Summary of Contents for FISCHER MA15F ... A Series

- Page 1 Operation manual MA15F ... A/B/C/D Diaphragm manometer for explosive areas Gas explosion protection zone 1 and 2, gases and vapours Dust explosion protection zone 21 and 22, dry dusts...

- Page 2 Great care was taken when compiling the texts and illustrations; Nevertheless, errors cannot be ruled out. The company FISCHER Mess- und Regeltechnik GmbH will not accept any legal responsibility or liability for this.

-

Page 3: Table Of Contents

FISCHER Mess- und Regeltechnik GmbH Table of Content Table of Content 1 Safety information ............................ 4 1.1 General .............................. 4 1.2 Personnel Qualification.......................... 4 1.3 Risks due to Non-Observance of Safety Instructions ................ 4 1.4 Safety Instructions for the Operating Company and the Operator............ 4 1.5 Unauthorised Modification ........................ 5... -

Page 4: Safety Information

1 | Safety information FISCHER Mess- und Regeltechnik GmbH 1 Safety information 1.1 General WARNING This operating manual contains instructions fundamental to the installation, op- eration and maintenance of the device that must be observed unconditionally. It must be read by the assembler, operator and the specialized personnel in charge of the instrument before it is installed and put into operation. -

Page 5: Unauthorised Modification

FISCHER Mess- und Regeltechnik GmbH Safety information | 1 • evident damage to the instrument • failure of the electrical circuits • longer storage outside the approved temperature range. • considerable strain due to transport Repairs may be carried out by the manufacturer only. -

Page 6: Pictogram Explanation

1 | Safety information FISCHER Mess- und Regeltechnik GmbH 1.8 Pictogram explanation DANGER Type and source of danger This indicates a direct dangerous situation that could lead to death or serious injury (highest danger level). a) Avoid danger by observing the valid safety regulations. -

Page 7: Product And Functional Description

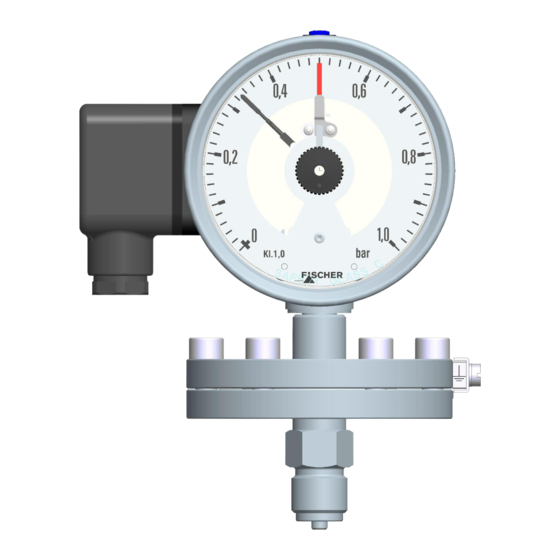

FISCHER Mess- und Regeltechnik GmbH Product and functional description | 2 2 Product and functional description 2.1 Delivery scope • Diaphragm manometer MA15 • Operating Manual 2.2 Product summary Manometer casing Contact element Contact element Scale Flange Ground connection Connecting shanks MA15F ... -

Page 8: Intended Use

2 | Product and functional description FISCHER Mess- und Regeltechnik GmbH 2.2.1 Type plate This type plate serves as an example of the information that is stated. The data shown is purely fictive, but does correspond to the actual conditions. For more information, please see the order code at the end of these instructions. -

Page 9: Function Diagram

FISCHER Mess- und Regeltechnik GmbH Product and functional description | 2 2.4 Function diagram Fig. 4: Function diagram 1 Motion train 2 Connecting rod 3 Flange 4 Diaphragm 2.5 Design and mode of operation The measuring element, the concentric corrugated diaphragm, is clamped between two flanges and the medium is applied on one side. -

Page 10: Assembly

3 | Assembly FISCHER Mess- und Regeltechnik GmbH 3 Assembly 3.1 Generalities The instrument may only be installed and commissioned by specialized person- nel familiar with the installation, commissioning and operation of this product. Specialized personnel are persons who can assess the work they have been assigned and recognize potential dangers by virtue of their specialized training, their skills and experience and their knowledge of the pertinent standards. - Page 11 FISCHER Mess- und Regeltechnik GmbH Assembly | 3 G½ Manometer connection G½ ca. 180 AF27 Ø20 Connection spigot according to Ø20 DIN EN 837-1 G½ Round shape U-shape Fig. 6: Siphon MZ1### • The transmitter must be positioned below the measuring point for liquid measurements.

