PoolPak PCP Series Operation And Maintenance Manual

Indoor/outdoor model

Hide thumbs

Also See for PCP Series:

- Operation and maintenance manual (46 pages) ,

- Installation manual (38 pages) ,

- Start-up procedures (20 pages)

Subscribe to Our Youtube Channel

Summary of Contents for PoolPak PCP Series

- Page 1 Operation and Maintenance Manual PCP Series Dehumidifiers PCP 3000 to PCP 6000 PCP 3030 to PCP 5050 Indoor/Outdoor Model FORM #: SVW11-PCPOMMBX-20180828 UPDATED: AUGUST 2018 © 2018 PoolPak LLC. All rights reserved.

-

Page 2: Table Of Contents

Basic Maintenance ........................27 Maintenance and Safety ..........................27 Maintenance Key Points ..........................27 Routine Maintenance Program ........................28 Specific Components Maintenance ......................29 3491 Industrial Drive York, Pennsylvania 17402 USA 717-757-2648 • Fax 717-757-5085 • www.PoolPak.com © 2018 PoolPak LLC. All rights reserved. SVW11-PCPOMMBX-20180828 ASHRAE 62.1-2013... - Page 3 Figure 15. Main Electric Panel........................25 TABLES Table 1. Dehumidifier-AC Combination* ......................9 Table 2. Most Common Alarms/Alerts ......................24 Table 3. Recommended Maintenance Tasks and Intervals................28 © 2018 PoolPak LLC. All rights reserved. PCP Series BX - Operation and Maintenance Manual |...

-

Page 4: General Information

Only qualified technicians should install, operate, maintain or service mechanical equipment including PoolPak’s dehumidification system. Make sure to read this manual before performing any installation tasks to familiarize yourself with the equipment as well as with any potential hazards. Always exercise caution! Beware of electrical power and high electrical voltage! •... -

Page 5: Reference And Additional Information

Any work (installation, start up, service, maintenance, repair, etc.) on any mechanical equipment (dehumidifier, outdoor condenser, fluid cooler, etc.) must be performed in accordance with respective PoolPak recommendations as well as submittal documentation, local Codes and Regulations, and appropriate field practices. -

Page 6: Basic Information

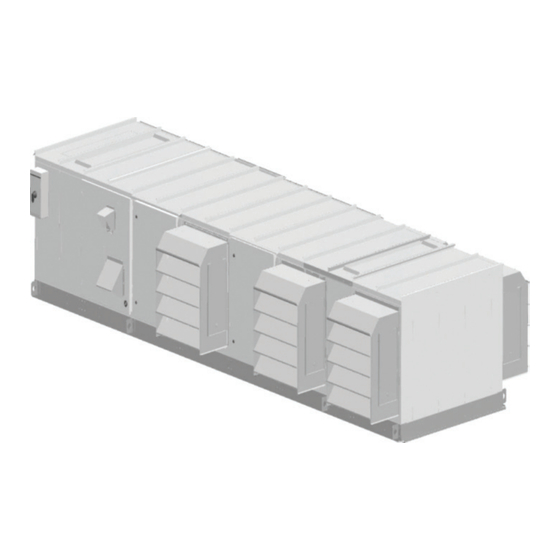

Figure 1 shows only one example of dehumidifier arrangement, refer to submittal documentation for specific details. Figure 1. Example PCP5000 with purge and piggy-backed condenser | PCP Series BX - Operation and Maintenance Manual www.poolpak.com | 717-757-2648... -

Page 7: Dehumidifier Options

For the specific required clearances information, as well as dehumidifier overall dimensions, distances to pipe connections, duct connections etc., refer to the submittal documentation. © 2018 PoolPak LLC. All rights reserved. PCP Series BX - Operation and Maintenance Manual |... -

Page 8: Dehumidifier External Systems Connection

(see Figure 1). If dehumidifier is not equipped with it, power lines to be brought directly to the main electric panel. Also, provisions are made to bring control and communication connections through the dehumidifier roof at the compressor compartment. | PCP Series BX - Operation and Maintenance Manual www.poolpak.com | 717-757-2648... -

