Summary of Contents for Sensopart FA 46 Series

- Page 1 Montage- und Bedienungsanleitung Mounting and operating instructions Instructions de service et de montage FA 46 301-OB 305-OB Vision-Sensor 301-CR Vision Sensor 305-CR Capteur de Vision 305-SO...

- Page 2 écrite de SensoPart Industriesensorik GmbH. Nous déclinons toute responsabilité concernant les fautes éventuelles d’impression et autres erreurs qui auraient pu intervenir lors du montage de cette brochure.

-

Page 3: Table Of Contents

Contents Contents ..................................48 General Information and Safety ........................50 1.1 Symbols ..............................50 1.2 Safety notes ...............................50 1.3 Components supplied ..........................51 1.4 Requirements for use ..........................51 Intended Use ..............................52 2.1 Field of application .............................52 2.2 Characteristics FA 46 301/305 Object detection ..................53 2.2.1 Sensor types .............................53 2.3 Characteristics FA 46 301/305 Codereader ....................54 2.3.1 Sensor types .............................54... - Page 4 Interfaces ................................81 8.1 Interfaces available ............................81 8.2 Functions of the programmable, digital input IN2..................81 8.3 Description of different cases with a signal diagram ..................81 8.3.1 IN2: „inactive“ ............................81 8.3.2 IN2: „enable trigger“ (IN2 = +U (24 V DC)) ..................82 8.3.3 IN2: „disable trigger“...

-

Page 5: General Information And Safety

Mounting and operating instructions General Information and Safety Symbols Important This symbol indicates sections of the text which must be strictly observed. Non-compliance with such instructions may cause injury or damage. Note This symbol indicates sections of the text which contain useful information. Note FA 46 Value-305 / FA 46 Value-301 This symbol marks text which explains the specific differences of the sensor FA 46-305 compared with the sensor FA 46-301. -

Page 6: Components Supplied

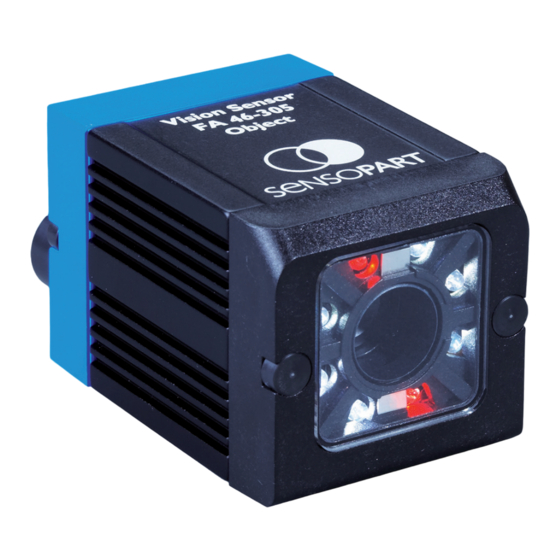

Mounting and operating instructions Components supplied • FA 46 Vision Sensor including integrated illumination (or as version with C-Mount lens without illumination) • CD-ROM with Computer software and Operating instructions • Operating instructions, mounting clamp, Allen key, screwdriver, 2 protective caps for M12 plug. Requirements for use Configuration of the FA 46 Vision Sensor requires a standard PC/Notebook (at least Pentium 4, 1GHz and 512 MB RAM, with Microsoft Windows 2000-SP4, XP SP2, Vista or Windows 7) with network connection or a network with... -

Page 7: Intended Use

Identification of products, components or packaging from printed or directly marked – punched or laser-etched – codes is common practice in many sectors of industry today. The Vision code reader from SensoPart immediately detects which part is in front of it: it can easily read numerous types of barcodes as well as printed and directly marked data matrix codes according to ECC 200 standard, and this on any base (metal, plastic, paper,glass). -

Page 8: Characteristics Fa 46 301/305 Object Detection

Mounting and operating instructions Characteristics FA 46 301/305 Object detection Number of Jobs Position tracking Number of detectors Type of detectors Pattern matching (X-, Y- Translation) Contour matching (X-, Y translation and rotational position) Grey threshold Contrast 4 Signal outputs 0-24 V DC PNP, 2 inputs Ethernet interface / data transmission Setup only RS 422 interface for data transmission... -

Page 9: Characteristics Fa 46 301/305 Codereader

Mounting and operating instructions Characteristics FA 46 301/305 Codereader Number of Jobs Position tracking Number of detectors Type of detectors Pattern matching (X-, Y- Translation) Datacode Barcode Grey threshold Contrastt 4 Signal outputs 0-24 V DC PNP, 2 inputs Ethernet interface / data transmission RS 422 interface for data transmission EtherNet/IP Logic... -

