Table of Contents

Advertisement

Operating instructions

DULCO

flex DFBa

®

Peristaltic Pump

EN

Please carefully read these operating instructions before use. · Do not discard.

The operator shall be liable for any damage caused by installation or operating errors.

The latest version of the operating instructions are available on our homepage.

Part no. 986228

Original Operating Instructions (2006/42/EC)

BA DX 020 12/15 EN

Advertisement

Table of Contents

Summary of Contents for ProMinent DULCOflex DFBa Series

- Page 1 Operating instructions DULCO flex DFBa ® Peristaltic Pump Please carefully read these operating instructions before use. · Do not discard. The operator shall be liable for any damage caused by installation or operating errors. The latest version of the operating instructions are available on our homepage. Part no.

- Page 2 Supplemental directives General non-discriminatory approach In order to make it easier to read, this document uses the male form in grammatical structures but with an implied neutral sense. It is aimed equally at both men and women. We kindly ask female readers for their understanding in this simplification of the text.

-

Page 3: Table Of Contents

Table of contents Table of contents Introduction................4 1.1 Explanation of the safety information......4 1.2 Users' qualifications............5 1.3 Identity code..............7 1.3.1 Identity Code for DULCO ® flex DFBa 010....7 1.3.2 Identity Code for DULCO ® flex DFBa 013....9 1.3.3 Identity Code for DULCO flex DFBa 016.... -

Page 4: Introduction

Introduction Introduction These operating instructions provide information on the technical data and functions of the DULCO ® flex peristaltic pump from the DFBa product range. 1.1 Explanation of the safety information Introduction These operating instructions provide information on the technical data and functions of the product. -

Page 5: Users' Qualifications

A trained user is a person who fulfils the requirements made of an instructed person and who has also received additional training specific to the system from ProMinent or another authorised distribution partner. Trained qualified per‐ A qualified employee is deemed to be a person who is able to assess the... - Page 6 Customer Service depart‐ Customer Service department refers to service technicians, who have ment received proven training and have been authorised by ProMinent to work on the system. Note for the system operator The pertinent accident prevention regulations, as...

-

Page 7: Identity Code

Introduction 1.3 Identity code Device identification / Identity code 1.3.1 Identity Code for DULCO ® flex DFBa 010 Identity code DFBa DULCO flex DFBa 010 ® Type DFBa 010, 0.023 l/revolution Power end/drive Pump without power end/drive Reduction gear system / 3 x 230 / 400 VAC 0.12 kW, 15 rpm, 21 l/h, 8 bar 0.12 kW, 20 rpm, 28 l/h, 8 bar 0.18 kW, 29 rpm, 40 l/h, 6 bar... - Page 8 Introduction Identity code DFBa DULCO flex DFBa 010 ® VA BSP 3/8" VA NPT 3/8" PP BSP 3/8" PVDF BSP 3/8" PVDF NPT 3/8" PVC NPT 3/8" Tri-Clamp, VA, 1/2" DIN 11851, VA NW10 Base plate Base plate, lacquered steel Base plate, stainless steel Portable unit + lacquered steel base plate Portable unit + stainless steel base plate...

-

Page 9: Flex Dfba 013

Introduction 1.3.2 Identity Code for DULCO flex DFBa 013 ® Identity code DFBa DULCO ® flex DFBa 013 Type DFBa 013, 0.039 l/revolution Power end/drive Pump without power end/drive Reduction gear system / 3 x 230 / 400 VAC 0.12 kW, 15 rpm, 35 l/h, 8 bar 0.12 kW, 20 rpm, 46 l/h, 8 bar 0.18 kW, 29 rpm, 67 l/h, 6 bar 0.18 kW, 46 rpm, 107 l/h, 4 bar... - Page 10 Introduction Identity code DFBa DULCO flex DFBa 013 ® PVDF BSP 3/8" PVDF NPT 3/8" PVC NPT 3/8" Tri-Clamp, VA, 1/2" DIN 11851, VA NW15 Base plate Base plate, lacquered steel Base plate, stainless steel Portable unit + lacquered steel base plate Portable unit + stainless steel base plate Leakage sensor without leakage sensor...