Page 9: Dehumidifier Optional Arrangement

For example, PCP3030 would have double-condenser, composed of two NC-Z-1 (see Figure 3 - Fig.1). *** The pump package is optional - the fluid cooler may be provided without it. © 2018 PoolPak LLC. All rights reserved. PCP Series BX - Operation and Maintenance Manual |... -

Page 10: Figure 3. Pcp3030 Double-Condenser

Generally, up to 36” side and 96” top clearances are required. For more information on clearances as well as equipment dimensions and other details, refer to the submittal documentation. Figure 3. PCP3030 Double-Condenser | PCP Series BX - Operation and Maintenance Manual www.poolpak.com | 717-757-2648... -

Page 11: Equipment Specific Data

Glycol mixture concentration is normally shown on Main Label – refer as needed. © 2018 PoolPak LLC. All rights reserved. PCP Series BX - Operation and Maintenance Manual |... -

Page 12: Figure 4. Main Label

General Information Figure 4. Main Label | PCP Series BX - Operation and Maintenance Manual www.poolpak.com | 717-757-2648... -

Page 13: Layout And Components

If the dehumidifier has the standard pool water heating option, the compressor circuit additionally includes the coaxial pool water heat exchanger (15) and refrigeration pool water heating valve. © 2018 PoolPak LLC. All rights reserved. PCP Series BX - Operation and Maintenance Manual |... -

Page 14: Figure 5. Bx Drawing

Layout and Components Figure 5. BX Drawing | PCP Series BX - Operation and Maintenance Manual www.poolpak.com | 717-757-2648... -

Page 15: Control System

OA intake to measure both the temperature and humidity of the outdoor air. Figure 7. Pressure Sensors © 2018 PoolPak LLC. All rights reserved. PCP Series BX - Operation and Maintenance Manual |... -

Page 16: Figure 8. Sensors And Safeties

Monitor; some optional control sensors and devices such as an air pressure differential sensor, current sensor(s). It may also be located in main electrical panel or in the dehumidifier in general. Figure 8. Sensors and Safeties | PCP Series BX - Operation and Maintenance Manual www.poolpak.com | 717-757-2648... -

Page 17: Outdoor Air Condensers And Fluid Coolers Layout And Components

Depending on type of fluid cooler, location of electrical box may slightly differ; in some cases, electrical box may be incorporated into pump package. © 2018 PoolPak LLC. All rights reserved. PCP Series BX - Operation and Maintenance Manual |... -

Page 18: Fluid Coolers Pump Package

• The pump package electrical sub-panel (40) contains the pump package electrical power and control apparatuses. • The pump package manifolds are usually equipped with pressure gauges, automatic air venting valve, draining and other valves. Figure 10. Pump Package | PCP Series BX - Operation and Maintenance Manual www.poolpak.com | 717-757-2648... -

Page 19: Sequence Of Operation

Externally installed Exhaust Fan(s) and Outdoor Air damper(s) could be also controlled by the dehumidifier control system. This applies to both, Minimum and Purge/Additional, fans and dampers. © 2018 PoolPak LLC. All rights reserved. PCP Series BX - Operation and Maintenance Manual |... -

Page 20: Heat Recovery Option

Dehumidification or Air Conditioning mode(s), control system would simply increase exhaust fan(s) speed signal to direct more stale return air outside and bring in more outdoor (dry/cool) air in, thus reducing supply air humidity and/or temperature (as needed). | PCP Series BX - Operation and Maintenance Manual www.poolpak.com | 717-757-2648... -

Page 21: Compressor(S)

• Dehumidifiers, equipped with pool water heating option, also engage the refrigeration pool water heating solenoid valve to reject heat into the pool water, based on pool water temperature. Figure 12. Piping Schematic © 2018 PoolPak LLC. All rights reserved. PCP Series BX - Operation and Maintenance Manual |... -

