Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for KNF N 2400.15

- Page 1 KNF 308934-308937 09/18 N 2400.15 TRANSLATION OF ORIGINAL OPERATING AND INSTALLATION INSTRUCTIONS ENGLISH DIAPHRAGM PUMP Note! Before operating the pump and the accessories, please read the operating instructions and pay attention to the safety precautions!

-

Page 2: Table Of Contents

KNF Neuberger GmbH Alter Weg 3 79112 Freiburg Contents Page Germany 1. About this document ..............3 Phone +49-(0)7664-5909-0 2. Use ....................5 Fax +49-(0)7664-5909-99 3. Safety ..................7 4. Technical Data ................10 E-mail: info@knf.de 5. Design and function ..............13 www.knf.de... -

Page 3: About This Document

WARNING warns of possible Death or serious injuries and/or danger serious damage are possible. CAUTION warns of a possi- Minor injuries or damage are bly dangerous possible. situation Tab. 1 Original-Operating and Installation Instructions, english, KNF 308934-308937 09/18... - Page 4 An activity to be carried out (a step) is specified here. 1. The first step of an activity to be carried out is specified here. Additional, consecutively numbered steps follow. This symbol refers to important information. Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

-

Page 5: Use

The pumps are provided for the operation with frequency converter in the speed range 500 – 1500 min (50 Hz) or 600 – 1800 min (60 Hz) respectively (see Chapter 7.2). Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18... - Page 6 Pumps designed to create either a vacuum or an overpressure must not be used for these two purposes simultaneously. An overpressure must not be applied to the suction side of the pump. Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

-

Page 7: Safety

This also applies for unusual operational situations. Note that the temperature of the medium increases when the pump compresses the medium (compressor operation). Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18... - Page 8 The pumps conform to the Directive 2011/65/EU (RoHS2). The following harmonized standards have been used: EN 60034-1 EN 61000-6-1/2/3/4 EN 60204-1 EN 60034-30-1 DIN EN 50581 Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

- Page 9 The pump is maintenance-free. But KNF recommends, checking repairs the pump regularly with regard to conspicuous changes in noise and vibrations. Only have repairs to the pumps carried out by the KNF Customer Service responsible. Housing with voltage-caring parts may be opened by technical personnel only.

-

Page 10: Technical Data

[bar rel*] -permanent operation 12.0 -intermittent 16.0 Ultimate vacuum [mbar abs.] <100 Delivery rate [l/min]** 120.0 Tab. 5 *bar rel related to1013hPa **Liters in standard state (1013 hPa, 20°C) Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18... - Page 11 The pumps are fitted as standard with PTC sensors to protect against overloading (see operating instructions of the motor). Weight Pump type Value N 2400.15 SPE Ca. 83 kg N 2400.15 STE Ca. 79 kg Tab. 9 Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

- Page 12 A leak test is able to verify that the original standard of gas-tightness has been achieved. *Values valid for helium leak test Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

-

Page 13: Design And Function

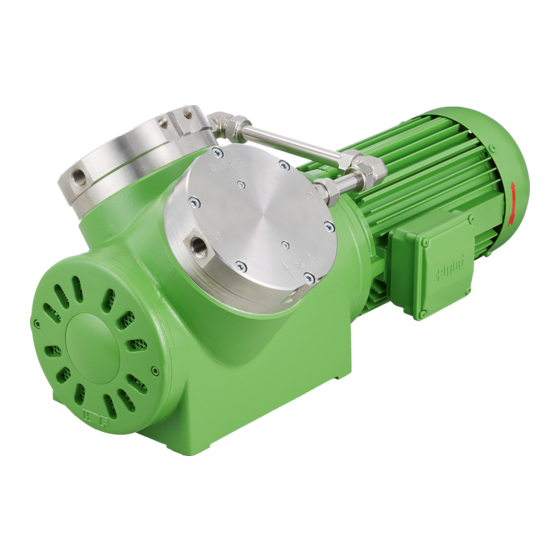

Design N 2400.15 STE Pneumatic pump inlet Pneumatic pump outlet Connection water cooling Union nut Pneumatic connection Motor Fan cover Terminal box (electrical connection) Fig. 2: Diaphragm N 2400.15 STE Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18... - Page 14 (1). The transfer chamber (3) is hermetically separated from the pump drive (7) by the diaphragm. Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

-

Page 15: Transportation

Parameter Value Storage temperature + 5°C to + 40°C Transport temperature - 10°C to + 60°C Permiss. Humidity (non- 30% to 85% condensing) Tab. 11 Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18... - Page 16 Transportation Diaphragm pump N 2400.15 Transportation with harness Fig. 4: Position of the harness (exemplary) 1. Pull the harness through among the pump (see Fig. 4). Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

