Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Operator's Manual

Advertisement

Table of Contents

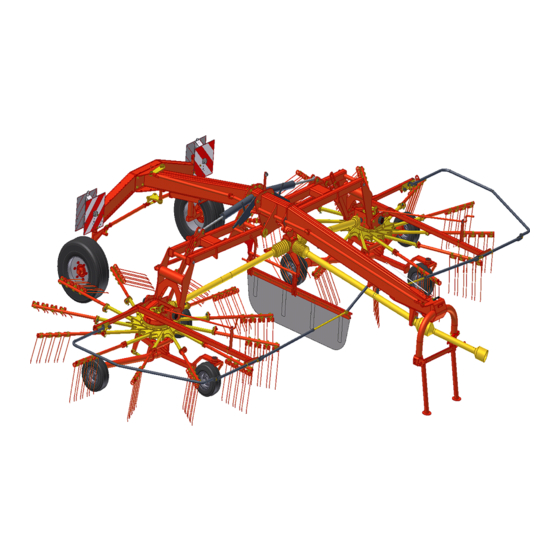

Summary of Contents for Kongskilde R+ 760

- Page 1 ORIGINAL INSTRUCTIONS - according to Directive 2006/42/EC, Annex I 1.7.4.1 OPERATOR’S MANUAL R+ 760 R+ 820 Rake Part number 81PIGB-185x edition English February 2018...

- Page 3 All the information, illustrations and technical specifications in this instruction manual describe the latest version at the time of publication. Kongskilde Industries A/S reserves the right to make changes or improvements in the design or construction of any part without incurring the obligations to install such changes on any unit previously delivered.

-

Page 4: Table Of Contents

CONTENTS In general Intended use Foreseeable misuse General safety instructions Technical data 1.4.1 Manufacturer’s address 1.4.2 Certificates 1.4.3 Marking of the machine 1.4.4 General technical data Safety Marking of safety instructions in the instruction manual Safety rules and accident prevention 2.2.1 Power take-off 2.2.2 Hydraulic system 2.2.3 Tyres... - Page 5 Mounting of the rake / preparation Special instructions Preparation of tractor 4.2.1 3-point suspension on the tractor 4.2.2 Placement of cord 4.2.3 Hydraulic system (throttling) 4.2.4 Electric system Connection of the rotary rake to the tractor 4.3.1 Connection to the link arms of the tractor 4.3.2 Hydraulic connection 4.3.3 Connection of lighting equipment 4.3.4 Connection of PTO shaft...

- Page 6 Service and maintenance of the rake Safety rules General maintenance instructions Cleaning of the machine and preparation for winter storage 7.3.1 Cleaning of the machine 7.3.2 Placement of the rake in the open 7.3.3 Winter storage Hydraulic system Wheels 7.5.1 Tyre pressure PTO shafts Replacement of bearing units Greasing...

-

Page 7: In General

1. IN GENERAL ___________________________________________________________________________ 1. IN GENERAL This instruction manual contains important information concerning operation, maintenance and adjustment of the machine. Furthermore, all safety instructions are mentioned and emphasized. Read the instruction manual carefully before using the machine. The instruction manual should be accessible for the operator. All safety instructions must be observed. -

Page 8: Foreseeable Misuse

1. IN GENERAL Foreseeable misuse Sweeping of e.g. farmyards with the rake tines or brooms fastened to these is not allowed. There is a risk that e.g. stones are thrown out from the working area of the machine with danger of personal injury or damage to objects. ... -

Page 9: Technical Data

15. Do not allow any children to be near when you are working with the machine. 16. Never stand between the tractor and the machine during connection and disconnection. Technical data 1.4.1 Manufacturer’s address Kongskilde Industries A/S DK-6400 Sønderborg – Denmark Phone: +45-74125252 1.4.2 Certificates - EC-Declaration of conformity (See page 68) PIGB-185X 02 R+760 –... -

Page 10: Marking Of The Machine

1. IN GENERAL 1.4.3 Marking of the machine The machine data are printed on the machine plate. The machine plate is placed in the right-hand side in the direction of travelling behind the suspension at the front frame. Machine plate The marking on the machine should neither be changed nor removed! The information on the machine plate can be written below so that it is always at... -

