Siemens SIMOTICS S-1FK2 Operating Instructions Manual

Hide thumbs

Also See for SIMOTICS S-1FK2:

- Configuration manual (164 pages) ,

- Operating instructions manual (98 pages) ,

- Service manual (60 pages)

Summary of Contents for Siemens SIMOTICS S-1FK2

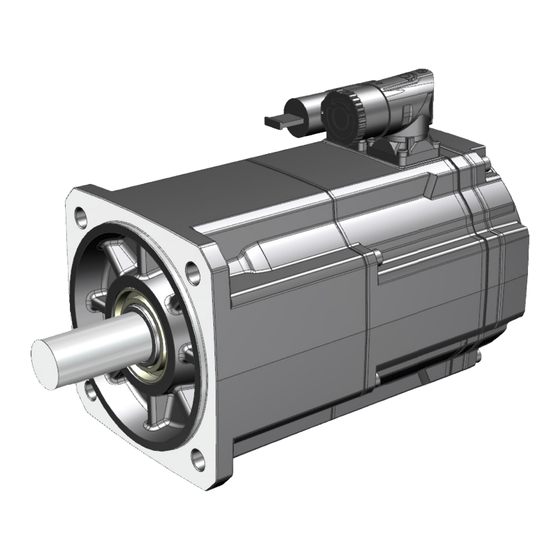

- Page 1 Edition 02/2022 OPERATING INSTRUCTIONS SIMOTICS S-1FK2 synchronous motors For SINAMICS S120 www.siemens.com/drives...

- Page 3 Introduction Fundamental safety instructions for the SIMOTICS documentation SIMOTICS Description of the motors Drive technology Mounting and options SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Preparing for use Operating Instructions Mounting Connecting Commissioning During operation Faults and their rectification Maintenance...

- Page 4 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 5: Introduction

About these operating instructions These operating instructions apply to the SIMOTICS S-1FK2 servo motor, referred to as "1FK2" in this document. The Operating Instructions provide information about the components that enable the target group to install, set up, test, commission, operate, and troubleshoot the products and systems correctly and safely. - Page 6 My Support Links and Tools (https://support.industry.siemens.com/cs/de/en/my) You can individually compile your personal library, e.g. for your documentation based on Siemens content, and adapt it for your own machine documentation. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 7 Later, you can log on with your login data. You can create your own personal library under "mySupport" using the following procedure. Precondition You have registered for and logged on to "Siemens Industry Online Support", hereinafter referred to as "SIOS". SIOS (https://support.industry.siemens.com/cs/de/en/) Procedure for creating a personal library 1.

- Page 8 Siemens does not control the information on these websites and is not responsible for the content and information provided there. The user bears the risk for their use.

-

Page 9: Table Of Contents

Preparing for use ..........................51 Shipping and packaging ..................... 51 Transportation and storage ....................52 4.2.1 Transport ........................... 52 4.2.2 Storage..........................55 Mounting ............................. 57 Safety instructions ......................57 SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 10 Motor replacement on reaching the bearing life ..............97 10.3 Repair, replacing the motor ....................98 Decommissioning and disposal ......................101 11.1 Safety instructions ......................101 11.2 Decommissioning, removing the motor ................102 11.3 Disposal........................... 103 SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 11 Dimension drawing 1F☐2105 ..................109 13.4 Dimension drawing 1F☐2205 ..................110 13.5 Dimension drawing 1F☐2☐06 ..................111 13.6 Dimension drawing 1F☐2208 ..................112 13.7 Dimension drawing 1F☐2210 ..................113 SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 12 Table of contents SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 13: Fundamental Safety Instructions For The Simotics Documentation

• Only use power supplies that provide SELV (Safety Extra Low Voltage) or PELV- (Protective Extra Low Voltage) output voltages for all connections and terminals of the electronics modules. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 14 • Tighten all power connections to the prescribed torque. • Check all power connections at regular intervals, particularly after equipment has been transported. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 15 • Therefore, if you move closer than 20 cm to the components, be sure to switch off radio devices, cellphones or WLAN devices. • Use the "SIEMENS Industry Online Support app" only on equipment that has already been switched off.