Page 10: Characteristics Fa 46 Solar

Mounting and operating instructions Characteristics FA 46 Solar Number of Jobs Position tracking Number of detectors Type of detectors Wafer detection 4 Signal outputs 0-24 V DC PNP, 2 inputs Ethernet interface / data transmission RS 422 interface for data transmission EtherNet/IP Logic Multilevel... -

Page 11: Installation Instructions

Mounting and operating instructions Installation Instructions Mechanical Installation To ensure maximum accuracy of detection, the FA 46 Vision Sensor should be protected from vibration. Secure the connection cables with cable binders to prevent crushing or slipping. Select a position for the FA 46 Vision Sensor in which interfering factors such as slight differences in the position of the object or variations in illumination have little or no effect. -

Page 12: Electrical Installation

Mounting and operating instructions Electrical installation The electrical installation of the FA 46 Vision Sensor must be carried out by a qualified electrician. When installing the FA 46 Vision Sensor , disconnect all electrical components from the power supply. When the unit is being used in a network, ensure that the network address (IP address) of the FA 46 Vision Sensor set by the manufacturer at 192.168.100.100/24 with Subnetmask 255.255.255.0 is free and is not in use for any other unit connected to the system. -

Page 13: 3.2.1.2 Focussing Screw

Mounting and operating instructions 3.2.1.2 Focussing screw Focussing screw to adjust focus. 3.2.1.3 24 V DC Connection M12 Connection socket for 24 V DC voltage supply and digital I/O. The exact plug connection see table2, chapter 8.5. 3.2.1.4 LAN Connection M12 Connection socket for Ethernet connection. -

Page 14: Network Settings

Mounting and operating instructions Network settings The following instructions indicate how to change the network configuration of the PC and the FA 46 Vision Sensor. If incorrect settings are used, the network connections in the computer may be lost. To be on the safe side, note the former settings for later use if required. Following this procedure, it may be necessary to re-start the system. - Page 15 - Double click on sensor in the list Sensor version is displayed in the SensoFind (e.g. 1.0.0.0). - PC / application- software starts Compatibility table and suitable software under www.sensopart.de Now the parameter setting of the sensor / application can be done Fig.

-

Page 16: 3.3.1.2. Network Connection - Setting The Ip Address Of The Fa 46 Vision Sensor

Mounting and operating instructions 3.3.1.2. Network Connection - Setting the IP address of the FA 46 Vision Sensor Before connecting the sensor in the network, check with the network administrator whether the sensor’s address has already been assigned (default: 192.168.100.100 with subnet mask 255.255.255.0). - Page 17 Check Sensor- and Softwareversion - Double click on sensor in list Sensor version is displayed in SensoFind (e.g. 1.0.0.0). Compatibility - PC software starts table and suitable software under www.sensopart.com Parameter settings can now be carried out on the sensor Fig. 11...

-

Page 18: Commissioning / Short Guide

System control Software FA 46 Vision Sensor Remove Start Progamme SensoPart FA 46 Vision Sensor Remove FA 46 SensoFind 3. In the start menu, the programme group “SensoPart / FA 46 Vision Sensor“ is created with the entry „FA 46 SensoFind“. -

Page 19: Sensofind

Mounting and operating instructions SensoFind In this programme, you can select a sensor or a sensor simulation for configuration or display (monitoring) and carry out different basic settings. Fig. 13 155-01202 A) Active sensors This list displays all the FA 46 Vision Sensors which can be controlled from the PC. B) Sensors for simulation mode All the sensors available for offline simulation are displayed here. -

Page 20: Configuring Or Displaying Sensors

Mounting and operating instructions 4.2.1 Configuring or displaying sensors In order to open a sensor for configuration or display, mark the required sensor in the list “Active sensors“, then click on the button “Configure“ to start the “SensoConfig“ module, or on the button “Display“ for the “SensoView“ module. 4.2.2 Sensor simulation To open a sensor for offline simulation, mark the required sensor in the “Sensors for simulation mode“... -

Page 21: Sensoconfig

Mounting and operating instructions SensoConfig With this programme, you can configure your FA 46 Vision Sensor for one or several inspection tasks (jobs) in six logical operating steps. Activate the “Configure” button in the SensoFind module to start SensoConfig. Fig. 16 155-01206 The different operating fields are: A) Menu and tool bar... -

Page 22: Job

Mounting and operating instructions 4.3.1 One job contains all the settings and parameters necessary for carrying out a specific inspection task. Jobs can be created here and several jobs can be managed. All global settings, valid for the entire job, e.g. shutter speed, amplification, illumination settings etc. -

Page 23: Position Tracking

Mounting and operating instructions 4.3.2 Position tracking Alignment compensation can be necessary for objects or characteristics whose position varies on the screen. Three different detection methods (alignment detectors) are available for this purpose. Position tracking is optional and is available for use with the methods: pattern matching, edge detection and contour. After selection of the position tracking method, set the operating zones on the parameter to be used for alignment tracking by adjusting the graphic frame to the appropriate position and size on the image. -