Page 11: General Technical Data

1. IN GENERAL 1.5.4 General technical data Technical data: R+760 R+820 Rotor diameter: 3.20 m 3.50 m Tine arms per rotor: Double tines per tine arm: Working width, max: 7.60 m 8.20 m Working width, min: 6.85 m 7.40 m For alfalfa: 6.50 7.00 m... -

Page 12: Safety

2. SAFETY ___________________________________________________________________________ 2. SAFETY Marking of safety instructions in the instruction manual In this instruction manual this symbol is used with reference to personal safety directly and indirectly through maintenance of the machine. This symbol (safety marking according to DIN 4844-W9) is supplemented with the following references: General references are marked with this symbol: Reference signs on the machine must be observed and kept in a readable condition. - Page 13 2. SAFETY 7. Always check the area around the machine before working, especially for children! Make sure that your view is sufficient! 8. Never allow anybody to be on the machine during work and transport. 9. The machine must be connected as per instructions and should only be secured/fastened at the prescribed devices! 10.

-

Page 14: Power Take-Off

2. SAFETY 24. Hydraulically foldable frames should only be activated when there are no persons in the swivel area! 25. At remote-controlled (e.g. hydraulically controlled) units may be places where there is danger of injury! 26. Lower the machine to the ground, stop the engine and remove the ignition key before leaving the tractor! 27. -

Page 15: Hydraulic System

2. SAFETY 10. Before starting the PTO check that there are no persons in the danger zone of the machine! 11. Never connect the PTO if the engine has stopped! 12. When working with the PTO make sure that no persons stand near the rotating PTO shaft. -

Page 16: Tyres

2. SAFETY 6. To avoid injury it is important to use appropriate tools when searching for leakages! 7. Liquid (hydraulic oil) under high pressure can penetrate the skin and cause serious injury! In case of injury, consult a doctor immediately! Danger of infection! 8. -

Page 17: Maintenance

2. SAFETY 2.2.5 Maintenance In general: When repairing or maintaining the machine it is especially important to ensure correct personal safety. Therefore, always park the tractor (if mounted) and the machine according to the GENERAL SAFETY RULES items 1-16 in the beginning of this instruction manual. - Page 18 2. SAFETY 1. Maintenance, service, cleaning and repair must only take place when the PTO and the engine have been stopped! - Remove the ignition key! - Apply the hand brake of the tractor or secure the rake so that it cannot move! 2.

-

Page 19: Placement Of Safety Signs On The Machine

2. SAFETY 2.3 Placement of safety signs on the machine Read the instruction manual and safety instructions carefully before using the machine, and observe the instructions! Stop the PTO and the engine and remove the ignition key before carrying out maintenance, repair and service! PIGB-185X 02 R+760 –... - Page 20 2. SAFETY Wait until all machine parts have come to a complete stop before touching them! Keep a safe distance from the rotating parts of the machine! Never stand in the swivel and folding area of the rotors! Check the safety pins for wear! If the thickness is less than 7 mm they must be replaced immediately! Risk of injury.

- Page 21 2. SAFETY Be aware of the rake tines of the rotor in transport position, risk of personal injury. After the first 5 hours of operation all bolt joints must be re-tightened. The hydraulic pressure should be maximum 210 bar. Warning sign, reflecting PIGB-185X 02 R+760 –...

-

Page 22: Placement Of Normal Reference Signs On The Machine

2. SAFETY Placement of normal reference signs on the machine LOGO Adjustment of working width PIGB-185X 02 R+760 – R+820 0218... - Page 23 2. SAFETY Adjustment of lifting height Decal tyre pressure Decal turning angle Decal adjustment of cam track Adjustment of number of revolutions PIGB-185X 02 R+760 – R+820 0218...

- Page 24 2. SAFETY Reference lifting eye Reference lubrication of cam track Decal adjustment of working height 40km/h sign PIGB-185X 02 R+760 – R+820 0218...