- Page 16 • When transporting or storing permanent-magnet motors always use the original packing materials with the warning labels attached. • Clearly mark the storage locations with the appropriate warning labels. • IATA regulations must be observed when transported by air. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 17 • Mount the motor so that it is not accessible in operation. Measures when maintenance is required: • Allow the motor to cool down before starting any work. • Use the appropriate personnel protection equipment, e.g. gloves. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 18: Equipment Damage Due To Electric Fields Or Electrostatic Discharge

Siemens’ products and solutions undergo continuous development to make them more secure. Siemens strongly recommends that product updates are applied as soon as they are available and that the latest product versions are used. Use of product versions that are no longer supported, and failure to apply the latest updates may increase customer’s exposure to cyber... -

Page 19: Residual Risks Of Power Drive Systems

– Component failure – Software errors – Operation and/or environmental conditions outside the specification – External influences/damage SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 20 6. Influence of network-connected communication systems, e.g. ripple-control transmitters or data communication via the network For more information about the residual risks of the drive system components, see the relevant sections in the technical user documentation. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 21: Description Of The Motors

• If you are affected, stay a minimum distance of 30 cm away from the motors (tripping threshold for static magnetic fields of 0.5 mT according to Directive 2013/35/EU). Please contact your local Siemens office in the following cases: • If you wish to use special versions and design variants whose specifications vary from the motors described in this document. -

Page 22: Technical Characteristics And Ambient Conditions

However, the use of the products in a typical machine application has been fully assessed for compliance with the main regulations in this directive concerning health and safety. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 23 Specifically developed motors and functions are the exceptions in this case. Here, it is crucial that you carefully observe the content of the quotation and that there is a UL or cUL mark on the rating plate! SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 24 Description of the motors 2.2 Technical characteristics and ambient conditions Quality systems Siemens AG employs a quality management system that meets the requirements of ISO 9001 and ISO 14001. Certificates for SIMOTICS motors can be downloaded from the Internet at the following link: Certificates for SIMOTICS motors (https://support.industry.siemens.com/cs/ww/de/ps/13347/...

-

Page 25: General Technical Features

Th.Cl.155 (F) EN60034 m: 6 kg IP 64 IC410 Encoder AM22DQC G02 RN 000 Siemens AG, DE-97616 Bad Neustadt Made in Germany ② Figure 2-2 Article number of the basic motor type (example illustration for 1FK2) Note ① The article number stated on the China Energy Label corresponds to the article number of the ②... -

Page 26: Ambient Conditions

A cooling system based on natural convection can be disturbed by unforeseen air movements. The limit value of 89 kPa covers applications at altitudes up to 1000 m. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 27: Degree Of Protection

With degree of protection IP65, it is not permissible for liquid to collect in the flange. The service life of the radial shaft seal ring is approximately 25000 operating hours. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 28: Noise Emission

Due to the decreasing air pressure in higher installation altitudes, the cooling of the motor deteriorates. Therefore, reduce the power of the motor as the installation altitude increases. Multiply the permissible torques or powers by the factors from the following table. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 29 1000 m above sea level (see Chapter "Data sheets and characteristic curves" in the Configuration Manual) Motor speed Derating factor from the table "Factors for reducing the power..." above SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 30 Factors for reducing the DC link voltage depending on the air pressure Installation altitude above sea Air pressure in hPa Reduction factor level in m 2000 3000 0.887 SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 31 As the DC link voltage is reduced, the converter output voltage also decreases. This reduces the operating range in the M-n diagram. The M-n diagrams are contained in the associated Configuration Manual. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 32: Structure Of The Article Number

Description of the motors 2.3 Structure of the article number Structure of the article number The article number describes the motor with the following structure. Article number structure for 1FK2 SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 33 (14 mm x 30 mm), only for 1FK2☐04 Encoder Absolute encoder, singleturn, 22-bit (encoder AS22DQC) Absolute encoder 22-bit + 12-bit multiturn (encoder AM22DQC) Connection system 2CC (two cable system) for S120 Version number Start SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 34: Rating Plate Data

