Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for KNF N86.16 Series

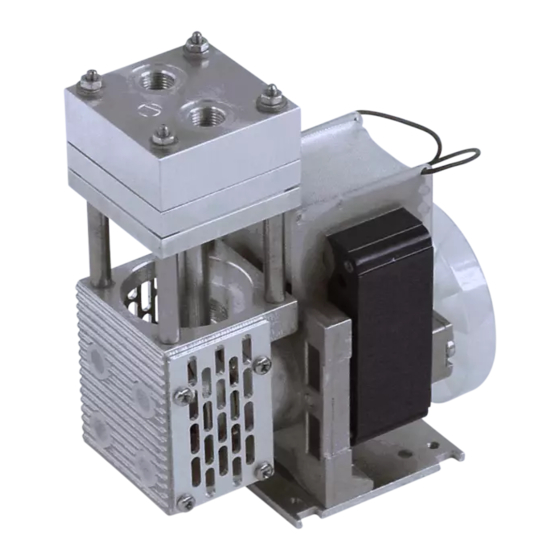

- Page 1 KNF121260-121531 04/20 N86.16 TRANSLATION OF ORIGINAL OPERATING AND INSTALLATION INSTRUCTIONS ENGLISH DIAPHRAGM VACUUM PUMPS AND COMPRESSORS Note! Before operating the pump and the accessories, please read the operating instructions and pay attention to the safety precautions!

-

Page 2: Table Of Contents

KNF Neuberger GmbH Alter Weg 3 79112 Freiburg Contents Page Germany 1. About this document ..............3 Phone +49-(0)7664-5909-0 2. Use.................... 4 Fax +49-(0)7664-5909-99 3. Safety ..................6 4. Technical Data ................9 E-mail: info@knf.de 5. Design and function ..............11 www.knf.de... -

Page 3: About This Document

Diaphragm Vacuum Pumps N86.16 About this document About this document 1.1. Using the Operating and Installation Instructions The Operating and Installation Instructions are part of the pump. Always keep the Operating and Installation Instructions handy in the work area. ... -

Page 4: Use

Diaphragm Vacuum Pumps N86.16 2.1. Proper use The pumps are exclusively intended for transferring gases and va- pors. Owner’s responsibility Only install and operate the pumps under the operating parameters Operating parameter and conditions and conditions described in Chapter 4. Technical Data. Only complete pumps may be taken into service. - Page 5 The pumps are not suitable for use with aggressive media. Other pumps in the KNF product line are designed for use with aggres- sive media. Please contact us for more information. The pumps must not be used to create vacuum and overpressure simultaneously.

-

Page 6: Safety

Safety Diaphragm Vacuum Pumps N86.16 Safety Note the safety precautions in Chapter 7. Installation and con- nection and 8. Operation. The pumps are built according to the generally recognized rules of the technology and in accordance with the occupational safety and accident prevention regulations. - Page 7 Project-specific pumps that are not fitted with a thermal switch must be protected by the user against the risk of overheating. In case of doubt, consult the KNF customer service. Environmental protection Store all replacement parts in a protected manner and dispose of them properly in accordance with the applicable environmental pro- tection regulations.

- Page 8 The pump is maintenance-free. But KNF recommends, checking repairs the pump regularly with regard to conspicuous changes in noise and vibrations. Only have repairs to the pumps carried out by the KNF Customer Service responsible. Housing with voltage-caring parts may be opened by technical per- sonnel only.

-

Page 9: E-Mail: Info@Knf.de 4. Technical Data

Diaphragm Vacuum Pumps N86.16 Technical Data Technical Data Pump materials Assembly Material Material N86AT.16E N86ST.16E Pump head Aluminium Stainless alloy Steel Diaphragm PTFE PTFE Valve plate PTFE PTFE Tab. 2 Pneumatic values Parameter Value Max. permissible operating pressure [bar] Ultimate vacuum [mbar abs.] Delivery rate at atm. - Page 10 Technical Data Diaphragm Vacuum Pumps N86.16 Other parameters Parameter Value Permissible ambient tempera- + 5 bis + 40 ture [°C] Permissible media tempera- + 5 bis + 240 ture [°C] Dimensions See Fig. 3, Chapter 7.1 Maximum permissible ambient 80% for temperatures up to relative humidity 31°C, decreasing linearly to 50% at 40°C.

-

Page 11: Www.knf.de 5. Design And Function

Diaphragm Vacuum Pumps N86.16 Design and function Design and function Design Pneumatic pump outlet Pneumatic pump inlet Electrical connection Fig. 1: Design N86.16 Function Diaphragm Pump Outlet valve Inlet valve Transfer chamber Diaphragm Eccentric Connection rod Pump drive Fig. 2: Pump head Diaphragm pumps transfer, compress (depending on pump ver- sion) and evacuate gases and vapors. -

Page 12: Transportation

Transportation Diaphragm Vacuum Pumps N86.16 Transportation Personal injury and/or damage to property because of false or improper transportation of the pump Due to false or improper transportation the pump can fall down, become damaged and injure people. CAUTION If necessary, use suitable aids (eyebolt, harness, lifting device, etc.). -