-

Page 25: Mounting Of The Machine After Delivery

3. MOUNTING OF THE MACHINE AFTER DELIVERY ___________________________________________________________________________ 3. MOUNTING OF THE MACHINE AFTER DELIVERY Mounting of the rotary rake must only be carried out by experts. The necessary tools and adjustment tools must be at disposal. After mounting a complete functional test of the machine must be carried out. -

Page 26: Turning Of Steering Knuckles / Mounting Of Steering

3. MOUNTING OF THE MACHINE AFTER DELIVERY Turning of steering knuckles / mounting of steering For transport by lorry the steering knuckles have been turned inwards and fixed in this position with a transport safety device. The steering rods have been loosened from the steering knuckles. -

Page 27: Mounting Of Warning Panels

3. MOUNTING OF THE MACHINE AFTER DELIVERY Mounting of warning panels The front and rear warning panels are folded in and fastened for transport by lorry (see picture on previous page). The upper screws are loosened and placed so that they fit into the holes and are then tightened again (see above figure). -

Page 28: Mounting Of Swath Guard

3. MOUNTING OF THE MACHINE AFTER DELIVERY Mounting of swath guard The swath guard is dismounted as a unit together with holders (1,2) and control rod (3) and is supplied on a pallet. Procedure: Holder (1) is screwed on under the gear. 4 x screw (Position A) 4 x washer... -

Page 29: Mounting Of Rotors

3. MOUNTING OF THE MACHINE AFTER DELIVERY Mounting of rotors R+760: For the transport by lorry the rotors are separated from the boom (6) at the cardinal fishplates (1). The steering fishplates (2, 3) are also separated from the rotor and remain at the boom. - Page 30 3. MOUNTING OF THE MACHINE AFTER DELIVERY R+820 For the transport by lorry the rotors are separated from the boom (6) at the cardinal fishplates (1). The steering fishplates (2, 3) are also separated from the rotor and remain at the boom. The steering fishplate 2 (uppermost with cam) must be mounted to the pin on the boom which is further out than the one for steering fishplate 3.

-

Page 31: Mounting Of Pto Drive Shafts

3. MOUNTING OF THE MACHINE AFTER DELIVERY Mounting of PTO drive shafts After mounting of the rotors, the PTO shafts must be connected. These are equipped with a protective cover in the one side. The PTO shafts from gearbox to rotor are pushed in and fastened to the gearbox with clamps. -

Page 32: Mounting Of Safety Frames

3. MOUNTING OF THE MACHINE AFTER DELIVERY Mounting of safety frames The safety frames (3) are dismounted from the rotor head as complete unit and are supplied on a pallet. These are fastened to the rotor head with 4 screws (4) each. The telescopic safety frames (1, 2) are folded up and fastened to the frame. -

Page 33: Mounting Of Hydraulic Lock (Optional Equipment)

3. MOUNTING OF THE MACHINE AFTER DELIVERY Mounting of hydraulic lock (optional equipment) The optional equipment “hydraulic lock” is not mounted from the factory. It must be mounted by the dealer or the user after delivery of a new machine or be retro-fitted. Procedure: 1. -

Page 34: Functional Test

3. MOUNTING OF THE MACHINE AFTER DELIVERY After mounting, the hose placement must be checked by carefully raising and lowering. The hose from the lifting cylinder to the valve should not get caught or squeezed anywhere. It must be as shown on the picture below. 3.10 Functional test After the preparation of the rotary rake, a functional test must be carried out. -

Page 35: Mounting Of Extra Wheels On Rotor Chassis (Optional Equipment)

3. MOUNTING OF THE MACHINE AFTER DELIVERY 3.11 Mounting of extra wheels on rotor chassis (optional equipment) In soft or wet fields it may be necessary to relieve the wheels on the rotor chassis. This can be done with the wheels (1) which can be supplied as optional equipment. These are spring-loaded and articulated. -

Page 36: Mounting Of The Rake / Preparation

4. MOUNTING OF THE RAKE / PREPARATION ___________________________________________________________________________ 4. MOUNTING OF THE RAKE / PREPARATION Always disengage the PTO drive shaft before maintaining, repairing and mounting. Stop the engine and remove the ignition key. Secure the tractor and the rotary rake so that they cannot move! ... -