Page 22: Outdoor Air Condenser And Fluid Cooler Operation

Boiler is controlled and operated via its own control system, responding to proper gas pressure, water flow, and will supply glycol at a constant temperature. Figure 13. Boiler Package Piping Schematic | PCP Series BX - Operation and Maintenance Manual www.poolpak.com | 717-757-2648... -

Page 23: Interface And Communication

Access to user settings (Setpoints) and commands (Stop/Restart Dehumidifier, etc.) User Access to advanced settings and features Advanced Context sensitive help presenting information related to the viewed page Help © 2018 PoolPak LLC. All rights reserved. PCP Series BX - Operation and Maintenance Manual |... -

Page 24: Alarms

For detailed information on TouchDisplay OP refer to CommandPak Control System Touch Display User ® Manual, provided with the dehumidifier (or contact PoolPak to obtain a copy). Alarms If the dehumidifier control system detects abnormal or unsafe for further operation situation, it issues Alarm (notification of such situation accompanied by respective component or entire dehumidifier stoppage and/or lockout) or Alert (notification of minor abnormal situation without any devices’... -

Page 25: Remote Communication (Virtual-Tech And Bms)

Continuous dehumidifier restarting (clearing alarms) without addressing actual issues may result in equipment malfunction, premature wear, and failure. For a complete list of alarms and alerts, refer to the Alarms Description information – contact PoolPak to obtain one. -

Page 26: Bms (Building Management System)

Communication to BMS can also be supported, depending on the type of communication protocol said BMS utilizes. The PoolPak equipment control software supports most common of them • different control software variation might be required to support different BMS communication protocols. Contact PoolPak if necessary. -

Page 27: Basic Maintenance

Basic Maintenance BASIC MAINTENANCE Although PoolPak equipment is built for minimal service downtime, periodic preventative maintenance is required to ensure maximum reliability, safety, and operating efficiency. WARNING To ensure equipment longevity and proper and efficient operation, the dehumidifier and its auxiliary systems and devices (outdoor condenser, fluid cooler, boiler package, etc.) must be maintained properly and regularly. -

Page 28: Routine Maintenance Program

Check gasket condition on all doors to ensure an airtight seal Check bolts on compressors, motor mounts, dehumidifier bases and coils and tighten if required Verify that the airflow around the remote condenser or dry cooler is unobstructed | PCP Series BX - Operation and Maintenance Manual www.poolpak.com | 717-757-2648... -

Page 29: Specific Components Maintenance

• Straighten any coil fins that have been bent during the cleaning process • Confirm the drain line is clear • Replace all panels and parts and restore electrical power to the equipment © 2018 PoolPak LLC. All rights reserved. PCP Series BX - Operation and Maintenance Manual |... -

Page 30: Warranty

This warranty applies to the original equipment owner and is not transferable. PoolPak LLC warrants as set forth ® and for the time periods shown below that it will furnish, through a PoolPak LLC authorized installing contractor ® or service organization, a new or rebuilt part for a factory installed part which has failed because of defect in workmanship or material. -

Page 31: Limitations

LLC will provide a replacement compressor for 60 months from the date of shipment provided the factory ® installed compressor fails as a result of manufacturing defect and is returned to the factory with transportation prepaid. This extended compressor warranty is subject to all the terms of the standard PoolPak LLC warranty ®... -

Page 32: Optional 10 Year Airside Coil Warranty

NE Series warranty but applied to the coil only. No charges attributed to the replacement of a component, except as detailed in above Initial 90-day Warranty, will be allowed unless specifically granted in writing beforehand by PoolPak ®... - Page 33 THIS PAGE INTENTIONAL LEFT BLANK.

- Page 34 PoolPak is a Dehumidified Air Solutions company and member of Dehumidified Air Services, a coast-to-coast service network of local customer support specialists. Backed by real-time remote monitoring and direct access to the engineers who designed and built your dehumidifier, Dehumidified Air Services is the only organization in North America that has the scale and expertise to deliver trouble-free pool dehumidification and unparalleled customer service.

Need help?

Do you have a question about the PCP Series and is the answer not in the manual?

Questions and answers