Maximum permissible speed of the motor n Data of the holding brake Certifications Manufacturer's address Standard for all rotating electrical ma‐ chines Stall current I Data matrix code SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 35: Mounting And Options

Dispose of the motor in accordance with WEEE Directive 2012/19/EU. Note Glue on the warning and information labels If product warning and information labels are provided, attach them to the product so that they are clearly visible. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 36: Shaft Extension

10 × 8 × 70 Shaft extensions 11 (k6) mm × 23 mm and 14 (k6) × 30 are only available without keyway and without shaft sealing ring (IP65). SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 37: Bearing Version

Mounting and options 3.3 Bearing version Bearing version The 1F☐2 motors have deep-groove ball bearings with lifetime grease lubrication. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 38: Permissible Radial And Axial Forces

All radial forces always refer to aligned forces. NOTICE Motor damage caused by circulating forces Circulating forces can cause bearing motion, and therefore damage the motor. • Circulating forces are not permissible. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 39 (L10h) of 25000 h. Radial force diagram 1F☐2☐03 Figure 3-2 Maximum permissible radial force F at a distance x from the shaft shoulder for a nominal bearing lifetime of 25000 h. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 40 3.4 Permissible radial and axial forces Radial force diagram 1F☐2☐04 Figure 3-3 Maximum permissible radial force F at a distance x from the shaft shoulder for a nominal bearing lifetime of 25000 h. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 41 3.4 Permissible radial and axial forces Radial force diagram 1F☐2105 Figure 3-4 Maximum permissible radial force F at a distance x from the shaft shoulder for a nominal bearing lifetime of 25000 h. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 42 3.4 Permissible radial and axial forces Radial force diagram 1F☐2205 Figure 3-5 Maximum permissible radial force F at a distance x from the shaft shoulder for a nominal bearing lifetime of 25000 h. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 43 3.4 Permissible radial and axial forces Radial force diagram 1F☐2☐06 Figure 3-6 Maximum permissible radial force F at a distance x from the shaft shoulder for a nominal bearing lifetime of 25000 h. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 44 3.4 Permissible radial and axial forces Radial force diagram 1F☐2208 Figure 3-7 Maximum permissible radial force F at a distance x from the shaft shoulder for a nominal bearing lifetime of 25000 h. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 45 3.4 Permissible radial and axial forces Radial force diagram 1F☐2210 Figure 3-8 Maximum permissible radial force F at a distance x from the shaft shoulder for a nominal bearing lifetime of 25000 h. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 46: Thermal Motor Protection

In this case, the thermal protection routine requires that the ambient temperature is specified in parameter p0613. For more details about parameter p0613, see "SINAMICS S120 List Manual". SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 47: Encoder

Resolution 4,194,304 = 22 bit 4,194,304 = 22 bit Absolute position Yes, one revolution Yes, 4096 revolutions (12 bits) Maximum angular error ± 100 " ± 100 " SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 48: Cooling

The motor is naturally cooled. The power loss is dissipated through thermal conduction, thermal radiation and natural convection. Note the specifications on thermally non-insulated mounting and on thermally insulated mounting. You will find information on this in the relevant configuration manual. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 49: Holding Brake

Axial forces on the shaft extension can damage motors with an integrated holding brake. • Avoid impermissible forces on the shaft extension. You can find the permitted axial forces in the section "Permissible radial and axial forces (Page 36)". SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 50: Technical Specifications

The technical data for the holding brake is contained in the Configuration Manual of the motor. 3.8.2 Technical specifications The following table contains technical specifications of the holding brakes: Note The following specifications apply to control with 24 V DC. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 51 If the brake is switched in two stages (two clicks), the first switching point is decisive for opening and the second for closing. Current Time Opening time Closing time Brake opened Figure 3-9 Terminology (time) for holding operation Holding torque M SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 52 Load moment of inertia of the mounting part on the motor with brake (kgm load 182.4 Constant for calculating the circular frequency and SI units The corresponding data is provided in the Configuration Manual SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 53: Preparing For Use

Note Siemens will not accept any claims for missing or incorrect items submitted at a later date. • Report any visible transportation damage to the delivery company immediately. • Report any visible defects or missing items to the competent Siemens office immediately. -