Page 37: Preparation Of Tractor

4. MOUNTING OF THE RAKE / PREPARATION Preparation of tractor 4.2.1 3-point suspension on the tractor The rakes R+760 and R+820 are equipped with hitch pins cat. 2. Depending on the equipment of the tractor, balls can be installed. The sideways movement of the link arms on the tractor must be minimised in order to avoid oscillation of the machine during work and transport. -

Page 38: Placement Of Cord

4. MOUNTING OF THE RAKE / PREPARATION 4.2.2 Placement of cord It should be possible to operate the cord for the locking pawl from the tractor seat. It must be ensured that it does not get jammed and is not placed on sharp edges. The cord must be relieved when the pawls are lowered. -

Page 39: Connection Of The Rotary Rake To The Tractor

4. MOUNTING OF THE RAKE / PREPARATION 4.3 Connection of the rotary rake to the tractor The instructions are based on a fully mounted rotary rake in locked transport position. 4.3.1 Connection to the link arms of the tractor Never stand between the tractor and the rake during connection to the tractor. -

Page 40: Hydraulic Connection

4. MOUNTING OF THE RAKE / PREPARATION 4.3.2 Hydraulic connection For the conversion from transport to working position of the rotary rakes R+760 and R+820 a single-acting outlet is needed. Make sure that there is a floating position so that the rake can follow the ground during operation. The stop valve on the machine side (ball valve) should be opened after the connection to the tractor hydraulics so that the coupling is not under pressure. -

Page 41: Connection Of Hydraulic Lock (Optional Equipment)

4. MOUNTING OF THE RAKE / PREPARATION 4.3.5 Connection of hydraulic lock (optional equipment) For the hydraulic lock there must be a 1-pole 12V socket on the tractor. The plug of the operating unit is connected on the tractor. Caution: Check the position of the switch before you start working. The valve for the hydraulic lock is open when there is no current on the valve! The operating unit is installed... -

Page 42: Handling Of The Rake During Working

5. HANDLING OF THE RAKE DURING WORKING ___________________________________________________________________________ HANDLING OF THE RAKE DURING WORKING The following description implies that the rake is completely mounted according to chapter 3 and connected to the tractor according to chapter 4. The machine is in transport position. Conversion of the rake from transport to working position 5.1.1 Release of rotor arms and lowering of rotor ... -

Page 43: Safety Frame Is Placed In Working Position

5. HANDLING OF THE RAKE DURING WORKING 5.1.3 Safety frame is placed in working position The safety frame (1) is swivelled 180° outwards, until the locking mechanism (2) is safely engaged above the safety frame (1). Starting the rotor The tractor PTO is connected at idle speed and the number of revolutions is increased to 380-450 rpm. -

Page 44: Conversion Of The Rake From Working To Transport Position

5. HANDLING OF THE RAKE DURING WORKING Conversion of the rake from working to transport position Before folding of the rake check that there are no persons in the swivel area. Check that there are no obstacles, e.g. trees, masts etc., which may hinder the folding. -

Page 45: Rotor Arms Are Raised And Locked

5. HANDLING OF THE RAKE DURING WORKING 5.4.3 Rotor arms are raised and locked The locking pawls are raised by pulling the cords. The rotors are folded to transport position. The locking pawls are locked by loosening the cord. ... -

Page 46: Adjustment Of Working Width

5. HANDLING OF THE RAKE DURING WORKING Adjustment of working width The rotary rakes R+760 and R+820 can be set to 3 different working widths. This adjustment can only take place when the machine is in transport position. The stop cock of the hydraulic hose must be closed during adjustment. -

Page 47: Alfalfa Position

5. HANDLING OF THE RAKE DURING WORKING 5.5.1 Alfalfa position The rotary rakes have a fourth position for adjustment of the working width. For this purpose the swath guard must be dismounted. The rotors are so close in working position that there is no room for the swath guard. This position is intended for crops which are intertwined in the stubbles and must be lifted once from the ground in the whole working width. -

