frequency output The MIS flowmeter provides a scalable frequency output. When this output is activated, the measurement variable (flow) associated with the frequency output is output proportionally as a frequency with a 1: 1 pulse / pause duration. The output frequency at the end of the measuring range can be set (parameter "maximum frequency").

- Page 42 0-10 V Measured value for 0 V MB start ≤ value ≤ Value 0 V output value 10 V Measured value for 10 V Value for 0 V ≤ Value 10 V output value ≤ Full scale page 42 MIS K01/0719...

- Page 43 Pulse output for the pulse 0.001-999 volume volume value input Sets the pulse Pulse width 1-20.000 1 ms width KofiCom Factory calibration mode on output 1 IO-Link This mode activates the IO-Link function on output 1 MIS K01/0719 page 43...

-

Page 44: User Service

10.7.2 User service / factory setting By activating this function, the user can reset the device to the factory settings. Any user settings will then be lost and the device will be back in delivery condition. page 44 MIS K01/0719... -

Page 45: Service / Factory Service

English language downloaded directly as a PDF and opened. The smartphone must have a QR code scanning app and a PDF reader app installed, as well as an internet connection. MIS K01/0719 page 45... -

Page 46: Device Default Settings

Info Manual Displays the QR code to download the instruction manual 10.10 Device default settings The flowmeter-MIS is delivered from the factory with following settings: Display – Dual Upper display – Flow Lower display – Partial quantity counter Out 1: IO-Link... -

Page 47: Status

(> 20 μs / cm) Flow measuring circuit Meas saturated Reduce flow rate overdriven Repair by KOBOLD Service No Subslave Internal hardware error necessary Simulation Simulation function active MIS K01/0719... -

Page 48: Dosing Function

12. Dosing function The standard MIS provides a simple dosing function. This can be permanently activated or deactivated in the settings menu under the menu item "dosing". If the dosing function is activated, fixed functions are assigned to the 2 outputs which... - Page 49 RESETTING the dosing value If the dosing process is finished or stopped, the dosing quantity can be reset to the default value by the function RESET. This function can also be triggered at the control input. MIS K01/0719 page 49...

- Page 50 During the dosing process, the presence of a flow value not equal to 0 is constantly monitored. For this purpose, the parameter "Timeout" is used to set the time after which the status message "Time Out" is triggered. The timeout value can be set between 0.5 sec and 10 sec. page 50 MIS K01/0719...

- Page 51 Value input 9999.99 [unit] -999.99 ≤ Activation Correction Value Value ≤ aktivated value input +999.99 [unit] ml, L, m3, List Unit galUS, galUK, galUs selection User Value Time out 0.5 - 10 sec 0.5 sec. input MIS K01/0719 page 51...

-

Page 52: Io-Link Function

13. IO-Link function As of firmware version REV190320, the MIS flowmeter has an IO-Link communication interface as standard. Process and diagnostic data can be accessed directly via this interface and the device can be parameterized. Output 1 is factory configured for IO-Link function. If the IO-Link communication mode is active, the "IOLINK"... -

Page 53: Technical Information

@ FS = 1000 Hz Alarm output: NPN, PNP, Push-Pull configurable max. 30 V max. 200 mA short-circuit proof Analogue output: active, 3-Leiter, 0(4)-20 mA, max. load 500 Ω or 0(2)-10 V , (R = 500 Ω) MIS K01/0719 page 53... - Page 54 Analog putput 0-10 V Switching output NPN/PNP/PP Switching output NPN/PNP/PP Pulse output PP Pulse output PP Frequency output PP Frequency output PP Communication mode M12 COM Communication mode IO-Link Control input Control input dosing function Dosing output page 54 MIS K01/0719...