Page 24: Detectors

Mounting and operating instructions 4.3.3 Detectors Different detectors can be selected and adjusted here to solve an inspection task. First the required detector is selected in the dialog box shown below. Fig. 19 155-01209 Then the operating and search zones are graphically set on the screen. If teach zones exist, they are taught imme- diately after completion of the settings. -

Page 25: Output

Mounting and operating instructions 4.3.4 Output The output module enables different settings of digital input / output and data output. Fig. 21 155-01211 Setting possibilities in the different tabs: · I/O, Logic Selection of digital signal outputs and definition and assignment of logical connection using the Boolean results of all detectors. -

Page 26: Results

Mounting and operating instructions 4.3.5 Results With this function, inspection is carried out on the PC, using all the settings, for control purposes. During this proce- dure execution times, for example, will not be updated as these values are only informative when implemented on the sensor itself. -

Page 27: Start Sensor

Mounting and operating instructions 4.3.6 Start Sensor When this function is activated, all settings are transferred to the sensor, stored in the flash memory and carried out e.g. in free run or in triggered mode according to the settings made. All information in the detector list, result field or under “Statistics“... -

Page 28: Sensoview

Mounting and operating instructions SensoView This programme is used for monitoring / checking connected sensors and for analysing inspection results. Senso- View is started via the “Display” button in SensoFind. The current image is displayed with the drawings for position tracking and the detectors (if “image transmission = active“... -

Page 29: Delay Times For Use Of Outputs Out1/2/3

Mounting and operating instructions Delay times for use of outputs OUT1/2/3 Case 1) No delay times used Case 2) Trigger delay = time between trigger and start of image recording in ms IN1 (Trigger) IN1 (Trigger) Evaluation time of sensor Evaluation time of sensor OUT4 (Ready/Busy) OUT4 (Ready/Busy) -

Page 30: Communication Via Ethernet Or Rs422

Mounting and operating instructions Communication via Ethernet or RS422 Data formats of commands and data output Transmission protocol Data transmission via RS422 is carried out with the following basic parameters: Baud rate between 9600 and 115200 baud depending on setting Data bits Parity none... -

Page 31: Data Output In Ascii

Mounting and operating instructions Job change-over (ASCII) Request String to Sensor Byte no. ASCII contents Significance Change Job Job number Job change-over (ASCII) Response String from Sensor Byte no. ASCII contents Significance Change Job Pass Fail Triggered Free run Job nummber Additional information Accepted in run mode: Accepted in configuration mode:... -

Page 32: Binary Transmission

Mounting and operating instructions Binary transmission 6.3.1 Commands to sensor in binary Trigger (Binary) Request string to sensor Byte no. Data type Contents Significance Unsigned Int 0x00 Length of telegram 0x00 0x00 0x05 Unsigned Char Trigger command 0x01 Trigger (Binary) Answer string from sensor Byte no. -

Page 33: Data Output In Binary

Mounting and operating instructions 6.3.2 Data output in BINARY Dynamically composed from user settings in the software Main string structure: <START> <OPTIONAL FIELDS> <PAYLOAD> <CHKSUM> <TRAILER> Fig. 30 155-01216 Further information can be found in the online help of the software. Numeric data are transferred in „Big Endian“... -

Page 34: Technical Data

Mounting and operating instructions Technical data Electrical data Operating voltage U 24 V DC ± 10% (absolute maximum 18 - 30 V) Residual ripple < 5 Vss Current consumption (no I/O ≤ 200 mA Inputs IN1 / IN2 high 10 V .. +U (+10%), low 0 ... - Page 35 Mounting and operating instructions Function and characteristic Object detection Number of test objects per sensor FA 46 305: n, n; FA 46 301: 1, n Evaluation modes • position tracking • pattern match with/without position detection • area test grey level •...

-

Page 36: Interfaces

Mounting and operating instructions Interfaces In this tab you select and activate the digital inputs/outputs used and the interfaces for data output. Interfaces available Parameters Functions and setting possibilities Internal I/O Assignment of the function of the programmable input IN2. See below for a detailed description. -

Page 37: In2: „Enable Trigger

Mounting and operating instructions 8.3.2 IN2: „enable trigger“ (IN2 = +U (24 V DC)) IN2 is programmed as enable/disable. For enable, +Ub (24V DC) must be present at IN2 to ensure that the sensor is started by a trigger. Each rising edge and IN1 = Trigger starts the sensor. Fig. -

