Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Siemens SIMOTICS S-1FK7 DYA Generation 2

- Page 3 ___________________ Introduction Fundamental safety ___________________ instructions ___________________ SIMOTICS Description of the motors ___________________ Mounting and options Drive technology S-1FK7 DYA G2 synchronous ___________________ Preparing for use motors with planetary gearbox ___________________ Mounting Operating Instructions ___________________ Connecting ___________________ Commissioning ___________________ Operation ___________________ Faults and their rectification ___________________...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Introduction

Before you start using the motor, you must read these Operating Instructions to ensure safe, problem-free operation and to maximize the service life. Siemens strives continually to improve the quality of information provided in these Operating Instructions. ● If you find any mistakes or would like to offer suggestions about how this document could be improved, contact the Siemens Service Center. - Page 6 If you want to use this function, you must first register. Later, you can log on with your login data. Training The following link provides information on SITRAIN - training from Siemens for products, systems and automation engineering solutions: SITRAIN (http://siemens.com/sitrain)

- Page 7 Products (http://www.siemens.com/motioncontrol) Websites of third parties This publication contains hyperlinks to websites of third parties. Siemens does not take any responsibility for the contents of these websites or adopt any of these websites or their contents as their own, because Siemens does not control the information on these websites and is also not responsible for the contents and information provided there.

- Page 8 Introduction S-1FK7 DYA G2 synchronous motors with planetary gearbox Operating Instructions, 05/2018, A5E44881183B AA...

-

Page 9: Table Of Contents

Table of contents Introduction ............................. 3 Fundamental safety instructions ......................11 General safety instructions ..................... 11 Equipment damage due to electric fields or electrostatic discharge ........16 Industrial security ........................17 Residual risks of power drive systems ..................19 Description of the motors ........................21 Use for the intended purpose .................... - Page 10 Table of contents Mounting ............................... 47 Safety instructions ........................47 Checklists prior to mounting ....................49 Mounting instructions ......................50 Mounting conditions ....................... 51 Attaching the output elements ....................52 Connecting ............................55 Safety instructions ........................55 Permissible line systems ......................56 Motor circuit diagram ......................

- Page 11 Table of contents Decommissioning and disposal ......................93 11.1 Safety instructions ........................93 11.2 Decommissioning ........................96 11.2.1 Removing the motor ........................ 96 11.2.2 Dismantling the motor ......................96 11.3 Disposal ..........................96 Technical data and dimension drawings ....................97 Glossary ...............................

- Page 12 Table of contents S-1FK7 DYA G2 synchronous motors with planetary gearbox Operating Instructions, 05/2018, A5E44881183B AA...

-

Page 13: Fundamental Safety Instructions

Fundamental safety instructions General safety instructions WARNING Electric shock and danger to life due to other energy sources Touching live components can result in death or severe injury. • Only work on electrical devices when you are qualified for this job. •... - Page 14 Fundamental safety instructions 1.1 General safety instructions WARNING Electric shock due to damaged motors or devices Improper handling of motors or devices can damage them. Hazardous voltages can be present at the enclosure or at exposed components on damaged motors or devices. •...

- Page 15 • If you come closer than around 2 m to such components, switch off any radios or mobile phones. • Use the "SIEMENS Industry Online Support app" only on equipment that has already been switched off. WARNING Unrecognized dangers due to missing or illegible warning labels Dangers might not be recognized if warning labels are missing or illegible.

- Page 16 Fundamental safety instructions 1.1 General safety instructions WARNING Unexpected movement of machines caused by inactive safety functions Inactive or non-adapted safety functions can trigger unexpected machine movements that may result in serious injury or death. • Observe the information in the appropriate product documentation before commissioning.

- Page 17 Fundamental safety instructions 1.1 General safety instructions WARNING Injury caused by moving or ejected parts Contact with moving motor parts or drive output elements and the ejection of loose motor parts (e.g. feather keys) out of the motor enclosure can result in severe injury or death. •...

