Subscribe to Our Youtube Channel

Summary of Contents for TYROLIT Hydrostress SB-E

- Page 1 Operating Instructions Feed Unit SB-E Index 000 Original operating instructions 10996787 en/10/03/2016...

- Page 2 All repairs must be carried out by trained personnel only. Our after-sales service is available to help ensure that your TYROLIT Hydrostress units remain in perfect working order.

-

Page 3: Table Of Contents

Feed Unit SB-E ........ - Page 4 EC Declaration of Conformity ........... Page 4 Feed Unit SB-E...

-

Page 5: Safety

Rinse any areas of the skin affected immediately with copious amounts of water. Failure to observe this regulation may result in allergic reactions or injury to the eyes. Feed Unit SB-E Page 5... -

Page 6: What To Do In An Emergency

Wear a breathing mask Read the instructions 2 Wear gloves Wear a helmet, goggles Before working on the unit and hearing protection Unplug mains connector 1.3.3 Sticker – information signs Do not steam clean Crane hook Hydraulic oil Page 6 Feed Unit SB-E... - Page 7 TYROLIT Hydrostress AG 1.3.4 Name plate Name plate Feed Unit SB-E Page 7...

-

Page 8: Description

Descriptions of the Wire Saw SB, the drive motor and the control unit WSE2226P are provided in their respective operating instructions. 2.4.1 Software – control unit WSE2226P The software version V3.46 must be installed on the control unit WSE2226P to be able to operate the feed unit. Page 8 Feed Unit SB-E... -

Page 9: Remote Controller / Control Unit Wse2226P

9 EMERGENCY STOP 3 Main motor potentiometer 10 Indicator lights 4 Water On/Off 11 Warning light (radio & battery) 5 Diameter selector switch 12 Position lock switch (traverse feed) 6 Feed joystick 13 Casing 7 Start switch Feed Unit SB-E Page 9... -

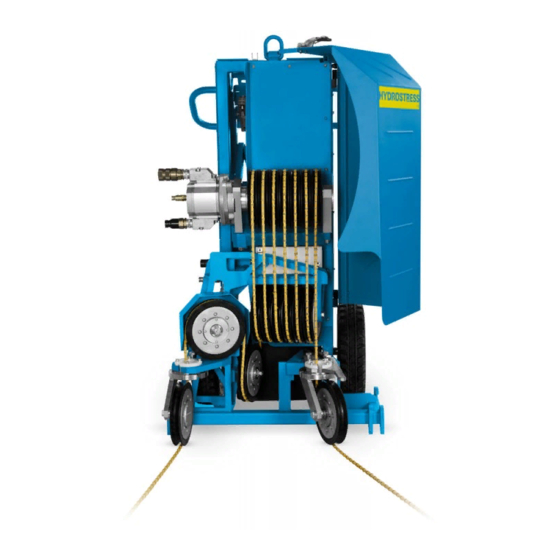

Page 10: Feed Unit Sb-E

TYROLIT Hydrostress AG Feed Unit SB-E 2.6.1 Intended Purpose The Wire Saw SB can be operated electrically in conjunction with the feed unit, the drive motor and the control unit WSE2226P. 2.6.2 Safety measures Any use other than for the intended purpose constitutes abuse or misuse. -

Page 11: Scope Of Supply

Scope of supply 1x Feed unit TYROLIT No. 10996500 1x 2-piece Feed cable/hose assembly TYROLIT No. 975672 1x Motor attachment kit WSE2226 SB TYROLIT No. 10996200 1x Operating Instructions / Spare parts list TYROLIT No. 10996786 Feed Unit SB-E Page 11... -

Page 12: Connecting The Feed Unit

9 Cables are not damaged Connecting the drive motor Connecting the power and feed cables to the control unit 9 Connectors are clean 9 Cables are not damaged Connecting the power and feed cables to the control unit Page 12 Feed Unit SB-E... -

Page 13: Connecting The Hydraulic And Feed Hoses

• Twist the locking ring of the coupling. If hoses cannot be connected or this cannot be done easily, they are under pressure. Depressurise the hoses by means of the pressure relief device. Never use force to connect couplings! Feed Unit SB-E Page 13... -

Page 14: Connecting The Mains Cable

9 The power supply is earthed and fitted with a residual current circuit breaker (FI type B; max. residual current 30mA) 9 Sufficient cable cross-sections: up to 25 m long 4 x 2.5 mm , more than 25 m long 4 x 4 mm Connecting the power and feed cables to the control unit Page 14 Feed Unit SB-E... -

Page 15: Operation

3 EMERGENCY STOP 10 Feed joystick 4 Pulse switch - control unit 11 Main switch - control unit 5 Start switch 12 Reset button 6 Feed potentiometer 13 Mains power supply selection switch 7 On/Off, main motor Feed Unit SB-E Page 15... -

Page 16: Starting The Wire Saw

X Press the main motor On/Off switch (7) on the remote controller to position I. – The electric motor starts when the main motor potentiometer is in the max. position. X The control unit WSE2226 has started up and is ready for operation. Page 16 Feed Unit SB-E... -