-

Page 11: Flex Dfba 016

Introduction 1.3.3 Identity Code for DULCO flex DFBa 016 ® Identity code DFBa DULCO ® flex DFBa 016 Type DFBa 016, 0.092 l/revolution Power end/drive Pump without power end/drive Reduction gear system / 3 x 230 / 400 VAC 0.18 kW, 14 rpm, 77 l/h, 8 bar 0.18 kW, 20 rpm, 110 l/h, 8 bar 0.25 kW, 32 rpm, 176 l/h, 4 bar 0.25 kW, 46 rpm, 253 l/h, 4 bar... - Page 12 Introduction Identity code DFBa DULCO flex DFBa 016 ® PVDF NPT 3/4" PVC NPT 3/4" Tri-clamp, VA, 1" DIN 11851, VA NW 20 Base plate Base plate, lacquered steel Base plate, stainless steel Portable unit + lacquered steel base plate Portable unit + stainless steel base plate Leakage sensor without leakage sensor...

-

Page 13: Flex Dfba 019

Introduction 1.3.4 Identity Code for DULCO flex DFBa 019 ® Identity code DFBa DULCO ® flex DFBa 019 Type DFBa 019, 0.123 l/revolution Power end/drive Pump without power end/drive Reduction gear system / 3 x 230 / 400 VAC 0.18 kW, 15 rpm, 110 l/h, 2 bar 0.18 kW, 20 rpm, 148 l/h, 2 bar 0.25 kW, 32 rpm, 236 l/h, 2 bar 0.25 kW, 46 rpm, 339 l/h, 2 bar... - Page 14 Introduction Identity code DFBa DULCO flex DFBa 019 ® Base plate, lacquered steel Base plate, stainless steel Portable unit + lacquered steel base plate Portable unit + stainless steel base plate Leakage sensor without leakage sensor with leakage sensor with leakage sensor and relay output Rotor Rotor with 2 rollers Batch control...

-

Page 15: Flex Dfba 022

Introduction 1.3.5 Identity Code for DULCO flex DFBa 022 ® Identity code DFBa DULCO ® flex DFBa 022 Type DFBa 022, 0.246 l/revolution Power end/drive Pump without power end/drive Reduction gear system / 3 x 230 / 400 VAC 0.25 kW, 17 rpm, 251 l/h, 8 bar 0.37 kW, 23 rpm, 339 l/h, 8 bar 0.55 kW, 38 rpm, 561 l/h, 4 bar 0.55 kW, 45 rpm, 664 l/h, 4 bar... - Page 16 Introduction Identity code DFBa DULCO flex DFBa 022 ® PVDF NPT 1" PVC NPT 1" Tri-clamp, VA, 1" DIN 11851, VA NW 25 Base plate Base plate, lacquered steel Base plate, stainless steel Portable unit + lacquered steel base plate Portable unit + stainless steel base plate Leakage sensor without leakage sensor...

-

Page 17: Safety And Responsibility

Safety and responsibility Safety and responsibility 2.1 General safety information WARNING! Live parts Possible consequence: Fatal or very serious inju‐ ries – Measure: The device must be disconnected from the power supply before it is opened – Isolate damaged, faulty or manipulated devices from the mains in order to de-energise. - Page 18 Safety and responsibility WARNING! Correct and proper use Possible consequence: Fatal or very serious inju‐ ries – The unit is not intended to convey or regulate gaseous or solid media – Do not exceed the rated pressure, speed or temperature for the pump –...

- Page 19 Safety and responsibility CAUTION! Environmental influences Possible consequence: Material damage right through to destruction of the unit – The device is not suitable for outdoor operation – Take suitable measures to protect the device from environmental influences such as: – UV rays –...