-

Page 18: Equipment Damage Due To Electric Fields Or Electrostatic Discharge

Fundamental safety instructions 1.2 Equipment damage due to electric fields or electrostatic discharge Equipment damage due to electric fields or electrostatic discharge Electrostatic sensitive devices (ESD) are individual components, integrated circuits, modules or devices that may be damaged by either electric fields or electrostatic discharge. NOTICE Equipment damage due to electric fields or electrostatic discharge Electric fields or electrostatic discharge can cause malfunctions through damaged... -

Page 19: Industrial Security

Siemens’ products and solutions undergo continuous development to make them more secure. Siemens strongly recommends that product updates are applied as soon as they are available and that the latest product versions are used. Use of product versions that are no longer supported, and failure to apply the latest updates may increase customer’s exposure... - Page 20 Fundamental safety instructions 1.3 Industrial security WARNING Unsafe operating states resulting from software manipulation Software manipulations (e.g. viruses, trojans, malware or worms) can cause unsafe operating states in your system that may lead to death, serious injury, and property damage. •...

-

Page 21: Residual Risks Of Power Drive Systems

Fundamental safety instructions 1.4 Residual risks of power drive systems Residual risks of power drive systems When assessing the machine- or system-related risk in accordance with the respective local regulations (e.g., EC Machinery Directive), the machine manufacturer or system installer must take into account the following residual risks emanating from the control and drive components of a drive system: 1. - Page 22 Fundamental safety instructions 1.4 Residual risks of power drive systems S-1FK7 DYA G2 synchronous motors with planetary gearbox Operating Instructions, 05/2018, A5E44881183B AA...

-

Page 23: Description Of The Motors

If you wish to use special versions and design variants whose specifications vary from the motors described in this document, then contact your local Siemens office. If you have any questions regarding the intended usage, please contact your local Siemens office. -

Page 24: Technical Features And Environmental Conditions

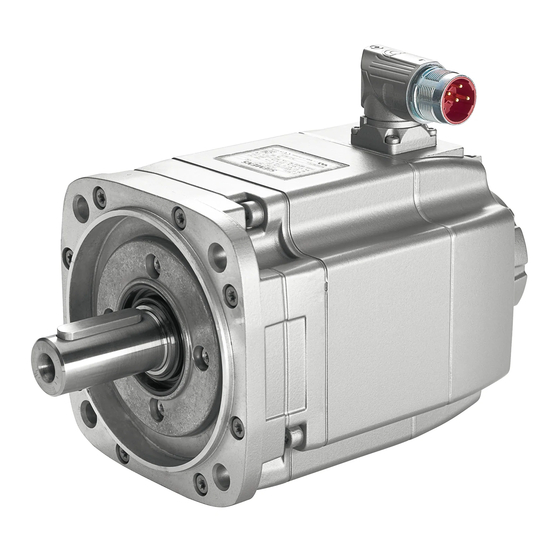

Description of the motors 2.2 Technical features and environmental conditions Typical applications 1FK7 DYA G2 synchronous motors have the following typical fields of application: ● Machine tools (e.g. auxiliary axes, feed drives) ● Robots and handling systems ● Packaging, plastics and textile machines ●... - Page 25 Quality systems Siemens AG employs a quality management system that meets the requirements of ISO 9001 and ISO 14001. Certificates for SIMOTICS motors can be downloaded from the Internet at the following link: Certificates for SIMOTICS motors (https://support.industry.siemens.com/cs/ww/de/ps/13347/cert)

-

Page 26: Technical Features

Description of the motors 2.2 Technical features and environmental conditions 2.2.2 Technical features Table 2- 1 Technical features of the motor Type of motor Permanent-magnet synchronous motor Magnet material Rare-earth magnetic material Cooling Natural cooling Insulation of the stator winding according to Temperature class 155 °C (F) for a winding tempera- EN 60034-1 ture of ΔT = 100 K at an ambient temperature of... - Page 27 Description of the motors 2.2 Technical features and environmental conditions Table 2- 2 Technical data of the 1FK7 DYA G2 geared motor Unit 1FK7032-2AK71-1☐☐3- 1FK7040-2AK71- 1FK7060-2AH71- Z A03 1☐☐3-Z A13 1☐☐3-Z A73 Transmission ratio Torsional backlash arcmin M2dyn Max. output torque 43.6 49.4 174.6...

