Summary of Contents for SMAR DT303

- Page 1 OPERATION, MAINTENANCE AND INSTRUCTIONS MANUAL PROFIBUS PA CONCENTRATION DENSITY TRANSMITTER MAY / 16 DT 303 VERSION 3 D T 3 0 3 M E...

- Page 2 Specifications and information are subject to change without notice. Up-to-date address information is available on our website. web: www.smar.com/contactus.asp...

- Page 3 The DT303 is available as a product on its own, but also replaces the circuit board for the DT301. They use the same sensor board. Refer to the maintenance section of this manual for instructions on upgrading.

- Page 4 Smar provides specific training to instruct and qualify such professionals. However, each country must comply with the local safety procedures,...

-

Page 5: Table Of Contents

Vcdng"qh"Eqpvgpvu" TABLE OF CONTENTS UGEVKQP"3"/"KPUVCNNCVKQP"0000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000"303" GENERAL ..................................1.1 RECOMMENDATION OF USING OF DT303 ......................1.1 MODELS OF DT303 ..............................1.1 FIXATION ..................................1.2 A - INDUSTRIAL MODEL TOP MOUNTING - BETWEEN CENTRE OF THE SENSORS 250 MM ......1.3 B – INDUSTRIAL MODEL SIDE MOUNTING ......................1.4 C –... - Page 6 MONITORING VIEW ..............................3.41 SIMULATING VALUES .............................. 3.43 UGEVKQP"6"/"OCKPVGPCPEG"RTQEGFWTGU00000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000"603" GENERAL ..................................4.1 PROCEDURE TO CHANGE THE DT303 MAIN BOARD .................... 4.1 DISASSEMBLY PROCEDURE ............................ 4.2 GROUP OF THE PROBE (16A, 16B, 19A OR 19B) ....................4.2 ELECTRONIC CIRCUIT .............................. 4.2 REASSEMBLE PROCEDURE .............................

- Page 7 Profibus system. (Section 3) Proceed with lower Verify Maintenance concentration trim. procedures (Section 4) * More information in Section 3 from DT303 Operation, Maintenance and Instructions Manual. ** Tip: The Brix of water is 0 (zero). XKK"...

- Page 8 FV525"⁄"Qrgtcvkqp."Ockpvgpcpeg"cpf"Kpuvtwevkqpu"Ocpwcn" XKKK"...

-

Page 9: General

General The DT303 has a built-in temperature sensor to compensate for temperature variations. At the factory, each transmitter is submitted to a temperature cycle process. The characteristics under different pressures and temperatures are recorded in the transmitter memory. At the field, this feature minimizes the temperature variation effect. -

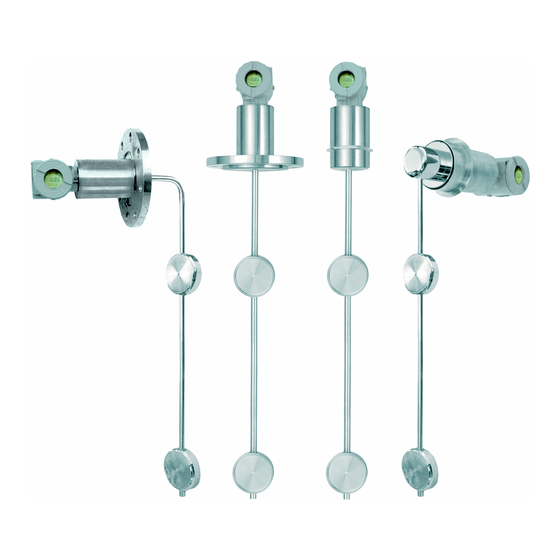

Page 10: Fixation

DT303 – Operation, Maintenance and Instructions Manual The industrial model uses flanged connection according to the standard ANSI B16.5 or DIN 2526. The sanitary model uses Tri-Clamp connection, allowing a fast connection to the process. The treatment of wet superficial is made according to the standard of rough 32 Ra. This method is according to the recommendation of 3A standard that is the sanitary standard largely used by food, medicines and drink industries. -

Page 11: A - Industrial Model Top Mounting - Between Centre Of The Sensors 250 Mm

Installation A - Industrial Model Top Mounting - Between Centre of the Sensors 250 mm Figure 1.1 – DT303 Dimensional (A) -