Page 54: Transportation And Storage

• Only use lifting slings that are suitable for the weight of the motor. • Attach the lifting slings as shown in the figure "Lifting and transporting with lifting slings". SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 55 • Do not use bent or damaged eyebolts. • Only use eyebolts with laminated fiber washers. • Loads applied transversely to the plane of the eyebolts are not permitted. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 56 1. Screw in the lifting eyes (eyebolts) depending on the position of the motor during transport. ① Position of the eyebolts 2. Hook the crossbar into the eyebolts (lifting eyes). Figure 4-2 Transporting the motor with a beam (example) SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 57: Storage

Store the motor in a dry, dust-free, and vibration-free indoor storage facility. Adhere to the following values: • v < 0.2 mm/s • Max. temperatures: -15° C to 55° C • Mean relative humidity < 75% SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 58 The following ambient conditions encourage the formation of condensation: • Significant ambient temperature fluctuations, • Direct sunshine, • High humidity during storage. Avoid these ambient conditions. Use a dehydrating agent in the packaging. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 59: Mounting

• Remove any loose parts or secure them so that they cannot be flung out. • Do not touch any moving parts. • Safeguard all moving parts using the appropriate touch protection. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 60 • Ensure that no temperature-sensitive parts come into contact with hot surfaces. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 61: Checklists Prior To Mounting

Are the mounting surfaces free of corrosion? Do the mounting dimensions (e.g. shaft diameter, shaft length, true run) on the customer machine meet the specification? SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 62: Mounting Instructions

Washer ISO 7092 Tightening torque for bolts (not for elec‐ in mm trical connections) 1F☐2☐03 5 (d2 = 9) 4 Nm 1F☐2☐04 6 (d2 = 11) 8 Nm 1F☐2205 SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 63 Tightening torque for bolts (not for elec‐ in mm trical connections) 1F☐2105 8 (d2 = 15) 20 Nm 1F☐2☐06 1F☐2☐08 10 (d2 = 18) 35 Nm 1F☐2☐10 12 (d2 = 20) 60 Nm SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 64: Mounting The Feather Key

3. Before operating the motor, you must mount drive elements, e.g. a belt pulley or a coupling, on the shaft extension with feather key. ❒ You have mounted the feather key. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 65: Mounting The Drive Elements

Motors with feather key are half-key balanced. The motors have been balanced with half a feather key. The motor dimensions can be found in section "Dimension drawings (Page 107)". SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 66: Vibration Response

The vibration acceleration is evaluated in the frequency range from 10 Hz … 2000 Hz. The maximum peak in the measurement time range is taken into consideration. The vibration values must not exceed the specified limits at any measuring location. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 67 End shield DE radial End shield NDE radial End shield DE radial End shield NDE axial End shield DE axial End shield NDE radial Figure 5-4 Measuring points for vibration values SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 68 Mounting 5.6 Vibration response SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 69: Connecting

• When connected to IT line supplies, a monitoring device must signal the first fault between an active part and ground. Eliminate this fault immediately. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 70: Permissible Line System Types

(secondary side) must be connected between the line supply and the drive system to protect the motor insulation from excessive stress. The majority of TT systems have a grounded external conductor, so in this case an isolating transformer must be used. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 71: System Integration

• Adapt the connecting cables to the type of use and the voltages and currents that occur. • Use prefabricated cables from SIEMENS (not in the scope of delivery). These cables reduce installation costs and increase operational reliability (see the Product Information). -

Page 72: Rotating The Connector On The Motor

Unscrew and open the socket connector completely to avoid damaging the pin contacts. Note Rotating the connectors • Do not exceed the permissible range of rotation. • To ensure the degree of protection, do not rotate more than 10 times. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 73 1F☐2☐06 1F☐2☐08 1F☐2☐10 Table 6-5 Maximum rotating torque for the connectors Connectors Max. torque when rotating Connector M17 8 Nm Connector M23 12 Nm Connector M40 20 Nm SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 74: Line Connection