-

Page 28: Environmental Conditions

Description of the motors 2.2 Technical features and environmental conditions 2.2.3 Environmental conditions You can classify the environmental conditions according to standard DIN EN 60721-3-3 for fixed installation locations that are weather protected. The environmental effects and their limit values are defined in various classes in this standard. With the exception of environmental influences "Condensation", "Low air temperature"... -

Page 29: Degree Of Protection

Description of the motors 2.2 Technical features and environmental conditions You find additional data on the environmental conditions, such as ambient temperatures or conditions for transport and storage of the motors, in the relevant chapters of this documentation. 2.2.4 Degree of protection 1FK7 DYA G2 motors are available with an IP64 degree of protection. -

Page 30: Derating Factors

Description of the motors 2.3 Derating factors Derating factors Under conditions other than those specified above (ambient temperature > 40° C or installation altitude > 1000 m above sea level), the permissible torques/powers are shown in the following table. Ambient temperatures and installation altitudes are rounded off to 5° C or 500 m respectively. - Page 31 Description of the motors 2.3 Derating factors Table 2- 6 Factors for reducing the maximum DC-link voltage Installation altitude up to [m] above mean sea Factor level 2000 3000 0.877 4000 0.775 5000 0.656 6000 0.588 7000 0.513 8000 0.444 As the DC-link voltage is reduced, the converter output voltage also decreases.

-

Page 32: Structure Of The Article Number

The article number comprises a combination of digits and letters. It is divided into three hyphenated blocks. Possible combinations can be found in Catalog D 21.4 (https://support.industry.siemens.com/cs/ww/de/view/109747019/en). Please note that not every theoretical combination is available. Description Position of the article number... - Page 33 Customer data on the rating plate -Y84 Can only be selected for SH36 Refer to the Catalog D 21.4 (https://support.industry.siemens.com/cs/ww/de/view/109747019/en) for more infor- mation. You can order the motors with additional special colors. Information on this can be found in Catalog D 21.4 (https://support.industry.siemens.com/cs/ww/de/view/109747019/en).

-

Page 34: Rating Plate Data

Description of the motors 2.5 Rating plate data Rating plate data The rating plate contains the technical data applicable to the delivered motor. A second rating plate is provided with the motor, and this should be used for documentation purposes. Figure 2-1 Content 1FK7 DYA G2 rating plate Table 2- 7... - Page 35 Description of the motors 2.5 Rating plate data Position Description / technical data Production address Certifications Product standard Mounting position 2D code S-1FK7 DYA G2 synchronous motors with planetary gearbox Operating Instructions, 05/2018, A5E44881183B AA...

- Page 36 Description of the motors 2.5 Rating plate data S-1FK7 DYA G2 synchronous motors with planetary gearbox Operating Instructions, 05/2018, A5E44881183B AA...

-

Page 37: Mounting And Options

Mounting and options Safety symbols on the motor The following warning and information labels are attached to the motor. "No impact or axial forces on the shaft extension" warning sign "Warning hot surface" warning sign. The warning sign is on one side of the housing. WEEE mark Dispose of the motor corresponding to the WEEE directive 2012/19/EU. -

Page 38: Thermal Motor Protection

Mounting and options 3.3 Thermal motor protection Thermal motor protection Two Pt1000 temperature sensors in the stator winding (one of which is reserve) monitor the motor temperature. Table 3- 1 Features and technical data Type Pt1000 Resistance when cold (20 °C) Approx. - Page 39 Mounting and options 3.3 Thermal motor protection 1FK703 to 1FK704: up to 2 ∙ I and speed ≠ 0 0 (60 K) 1FK706: up to 4 ∙ I and speed ≠ 0 0 (60 K) NOTICE Destruction of the motor for a thermally critical load For load applications that are critical from a thermal perspective, e.g.