Page 12: B - Industrial Model Side Mounting

DT303 – Operation, Maintenance and Instructions Manual B – Industrial Model Side Mounting (14,4) (9,65) (5,73) (0,24) (3,23) (3,50) ELECTRICAL CONNECTION FLANGED CONNECTION 4” Figure 1.1 – DT303 Dimensional (B) -

Page 13: C - Sanitary Model Top Mounting - Between Centre Of The Sensors 500 Mm

Installation C – Sanitary Model Top Mounting - Between Centre of the Sensors 500 mm (3,27) ELECTRICAL CONNECTION (3,50) 4 TRI-CLAMP CONNECTION (4,72) Figure 1.1 – DT303 Dimensional (C) -

Page 14: D - Sanitary Model Side Mounting

DT303 – Operation, Maintenance and Instructions Manual D – Sanitary Model Side Mounting (11,53) (9,05) (2,48) (3,50) ELECTRICAL CONNECTION 4” TRI-CLAMP CONNECTION Figure 1.1 – DT303 Dimensional (D) -

Page 15: E - Industrial Model Top Mounting

Installation E – Industrial Model Top Mounting (3,23) ELECTRICAL CONECTION (3,50) 4” FLANGED CONNECTION Figure 1.1 – DT303 Dimensional (E) - Page 16 DT303 – Operation, Maintenance and Instructions Manual F - Sanitary Model Top Mounting - Between Centre of the Sensors 800 mm Electrical Connection Flange Connection 4" RF ANSI B16,5 150# 15,8 Figure 1.1 – DT303 Dimensional (F)

-

Page 17: A - Typical Installation For Low Flow Tank (Industrial Model)

2” Sch 5 S Sch. 5S ext. 60,3) Curve 2” 90º RL Sch. 5S Reduction 2” x 1” Curve 1” 90º RL Sphere Valve Drain 1” Sch. 5S Sch. 5 S (7,72) Figure 1.2 – Typical Installation for DT303 (A) -

Page 18: B - Typical Installation For Flow Tank (Sanitary Model)

Reduction 4” x 2” Tube 2” Sch. 5 S Sch. 5 S ext. 60,3) Curve 2” 90º RL Sch. 5 S Curve 1 1/2” 90º ext. 38,1) Reduction 2 1/2” x 1 1/2” Figure 1.2 – Typical Installation for DT303 (B) 1.10... -

Page 19: C - Typical Installation For High Flow Tank (Industrial Model)

Sch. 5 S ext. 114,3) Curve 4” 90º RC Sch 5 S Curve 2” 90º RC Reduction 4” x 2” Sphere Valve Drain 1” Sch. 5 S Sch. 5 S (6,89) Figure 1.2 – Typical Installation for DT303 (C) 1.11... -

Page 20: D - Typical Installation In Overflow Tanks

DT303 – Operation, Maintenance and Instructions Manual D – Typical Installation In Overflow Tanks Electrical Connection Flange connection 4" RF ANSI B16,5 150# 15,8 Figure 1.2 – Typical Installation for DT303 (D) 1.12... -

Page 21: E - Typical Installation In Tank (Industrial Model)

Installation E – Typical Installation In Tank (Industrial Model) (4,72) (3,15) FLANGE 4” ANSI B16,5 MINIMUM LEVEL MINIMUM DIAMETER 20” Figure 1.2 – Typical Installation for DT303 (E) 1.13... -

Page 22: F - Typical Installation In Tank (Sanitary Model)

DT303 – Operation, Maintenance and Instructions Manual F – Typical Installation In Tank (Sanitary Model) (2,24) TRI-CLAMP 4” DT301 MINIMUM LEVEL MINIMUM DIAMETER 20” Figure 1.2 – Typical Installation for DT303 (F) 1.14... -

Page 23: G - Typical Installation In Tank (Industrial Model)

Installation G - Typical Installation In Tank (Industrial Model) (4,72) (3,15) Flange 4” ANSI B16,5 MINIMUM LEVEL PROTECTION DEVICE PROTECTION DEVICE MINIMUM DIAMETER 20” Figure 1.2 – Typical Installation for DT303 (G) 1.15... -

Page 24: H - Typical Installation For Low Flow Tank With

DT303 – Operation, Maintenance and Instructions Manual H - Typical Installation For Low Flow Tank With Figure 1.2 – Typical Installation for DT303 (H) 1.16... -