-

Page 20: Functional Description

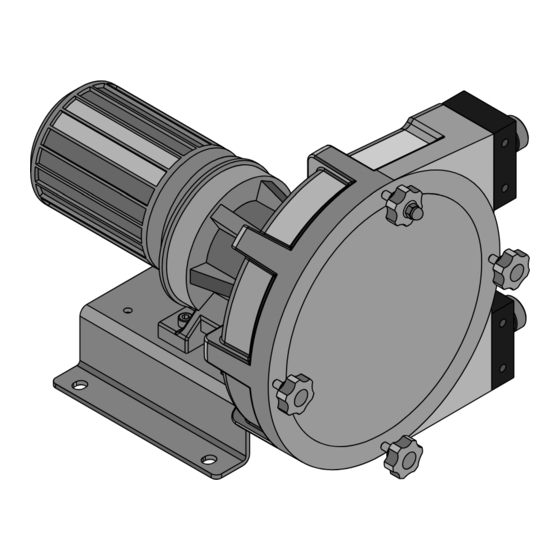

Functional description Functional description Brief functional description The package contents supplied with the DULCO flex DFBa is ® selectable via the identcode. The DULCO flex DFBa is a displacement pump. The feed chem‐ ® ical is conveyed by the rotor squeezing the hose in the direction of flow. -

Page 21: Overview Of The Device

Functional description 3.2 Overview of the Device P_DX_0017_SW Fig. 1: Diagram of functional principle Housing Rotor Rollers Hose... -

Page 22: Transport, Storage, Assembly And Installation

Transport, storage, assembly and Installation Transport, storage, assembly and Installation User qualification, transport and storage: trained user, see Ä Chapter 1.2 ‘Users' qualifications’ on page 5 User qualification, installation: trained qualified personnel, see Ä Chapter 1.2 ‘Users' qualifications’ on page 5 User qualification, electrical installation: Electrical technician, Ä... -

Page 23: Ambient Conditions

Transport, storage, assembly and Installation 4.3.1 Ambient conditions NOTICE! Ambient conditions Possible consequence: Damage to property and increased wear and tear Install in the following order. If the pump is to be installed outdoors, protect it against sunlight and the influences of the weather. When positioning the pump, ensure that there is sufficient room for access for all types of mainte‐... -

Page 24: Alignment Of The Discharge Side

Transport, storage, assembly and Installation 4.3.3 Alignment of the discharge side The discharge line is to be kept as straight and short as possible, in order to avoid performance reduction. The diameter must correspond to the rated diameter of the pump hose. - Page 25 Transport, storage, assembly and Installation P_DX_0021_SW Fig. 3: Squeezing the hose Normal shape of hose Excessive squeezing (increased wear and tear on the pump and hose) Perfect squeezing Insufficient squeezing (medium backflowing in the cavity will destroy the hose within a short period of time) The spacer plates are factory-fitted.

- Page 26 Transport, storage, assembly and Installation Tab. 5: DFBa 013 / Number of spacer plates of 0.5 mm thickness (except Norprene and TYGON ® ® 0-19 20-39 40-59 60-79 80-99 4.0 * * Delivery state Tab. 6: DFBa 013 / Number of spacer plates of 0.5 mm thickness (Norprene and TYGON) ®...

-

Page 27: Performance Curves

Transport, storage, assembly and Installation Tab. 9: DFBa 019 / Number of spacer plates of 0.5 mm thickness (Norprene and TYGON ® ® 0-19 20-39 40-59 60-79 80-99 2.0 * * Delivery state Tab. 10: DFBa 022 / Number of spacer plates of 0.5 mm thickness (except Norprene ®... - Page 28 Transport, storage, assembly and Installation l /h 110 120 130 1/min 8 bar 4 bar 2 bar P_DX_0022_SW Fig. 4: DFBa 10 l /h 33 0 30 0 27 0 24 0 21 0 18 0 15 0 12 0 80 90 100 110 120 130 140 1/min 8 bar...

- Page 29 Transport, storage, assembly and Installation l /h 100 110 120 130 140 1/min 2 bar 8 bar 4 bar P_DX_0015_SW Fig. 6: DFBa 016 l /h 1040 90 100 110 120 130 140 1/min P_DX_0016_SW Fig. 7: DFBa 019...