Page 13: Installation And Connection

Diaphragm Vacuum Pumps N86.16 Installation and connection Installation and connection Only install and operate the pumps under the pneumatic operating parameters and conditions described in Chapter 4, Technical Data. Observe the safety precautions (see Chapter 3). Heating element Since the insulating material of the heating elements is hygro- scopic, before connecting the heating element, it may be nec- essary to check the insulation resistance with a suitable meas- uring instrument (megaohmmeter with 500V DC test voltage,... - Page 14 Installation and connection Diaphragm Vacuum Pumps N86.16 Cooling air supply Danger of burns from hot surfaces Hot surfaces may be caused by overheating of the pump. WARNING Install the pump so that the motor fan can intake sufficient cooling air. Immediate ambient of the hot ...

- Page 15 Diaphragm Vacuum Pumps N86.16 Installation and connection 7.2. Electrical connection Extreme danger from electrical shock Only have the pump connected by an authorized specialist. Only have the pump connected when the power DANGER supply is disconnected. When connecting the device to a power source, the relevant standards, directives, regulations, and technical standards must be observed.

- Page 16 If the pump s used as a vacuum pump, safely discharge the pump exhaust at the pump’s pneumatic outlet. Disengaging KNF recommends mechanically disengaging the pump from the piping system. This can be achieved with flexible tubing or pipes, for example. This will avoid transferring to the system any pump oscillations that may arise.

-

Page 17: Operation

Diaphragm Vacuum Pumps N86.16 Operation Operation Danger of burns from hot pump parts or hot medium During or after operation of the pump, some pump parts may be hot. WARNING Allow the pump to cool after operation. Take safety precautions against the contact of hot parts/media. - Page 18 Run the pump for a few minutes to warm it up before handling saturated or nearly saturated vapors. KNF recommends: When transferring aggressive media, flush the pump prior to switch off (see Chapter 9.2.1) to increase the service life of the diaphragm.

-

Page 19: Servicing

9.2.1. Flushing pump When transferring dangerous and environmentally hazardous me- dia, KNF recommends flushing the pump at atmospheric pressure for a few minutes prior to switch-off (if necessary for safety rea- sons: with an inert gas) to extend the service life of the diaphragm. - Page 20 Fork wrench or socket wrench 5.5 mm Pin-wrench for two hole nuts, pin diameter 4 mm (available as “wrench for retainer plate”, a KNF accessory, see Chapter 11.2) Holding tool (see accessory, Chapter 11.2). Heat-resistant thread adhesive (e.g. DELO ML 5327) Felt-tip pen Tab.

- Page 21 Diaphragm Vacuum Pumps N86.16 Servicing Carrier Wave diaphragm Intermediate plate Head plate Disk spring Retainer plate Diaphragm support Connecting rod extension 10 O-ring 11 Valve plate 12 Washer 13 Fan M Mark Fig. 4: N86.16 Fig. 5: Pump head (exploded drawing) The following item numbers refer to Fig.

- Page 22 Servicing Diaphragm Vacuum Pumps N86.16 a) Preparatory step 1. Disconnect the pump from the power supply; check that the pump is electrically dead and secure this. b) Removing pump head 1. Mark the position of carrier (1), intermediate plate (3), and head plate (4) relative to each other by a drawing line (M) with a felt-tip marker.

- Page 23 1. Reconnect the pump to the electricity supply. 2. Ensure that the discarded parts and materials are safely and correctly disposed of. If you have any questions about servicing call our technical adviser (contact data: see www.knf.com). Translation of original Operating and Installation Instructions, english, KNF121260-121531 04/20...

-

Page 24: Troubleshooting

Troubleshooting Diaphragm Vacuum Pumps N86.16 10. Troubleshooting Extreme danger from electrical shock! Disconnect the pump power supply before work- ing on the pump. Make sure the pump is de-energized and se- DANGER cure. Check the pump (see Tab. 12 and Tab. 13). Pump does not transfer Cause Fault remedy... - Page 25 Fault cannot be rectified If you are unable to identify any of the specified causes, send the pump to KNF Customer Service (contact data: see www.knf.com). 1. Flush pump with air at atmospheric pressure for a few minutes (if necessary for safety reasons: with inert gas) to free the pump head of dangerous or aggressive gases (see Chapter 9.2.1).

-

Page 26: Spare Parts And Accessories

Spare parts and accessories Diaphragm Vacuum Pumps N86.16 11. Spare parts and accessories 11.1. Spare part set A spare part set consists of: Spare part Position number Quantity Valve plate (11) Wave diaphragm O-ring (10) Tab. 14 Spare part set Order number N86.16 032522... -

Page 27: Returns

Prerequisite for repairing a pump by KNF is a completed Decon- tamination Form. This is made available on the KNF website as a download. To find the form, select your country on the overview page (www.knf.com). You can find the Decontamination Form in the download area. - Page 28 KNF worldwide Find your local KNF partner on www.knf.com...

Need help?

Do you have a question about the N86.16 Series and is the answer not in the manual?

Questions and answers