Page 25: I - Typical Installation In Tank For Interface Level (Industrial Model)

Installation I - Typical Installation In Tank For Interface Level (Industrial Model) FLANGE 4” ANSI B16,5 TANK (4,72) (3,15) SENSOR INTERFACE LEVEL WATER SENSOR Figure 1.2 – Typical Installation for DT303 ( I ) 1.17... -

Page 26: J - Typical Installation In Tank For Stand Pipe Interface Level (Industrial Model)

DT303 – Operation, Maintenance and Instructions Manual J - Typical Installation In Tank For Stand Pipe Interface Level (Industrial Model) FLANGE 4” ANSI B16,5 TANK DRAIN VENT INTERFACE LEVEL WATER DIAMETER 4” DIAMETER 1” DRAIN Figure 1.2 – Typical Installation for DT303 (J) 1.18... -

Page 27: Housing Rotation

Figure 1.4 - Terminal Block The DT303 uses the 31.25 kbit /s voltage mode option for the physical signaling. All other devices on the same bus must use the same signaling. All devices are connected in parallel along the same pair of wires. -

Page 28: Bus Topology And Network Configuration

DT303 – Operation, Maintenance and Instructions Manual Bus Topology and Network Configuration Wiring Other types of cable may be used, other than for conformance testing. Cables with improved specifications may enable longer trunk length or superior interface immunity. Conversely, cables with inferior specifications may be used subject to length limitations for trunk and spurs plus possible nonconformance to the RFI/EMI susceptibility requirements. -

Page 29: Intrinsic Safety Barrier

Use of SB312LP, DF47-12 or DF47-17 is recommended. Jumper Configuration In order to work properly, the jumpers J1 and W1 located in the DT303 main board must be correctly configured (see table 1.1). This jumper enables the simulation mode parameter in the AI block. -

Page 30: Installation In Hazardous Areas

Required” could be applied for Explosion Proof Version. (CSA Certification). The standard plugs provided by Smar are certified according to the standards at FM, CSA and CEPEL. If the plug needs to be replaced, a certified plug must be used. -

Page 31: Functional Description - Sensor

Section 2 OPERATION The DT303 Concentration/ Density Transmitters uses capacitive sensors (capacitive cells) as pressure sensing elements. (See figure 2.1). This is exactly the same sensor as the DT301 series uses, the sensor modules are therefore interchangeable. Figure 2.1 - Capacitive Cell... -

Page 32: Functional Description - Electronics

DT303 – Operation, Maintenance and Instructions Manual Functional Description – Electronics Refer to the block diagram (See figure 2.2). The function of each block is described below. SENSOR ASSEMBLY MAIN CIRCUIT BOARD PROBE POWER SUPPLY ISOLATION FIRMWARE DOWNLOAD INTERFACE LOCAL ADJUSTE... - Page 33 Operation Fieldbus Modem Monitors line activity, modulate and demodulate communication signals, inserts and deletes start and end delimiters and checks integrity of frame received. Power Supply Takes power of the loop-line to power the transmitter circuitry. Power Isolation Isolates the signals to and from the input section, the power to the input section must be isolated. Display Controller Receives data from the CPU identifying which segments on the liquid crystal Display use to turn on.

- Page 34 DT303 – Operation, Maintenance and Instructions Manual...

-

Page 35: Dt303 Cyclical Configuration

45.45 kbits/s (Siemens), 93.75 kbits/s (P+F) and 12 Mbits/s (P+F, SK2) .If we had the link device, it can be up to 12 Mbits/s. Add the DT303, specifying the address in the bus. -

Page 36: Transducer Block

DT303 – Operation, Maintenance and Instructions Manual - The watchdog condition can also be activate, where after the communication loss detection for the slave device with the master, the equipment can change to a fail safe condition. Transducer Block Transducer block insulates function block from the specific I/O hardware, such as sensors, actuators. - Page 37 This parameter is used to enable the zero cut-off for pressure measuring. EEPROM_FLAG This parameter is used to indicate EEPROM saving process. Indicates the DT303 range code: 0 - Range 1 (0.5 @ 1.8 g/cm DT_RANGE_CODE 1 - Range 2 (1.0 @ 2.50 g/cm ...