-

Page 40: Encoder

Mounting and options 3.4 Encoder Encoder Encoder systems with DRIVE-CLiQ interface Motors with a DRIVE-CLiQ encoder interface should be used with the SINAMICS S110/S120 converter system. Signal transmission to the converter is performed digitally. They have an electronic rating plate that simplifies commissioning and diagnostics. The motor and encoder system are automatically identified and all motor parameters are automatically set, see SINAMICS Equipment Manual. -

Page 41: Cooling

Mounting and options 3.5 Cooling Cooling 1FK7 DYA G2 is non-ventilated. The housing surface is sufficient for dissipating heat losses where there is free convection. Note Dust deposits prevent heat radiation Dust deposits prevent heat radiation and cause a high housing temperature. •... -

Page 42: Properties

Mounting and options 3.6 Holding brake 3.6.2 Properties ● The holding brake is used to clamp the motor shaft when the motor is at a standstill. The holding brake is not a working brake for braking the rotating motor. WARNING Danger to life caused by unintended movements of the machine or installation If you ignore the permissible number of braking operations, the braking effectiveness of the holding brake can be irreversibly reduced. -

Page 43: Options

EMERGENCY STOP operation. Options Descriptions of the options are provided in the Configuration Manual (https://support.industry.siemens.com/cs/document/55379345?lc=de- WW&pnid=13349&dl=en) of the 1FK7 G2 motor S-1FK7 DYA G2 synchronous motors with planetary gearbox Operating Instructions, 05/2018, A5E44881183B AA... - Page 44 Mounting and options 3.7 Options S-1FK7 DYA G2 synchronous motors with planetary gearbox Operating Instructions, 05/2018, A5E44881183B AA...

-

Page 45: Preparing For Use

● Upon receipt of the delivery, check immediately whether the items delivered match the accompanying documents. Note Siemens will not accept any claims for missing or incorrect items submitted at a later date. ● Report any visible transportation damage to the delivery company immediately. -

Page 46: Transportation And Storage

Preparing for use 4.2 Transportation and storage Transportation and storage 4.2.1 Transport WARNING Danger of the motor down due to incorrect transport and/or lifting Due to incorrect transport and/or lifting, the motor can fall and cause death, severe injury and/or damage to property. •... -

Page 47: Storage

Preparing for use 4.2 Transportation and storage Setting down the motor WARNING Danger of severe injury due to unintentional movements of the motor If the motor is not secured after being set down, unintentional movements of the motor can cause serious injury. •... - Page 48 Preparing for use 4.2 Transportation and storage Long-term storage Note Storage time up to two years The storage time affects the properties of the roller bearing grease. • Store the motor for up to two years at -15° C to 55° C. If you intend to place the motor in storage for longer than six months, you must ensure that the storage area satisfies the following conditions.

-

Page 49: Mounting

Mounting Safety instructions WARNING Danger of the motor down due to incorrect transport and/or lifting Due to incorrect transport and/or lifting, the motor can fall and cause death, severe injury and/or damage to property. • Lifting devices, ground conveyors, and load suspension equipment must comply with requirements. - Page 50 Mounting 5.1 Safety instructions WARNING Danger to life due to unpredictable movements of the system The system can perform unpredictable movements under load that can cause death or severe injury. • De-energize the system before starting work. • Disconnect all loads from the system. •...

-

Page 51: Checklists Prior To Mounting

Mounting 5.2 Checklists prior to mounting Checklists prior to mounting Note Required checks The checklists below do not purport to be complete. It may be necessary to perform additional checks and tests in accordance with the situation specific to the particular installation site. -

Page 52: Mounting Instructions

Mounting 5.3 Mounting instructions Mounting instructions Note Observe the technical data on the rating plate on the motor enclosure. ● Observe the data on the rating plate, as well as the warning and information plates on the motor. ● Check the permissible ambient conditions (e.g. temperature, installation altitude) at the installation location. -