-

Page 12: Electrical Connections

3 | Assembly FISCHER Mess- und Regeltechnik GmbH b) Settable damping reactor In operating mode, the damping throttle must be set so that the output signal follows the pressure changes with a delay. G½ Manometer connection AF27 Setting screw Connection spigot according to DIN EN 837-1 G½... -

Page 13: Use In Areas At Risk Of Explosion

FISCHER Mess- und Regeltechnik GmbH Assembly | 3 3.3.3 Rotation angle transducer acc. to data sheet KE09 For more technical information about the rotation angle transducer, please see the data sheet KE09. You can request the data sheet on request or via our web- server www.fischermesstechnik.de. - Page 14 3 | Assembly FISCHER Mess- und Regeltechnik GmbH 3.4.2 Differential pressure transmitter with magnetic spring contacts MA15 … 1B II 2G Ex h IIC T4 Gb Simple electric operating equipment acc. to EN60079-11 sec: 5.7 in explosive areas Zone 1 and 2.

- Page 15 FISCHER Mess- und Regeltechnik GmbH Assembly | 3 3.4.3 Differential pressure transmitter with inductive contacts MA15 … 1C II 2G Ex h IIC T4 Gb II 2D Ex h IIIC T95°C Db Explosive areas Zone 1 and 2, and 21 and 22, risk from gases and dry dust.

- Page 16 3 | Assembly FISCHER Mess- und Regeltechnik GmbH 3.4.4 Differential pressure transmitter with rotation angle transducer MA15 … 2D II 2G Ex h IIC T4 Gb Explosive areas Zone 1 and 2, risk from gases. Rotation angle transducer: KE0905#9 Allowed temperatures: •...

-

Page 17: Commissioning

FISCHER Mess- und Regeltechnik GmbH Commissioning | 4 4 Commissioning 4.1 General All electrical supply, operating and measuring lines, and the pressure connec- tions must have been correctly installed before commissioning. All supply lines are arranged so that there are no mechanical forces acting on the device. -

Page 18: Switch Point Setting

4 | Commissioning FISCHER Mess- und Regeltechnik GmbH 4.3 Switch point setting There is an adjustment lock attached to the front pane of the measuring unit on units with installed limit signal encoders. Using the detachable adjustment key, the contacts attached to the target indicators can be set to any point along the scale. -

Page 19: Servicing

FISCHER Mess- und Regeltechnik GmbH Servicing | 5 5 Servicing 5.1 Maintenance To ensure reliable operation and a long service life, we recommend carrying out the following test on a regular basis: • Check the reading. • Checking the switch function in connection with the downstream compon- ents. -

Page 20: Disposal

5 | Servicing FISCHER Mess- und Regeltechnik GmbH 5.5 Disposal WARNING Incorrect disposal may pose a risk to the environment. Please help to protect the environment by always disposing of the work pieces and packaging materials in compliance with the valid national waste and recyc- ling guidelines or reuse them. -

Page 21: Technical Data

FISCHER Mess- und Regeltechnik GmbH Technical Data | 6 6 Technical Data 6.1 Standard version The measuring variable is pressure and/or under-pressure in gaseous, liquid, aggressive, highly viscous or soiled media. The diaphragm manometer fulfils the requirements of the standard EN 837-3. -

Page 22: Options

6 | Technical Data FISCHER Mess- und Regeltechnik GmbH Protection IP66 acc. to EN 60529 / IEC 60529 Materials Housing CrNi Steel 1.4404 Motion train CrNi steel 1.4301 Dial face and needle Aluminium (painted) Inspection disk Safety laminated glass Connecting port (contact with medium) CrNi-steel 1.4404 (AISI 316L) Connection flange (contact with me- CrNi-steel 1.4404 (AISI 316L) -