-

Page 38: Concentration Density Transducer Block Parameter Attributes

DT303 – Operation, Maintenance and Instructions Manual Parameter Description SCALE_IN Scale for Pressure measurement. Scale for the output. The related values are according to the measured type. The related unit is the SCALE_OUT PRIMARY_VALUE_UNIT. This parameter contains the index code for the material of the diaphragm, which comes in contact with SENSOR_DIAPHRAGM_MATERIAL the process media. - Page 39 Unsigned 8 REMOTE_SEAL_TYPE Simple Unsigned 8 REMOTE_SEAL_FLUID Simple Unsigned 8 REMOTE_SEAL_ISO_MTRL Simple Unsigned 8 REMOTE_SEAL_NUMBER Simple Unsigned 8 DEV_MODEL Array Unsigned 8 DT303 MANUFACT_ID Simple Unsigned 16 0x003e GRAVITY Simple Float 9.80665 HEIGHT Simple Float 0.500 MEASURED_TYPE Simple Unsigned 8...

-

Page 40: Concentration Density Transducer Block View Object

DT303 – Operation, Maintenance and Instructions Manual Parameter usage/ Default – Index Parameter Mnemonic Object Type Data Type Store Size Access Type of value transport SOLID_COEFF_POL_0 Simple Float SOLID_COEFF_POL_1 Simple Float SOLID_COEFF_POL_2 Simple Float SOLID_COEFF_POL_3 Simple Float SOLID_COEFF_POL_4 Simple Float... - Page 41 Configuration Relative Parameter Mnemonic View_1 View_2 View_3 View_4 Index SECONDARY_VALUE_2 SECONDARY_VALUE_2_UNIT LIN_TYPE SCALE_IN SCALE_OUT 36-44 NOT USED MAX_SENSOR_VALUE MIN_SENSOR_VALUE MAX_TEMPERATURE MIN_TEMPERATURE 49-59 RESERVED CAL_TEMPERATURE BACKUP_RESTORE FACTORY_CURVE_BYPASS FACTORY_CURVE_X FACTORY_CURVE_Y FACTORY_CURVE_LENGTH PRESS_LIN_NORMAL PRESS_NORMAL CUTOFF_FLAG COEFF_POL POLYNOMIAL_VERSION SENSOR_RANGE_CODE TRD_TRANSDUCER_TYPE XD_ERROR MAIN_BOARD_SN EEPROM_FLAG ORDERING_CODE FLANGE_MATERIAL FLANGE_TYPE O_RING_MATERIAL...

-

Page 42: How To Configure The Transducer Block

The Profibus View configuration software from Smar or the Simatic PDM (Process Device Manager) configuration software from Siemens, for example, can configure many parameters of the Input... - Page 43 Configuration The device was created as DT303 Here, you can see all blocks instantiated. As you can see the Transducer and Display are treated as special type of Function Blocks, called Transducer Blocks. Figure 3.2 – Function and Transducer Block – Simatic PDM...

- Page 44 DT303 – Operation, Maintenance and Instructions Manual The Primary Value Type indicates the density measurement The user can select the Measured Type selecting: - Density (g/cm³), - Density (Kg/m³), - Relative Density @ 20°C - Relative Density @ 4°C - Baume,...

- Page 45 Configuration Using the next window the user can configure the units according to the Transducer Block Diagram: Figure 3.4 – Scale Units for Transducer Block 3.11...

-

Page 46: Advanced Settings

%sol = a0 + a1 bme1 + a2 bme2 + a3 bme3 + a4bme4 + a5 bme5 The table and the graph below indicate the application of the DT303 polynomial that relates Baume degree to solid percent, generating the polynomial: y = 0.004768x4 - 0.760813x3 + 45.407284x2 - 1200.648795x + 11919.089787. - Page 47 Configuration POLYNOMIAL REGRESSION %SOL. y = 0.004768x - 0.760813x + 45.407284x - 1200.648795x + 11919.089787 56,7 37,7 57,5 57,9 38,3 58,2 38,4 58,3 38,5 10 38,6 59,2 59,3 12 39,4 59,6 °Baume 13 39,7 60,5 61,2 61,8 Concentration Percentage (% conc) For applications that demand other relation among measures, the polynomial used is: f(a,d,t) = a d + a...

- Page 48 DT303 – Operation, Maintenance and Instructions Manual Clicking in “General Concentration”, the user will get the following screen: 3.14...