- Page 17 3. Make sure that the lifting load cannot be transferred from the belt to the pump connection. 4. Use a lifting device to lift the pump out of the packaging. 5. Place the pump carefully at the installation location. Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

-

Page 18: Installation And Connection

7.1. Installation of the pump Before installation, store the pump at the installation location to bring it up to ambient temperature. See Fig. 6 (pump series N 2400.15 SPE) and Fig. 7 (pump Mounting dimensions series N 2400.15 STE) for mounting dimensions. - Page 19 Diaphragm pump N 2400.15 Installation and connection Fig. 7: Mounting dimensions pump series N 2400.15 STE (All dimensional tolerances conform to DIN ISO 2768-1, Tolerance Class V) Cooling air supply Danger of burns from hot surfaces Hot surfaces may be caused by overheating of the pump.

- Page 20 For max. operating current of the pump see pump’s type plate. It is recommended that an additional “Emergency Stop” switch is installed. The pump must be installed so that contact with live parts is impossible. Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

- Page 21 If the pump s used as a vacuum pump, safely discharge the Pump exhaust pump exhaust at the pump’s pneumatic outlet. Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

- Page 22 3. Lay the suction and pressure line at a downward angle to pre- vent condensate from running into the pump. Pneumatic noises can be reduced or dissipated by using a silencer (see Chapter 11.2 Accessory). Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

- Page 23 The base plate is shown as an additional accessory in the fol- lowing dimension drawings. Fig. 8: Mounting dimensions pump series N 2400.15 SPE (All dimensional tolerances conform to DIN ISO 2768-1, Tolerance Class V) Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

- Page 24 Installation and connection Diaphragm pump N 2400.15 Fig. 9: Mounting dimensions pump series N 2400.15 STE (All dimensional tolerances conform to DIN ISO 2768-1, Tolerance Class V) Operate the water connection up to max. 1.0 bar. Drain water runoff safely.

-

Page 25: Operation

If the air or gas quantity in the pressure line is throttled or regulated, make sure that the maxi- mum permissible operating pressure is not ex- ceeded. Ensure that the pump outlet is not closed or constricted. Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18... - Page 26 Switching off the pump / removing from operation pneumatic pressure in pump). Before recommissioning, the relevant norms, directives, regu- Recommissioning lations and technical standards must be observed at the power source. Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

-

Page 27: Servicing

Only use solvents for cleaning if the head materials cannot be attacked (check the resistance of the materials). If compressed air is available, blow out the components. Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18... - Page 28 ‘wrench for retainer plate’, a KNF accessory, see Chapter 11. Felt-tip pen Hot air blower Adhesive (Delo ML5249) or comparable product Tab. 15 *According to accessories list, Chapter 11 Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

- Page 29 This helps avoid incorrect assembly later. 4. Undo the six hexagon socket head cap screws (1) and the two screws (6); lift off head plate (4) and intermediate plate (14). Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

- Page 30 9. Only .13: Fit the new O-ring (12) in the housing (13). 10. Only .13: Fit the new O-ring (11) in the diaphragm support (9). Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

- Page 31 (1) diagonally (tightening torque: 9 Nm). In order to ensure the required gas tightness of the pump head after maintenance, a leak test must be carried out. Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

- Page 32 9. Remount the pneumatic connection or the interstage cooler. To do so, tighten the union nut in the original position (as it was marked during disassembly, see Fig. 11). Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

-

Page 33: Troubleshooting

Remove the jamming parts and particles. or partially jammed. Clean head components. Head parts are soiled. Replace diaphragm and reed valves (see Chapter 0). Diaphragm or reed valves are worn. Tab. 17 Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18... - Page 34 2. Clean the pump (see Chapter 9.2.2). 3. Send the pump, together with completed Health and Safety Clearance and Decontamination Form (Chapter 13), to KNF stating the nature of the transferred medium. Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18...

-

Page 35: Spare Parts And Accessories

Connection water cooling device 305444 N 2400.15 SPE N 2400.15 STE Base plate with rubber-bonded metals: 304476 N 2400.15 SPE N 2400.15 STE Inlet filter G 1/2 316662 Tab. 20 Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18... -

Page 36: Returns

For optimal processing of a return, a copy of this declaration should be sent in advance via e-mail, regular mail, or fax to KNF Customer Service (contact data: see www.knf.com). In order to avoid endangering employees who open the shipment’s packag-... -

Page 37: Health And Safety Clearance And Decontamination Form

Diaphragm pump N 2400.15 Health and safety clearance and decontamination form 13. Health and safety clearance and decon- tamination form Translation of original Operating and Installation Instructions, english, KNF 308934-308937 09/18... - Page 40 KNF worldwide Find your local KNF partner on www.knf.com...

Need help?

Do you have a question about the N 2400.15 and is the answer not in the manual?

Questions and answers