Page 23: Dimensional Drawings

FISCHER Mess- und Regeltechnik GmbH Technical Data | 6 Measuring system • O applications 'Oil and grease' In compliance with the requirements of the Chemical Professional Associ- ation, all parts that come into contact with the medium are cleaned (see or- der code filling fluids) •... - Page 24 6 | Technical Data FISCHER Mess- und Regeltechnik GmbH 6.3.2 Model with contacts Ød1 Fig. 13: Dimension drawing MA15F with contacts Housing Ød1 Bayonet ring housing Safety housing 6.3.3 Process connection 6.3.3.1 Version with collar flange The dimensions stated apply for all housing models NG100 and NG160.

- Page 25 FISCHER Mess- und Regeltechnik GmbH Technical Data | 6 6.3.3.2 Version with DIN connection flange The dimensions stated apply for all housing models NG100 and NG160. Ød2 ØD Fig. 15: Connection flange Measuring range ≤ 400 ØD Ød2 mbar Ø Thread Measuring range ≥...

- Page 26 6 | Technical Data FISCHER Mess- und Regeltechnik GmbH 6.3.3.4 Connecting shanks DIN 837 ANSI B1.20.1 Centring pin Fig. 16: Connecting shanks G (Thread) G¼B G⅜B G½B 17.5 M20 x 1.5 17.5 ¼-18 NPT ½-14 NPT 26 / 36 BA_EN_MA15_ATEX...

-

Page 27: Order Codes

FISCHER Mess- und Regeltechnik GmbH Order Codes | 7 7 Order Codes Code no. 10 11 12 Type [2.3] Measuring range 0 … 16 mbar 0 … 25 mbar 0 … 40 mbar 0 … 60 mbar 0 … 100 mbar 0 …... - Page 28 7 | Order Codes FISCHER Mess- und Regeltechnik GmbH Rated pressure of the measuring system 10 bar (Measuring ranges ≤ 250 mbar) 40 bar (Measuring ranges ≥ 400 mbar) Design of the measuring system CrNi Steel 1.4404 CrNi steel 1.4404 with diaphragm in Hastelloy C CrNi steel 1.4404 with PFA coating...

- Page 29 FISCHER Mess- und Regeltechnik GmbH Order Codes | 7 [10] Special functions Zero-point correction with setting screw Zero-point correction micro adjust- ment indicator Zero-point correction with setting Adjustable marker needle screw ♣) Zero-point correction with setting Resettable drag needle screw...

-

Page 30: Attachments

8 | Attachments FISCHER Mess- und Regeltechnik GmbH 8 Attachments 8.1 EU Declarations of conformity Fig. 17: CE_DE_MA15F_1B_Page1 30 / 36 BA_EN_MA15_ATEX... - Page 31 FISCHER Mess- und Regeltechnik GmbH Attachments | 8 Fig. 18: CE_DE_MA15F_1B_Page2 BA_EN_MA15_ATEX 31 / 36...

- Page 32 8 | Attachments FISCHER Mess- und Regeltechnik GmbH Fig. 19: CE_DE_MA15F_1C_Page1 32 / 36 BA_EN_MA15_ATEX...

- Page 33 FISCHER Mess- und Regeltechnik GmbH Attachments | 8 Fig. 20: CE_DE_MA15F_1C_Page2 BA_EN_MA15_ATEX 33 / 36...

- Page 34 8 | Attachments FISCHER Mess- und Regeltechnik GmbH Fig. 21: CE_DE_MA15F_2D_Page1 34 / 36 BA_EN_MA15_ATEX...

- Page 35 FISCHER Mess- und Regeltechnik GmbH Attachments | 8 Fig. 22: CE_DE_MA15F_2D_Page2 BA_EN_MA15_ATEX 35 / 36...

- Page 36 8 | Attachments FISCHER Mess- und Regeltechnik GmbH Fig. 23: CE_DE_MA15F_0A 36 / 36 BA_EN_MA15_ATEX...

Need help?

Do you have a question about the MA15F ... A Series and is the answer not in the manual?

Questions and answers