-

Page 49: Configuration Via Local Adjustment

Configuration via Local Adjustment For configuration via local adjustment is necessary the Standard Parameters Descriptions, Specific Parameters and Parameter Attribute Table of the Transducer Block in the DT303 Operation, Maintenance and Instructions Manual and the Function Block Instruction Manual. Tranducer Block Configuration a.1) Density / Inferior and Superior concentration calibration:... - Page 50 PRMT: Select the value 32 (SECONDARY_VALUE_UNIT – Secondary Variable Unit), according to Standard Parameters Descriptions, Specific Parameters and Parameter Attribute Table of the Transducer Block in the DT303 Operation, Maintenance and Instructions Manual; ITEM: The SECONDARY_VALUE_UNIT – Secondary Variable Unit is a parameter necessary to configure the element: 1000 = Temperature in Kelvin;...

- Page 51 AUTO_CAL_POINT_HI (Water – relative index equal to 96); MEASURED_TYPE (relative index equal to 90). NOTE The unit for output is selected using the type of measurement (see Unit Code for DT303). Using the local adjustment configuration procedure, configure the parameter MEASURED_TYPE and AUTO_CAL_POINT_LO as: CONF: Select a LCD, for example LCD2;...

- Page 52 PRMT: Configure the value 96 (AUTO_CAL_POINT_HI – Self Calibration of the Superior Value) according to Standard Parameters Descriptions, Specific Parameters and Parameter Attribute Table of the Transducer Block in the DT303 Operation, Maintenance and Instructions Manual; ITEM: The AUTO_CAL_POINT_HI – Inferior Value Calibration is a simple parameter and is not necessary to configure the element.

- Page 53 Configuration See below the configuration screens of the Transducer Block using the Profibus View. Figure 3.6 - Transducer Block and Function – Profibus View Figure 3.7 - Scale Units – Profibus View Figure 3.8 - Advanced Settings – Profibus View Figure 3.9 - Concentration General Units –...

-

Page 54: How To Configure The Analog Input Blocks

Using this window, the user can configure the block mode operation, selects the channel, scales and unit for input and output value and the damping. The DT303 has three AI blocks. These blocks can be configured as: 1° AI Block: for concentration unit configuration;... - Page 55 Configuration Selecting the page "Advanced Settings", the user can configure the conditions for alarms and warnings, as well the fail safe condition. Please, see the window: The user can Alarm/Warning limits. The fail safe conditions. Figure 3.11 – Advanced Settings for Analog Input Block In online configuration for the Analog Input Block, please, go to the main menu and select "Device - Online Configuration - Analog Input - Block Mode": The user can set...

- Page 56 DT303 – Operation, Maintenance and Instructions Manual See below the configuration screens of the Analog Input Block using the Profibus View. Figure 3.13 – Basic Settings – AI Block Figure 3.14 – Advanced Settings – AI Block Figure 3.15 – Online Configuration – AI Block...

-

Page 57: Lower And Upper Concentration / Density Calibration

The calibration is used to match the reading with the correct concentration/density. Please, sure that the DT303 is measuring concentration/density. Using Profibus View or Simatic PDM, in the Transducer Block screen, select the primary value type to “Density”. -

Page 58: Lower And Upper Concentration/ Density Self-Calibration

DT303 – Operation, Maintenance and Instructions Manual If is required an adjustment of unit, please just select the desired unit using the Measured Type parameter according to the application: Figure 3.17 – Measured Type Selection If the adjust requires a changing of measured values, please, calibrate the device with reference, according to these steps: - Wait the process stabilizes and collect a sample;... - Page 59 Primary Value and Status and the result of calibration procedure. First Step – Air Self-Calibration Place the DT303 in work position (vertical) and facing the air, wait approximately 5 minutes for stabilization, choose Kg/m³ for measurement unit and then click to the “Write” button. After this method, please return the Measured Type to the previous selection.