Page 53: Mounting Conditions

Mounting 5.4 Mounting conditions Tightening torques for fastening bolts Motor Screw Tightening torque Property class of the ±10 % [Nm] screws 1PV513x/ M 12 1FV513x M12 (screw-in depth, 25...30 mm) M 16 10.9 1FV516x M12 (screw-in depth, 18...20 mm) The mounting tools to be used are a torque wrench or pneumatic or impact power screwdriver with automatic switch-off. -

Page 54: Attaching The Output Elements

Mounting 5.5 Attaching the output elements Attaching the output elements NOTICE Damage to the motor due to runout on the shaft extension Runout and thrust on the shaft extension of the motor can damage the motor. • Mount the motor without runout and thrust on the shaft extension. NOTICE Damage to shaft sealing rings caused by heating When mounting input and output elements with the heat treatment, shaft sealing rings can... - Page 55 Mounting 5.5 Attaching the output elements Assemble the input and output elements in such a way as to minimize the stress on shafts and bearings from transverse forces. Correct Incorrect low stress on shafts and bearings high stress on shafts and bearings Mount or remove the power output elements (e.g.

- Page 56 Mounting 5.5 Attaching the output elements S-1FK7 DYA G2 synchronous motors with planetary gearbox Operating Instructions, 05/2018, A5E44881183B AA...

-

Page 57: Connecting

Connecting Safety instructions WARNING Electric shock and danger to life due to other energy sources Touching live components can result in death or severe injury. • Only work on electrical devices when you are qualified for this job. • Always observe the country-specific safety rules. Generally, the following six steps apply when establishing safety: 1. -

Page 58: Permissible Line Systems

Connecting 6.2 Permissible line systems Permissible line systems In combination with the drive system, the motors are generally approved for operation on TN and TT systems with grounded neutral and on IT systems. In operation on IT systems, the occurrence of a first fault between an active part and ground must be signaled by a monitoring device. -

Page 59: System Integration

• Only grounded personnel with grounded tools may touch the component connections. • Heed the EMC information provided by the manufacturer of the converter. ● Use prefabricated cables from SIEMENS (not in the scope of delivery). These cables reduce installation costs and increase operational reliability (see the Product Information). - Page 60 Connecting 6.4 System integration Current-carrying capacity for power and signal cables The current-carrying capacity of PVC/PUR-insulated copper cables is specified for routing types B1, B2 and C under continuous operating conditions in the table with reference to an ambient air temperature of 40° C. For other ambient temperatures, the values must be corrected by the factors from the "Derating factors"...

-

Page 61: Rotating The Connector At The Motor

Connecting 6.4 System integration 6.4.1.1 Rotating the connector at the motor Power connectors and signal connectors can be rotated to a different angle to a limited extent. Use a suitable socket connector to rotate the angle plug. Unscrew and open the socket connector completely to avoid damaging the pin contacts. For encoders with integrated Sensor Module (DQI), the cable outlet towards the top is fixed. - Page 62 Connecting 6.4 System integration Ability to rotate the connectors on motors with DRIVE-CLiQ interface and M17 round connector Power connector, Size 1 M17 signal connector with DRIVE-CLiQ Figure 6-2 Ability to rotate connector versions with M17 round connector ① Rotation range of the power connector Motor Connector size Angle α...

- Page 63 Connecting 6.4 System integration Ability to rotate the connectors on motors with resolver and SMI Power connector, Size 1 RJ45 signal connector with SMI Output cam on the connector foot to limit the twistability Figure 6-3 Ability to rotate resolver versions with SMI ①...

-

Page 64: Routing Cables In A Damp Environment

Connecting 6.4 System integration 6.4.1.2 Routing cables in a damp environment Note If the motor is mounted in a humid environment, the power and signal cables must be routed as shown in the following figure. Figure 6-4 Routing cables in a damp environment 6.4.2 Connecting to a converter Selecting and connecting the cables... - Page 65 Connecting 6.4 System integration Connection scheme for the motor to the S120 Power Module and Motor Module Booksize and Compact with a MOTION CONNECT cable For connector size 1 Connector, size 1 SPEED CONNECT connector, size 1 Terminal for the cable shield Pin assignment Circuit diagram Cable shield...