The connector pin assignment is as follows. M17 signal connector, with DRIVE-CLiQ TX-P TX-N RX-P RX-N 24 V The signal connector can be twisted in a certain range. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 75: Connecting To A Converter

6.3.4.1 Selecting and connecting cables • Use prefabricated MOTION CONNECT cables from SIEMENS or shielded connecting cables. The appropriate cables for your motor are listed in the Configuration Manual. • The prefabricated MOTION CONNECT cables reduce installation costs and increase the... - Page 76 BD1+ and BD2- = brake cable without lettering, 1.5 mm , shielded together PE = protective conductor Cable shield Conductor designations Recommended length of the cable ends: 105 mm SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 77 BD1+ and BD2- = brake cable without lettering, 1.5 mm , shielded together PE = protective conductor Cable shield Conductor designations Recommended length of the cable ends: 105 mm SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 78 Recommended length of the cable ends: 105 mm Locking the round connectors Properly lock the connected round connector at the motor. Information on locking is provided in Chapter "Handling the quick-action locking (Page 77)". SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 79: Handling The Quick-Action Locking

You can connect quick-connection cables with SPEED-CONNECT as well as conventional cables with screw locks (fully threaded) to the motor connector. Note We recommend cables with SPEED-CONNECT because they are easier to use. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 80 Maximum locking up to the end stop Note A secure connection is only guaranteed from position A onward. You have established a secure connection. Releasing a SPEED-CONNECT connection Procedure SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 81 If you are operating the motor in environments in which moisture can arise follow the installation instructions below. Figure 6-1 Permissible and impermissible cable routing when connecting in a damp environment SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 82 Connecting 6.3 System integration SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 83: Commissioning

• Never touch the terminals when making measurements or immediately after the measurement. • Check the connected supply feeder cables to ensure that the line supply voltage cannot be connected. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 84 Impermissible speeds can cause damage to the motor. • Ensure that the maximum permissible speed is not exceeded. Realize this using a suitable control system or activate the speed monitoring function in the drive. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 85 Operating the motor holding brake outside its permissible voltage range at the motor connection will damage the brake. • Ensure that the motor holding brake is only operated within its permissible voltage range. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 86: Checklists For Commissioning

Has the belt drive tension been correctly adjusted? • Have the gear tooth flank and gear tooth tip play as well as radial play been correctly adjusted for geared outputs? SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 87 Table 7-6 Checklist (6) - Checks regarding the optional brake Check Is the brake open when the operating voltage is applied? Does the brake open and close correctly? SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 88: Commissioning Procedure

2. Follow the steps of the commissioning tool to commission the motor ❒ You have commissioned the motor. Switching off • Switch off the motor at the frequency converter. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 89: Switching On And Switching Off

3. Check the function of the safety equipment. 4. Check whether the motor reaches the required parameters ❒ You have switched on the motor. Switching off • Switch off the motor at the frequency converter. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 90 Commissioning 7.4 Switching on and switching off SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 91: During Operation

Make sure that: • The power consumption is in the specified range • Cooling is ensured • There is no abnormal motor noise • The motor does not overheat SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 92: Stoppages

Chapter "Commissioning (Page 81)". • Before switching on to recommission the system, carefully observe the notes in Chapter "Switching on and switching off (Page 87)". SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 93: Faults And Their Rectification

Humming sound in operation High temperature rise under no-load oper‐ ation High temperature rise under load Uneven running Grinding sound, running noise Radial vibrations M N O P Axial vibrations SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 94 Fault originating from the gearbox Adjust/repair gearbox If the fault still cannot be resolved after taking the measures stated above, please contact the manufacturer or the Siemens Service Center. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 95: Maintenance

• Prevent oil from leaking. • Absorb leaked oil immediately with a binding agent for oil or similar. • Rough up the hazardous location. • Mark the hazardous location. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 96 When you clean using compressed air, this can stir up dust, metal chips and cleaning agents, and so cause injuries. • When cleaning using compressed air, make sure you use suitable extraction equipment and wear protective equipment (safety goggles, protective suit, etc.). SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 97 • The motor must not be lifted or transported by means of the power connector or signal connector. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 98: Inspection And Maintenance