-

Page 60: Via Local Adjustment

DT303 – Operation, Maintenance and Instructions Manual WARNING It is recommendable, for every new calibration, to save existing trim data, by means of parameter BACKUP_RESTORE, using option "Last Cal Backup". Via Local Adjustment Concentration/Density Calibration The calibration process is always with reference, it means that the user must apply to the transmitter the measuring conditions. -

Page 61: Sensor Information

Configuration (NEW_UPPER - TRIMMED_VALUE) < SENSOR_HI_LIMIT * 0.1 Otherwise, Excessive Correction. (NEW_UPPER - CAL_POINT_LO) >CAL_MIN_SPAN * 0,75 Otherwise, Invalid Calibration Request. Lower: SENSOR_RANGE.EU0 < NEW_LOWER < SENSOR_HI_LIMIT * 1.25 Otherwise, Invalid Calibration Request SENSOR_LO_LIMIT < TRIMMED _VALUE < SENSOR_HI_LIMIT * 1.25 Otherwise, Out of Range. -

Page 62: Temperature Calibration

DT303 – Operation, Maintenance and Instructions Manual Sensor Construction Information Figure 3.21 – Simatic PDM Transducer Block – Sensor Information Some parameters are only factory configured (e.g. Sensor Type, Module Fill Fluid, etc.). Temperature Calibration NOTE The temperature calibration screens of the Profibus View are similar to Simatic PDM screens. -

Page 63: Sensor Data Reading

If necessary, please return the device to Smar according to Section 4. Always when DT303 is on, is verified if the serial number of the sensor in the sensor board is the same that the saved serial number in EEPROM in the main board. When these numbers are different (a swap of sensor set or main board was carried through) the data stored in the EEPROM of sensor board is copied to the EEPROM of the main board. -

Page 64: Transducer Display - Configuration

DT303 – Operation, Maintenance and Instructions Manual On the main menu of the Simatic PDM, selecting "Device Factory - Backup/Restore", the user can select backup and restore operations: By selecting the This parameter is options used to save or contained in the... -

Page 65: Definition Of Parameters And Values

Adjustment". It is significantly the resources on this transducer display, also all the Series 303 field devices from Smar has the same methodology to handle with it. So, since the user has learned once, he is capable to handle all kind of field devices from Smar. - Page 66 DT303 – Operation, Maintenance and Instructions Manual The option “Write” should be selected in order to execute the upgrade of local adjustment tree. After this step, all selected parameters will be shown on the LCD display. Figure 3.26 – Parameters for Local Adjustment Configuration The window "Local Address Change"...

- Page 67 Configuration On the LCD interface always will be shown parameters according to toggle selection. If the user does not want to show any parameter, is only necessary to opt for "none" when configure the LCD pages: Selecting “None”, for example, the LCD-II will not be shown on the LCD display...

-

Page 68: Local Adjustment Tree - Quick Guide

DT303 – Operation, Maintenance and Instructions Manual Local Adjustment Tree – Quick Guide 3.34... -

Page 69: Programming Using Local Adjustment

Without display, the local adjustment is not possible. Figure 3.30 - Local Adjustment Holes Table shows the actions on the Z and S holes on the DT303 when Local Adjustment is enabled. HOLE ACTION Initializes and rotates through the available functions. - Page 70 DT303 – Operation, Maintenance and Instructions Manual MAIN BOARD Figure 3.31 - J1 and W1 Jumpers In order to start the Place the magnetic local adjustment, tool in orifice S and place the magnetic wait during 5 tool in orifice Z and seconds.

- Page 71 By keeping the tool inserted in this orifice the local adjustment menu will rotate. Figure 3.34 – Step 3 – DT303 In order to range the In order to decrement lower value (lower), the lower value, place...

-

Page 72: Monitoring View

DT303 – Operation, Maintenance and Instructions Manual In order to change the In order to address value, simply decrement the take off the magnetic tool address value, from orifice Z as soon as place the magnetic ADDR is shown on the tool in orifice Z to display. - Page 73 Configuration The Output Value for Analog Input Block Figure 3.39 – Analog Input Block Monitoring View – Simatic PDM Figure 3.40 – Monitoring View – Profibus View 3.39...

-

Page 74: Simulating Values

Cyclical Diagnosis Via cyclic communication is possible to verify diagnostics from the DT303 using the Profibus Master Class 1 or even via acyclic communication via Master Class 2. The Profibus-PA devices provide up to 4 standard diagnoses bytes via Physcial Block (see figure 3.42 and 3.43) and when the most... - Page 75 Configuration Figure 3.43 – Cyclic Diagnosis mapping for 4 bytes of Physical Block. Unit_Diag_bit is described in the GSD file Profibus-PA device. See below a description part of a GSD file for the 4 bytes and more detail: ;----------- Description of device related diagnosis: --------------------- Unit_Diag_Bit(16) = "Error appears"...