-

Page 66: Connecting The Holding Brake

Connecting 6.4 System integration 6.4.3 Connecting the holding brake Direct connection The holding brake in the motor is directly connected to the SINAMICS converter using MOTION-CONNECT power cables with integrated brake connecting cable. See Chapter "Connecting to a converter (Page 62)" Connection to external power supply You can also control the holding brake via an external power supply. - Page 67 Connecting 6.4 System integration Note Integrate a protective circuit into the incoming cable. In this way, you avoid switching overvoltages and possible influence of the installation environment. See the figure below Motor Contactor Circuit-breaker Holding brake Varistors Figure 6-5 Suggested circuit for the external power supply with protective circuit Table 6- 1 Example: Electrical components for the suggested circuit Electrical...

-

Page 68: Line Connection

Connecting 6.4 System integration 6.4.4 Line connection Connector types The power connection is a connector, Size 1. Brake contacts BD1+ BD2- The motors are equipped with SPEED-CONNECT connectors. You can also connect quick-connection cables with SPEED-CONNECT to motor connectors as conventional cables with screw locks (fully threaded). Note We recommend cables with SPEED-CONNECT because they are easier to use. - Page 69 Connecting 6.4 System integration 3. Push the power connector onto the motor connecting socket up to the end stop. 4. Rotate the union nut by hand in the direction of "close" through at least 45° (position A) – or up to the end stop (position B) Minimum locking Maximum locking up to the end stop Note...

-

Page 70: Signal Connection

Connecting 6.4 System integration 6.4.5 Signal connection 6.4.5.1 Motors with DRIVE-CLiQ interface Motors designed for SINAMICS drive systems have an integrated encoder and temperature evaluation system as well as an electronic rating plate. The motors are connected to the converter system via a DRIVE-CLiQ interface. The following variants are possible for the DRIVE-CLiQ connection: Analog value encoder Resolver... -

Page 71: Handling The Drive-Cliq Connection System

Connecting 6.4 System integration 6.4.5.2 Handling the DRIVE-CLiQ connection system Design of the DRIVE-CLiQ connection system with RJ45 connector The DRIVE-CLiQ connection method with the RJ45 connector has the following components: DRIVE-CLiQ connector with RJ45Plus DRIVE-CLiQ socket with RJ45plus Rotatable locking ring Tabs (2, opposite each other) Latches (2, opposite each other) S-1FK7 DYA G2 synchronous motors with planetary gearbox... - Page 72 Connecting 6.4 System integration Insertion Procedure 1. Check whether the locking ring of the connector is in the "locked" position. If not, turn the locking ring clockwise into the "locked" position. Note In the "locked" position, the tabs are flush against the connector. Locking ring in the "locked"...

- Page 73 Connecting 6.4 System integration Both tabs must engage in both latches. The correct DRIVE-CLiQ connection is made when ● the locking ring is in the "locked" position, ● both tabs are engaged in both latches. You have established a DRIVE-CLiQ connection. ❒...

- Page 74 Connecting 6.4 System integration Removal Procedure 1. Turn the locking ring of the connector counterclockwise into the "unlocked" position. Turn the locking ring counterclockwise. → Both tabs are pressed away by the latches. 2. Check that the two tabs are disengaged from the latches. 3.

-

Page 75: Commissioning

Commissioning Safety instructions WARNING Electric shock when connected to inadequately grounded line supplies Connecting a motor to an inadequately grounded line supply can result in death, severe injury and damage to the motor if a fault occurs. • Connect motors, as part of the drive system, to TN and TT line supplies with a grounded neutral point or to IT line supplies. - Page 76 Commissioning 7.1 Safety instructions WARNING Electric shock when checking the insulation resistance During the measurement and immediately afterward, high voltages can be present at the terminals that can cause death or severe injury as result of an electric shock. Contact with live parts causes electric shocks. •...

- Page 77 Commissioning 7.1 Safety instructions NOTICE Thermal damage to temperature-sensitive parts Some parts of the frame of electric motors can reach temperatures that exceed 100° C. If temperature-sensitive parts, e.g. electric cables or electronic components, come into contact with hot surfaces, these parts could be damaged. •...

