Table of Contents

Advertisement

Quick Links

1^

REFERENCE GUIDE

^2

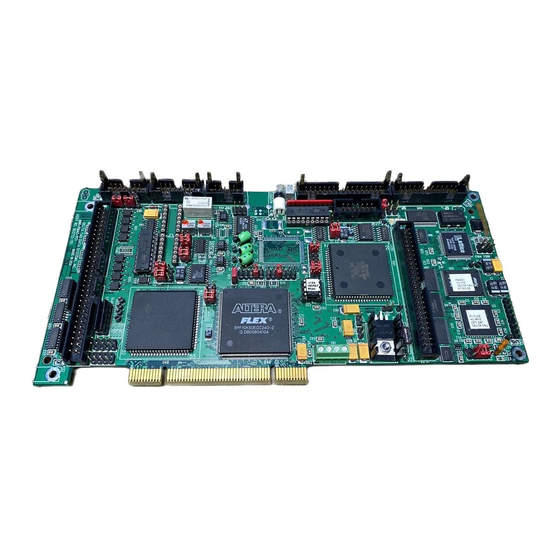

PMAC Quick Reference

USER MANUAL

Single Source Machine Control

21314 Lassen Street Chatsworth, CA 91311 // Tel. (818) 998-2095 Fax. (818) 998-7807 // www.deltatau.com

^3

Reference Guide for PMAC Products

^4

3A0-PMACQR-xPRx

^5

September 29, 2009

Power // Flexibility // Ease of Use

Advertisement

Table of Contents

Need help?

Do you have a question about the PMAC PC and is the answer not in the manual?

Questions and answers