Page 48: Further Instructions For Working And Driving With The Machine

5. HANDLING OF THE RAKE DURING WORKING Further instructions for working and driving with the machine This machine is equipped with mechanical power steering. This means that the rake approximately follows the track of the tractor. This means that the machine has a very good manoeuvrability. -

Page 49: Securing Of Tines In Transport Position

5. HANDLING OF THE RAKE DURING WORKING For the use of this equipment the tractor must be equipped with a 12V socket. The equipment can also be used through an adaptor for the cigarette lighter. The valve is controlled through an operation unit which is installed in the tractor cabin. -

Page 50: Placement Of Tine Guards

5. HANDLING OF THE RAKE DURING WORKING 5.8.1 Placement of tine guards The tine guards (1) are placed on the tines. No further securing is needed. The tine guards must be placed on the tines in all operating conditions except the working position! 5.8.2 Securing of tine guards during working When the tine guards are not in use, they are stored under the rear frame. -

Page 51: Disconnection Of The Machine

5. HANDLING OF THE RAKE DURING WORKING 5.9 Disconnection of the machine: The rake should either be lowered to working position or be in transport position with the locking pawls safely engaged. The hydraulic system should not be under pressure and the ball valve must be closed. -

Page 52: Basic Adjustment Of The Rake

6. BASIC ADJUSTMENT OF THE RAKE ___________________________________________________________________________ 6. BASIC ADJUSTMENT OF THE RAKE Basic adjustment is carried out with stopped rotors! The tractor engine must be stopped. Never work under the rotors without sufficient support! Height of the link arms Adjust the link arms of the tractor to a height of 68 cm above the ground. -

Page 53: Adjustment Of Crop Delivery Time

6. BASIC ADJUSTMENT OF THE RAKE Adjustment of crop delivery time For adjustment of the crop delivery time the position of the cam track in the rotor can be changed. The adjustment device is placed under the rotor. From the factory the adjustment is set to 70 mm. If the crop delivery time should be later or earlier, the adjustment is changed as follows: ... -

Page 54: Adjustment Of The Rotor Inclination Sideways

6. BASIC ADJUSTMENT OF THE RAKE Adjustment of the rotor inclination sideways For individual adjustment to different material the innermost support wheel on the rotor chassis is placed on an eccentric axle journal (1). To make the adjustment the fixing bolt (2) is removed from the middle position, a wrench (size 30) is applied and the axle journal is turned. -

Page 55: Driving Speed And Number Of Revolutions

6. BASIC ADJUSTMENT OF THE RAKE Driving speed and number of revolutions The driving speed and the number of revolutions during raking depend on the following: The type of crop The amount of crop The ground conditions ... -

Page 56: Service And Maintenance Of The Rake

7. SERVICE AND MAINTENANCE OF THE RAKE ___________________________________________________________________________ 7. SERVICE AND MAINTENANCE OF THE RAKE 7.1 Safety rules Maintenance, service, cleaning and repair must only take place when the PTO and the engine have been stopped. Remove the ignition key! ... -

Page 57: Placement Of The Rake In The Open

7. SERVICE AND MAINTENANCE OF THE RAKE 7.3.2 Placement of the rake in the open If the rake is placed in the open for a longer period, all bearings must be greased according to the lubrication schedule. Parts polished with use and the piston rods of the hydraulic cylinder must be cleaned and brushed with grease to protect against wind and weather. -

Page 58: Wheels

7. SERVICE AND MAINTENANCE OF THE RAKE Wheels The wheels must be checked regularly for damage and correct tyre pressure. Wheel nuts must be checked regularly and re-tightened if necessary! Repair of wheels should only be made by experts and with correct tools! ... -

Page 59: Replacement Of Bearing Units

7. SERVICE AND MAINTENANCE OF THE RAKE Replacement of bearing units If a bearing unit is damaged it can be replaced without disassembling the whole rotor. Divided cover plate (3) Procedure when replacing the bearing unit: The fixing screws (1) of the bearing unit are removed. ... -

Page 60: Greasing

8. GREASING ___________________________________________________________________________ 8. GREASING Maintenance, service, cleaning and repair must only take place when the PTO and the engine have been stopped. Remove the ignition key! Take care that oil and grease do not get in contact with your skin. ... -