-

Page 78: Checklists For Commissioning

Commissioning 7.2 Checklists for commissioning Checklists for commissioning Note Required checks The lists below do not purport to be complete. It may be necessary to perform additional checks and tests appropriate for the situation specific to the particular installation site. Before commissioning the system, check that it is properly installed and connected. - Page 79 Commissioning 7.2 Checklists for commissioning Table 7- 2 Checklist (2) - checks regarding the mechanical system Check Have all touch protection measures for moving and live parts been fitted and are they functional? Has the motor been correctly mounted and aligned? Can you rotate the rotor without it touching the stator? Have all fastening screws, fastening elements, and electrical connections been tight- ened with the prescribed torques and properly attached?

-

Page 80: Commissioning Procedure

Commissioning 7.3 Commissioning procedure Commissioning procedure Commissioning Precondition ● You have worked through the commissioning checklists. ● Ensure that the converter is correctly parameterized. ● Check whether sufficient heat is dissipated from the motor. Note EMERGENCY OFF To avoid accidents, inform yourself about the EMERGENCY OFF function before you switch on the system. -

Page 81: Switching On And Switching Off

Commissioning 7.4 Switching on and switching off Switching on and switching off Note EMERGENCY OFF To avoid accidents, inform yourself about the EMERGENCY OFF function before you switch on the system. The motor is switched on and off using the frequency converter. ●... -

Page 83: Operation

Operation Safety instructions WARNING Do not remove covers when the motor is running Rotating or live parts are dangerous. Death, serious injury, or material damage can result if the required covers are removed. All covers that prevent personnel from coming into contact with active or rotating parts, ensure compliance with the required degree of protection, or ensure proper air guidance and, in turn, effective cooling must not be opened/removed during operation. -

Page 84: Switching On And Switching Off

Operation 8.2 Switching on and switching off Switching on and switching off Note EMERGENCY OFF To avoid accidents, inform yourself about the EMERGENCY OFF function before you switch on the system. The motor is switched on and off using the frequency converter. ●... -

Page 85: During Operation

Operation 8.3 During operation During operation While the motor is operating, ensure that the specified parameters are maintained. Make sure that: ● The power consumption is in the specified range ● There is no abnormal motor noise ● The motor does not overheat Note Observe the maintenance intervals Service the motor at the prescribed maintenance intervals. - Page 86 Operation 8.4 Stoppages S-1FK7 DYA G2 synchronous motors with planetary gearbox Operating Instructions, 05/2018, A5E44881183B AA...

-

Page 87: Faults And Their Rectification

Faults and their rectification WARNING Danger to life for operation without functioning protective devices Operation without functioning protective devices can cause death or severe injury. • Operate the motor, even in test operation, only with functioning protective devices. WARNING Risk of vertical axes dropping as a result of a defective gearbox If you use the 1FK7 DYA G2 to drive a vertical axis, then a defective gearbox can cause parts and components to fall resulting in death or severe injury. - Page 88 Fault originating from the gear unit Adjust/repair gear unit If the fault still cannot be resolved after taking the measures stated above, please contact the manufacturer or the Siemens Service Center. S-1FK7 DYA G2 synchronous motors with planetary gearbox Operating Instructions, 05/2018, A5E44881183B AA...

-

Page 89: Maintenance

Maintenance 10.1 Safety instructions If you have any questions, please contact the manufacturer, quoting the machine type and serial number. WARNING Electric shock when live parts are touched Death or serious injury can result when live parts are touched. • Only work on electrical equipment if you are appropriately qualified. •... - Page 90 Maintenance 10.1 Safety instructions WARNING Slipping on leaked oil Leaked oil can result in slipping or falling and cause death or severe injury. • Prevent oil from leaking • Absorb leaked oil immediately with a binding agent for oil or similar. •...

- Page 91 Maintenance 10.1 Safety instructions CAUTION Injuries caused by stirred-up foreign bodies and dust when working with compressed air When you clean using compressed air, this can stir up dust, metal chips and cleaning agents, and so cause injuries. • When cleaning using compressed air, make sure you use suitable extraction equipment and wear protective equipment (safety goggles, protective suit, etc.).