-

Page 55: Order Codes

15. Order Codes Order Details (Example: MIS-H 330B1 HH 100) Model Material Flange type/size Material Measuring and Transmitter process earthing electrodes mounting connection 330B = DN80 PN16 form A DIN EN 1092-1 335B = DN100 PN16 form A ® H = hard rubber... -

Page 56: Dimensions

3“ (DN80) 178.8 4“ (DN100) 183.7 3“ (DN80) 177.3 152.4 ASME 4“ (DN100) 185.2 190.5 Weight Nominal size Pressure rating NBR lining [mm] [inch] Weight [kg] PN16 / Cl. 150 PN16 / Cl. 150 15.6 page 56 MIS K01/0719... -

Page 57: Annex

0 ‐ 2 Flow 24 Bit IntegerT 1/1000 +/‐8388,608 L/min ‐45 3 ‐ 6 Volume 32 Bit FloatT +/‐1,4*10 ... +/‐3,4*10 L 7 ‐ 8 reserved 14 Bit BooleanT Status OUT1 1 Bit BooleanT 0 / 1 Status OUT2 1 Bit BooleanT 0 / 1 MIS K01/0719 page 57... -

Page 58: Io-Link Diagnostic Information

6215 Temperature Sensor Error 4 Error no sensor attached 0x1848 6216 Measuring Circuit Saturated 2 Warning ADC out of range 0x1849 6217 Counter Overflow 2 Error volume or partvolume counter overflowed 0x184A 6218 Dosing Timeout Warning indicates that the no flow timeout of the dosing function is active 0x184B 6219 Simulation Active Warning indicates that one of the simulations is running page 58 MIS K01/0719... -

Page 59: Io-Link Device-Specific System Commands

17.3 IO-Link device-specific system commands Command (hex) Command (hex) Command name 0x82 130 Restore factory settings 0xA0 160 Reset part volume counter 0xA1 161 Start flow simulation 0xA2 162 Stop flow simulation 0xA5 165 Start part volume simulation 0xA6 166 Stop part volume simulation 0xA7 167 Events Handling ON 0xA8 168 Events Handling OFF 0xA9 169 Reset MinMax for Flow MIS K01/0719 page 59... -

Page 60: Io-Link Isdu Parameter Table

StringT parameter 0x0016 Hardware max. 8 StringT Revision 0x0017 Firmware Firmware Revision max. 8 StringT Revision is constant in FW 0x0018 Application tag name is from 32 StringT DeviceTag user configurable 0x0019 FunctionTag function tag is 32 StringT from user configurable 0x0020 LocationTag location tag is 32 StringT from user configurable page 60 MIS K01/0719... - Page 61 (1) ‐ Value (2) ‐ MinMax 0x010C LeftHotkey Source for the left (0) ‐ Flow 1 UIntegerT Source hotkey (1) ‐ Volume (3) ‐ Part Volume 0x010D RightHotkey Source for the (0) ‐ Flow 1 UIntegerT Source right hotkey (1) ‐ Volume (3) ‐ Part Volume 0x010E Sensitivity Sensitivity for the (0) ‐ low 1 UIntegerT OpticalKeys optical keys (1) ‐ middle (2) ‐ high MIS K01/0719 page 61...

- Page 62 FloatT Threshold alarmoutput 0x0119 OUT1Alarm Threshold for the OUT1AlarmT 4 FloatT Lower alarmoutput used hreshold Threshold by the windowfunction 0x011D OUT1Alarm Switching 9999,0 ‐9999,0 4 FloatT Hysteresis hysteresis for the alarmoutput 0x0121 OUT1Alarm How many times 1 UIntegerT Suppression the threshold must Factor be hit in order to switch the alarm output page 62 MIS K01/0719...

- Page 63 4 FloatT Value0V slot used for the Value10V 0V scaling point 0x0134 OUT1Analog The value from the OUT1Analog 4 FloatT Value2V slot used for the Value10V 2V scaling point 0x0138 OUT1Analog The value from the 100,0 OUT1Analog 4 FloatT Value10V slot used for the Value0V 10V scaling point 0x013C OUT1Pulse The volume 999,9 4 FloatT Volume represented by one pulse MIS K01/0719 page 63...

- Page 64 (0) ‐ disabled 1 UIntegerT the output ‐> (1) ‐ Alarm Output 0‐20mA, Pulse, (2) ‐ 4‐20mA Frequency, etc. (3) ‐ 0‐20mA (4) ‐ 2‐10V (5) ‐ 0‐10V (6) ‐ Pulse Output (7) ‐ Frequency Output 0x0165 OUT2Alarm Limit or window (0) ‐ Limit 1 UIntegerT Function function for the (1) ‐ Window alarm output 0x0166 OUT2Alarm Alarmoutput NPN, (0) ‐ NPN 1 UIntegerT OutputType PNP or Pushpull (1) ‐ PNP (2) ‐ PushPull page 64 MIS K01/0719...