- Page 76 DT303 – Operation, Maintenance and Instructions Manual Unit_Diag_Bit(51) = "Not used 51" Unit_Diag_Bit(52) = "Not used 52" Unit_Diag_Bit(53) = "Not used 53" Unit_Diag_Bit(54) = "Not used 54" Unit_Diag_Bit(55) = "Extension Available" ;Byte 05 TRD Block & PHY Block Unit_Diag_Bit(56) = "Sensor failure"...

- Page 77 Identifier_Number_Selector is changed from "Profile Specific" to "Manufacturer Specific" or vice- versa, one must wait 5 seconds while is saved. Then, turn the DT303 off and turn it on again. So, the Identifier Number is updated to the communication level. If the equipment is in "Profile Specific"...

- Page 78 DT303 – Operation, Maintenance and Instructions Manual 3.44...

-

Page 79: General

The transmitter eventually can require maintenance, and then it may be changed in the field. In this case, the possibly damaged sensor should be returned to Smar for evaluation and, if necessary, repair. Refer to the item "Returning Materials" at the end of this Section. -

Page 80: Disassembly Procedure

DT303 - Operation, Maintenance and Instructions Manual This procedure must be done, when the temperature is steady, a temperature standard must be used as a reference to adjust the DT temperature. After the temperature trim, make the self-calibration according to the Section 3. -

Page 81: Reassemble Procedure

Electronic Circuit Plug sensor connector and power supply connector to main board. Attach the display to the main board. Observe the four possible mounting positions. The Smar mark indicates up position. Figure 4.2 - Four Possible Positions for the Display Anchor the main board and display with their screws (3). -

Page 82: Upgrading Dt301 To Dt303

Upgrading DT301 to DT303 The sensor and casing of the DT301 is exactly the same as the DT303. By changing the circuit board of the DT301 it becomes a DT303. Upgrading the DT301 to a DT303 is therefore the same as the procedure for replacing the main board described above. - Page 83 Maintenance Procedures Figure 4.3 – Exploded View - Sanitary Model...

- Page 84 DT303 - Operation, Maintenance and Instructions Manual Figure 4.4 - Exploded View – Industrial Model...

- Page 85 NOTE 1: For category A, it is recommended to keep, in stock, 25 parts installed for each set, and for category B, 50. NOTE 2: Includes terminal block, bolts, caps and identification plate without certification. NOTE 3: The main board of DT303 and probe are items. NOTE 4: O-rings are packaged in packs of 12 units.

- Page 86 DT303 - Operation, Maintenance and Instructions Manual 400-0244 Sanitary Model Probe COD. RANGE Minimum Span 1.8 g/cm3 0,025 g/cm 2.5 g/cm 0,025 g/cm 5.0 g/cm 0,025 g/cm COD. Diaphragm Material Hastelloy C276 316L SST Tantalum Others – Specify COD. Fill Fluid...

-

Page 87: Filling Fluids

The table 5.1 presents the filling fluids, which are available for the DT303, together with some physical properties and applications. THERMAL... -

Page 88: Performance Specifications

DT303 – Operation, Maintenance and Instructions Manual Static Pressure Limits 70 kgf/cm (7 MPa) (1015 PSI) Humidity Limits 0 to 100% RH Performance Specifications Reference conditions: range starting at zero, temperature 25ºC (77ºF), atmospheric pressure, power supply of 24 Vdc, silicone oil fill fluid, isolating diaphragms in 316L SS and digital trim equal to lower and upper range values. -

Page 89: Ordering Code

Technical Characteristics Ordering Code MODEL SANITARY CONCENTRATION/DENSITY TRANSMITTER CODE Range Minimum Span 1.8 g/cm 0.025 g/cm 2.5 g/cm 0.025 g/cm Note: For the concentration units: °Brix, °Plato, °INPM, °GL and °Baumé, specify code1. 5.0 g/cm 0.025 g/cm CODE Wetted Parts Material Hastelloy C276 316L SST Probe in 316 SST and Diaphragms in Hastelloy C276... - Page 90 DT303 – Operation, Maintenance and Instructions Manual MODEL SANITARY CONCENTRATION/DENSITY TRANSMITTER (CONTINUATION) CODE Identification Plate FM: XP, IS, NI, DI EXAM (DMT): EX-IA; NEMKO: EX-D CEPEL: EX-D, EX-IA Without Certification EXAM (DMT) GRUPO I, M1 EX-IA NEPSI: EX-IA CODE Housing Material (1) (2)