- Page 30 Transport, storage, assembly and Installation l /h 1500 1350 1200 10 50 10 0 1/min 8 bar 4 bar 2 bar P_DX_0024_SW Fig. 8: DFBa 022...

-

Page 31: Commissioning

Commissioning Commissioning Ä Chapter User qualification, commissioning: trained user, see 1.2 ‘Users' qualifications’ on page 5 5.1 Testing prior to commissioning the pump The following tests are to be carried out: Ensure that the pump has not been damaged during transpor‐ tation or storage. -

Page 32: Operating The Dfba

Operating the DFBa Operating the DFBa User qualification, operation: instructed persons, see Ä Chapter 1.2 ‘Users' qualifications’ on page 5 The peristaltic pump is to be fully integrated into the customer's designated plant and is then controlled by this plant. It is not pos‐ sible to operate the pump directly. -

Page 33: Maintenance, Repair, Malfunctions, Disposal And Spare Parts

Maintenance, repair, malfunctions, disposal and spare parts Maintenance, repair, malfunctions, disposal and spare parts User qualification, maintenance and disposal: instructed per‐ Ä Chapter 1.2 ‘Users' qualifications’ on page 5 sonnel, see User qualification, repair and troubleshooting: trained user, see Ä Chapter 1.2 ‘Users' qualifications’ on page 5 WARNING! Danger from hazardous substances! Possible consequence: Fatal or very serious inju‐... -

Page 34: Troubleshooting

Maintenance, repair, malfunctions, disposal and spare parts Remove the pressure flange from the pump housing Remove the pump hose to be exchanged Dismantle the hydraulic connections from both pump hose ends Exchanging the pump hoses - installa‐ Clean the interior surfaces of the pump housing tion Lubricate the internal surfaces of the pump housing at the contact surfaces to the pump hose... - Page 35 Maintenance, repair, malfunctions, disposal and spare parts Problem Possible cause Solution High viscosity of medium Reduce viscosity, as far as pos‐ sible Air introduction in the suction con‐ Check connections and accesso‐ nections ries for air tightness Vibrations on pumps and pipelines The pipes are not correctly fas‐ Fasten pipes correctly (e.g.

-

Page 36: Disposal Of Used Parts

Note the national regulations and legal stand‐ ards that currently apply in your country Remove and dispose of the pump hose on site before returning the pump to ProMinent Dosiertechnik GmbH, Heidelberg/Germany. ProMinent GmbH, Heidelberg//Germany will take back clean used parts. -

Page 37: Spare Parts

Maintenance, repair, malfunctions, disposal and spare parts 7.5 Spare parts P_DX_0018_SW Fig. 9: Exploded view of spare parts for DFBa 010/013 DFBa 010 see Fig. 9 Item Description Quantity Reference Part number Pump housing 102.01.01 Rotor (2 rollers) 102.01.03 Rotor shaft 102.01.04 Roller ball bearings 102.01.02... - Page 38 Maintenance, repair, malfunctions, disposal and spare parts DFBa 010 see Fig. 9 Item Description Quantity Reference Part number Connector VA-NPT 102.00.17 Connector PP-NPT 102.00.18 Connector PVDF-NPT 102.00.19 DIN connector 102.00.20 SMS connector 102.00.21 Connector TRI-CLAMP 102.00.22 Pressure flange, standard 102.00.11 Pressure flange, thermoplastic hose 102.00.23 Base plate...

- Page 39 Maintenance, repair, malfunctions, disposal and spare parts DFBa 013 see Fig. 9 Item Description Quantity Reference Part number Front cover seal 102.01.05 Connector VA-BSP 103.00.10 Connector PP-BSP 103.00.15 Connector PVDF-BSP 103.00.16 Connector VA-NPT 103.00.17 Connector PP-NPT 103.00.18 Connector PVDF-NPT 103.00.19 DIN connector 103.00.20 SMS connector...