-

Page 92: Inspection And Maintenance

Service and maintenance must only be performed by properly authorized qualified personnel. Only use original SIEMENS parts. Siemens Service Centers distributed around the globe can maintain and repair the motor. To do this, contact your local Siemens representative. ● Perform the following maintenance measures as listed in the table. -

Page 93: Checking Tightness Of Fastening Bolts

Maintenance 10.2 Inspection and maintenance 10.2.2 Checking tightness of fastening bolts Note Replace unusable headless screws with headless screws of the same design and property class. ● Switch off the power supply to the drive unit. ● Check all fixing screws for tightness using a torque wrench. You will find the permissible torques in chapter Mounting instructions (Page 50) 10.2.3 Cleaning... -

Page 94: Bearing Replacement Interval

50%. 10.3 Repair The Siemens Service Center Bad Neustadt and other regional service sites throughout the world can handle or organize the maintenance/repair of the motors. Contact your regional Siemens contact if you require this service. -

Page 95: Decommissioning And Disposal

Decommissioning and disposal 11.1 Safety instructions Removing the motor from the machine WARNING Electric shock when live parts are touched Death or serious injury can result when live parts are touched. • Only work on electrical equipment if you are appropriately qualified. •... - Page 96 Decommissioning and disposal 11.1 Safety instructions WARNING Slipping on leaked oil Leaked oil can result in slipping or falling and cause death or severe injury. • Prevent oil from leaking • Absorb leaked oil immediately with a binding agent for oil or similar. •...

- Page 97 Dismantling the motor Note The rotor in a motor containing permanent magnets must only be removed by the manufacturer. • Contact the Siemens Service Center (https://support.industry.siemens.com/sc/ww/en/sc/2090). S-1FK7 DYA G2 synchronous motors with planetary gearbox Operating Instructions, 05/2018, A5E44881183B AA...

-

Page 98: Decommissioning

Dismantling the motor Note The rotor in a motor containing permanent magnets must only be removed by the manufacturer. Contact the Siemens Service Center. 11.3 Disposal Recycling and disposal For environmentally-friendly recycling and disposal of your old device, please contact a company certified for the disposal of waste electrical and electronic equipment, and dispose of the old device as prescribed in the respective country of use. -

Page 99: Technical Data And Dimension Drawings

WW&pnid=13349&dl=en) of 1FK7 G2 in Chapter "Technical data and characteristics". Adapt the values for operating the motors according to Chapter "Derating factors (Page 28)". Dimension drawings for 1FK7 DYA G2 are available in the product notification Product notification (https://support.industry.siemens.com/cs/ww/de/view/109756257/en) or in the DT Configurator. DT CONFIGURATOR In the DT CONFIGURATOR - you can simply and quickly find ●... -

Page 101: Glossary

Glossary 2D code Data Matrix code for reading out the motor data. The code is defined in ISO/IEC 16022. Rated torque M Thermally permissible continuous torque in S1 duty at the rated motor speed. Rated speed n The characteristic speed range for the motor is defined in the speed-torque diagram by the rated speed. - Page 102 Glossary Mounting position Spatial arrangement of a motor after it has been mounted Maximum permissible speed (mechanical) n The maximum mechanically permissible speed is n . It is defined by the centrifugal max mech forces and frictional forces in the bearing. Maximum output torque of the gearbox M 2Dyn Maximum permissible output torque of the geared motor that may be output for a short...

-

Page 103: Index

Index RoHS, 23 Bearing change interval, 92 Siemens Service Center, 5 Certificates EAC, 23 Target group, 3 Technical features, 24 EC Declaration of Conformity, 23 UL and cUL, 23 Technical Support, 5 Commissioning, 76 Thermal motor protection, 36 Correct usage, 21...

Need help?

Do you have a question about the SIMOTICS S-1FK7 DYA Generation 2 and is the answer not in the manual?

Questions and answers