- Page 91 Technical Characteristics MODEL INDUSTRIAL CONCENTRATION/DENSITY TRANSMITTER CODE Range Minimum Span 1.8 g/cm 0.025 g/cm 2.5 g/cm 0.025 g/cm Note: For the concentration units: °Brix, °Plato, °INPM, °GL and °Baumé, specify code1. 5.0 g/cm 0.025 g/cm CODE Diaphragm Material / Probe Hastelloy C276 / Hastelloy C276 316L SST / 316L SST Hastelloy C276 / 316L SST...

-

Page 92: Optional Items

DT303 – Operation, Maintenance and Instructions Manual MODEL INDUSTRIAL CONCENTRATION/DENSITY TRANSMITTER (CONTINUATION) CODE Identification Plate FM: XP, IS, NI, DI EXAM (DMT): EX-IA; NEMKO: EX-D CEPEL: EX-D, EX-IA Without Certification EXAM (DMT) GRUPO I, M1 EX-IA NEPSI: EX-IA CODE Housing Material (1) (2) - Page 93 Crrgpfkz"C" " CERTIFICATIONS INFORMATION Gwtqrgcp"Fktgevkxg"Kphqtocvkqp" Consult www.smar.com for the EC declarations of conformity for all applicable European directives and certificates. ATEX Directive (94/9/EC) – “Electrical equipment and protective system intended for use in potential explosive atmospheres” The EC-Type Examination Certificate had been released by Nemko AS (CE0470) and/or DEKRA EXAM GmbH (CE0158), according to European Standards.

-

Page 94: North American Certifications

Environmental Protection - Enclosure Types (Type X): Supplementary letter X meaning special condition defined as default by Smar the following: Saline Environment approved - salt spray exposed for 200 hours at 35ºC. (Ref: NEMA 250). - Ingress protection (IP W): Supplementary letter W meaning special condition defined as default by Smar the following: Saline Environment approved - salt spray exposed for 200 hours at 35ºC. - Page 95 Egtvkhkecvkqpu"Kphqtocvkqp" " Special conditions for safe use: Repairs of the flameproof joints must be made in compliance with the structural specifications provided by the manufacturer. Repairs must not be made on the basis of values specified in tables 1 and 2 of EN/IEC 60079-1. The Essential Health and Safety Requirements are assured by compliance with: EN 60079-0:2012 General Requirements EN 60079-1:2007 Flameproof Enclosures “d”...

-

Page 96: Identification Plate

FV525"⁄"Qrgtcvkqp."Ockpvgpcpeg"cpf"Kpuvtwevkqpu"Ocpwcn" " Kfgpvkhkecvkqp"Rncvg"cpf"Eqpvtqn"Ftcykpi" Identification Plate EXAM and NEMKO C06"... - Page 97 Egtvkhkecvkqpu"Kphqtocvkqp" " CEPEL C07"...

- Page 98 FV525"⁄"Qrgtcvkqp."Ockpvgpcpeg"cpf"Kpuvtwevkqpu"Ocpwcn" " C08"...

-

Page 99: Control Drawing

Egtvkhkecvkqpu"Kphqtocvkqp" " Control Drawing Factory Mutual (FM) C09"... - Page 100 FV525"⁄"Qrgtcvkqp."Ockpvgpcpeg"cpf"Kpuvtwevkqpu"Ocpwcn" " C0:"...

- Page 101 Appendix B SRF – Service Request Form Proposal No.: Density Transmitters Company: Unit: Invoice: COMMERCIAL CONTACT TECHNICAL CONTACT Full Name: Full Name: Function: Function: Phone: Extension: Phone: Extension: Fax: Fax: Email: Email: EQUIPMENT DATA Model: Serial Number: Sensor Number: Firmware Version: Technology: ( ) HART®...

- Page 102 DT303 – Operation, Maintenance and Instructions Manual...

Need help?

Do you have a question about the DT303 and is the answer not in the manual?

Questions and answers