- Page 40 Maintenance, repair, malfunctions, disposal and spare parts P_DX_0014_SW Fig. 10: Exploded view of spare parts for DFBa 016/019 DFBa 16 see Fig. 10 Item Description Quantity Reference Part number Pump housing 101.03.01 Rotor 101.02.03 Rotor shaft 101.01.04 Roller ball bearings 101.01.36 Roller ⌀45 105.01.07...

- Page 41 Maintenance, repair, malfunctions, disposal and spare parts DFBa 16 see Fig. 10 Item Description Quantity Reference Part number Connector VA-NPT 101.00.16 Connector PP-NPT 101.00.17 Connector PVDF-NPT 101.00.18 DIN connector 101.00.19 SMS connector 101.00.20 Connector TRI-CLAMP 101.00.21 Pressure flange, standard 101.03.22 Pressure flange, thermoplastic hose 101.03.23 Base plate...

- Page 42 Maintenance, repair, malfunctions, disposal and spare parts DFBa 019 see Fig. 10 Item Description Quantity Reference Part number Front cover 101.00.12 Front cover seal 101.00.11 Connector VA-BSP 105.00.13 Connector PP-BSP 105.00.14 Connector PVDF-BSP 105.00.15 Connector VA-NPT 105.00.16 Connector PP-NPT 105.00.17 Connector PVDF-NPT 105.00.18 DIN connector...

- Page 43 Maintenance, repair, malfunctions, disposal and spare parts 18 17 14 21 9 10 15 P_DX_0019_SW Fig. 11: Exploded view of spare parts for DFBa 22 DFBa 022 see Fig. 11 Item Description Quantity Reference Part number Pump housing 113.00.01 Rotor 113.00.02 Rotor shaft 113.00.03...

- Page 44 Maintenance, repair, malfunctions, disposal and spare parts DFBa 022 see Fig. 11 Item Description Quantity Reference Part number Connector VA-NPT 113.00.13 Connector PP-NPT 113.00.14 Connector PVDF-NPT 113.00.15 DIN connector 113.00.16 SMS connector 113.00.17 Connector TRI-CLAMP 113.00.18 Pressure flange, standard 113.00.19 Pressure flange, thermoplastic hose 113.00.20 Base plate...

-

Page 45: Technical Data For Dfba

Technical data for DFBa Technical data for DFBa Type Feed rate P max. Pump Rollers/ Hose Solids Weight Con‐ capacity nector DFBa in l/revo‐ in bar Shoes interior max. without lution at max. power ⌀ in mm ⌀ in mm pressure end/drive in l/h... -

Page 46: Dimensions Dfba 016 / 019

Technical data for DFBa 8.2 Dimensions DFBa 016 / 019 P_DX_0026_SW Fig. 13: Dimensions DFBa 016 / 019 A 119 mm H 75 mm 60 mm 170 mm D 190 mm K 265 mm E 30 mm 3/4" BSP (016) / 1" BSP (019) 160 mm Dependent on selected drive G 30 mm... -

Page 47: Dimensions Dfba 022

Technical data for DFBa 8.3 Dimensions DFBa 022 P_DX_0027_SW Fig. 14: Dimensions DFBa 022 A 110 mm H 95 mm 85 mm 210 mm D 245 mm K 355 mm E 25 mm 1" BSP 175 mm Dependent on selected drive G 25 mm... -

Page 48: Dfba Technical Appendices

In accordance with DIRECTIVE 2006/42/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL, Appendix I, BASIC HEALTH AND SAFETY REQUIREMENTS, section 1.7.4.2. C. ProMinent GmbH Im Schuhmachergewann 5 - 11 D - 69123 Heidelberg, hereby declare that the product specified in the following, complies... -

Page 49: Index

Index Index Action, step by step ......2 Unauthorised access ..... . 17 Applied harmonised standards . - Page 52 ProMinent GmbH Im Schuhmachergewann 5 - 11 69123 Heidelberg Telephone: +49 6221 842-0 Fax: +49 6221 842-419 Email: info@prominent.com Internet: www.prominent.com 986228, 3, en_GB © 2015...

Need help?

Do you have a question about the DULCOflex DFBa Series and is the answer not in the manual?

Questions and answers