Page 17: Tool Soft Start

0 to 100%. The tool stations must not be changed during operation. It is possible to reduce the speed of the diamond wire via the potentiometer for the main motor. That simultaneously lowers the cutting capacity. Feed Unit SB-E Page 17... -

Page 18: Power Control

The feed speed is automatically supported during the cutting process by an assisted feed. Manually adjusting the feed speed 9 Control unit WSE2226 has been started X Select the required feed speed via the feed potentiometer (6). Page 18 Feed Unit SB-E... -

Page 19: Switching Off The Control Unit Wse2226P

X Using a damp cloth clean the control unit WSE2226, the feed unit, the radio remote controller and cables. Products containing solvents can damage parts of the control unit WSE2226, the radio remote controller and cables. Feed Unit SB-E Page 19... -

Page 20: Deactivating The Emergency Stop

X Feed potentiometer (6) X Feed joy stick (10) X Main motor On/Off (7) X Turn the EMERGENCY STOP button (3) clockwise X Press the pulse switch (4) on the control unit to the ON position Page 20 Feed Unit SB-E... -

Page 21: Servicing And Maintenance

It is forbidden to use high pressure cleaning equipment to clean the unit. The feed unit can be damaged if cleaned using high pressure cleaning equipment. Products containing solvents can damage parts of the feed unit and the cables. Feed Unit SB-E Page 21... -

Page 22: Changing The Hydraulic Oil

3 Oil drain plug Recycling waste TYROLIT Hydrostress units are manufactured using a high proportion of recyclable materials. A prerequisite for recycling is proper material separation. In many countries, TYROLIT is already prepared for taking back your used equipment for recycling. Contact TYROLIT customer service or your sales adviser. -

Page 23: Malfunctions

X Check the power supply. the control unit WSE2226P too small. Electric motor of feed unit Switch faulty on the control unit X Contact TYROLIT Hydrostress AG after-sales service. not running. WSE2226P. EMERGENCY STOP activated on the con- X Deactivate the EMERGENCY STOP. -

Page 24: Technical Data

TYROLIT Hydrostress AG Technical data Dimensions Measurements in mm Weights Weight Parameter Value Hydraulic unit (with hydraulic oil) 22 kg Feed unit, complete 35 kg Design Lightweight construction to facilitate one-man transport Page 24 Feed Unit SB-E... -

Page 25: Recommended Ambient Temperature

Highest value of sound pressure level L 105 dB pCpeak Sound power level L 97 dB(A) * Conditions for the measurement: * Diamond wire not in cutting operation under full load Name plate Name plate Feed Unit SB-E Page 25... -

Page 26: Hydraulic Unit

Couplings and hoses Plug-in couplings Type FD and FF, non-drip Hoses Length 8m (filled with hydraulic oil) 7.7.3 Operating resources – hydraulic oil Oil quality: TYROLIT Hydrostress AG recommends: Hydraulic oil: HLP / ISO VG 46 Page 26 Feed Unit SB-E... - Page 27 1x Mains output cable 6mm² 2m / CEE63 5p 6h coupling TYROLIT Art. no. 10996554 1x Feed cable (2.5m / without central cable gland) TYROLIT Art. no. 10995177 1x Motor cable TYROLIT Art. no. 10995178 1x Sensor cable TYROLIT Art. no. 10996212 Feed Unit SB-E Page 27...

-

Page 28: Connection Components

Water cooling the power semi- conductors Cooling water flow rate Min. 4 l/min at max 25 °C Water connection 2 to 6 bar Usage temperature -10 to 40°C Control unit WSE2226 incl. remote controller Page 28 Feed Unit SB-E... - Page 29 390 V Frequency 400 Hz Gears 2 (gear I i=6 / gear II i=3) Speed 8000 rpm Power 26 kW Current 38 A Protection class IP67 Operating mode Number of poles Insulation class Feed Unit SB-E Page 29...

- Page 30 TYROLIT Hydrostress AG 7.8.3 Hydraulic cylinder Hydraulic cylinder Hydraulic cylinder Type Hydraulic cylinder 2T MP1 Article number 10981872 Dimensions Dm 50 / 25 x 150 Connections G 3/8 " Page 30 Feed Unit SB-E...

-

Page 31: Transport

Before transporting the feed unit by crane, remove all attachments (hoses, cables and the control unit). Failure to observe this regulation may lead to serious physical injury, possibly even death, and to property damage. Crane transport 1 Transport handle 2 Crane shackle Feed Unit SB-E Page 31... -

Page 32: Ec Declaration Of Conformity

Applied standards EN ISO12100: 2010 EN 60204-1: 2006 / A1:2009 EN 61000-6-2 / A2: 2005 EN 61000-6-4 / A2: 2007 TYROLIT Hydrostress AG Witzbergstrasse 18 CH-8330 Pfäffikon Switzerland Pfäffikon, 11/03/2016 Pascal Schmid Head of Development Page 32 Feed Unit SB-E... - Page 33 TYROLIT Hydrostress AG Notes: Feed Unit SB-E Page 33...

- Page 34 TYROLIT Hydrostress AG Page 34 Feed Unit SB-E...

Need help?

Do you have a question about the SB-E and is the answer not in the manual?

Questions and answers