- Page 65 (0) the analogoutput stays in his equivalent range (e.g. 4‐ 20mA) 0x0177 OUT2Analog The value from the OUT2Analog 4 FloatT Value0mA slot used for the Value20mA 0mA scaling point 0x017B OUT2Analog The value from the OUT2Analog 4 FloatT Value4mA slot used for the Value20mA 4mA scaling point 0x017F OUT2Analog The value from the 100,0 OUT2Analog 4 FloatT Value20mA slot used for the Value0mA 20mA scaling point MIS K01/0719 page 65...

- Page 66 0x019C OUT2 The overflow 1 UIntegerT FrequencyOverfl frequency in ow percent of the max frequency 0x019D OUT2 The value from the OUT2 4 FloatT FrequencyValue0 slot used for the Frequency Hz 0Hz scaling point ValueMaxHz 0x01A1 OUT2 The value from the 100,0 OUT2 4 FloatT Frequency slot used for the Frequency ValueMaxHz max Hz scaling Value0Hz point page 66 MIS K01/0719...

- Page 67 1 UIntegerT MenuLocked menu is locked or (1) ‐ locked not 0x01D0 SimulationAutoS Auto stop for 1 UIntegerT top Simulation after time in minute Misc 0x01D2 Language Language selection 0 (0) ‐ English 1 UIntegerT Selection (1) ‐ German (2) ‐ French (3) ‐ Spanish 0x0262 Operating Operating hours 4294967296 4 UIntegerT HoursCount counter MIS K01/0719 page 67...

- Page 68 0x031F SimTimingInterv Timinig in ms 50000 2 UIntegerT als between intervals 0x0321 ValueInSiUnit Saved flow value 999999,0 ‐999999,0 4 FloatT in SI unit [L/min] 0x0325 MinValueInSi Saved min flow 999999,0 ‐999999,0 4 FloatT Unit value in SI unit [L/min] 0x0329 MaxValueInSi Saved max flow 999999,0 ‐999999,0 4 FloatT Unit value in SI unit [L/min] page 68 MIS K01/0719...

- Page 69 (0) ‐ Static 1 UIntegerT Simulation: (1) ‐ Triangle Static,Triangle or (2) ‐ Monotonic Monotonic 0x0441 SimStartValue Value to start with 9999,0 ‐9999,0 4 FloatT the simulation 0x0445 SimIncrement Incrementation 10,0 999,0 ‐999,0 4 FloatT Value value of the simulation 0x0449 SimNumber Number of 65000 2 UIntegerT Intervals intervals to simulation MIS K01/0719 page 69...

- Page 70 Index Name Description Factory Max Value Min Value Length Data Type Access [hex] default [Bytes] 0x044B SimTiming Timinig [ms] 50000 2 UIntegerT between intervals Intervals 0x044D ValueInSiUnit Saved part volume 999999,0 ‐999999,0 4 FloatT value in SI unit [L] Legend MRE Measuring Range End MRS Measuring Range Start page 70 MIS K01/0719...

-

Page 71: Manufacturer's Declaration

18. Manufacturer’s Declaration MANUFACTURER'S DECLARATION OF CONFORMITY Kobold Messring GmbH Nordring 22-24 65719 Hofheim Germany declare under our own responsibility that the product(s): MIS-1********** (IO-Link Device) to which this declaration refers conform to: IO-Link Interface and System Specification, V1.1, July 2013 (NOTE 1,2) ... -

Page 72: Eu Declaration Of Conformance

19. EU Declaration of Conformance We, KOBOLD Messring GmbH, Hofheim-Ts, Germany, declare under our sole responsibility that the product: Electromagnetic flowmeter Model: MIS-... to which this declaration relates is in conformity with the standards noted below: EN 61326-1:2013 Electrical equipment...

Need help?

Do you have a question about the MIS and is the answer not in the manual?

Questions and answers