Page 61: Grease Spots On The Rake

8. GREASING Grease spots on the rake: 8.2.1 Steering 1. Steering knuckle (both sides) - monthly/ 200 hours - 2 grease points 2. Steering rod (left and right) - monthly/ 200 hours - 4 grease points 3. Steering rod eye - monthly/ 200 hours - 1 grease point 4. -

Page 62: Suspension

8. GREASING 8.2.3 Suspension 8. Bearing suspension - weekly/ 50 hours - 1 grease point 8.3 Grease points at rotor 8.3.1 Rotor gear 9. Rotor housing /disc wheel (both rotors) - daily/8 hours 2 grease points PIGB-185X 02 R+760 – R+820 0218... -

Page 63: Grease Chart Overview

8. GREASING Grease chart overview PIGB-185X 02 R+760 – R+820 0218... -

Page 64: Bevel Gearbox

8. GREASING 8.5 Bevel gearbox The bevel gear is maintenance-free. If gear oil is to be filled up due to loss of oil or repair: Oil content: 1l Oil type: Gear oil SAE 90 On the grease chart overview the position of the gear is shown with number 11. Drained oils must be handed over to a destruction company! PIGB-185X 02 R+760 –... -

Page 65: Machine Disposal

9. MACHINE DISPOSAL ___________________________________________________________________________ 9. MACHINE DISPOSAL: When the machine is worn-out it must be disposed of in a proper way. Observe the following: • The machine must not be placed somewhere outside, - it must be emptied of oil (gearboxes and hydraulic system). These oils must be handed over to a destruction company. -

Page 66: Supplement

10. SUPPLEMENT Translation from Norm EN ISO 4254-10 Supplement C (informative) Stability with the combination tractor – rotary tedder and rake This supplement concerns 6.1.f) in this part of ISO 4254 which deals with the requirement of informing of possible loss of the tractor’s stability due to the connection of the machine. The following text is a suggestion to the manufacturer with the purpose of making it possible for him to provide suitable and complete information. - Page 67 10. SUPPLEMENT List of signs The tractor’s own weight [kg] [kg] Front axle load with empty tractor [kg] Rear axle load with empty tractor [kg] Total weight rear-mounted implement/rear ballast [kg] Total weight front-mounted implement/front ballast a [m] Distance between centre of gravity front-mounted implement/front ballast and middle of front axle 2) 3) The tractor’s wheel distance...

-

Page 68: Warranty

11. WARRANTY 11. WARRANTY Your machine is warranted according to legal rights in your country and the contractual agreement with the selling dealer. No warranty shall, however, apply if the machine has not been used, adjusted and maintained according to the instructions given in this operator's manual. - Page 69 11. WARRANTY EF-overensstemmelseserklæring/ EG-Konformitätserklärung/ EC Declaration of Conformity/ Déclaration CE de conformité/ Dichiarazione CE di conformita/ EG Verklaring van Overeenstemming/ EG-försäkran om överensstämmelse/ EY-vaatimustenmukaisuusvakuutus/ Declaración de conformidad CE/ Deklaracja Zgodności WE./ Декларация за съответствие EO/ EK Megfelelőségi Nyilatkozat /ES Prohlášení o shodě/ EB Atitikties deklaracija/ ES prehlásenie o zhode/ Declaraţia de conformitate CE/ Vastavuse Deklaratsioon EÜ...

- Page 70 - is in conformity with the provisions of the Machinery Directive 2006/42/EC and if relevant also the provisions of the EMC Directive 2014/30/EU. - est conforme aux dispositions de la Directive relatives aux machines 2006/42/CE et également aux dispositions de la Directive sur la Directive EMC 2014/30/UE.

- Page 72 Kongskilde dealer. © 2018 CNH Industrial Belgium N.V. All Rights Reserved. Kongskilde is a trademark registered in the United States and many other countries, owned by or licensed to CNH Industrial N.V., its subsidiaries or affiliates. Any trademarks referred to herein, in association with goods and/or services of companies, other than owned by or licensed to...

Need help?

Do you have a question about the R+ 760 and is the answer not in the manual?

Questions and answers