Page 38: In2: Job 1 Or 2

Mounting and operating instructions 8.3.4 IN2: Job 1 or 2 IN2 programmed as level-dependent switching between job 1 and job 2. Only possible when OUT4 (Ready/Busy) = high. With the first edge on IN2, OUT4 (Ready/Busy) is set to low. OUT4 (Ready/Busy) remains low until switch-over to the new job occurs. -

Page 39: In2: Teach Temp. / Perm

Mounting and operating instructions 8.3.6 IN2: teach temp. / perm. IN2 for re-teaching samples of all detectors and if necessary alignment tracking of the current job. Only possible when OUT4 (Ready/Busy) = high. A rising flank on IN2 initiates teaching, during which a high level must exist at IN2 at least until the next trigger (IN1), so that an image of an inspection part can be recorded in the correct position. -

Page 40: Size Of Field Of View/Operating Distances

Mounting and operating instructions Size of field of view/Operating distances Field vs. Distance @ f=6 70.00 60.00 Field of view X 50.00 Field of view Y 40.00 30.00 20.00 10.00 0.00 Fig. 37 155-01223 Distance [mm] Field vs. Distance @ f=12 35.00 30.00 Field of view X... -

Page 41: Care And Maintenance

For update, you require an MSF file which matches your sensor type and contains the latest software version for the sensor. The MSF file for the respective latest sensor version can be found on http://www.sensopart.com/. If in doubt, contact the SensoPart support team under tel.: +49 (0)7665 94769-750 / support@sensopart.com. Please ensure you have the correct file before beginning the update. -

Page 42: Faqs

Mounting and operating instructions FAQs How can I change the IP address set for the sensor? Follow the steps described under “Network settings” and “Setting the FA 46 Vision Sensor’s IP address” in chapter 3.3. How can I just test connection to the FA 46 Vision Sensor? Go into the start menu of the operating system, open “Execute”... - Page 43 Mounting and operating instructions Description Order type Part no. Ethernet adapter cable, 0.2m, M12, 8 pin, male/M12, 4-pin, male CI L8MGK/L4MGK-S-0,2m-PUR 902-51773 Ethernet connector RJ45, shielded AA-RJ45 902-51694 Ethernet cross-over cable, 1 m, RJ45, shielded CI RJ45S 1m K 902-51695 Interface cable, 3 m, straight connector CI L5FK-3m-G-PUR 902-51696...

-

Page 44: Io-Box Fa 45

Mounting and operating instructions 8.10.1 IO-Box FA 45 Fig. 39 155-01091 The IO-Box converts serial data from the sensor’s RS422 interface to up to 32 discrete signal outputs, whereby an output of individual results is possible without complex PLC programming. Reversely, data can be transferred to the sensor via 8 inputs, for example to switch over the parameter set for a change in product. -

Page 45: Scale Drawings

Mounting and operating instructions 8.11 Scale drawings Vision Sensor FA 46-305-x xxx-xx O... 153-00846 Codereader Vision Sensor C-Mount FA 46-305-x xxx-xx OCS... 153-00847 Codereader Mounting clamp MK 45 Mounting bracket MA 45 153-00480 153-00482 (supplied with sensor) FA 46 Vision Sensor GB - 068-14297 - 10.02.2011-05... - Page 46 Mounting and operating instructions Mounting brackel MA 45 L Mounting block MB 45 153-00600 153-00481 Mounting rod MST 45-x Mounting link MZ 45 153-00545 153-00546 x = 200 MST 45-20 x = 300 MST 45-30 x = 400 MST 45-40 FA 46 Vision Sensor GB - 068-14297 - 10.02.2011-05...

- Page 47 Mounting and operating instructions Mounting plate MP 45 C-Mount protective case LPT 45 CM 6,6 153-00547 153-00588 I ) Illumination LZS 153-00202/153-00203 II ) Illumination LZS FA 46 Vision Sensor GB - 068-14297 - 10.02.2011-05...

-

Page 48: Type Key Fa 46 Vision Sensor

Mounting and operating instructions Example of a retaining device (for individual parts see chapter 8.10) 153-00435 Mounting hinge (MG 45) Mounting block rod (MB 45) Mounting angle (MA 45) Mounting clamp dovetail (MK 45) Mounting rod (MST- 45-x) Mounting plate (MP 45) Mounting rod (MST- 45-x) 8.12 Type key FA 46 Vision Sensor... - Page 50 Kontaktadressen / Contact addresses / Contacts Deutschland France SensoPart Industriesensorik GmbH SensoPart France SARL Am Wiedenbach 1 11, rue Albert Einstein D-79695 Wieden Espace Mercure Tel.: +49 (0) 7665 - 94769 - 0 F-77420 Champs - Marne la Vallée Fax: +49 (0) 7665 - 94769 - 765 Tél.: +33 (0) 1 64 73 00 61...

Need help?

Do you have a question about the FA 46 Series and is the answer not in the manual?

Questions and answers