The maintenance and repair of the motor can be performed in authorized Siemens Service Centers all over the world. Contact your personal Siemens representative if you would like to take advantage of this service. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120... -

Page 99: Cleaning

The maintenance and repair of the motor can be performed in authorized Siemens Service Centers all over the world. Contact your personal Siemens representative if you would like to take advantage of this service. More information is provided in Chapter "Repair, replacing the motor (Page 98)". -

Page 100: Repair, Replacing The Motor

If you want to replace the motor with a motor with a different article number, you must perform converter commissioning after replacing the motor. You will find more precise information in the manual for the converter in question SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 101 – Connect the motor plug. Detailed information is provided in Chapter "Notes for connecting the round connector at the motor". 3. Switch the converter on. ❒ You have replaced the motor. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 102 Maintenance 10.3 Repair, replacing the motor SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 103: Decommissioning And Disposal

Motors and machine components can fall when being dismantled from the machine. They can cause serious injury or property damage. • Secure the machine components being dismantled to prevent them falling. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 104: Decommissioning, Removing The Motor

4. Remove the fixing elements from the motor. 5. Transport the motor to a suitable location for disposal. You have removed the motor. ❒ Dispose of the motor in accordance with the local legal requirements. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 105: Disposal

For environmentally-friendly recycling and disposal of your old device, please contact a company certified for the disposal of waste electrical and electronic equipment, and dispose of the old device as prescribed in the respective country of use. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 106 Decommissioning and disposal 11.3 Disposal SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 107: Technical Data And Characteristics

Technical data and characteristics You will find the technical data for the various frame sizes of the motors in the configuration manual in Chapter "Technical data and characteristics". SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 108 Technical data and characteristics SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

-

Page 109: Dimension Drawings

/ mm Motors max. 480 V 1F☐2103-2AH 14 (h6) 11 (k6) 1F☐2203-2AK 1F☐2103-4AH 1F☐2203-4AK You will find further dimensions in the dimension drawings in the relevant catalog. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 110: Dimension Drawing 1F☐2☐04

/ mm d / mm l / mm 1F☐2104-4 19 (k6) 14 (k6) 1F☐2☐04-5 1F☐2☐04-6 You will find further dimensions in the dimension drawings in the relevant catalog. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 111: Dimension Drawing 1F☐2105

Overall length of the motor without brake with brake k / mm k1 / mm 1F☐2105-4 1F☐2105-6 You will find further dimensions in the dimension drawings in the relevant catalog. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 112: Dimension Drawing 1F☐2205

/ mm o / mm k1 / mm o1 / mm 1F☐2205-2 1F☐2205-4 You will find further dimensions in the dimension drawings in the relevant catalog. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 113: Dimension Drawing 1F☐2☐06

/ mm k1 / mm 1F☐2106-3 1F☐2106-4 1F☐2106-6 1F☐2206-2 1F☐2206-4 You will find further dimensions in the dimension drawings in the relevant catalog. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 114: Dimension Drawing 1F☐2208

Overall length of the motor without brake with brake k / mm k1 / mm 1F☐2208-3 1F☐2208-4 1F☐2208-5 You will find further dimensions in the dimension drawings in the relevant catalog. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... -

Page 115: Dimension Drawing 1F☐2210

/ mm k1 / mm 1F☐2210-3A☐ 1F☐2210-4AB 1F☐2210-4AC 1F☐2210-4AF 1F☐2210-5A☐ You will find further dimensions in the dimension drawings in the relevant catalog. SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD... - Page 116 Dimension drawings 13.7 Dimension drawing 1F☐2210 SIMOTICS S-1FK2 synchronous motors for SINAMICS S120 Operating Instructions, 02/2022, A5E46089564B AD...

- Page 118 More information Siemens: www.siemens.com/simotics Industry Online Support (service and support): www.siemens.com/online-support Industry Mall: www.siemens.com/industrymall Siemens AG Digital Industries Motion Control Postfach 31 80 91050 ERLANGEN Germany Scan the QR code for more informa- tion about SIMOTICS.

Need help?

Do you have a question about the SIMOTICS S-1FK2 and is the answer not in the manual?

Questions and answers